Creating smooth and symmetrical 3d printed spheres demands precision at every stage. You must focus on design, preparation, and post-processing to achieve professional results. A well-designed sphere ensures structural integrity and visual appeal. By refining your techniques and paying attention to detail, you can transform ordinary prints into flawless creations.

Key Takeaways

- Begin with good CAD software to create your spheres. Try programs like Fusion 360 or Tinkercad for simple and precise designs.

- Make sure your design is even and smooth. Use mirror tools and fix rough edges for a perfect look.

- Pick the correct file type for printing. STL files work best to keep your design accurate while printing.

Designing 3D Printed Spheres

Using CAD Software for Sphere Design

To create precise spheres, you need to start with reliable CAD (Computer-Aided Design) software. Tools like Fusion 360, Tinkercad, or SolidWorks allow you to design spheres with accuracy. Begin by selecting the sphere shape from the software's geometric library. Most CAD programs provide a pre-built sphere option, which you can customize to fit your requirements.

When designing and printing spheres, focus on the resolution of your model. Higher resolution ensures smoother curves and fewer visible facets. Adjust the polygon count or surface detail settings in your CAD software to achieve this. Save your design frequently to avoid losing progress.

Ensuring Symmetry and Smoothness in the Sphere

Symmetry is crucial when designing spheres. Even minor imperfections can result in uneven surfaces during printing. Use the mirroring or symmetry tools in your CAD software to ensure the sphere remains perfectly balanced. These tools automatically replicate changes across all sides of the sphere, maintaining uniformity.

Smoothness is equally important. Check the surface quality of your design by zooming in on the sphere. If you notice jagged edges or visible polygons, refine the model by increasing the resolution or applying a smoothing modifier. This step minimizes the risk of layer lines appearing on the final print.

Adjusting Dimensions and Scaling for Precision

Accurate dimensions are essential for functional or decorative spheres. Use the measurement tools in your CAD software to set the exact diameter of the sphere. If you're designing a sphere to fit into a specific assembly, account for tolerances to ensure a proper fit.

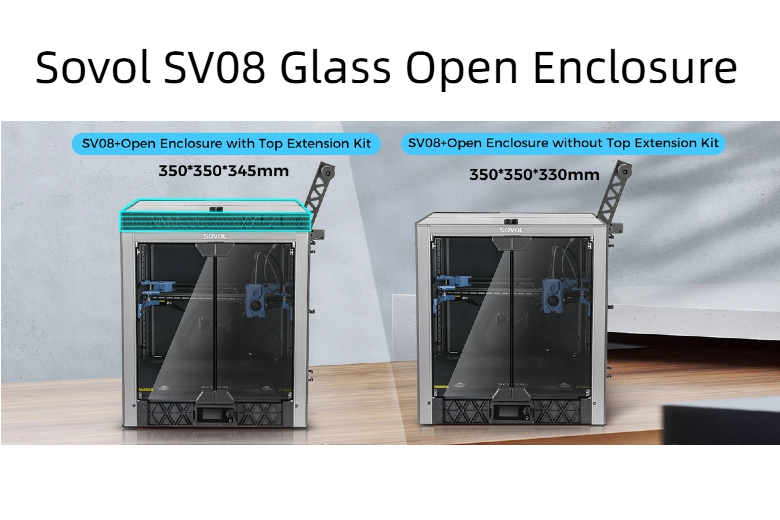

Scaling is another critical factor. Before exporting your design, verify that the sphere's size matches your 3D printer's capabilities. Oversized models may not fit on the print bed, while undersized ones might lack the desired detail. Most CAD software includes a scaling feature that allows you to adjust the size without altering the sphere's proportions.

Preparing the 3D Model for Printing

Choosing the Right File Format for 3D Printing Spheres

Selecting the correct file format ensures your spheres retain their design fidelity during the printing process. Formats like STL (Standard Tessellation Language) are widely used for 3D printing due to their compatibility with most slicer programs. STL files accurately represent the geometry of your sphere, making them ideal for smooth and symmetrical prints.

Other formats, such as OBJ, offer additional features like color and texture mapping, which can be useful for decorative spheres. For complex geometries, advanced techniques like FRESH (Freeform Reversible Embedding of Suspended Hydrogels) enhance structural reinforcement, ensuring stability during printing.

|

Evidence Description |

Impact on Print Fidelity |

|---|---|

|

Stability of gelatin microspheres |

Maintains form during printing and crosslinking, preventing collapse |

|

Increased biomechanical properties with Ru(bpy)3/SPS |

Improves compressive strength and overall print quality |

|

Successful printing of hollow conduits |

Demonstrates elasticity and strength, indicating high fidelity in print shape and stability |

Optimizing Slicing Software Settings for Spheres

Slicing software plays a critical role in preparing your sphere for printing. Programs like Cura or PrusaSlicer convert your 3D model into instructions for the printer. Import your file using drag-and-drop or the "Add object" feature, then position and resize the sphere to fit the build plate.

