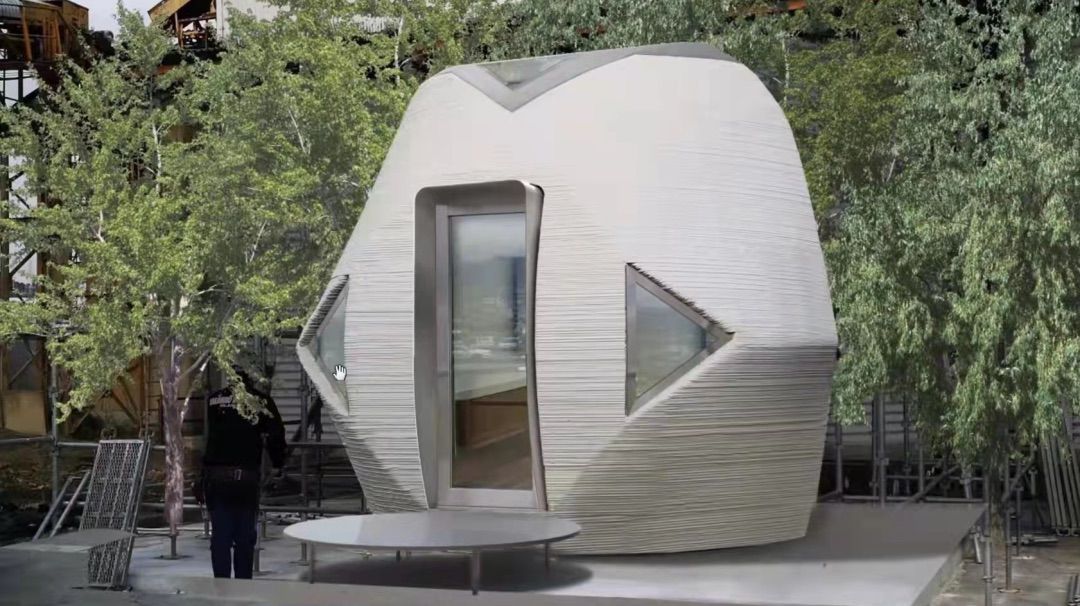

3D printed housing projects are emerging across the globe—from deployable 3D printers and affordable housing to expo pavilions and even Starbucks locations. Concrete companies, real estate developers, the military, and major construction firms are all experimenting with this technology.

01. Modular & Demountable Architecture

TIP is a billion-dollar truck company. Losberger DeBoer, based in the Netherlands, earns around $270 million annually by renting large tents and temporary structures. They are part of the demountable building rental market, which includes containers, tents, and prefabricated modules. These temporary buildings can be quickly transported and serve as classrooms, hospitals, or airplane hangars. The market caters to needs ranging from one-week music festivals to temporary apartment buildings lasting over a year.

The modular building market may be worth up to $100 billion. It includes both demountable structures and others of a different classification. Whether designed for events, disaster relief, or to accommodate students or workers flooding into a city, these structures are temporary and meant to be moved.

Polymer 3D printing can be used for molds, and concrete 3D printing can create temporary structures or structural components. Imagine a 3D printer laying the foundation for a modular "island" made of other structures. Or envision a container hospital needing only a printed base. 3D printing could also help create temporary polymer structures and recycle old components.

Tents could be joined using locally printed connectors, or a large concert stage could be 3D printed on-site. Large structures, which are difficult to transport by trailer, could be constructed on location. For example, arches could be printed, then fitted with canvas tents. Disaster-relief foundations could be 3D printed and later repurposed for other structures.

Sources:

- "New Business: Temporary, Migratory, & Modular 3D Printed Architecture" – 3DPrint.com

- "Modular construction on the rise" – Losberger De Boer Optimizely+3Losberger

02. Migratory Architecture

This model involves using factory-based 3D printing to mass-produce containerized 3D-printed building components. These can include walls, furniture, homes, rooms, and more—often made from recycled materials. The structures can be customized quickly and partially reused for new builds.

This enables true mobile architecture: imagine a ski lodge that serves tourists in Northern Europe during the winter and then moves to the Mediterranean in the summer. Key elements—like foundations and surrounding structures—could be replicated at both locations.

This business model opens up a mobile housing market that continually meets shifting demand. Locals might be more open to vacation homes if they’re only present for part of the year. Or maybe homes built in flood zones could be quickly disassembled in an emergency.

This idea is economically feasible and potentially sustainable. For reference, Airbnb generated $2.4 billion from temporary vacation accommodations alone, and the broader opportunity could be much larger.

Sources:

- "New Business: Temporary, Migratory, & Modular 3D Printed Architecture" – 3DPrint.com

- "Airbnb and urban population change: an empirical analysis" – Taylor & Francis Online

03. Temporary Architecture with Sustainable Materials

In Japan, wooden homes built with traditional joinery can be disassembled—a centuries-old form of temporary architecture. In contrast, buildings elsewhere often rely heavily on concrete, which consumes massive amounts of energy, water, and emits CO₂. In fact, up to 11% of global CO₂ emissions come from building materials and construction.

The embedded carbon of new homes can range from 15 to 100 tons of CO₂. Through 3D printing, companies like WASP have shown that buildings can be constructed from locally available materials. Projects like Earth homes, Dior cabins, and expo pavilions have already utilized this method.

What if we systematically built temporary structures using sustainable materials? One idea: collect all the plastic bottles on a university campus and use them to 3D print the walls of a sports facility.