Adaptive layer height settings significantly improve surface quality. This feature adjusts the layer height dynamically, reducing the "ladder effect" often seen on curved surfaces. It also decreases print time by up to 27%, making it an efficient choice for spheres. Fixed layer heights, such as 0.2 mm, may result in visible ridges, so avoid them for smoother results.

Setting Layer Height, Infill, and Supports for Smooth Results

Fine-tuning layer height, infill, and supports ensures your spheres print with precision. A smaller layer height, such as 0.1 mm, creates smoother surfaces by minimizing visible lines. For infill, choose a pattern like gyroid or honeycomb to maintain structural integrity without adding unnecessary weight.

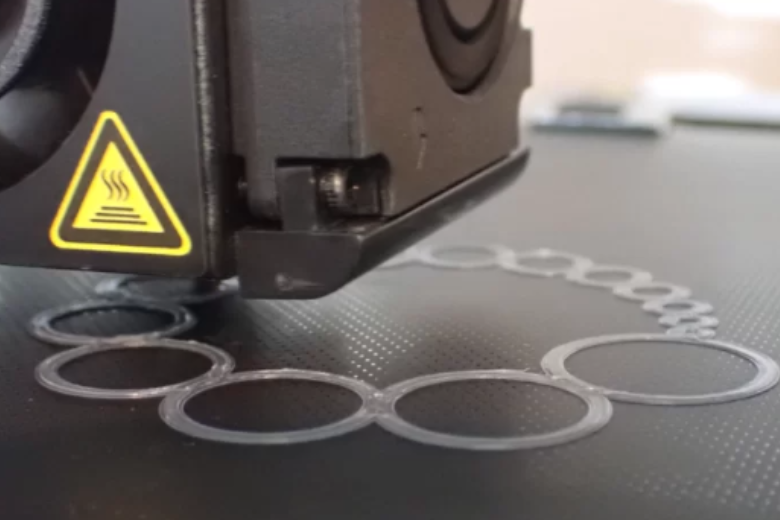

Supports are essential for spherical designs, especially if your sphere includes overhangs. Use tree supports for minimal contact with the sphere's surface, reducing post-processing work. Horizontal orientation during printing improves accuracy and reduces material usage, as studies have shown.

Note: Always test your settings with a small prototype before committing to the final print. This approach helps you identify and resolve issues early.

Printing the Sphere with Precision

Selecting the Best Materials for 3D Printing Spheres

Choosing the right materials is critical for achieving smooth and precise 3d printing spheres. Each material behaves differently during the printing process, influencing the final quality of your sphere. PLA (Polylactic Acid) is a popular choice for beginners due to its ease of use and minimal warping. It produces clean surfaces, making it ideal for decorative spheres. ABS (Acrylonitrile Butadiene Styrene), on the other hand, offers greater durability and heat resistance, which is beneficial for functional spheres.

For advanced applications, consider using PETG (Polyethylene Terephthalate Glycol) or resin. PETG combines the strength of ABS with the ease of printing associated with PLA. Resin, used in SLA (Stereolithography) printers, delivers exceptional detail and smoothness, making it perfect for intricate designs. However, it requires post-curing to achieve optimal strength.

Fine-Tuning Printer Settings for Smooth Spheres

Printer settings play a pivotal role in the quality of your 3d printing spheres. Start by reducing the layer height to 0.1 mm or lower. This minimizes the stair-stepping effect, resulting in smoother surfaces. Adjust the print speed to a moderate level, as printing too fast can compromise accuracy. A speed of 40-60 mm/s works well for most materials.

Calibrate the nozzle temperature based on the material you are using. For PLA, a range of 190-220°C is suitable, while ABS requires 230-250°C. Incorrect temperatures can lead to issues like stringing or uneven extrusion, which affect the sphere's finish. Additionally, ensure the bed temperature matches the material's requirements to prevent warping.

|

Factor |

Impact on Precision |

|---|---|

|

Layer Height |

Reducing layer height minimizes stair-stepping effect on spherical surfaces. |

|

Material Behavior |

Different materials exhibit varying shrinkage, affecting final dimensions. |

|

The accuracy of the printer directly influences the achievable tolerances. |

|

|

Part Geometry |

Bulky designs can lead to more shrinkage, impacting precision. |

Troubleshooting Issues Like Layer Lines and Uneven Surfaces

Even with careful preparation, you may encounter issues like layer lines or uneven surfaces when 3d printing spheres. These imperfections can detract from the sphere's appearance and functionality. To address layer lines, increase the print resolution by lowering the layer height. If the problem persists, inspect the nozzle for clogs or wear, as these can disrupt filament flow.

Uneven surfaces often result from poor bed leveling or inconsistent extrusion. Recalibrate the print bed to ensure it is perfectly level. Use a feeler gauge or a piece of paper to check the distance between the nozzle and the bed. For extrusion issues, verify that the filament spool feeds smoothly into the printer.

The ViLim Ball case study highlights effective techniques for mitigating these problems. High-density supports help maintain the sphere's geometry, reducing visible marks. Orienting the print to minimize overhangs ensures better surface quality. Selecting materials with good dimensional stability further enhances the sphere's finish.

- High-density supports maintain geometry and minimize visible marks.

- Careful orientation supports overhangs and inner features.

- Materials with smooth outer surfaces improve dimensional stability.

Post-Processing 3D Printed Spheres

Sanding and Polishing for a Flawless Finish

Sanding is a crucial step in achieving a smooth surface on your 3D printed spheres. Start with coarse-grit sandpaper (around 120 grit) to remove visible layer lines. Gradually move to finer grits, such as 400 or 600, to refine the surface. For the best results, sand in a circular motion to maintain the sphere's symmetry. Wet sanding, where you use water to reduce friction, can further enhance the finish and prevent overheating.

Polishing takes your sphere to the next level. Use a polishing compound and a soft cloth to buff the surface. This process eliminates micro-scratches and gives the sphere a glossy appearance. For resin-printed spheres, consider using a UV-curing process after polishing to harden the surface and enhance durability.

Using Fillers to Smooth Out Imperfections

Fillers are excellent for addressing minor flaws in your 3D printed spheres. Apply a thin layer of filler, such as epoxy resin or automotive putty, to the surface. Spread it evenly using a spatula or your fingers while wearing gloves. Once the filler dries, sand it down to blend seamlessly with the sphere's surface.

Fillers not only improve aesthetics but also enhance the mechanical properties of your spheres. Studies show that fillers can increase hardness and elasticity, making your spheres more durable. Despite minor microstructural flaws, the overall quality of the spheres remains high, proving the effectiveness of fillers in mitigating imperfections.

Painting and Coating for a Professional Look

Painting adds a professional touch to your 3D printed spheres. Begin by applying a primer to ensure the paint adheres well. Use spray paint for an even coat, holding the can about 8-10 inches away from the sphere. Apply multiple thin layers, allowing each to dry before adding the next.

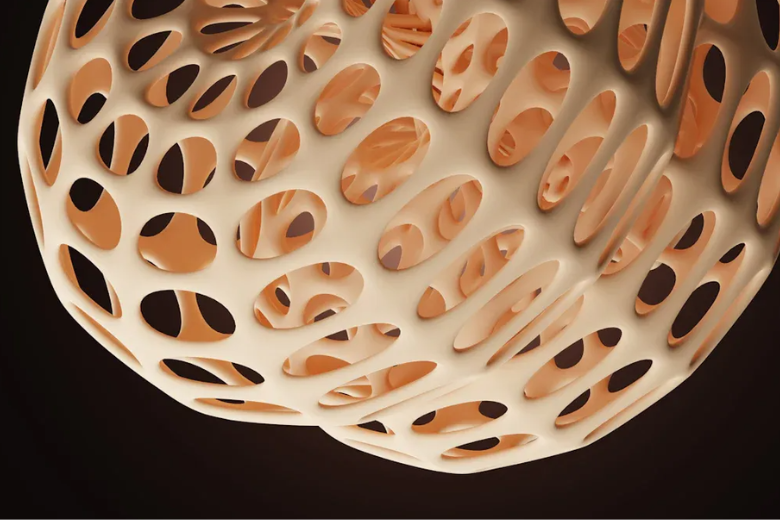

For a more durable finish, consider adding a clear coat or varnish. This step not only protects the paint but also enhances the sphere's shine. If you want a unique look, experiment with metallic or pearlescent paints. These options highlight the benefits of 3D printing spheres by showcasing their smooth and symmetrical surfaces.

Mastering the art of creating a perfect 3d printed sphere involves careful attention to design, preparation, printing, and post-processing. Experiment with different techniques to refine your skills and achieve better results. Patience and consistent practice will help you overcome challenges and produce smooth, professional-quality spheres that showcase your expertise.

FAQ

How do you prevent layer lines on 3D printed spheres?

Lower the layer height in your slicer settings. Use adaptive layer height for curved surfaces. Sanding and polishing after printing also help achieve smoother results.

What is the best material for printing durable spheres?

PETG offers a balance of strength and ease of printing. For intricate designs, resin provides exceptional detail but requires post-curing for durability.

Can you print hollow 3D spheres?

Yes, hollow spheres are possible. Use a low infill percentage or design internal voids in your CAD software. Add supports to maintain structural integrity during printing.

Deja un comentario

Todos los comentarios se moderan antes de ser publicado.

Este sitio está protegido por hCaptcha y se aplican la Política de privacidad de hCaptcha y los Términos del servicio.