If a building can be crushed and reused, does it need reconfiguration? Yes, but energy costs are a factor. A more elegant solution may involve natural geopolymers, soil, mud, sand, or similar materials. These could be 3D printed into structures designed to decay or dissolve over a specific time frame.

For example, a building might melt with the application of baking soda and vinegar—making it sustainable and biodegradable. This opens up the concept of vanishing architecture that adapts to context and leaves no trace.

Sources:

- "3D printed house TECLA - Eco-housing" – WASP

- "TOVA: 3D Printed Prototype Using Earth" – IAAC

- "This 3D-printed house is made entirely from mud" – WIRED

Extended reading: 3D Printed House Benefits and Challenges Explained

FAQ

1. What materials are commonly used in 3D printed architecture?

You’ll find materials like high-performance polymers, carbon-fiber composites, eco-friendly concrete, and recycled plastics. These materials enhance durability, sustainability, and design flexibility.

2. How does 3D printing reduce construction waste?

Precision printing ensures exact material usage, minimizing waste by up to 60%. This process eliminates over-ordering and measurement errors common in traditional construction.

Tip: Opt for projects that integrate recycled materials to further reduce waste.

3. Can 3D printed buildings withstand extreme weather conditions?

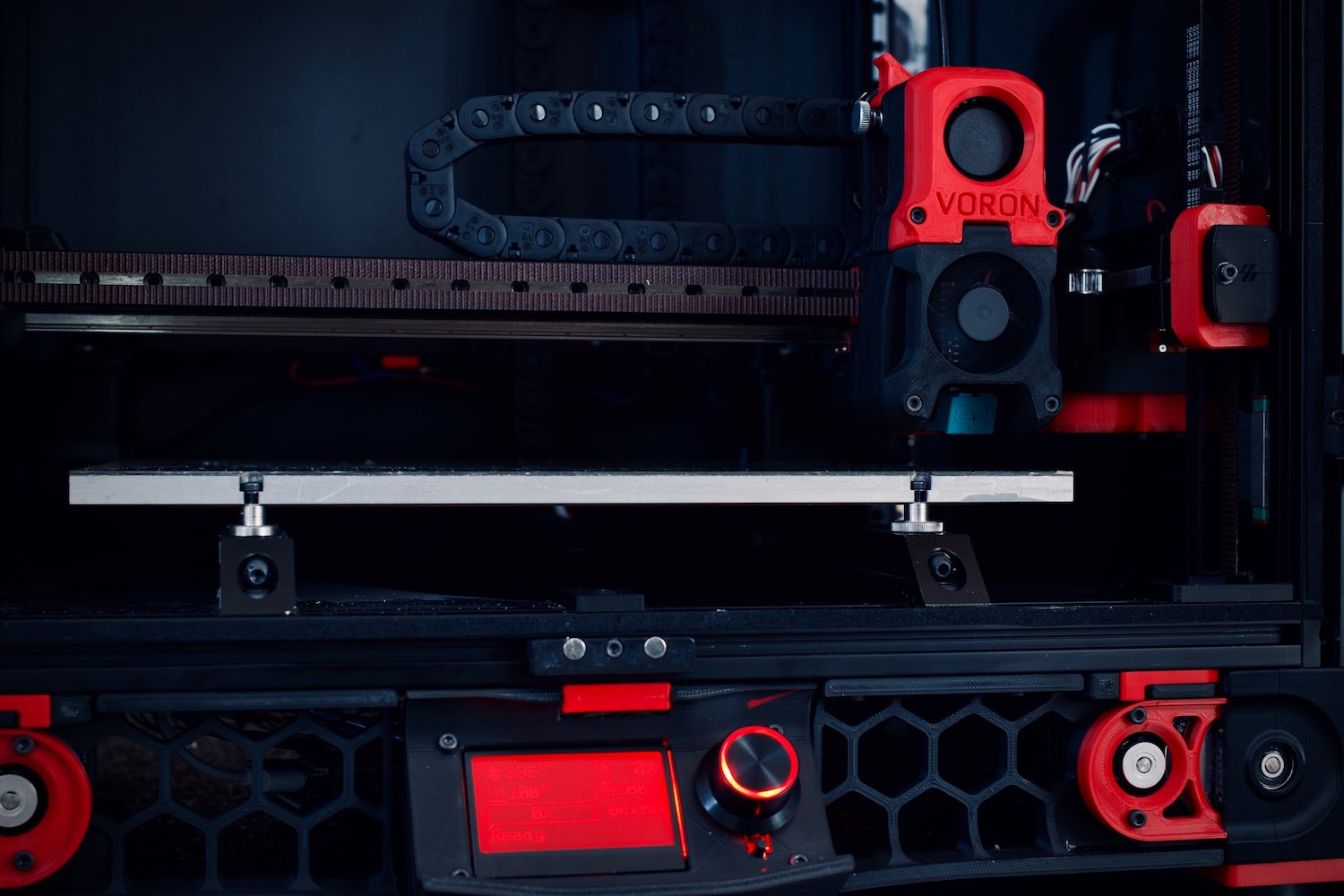

Yes, advanced materials like ABS and PETG improve durability. Researchers also enhance metal microstructures during printing, ensuring buildings resist harsh environments like extreme temperatures and humidity.

4. How affordable is 3D printed housing?

3D printed homes can cost 30% less than traditional construction. For example, disaster-relief homes in Texas were built for $4,000 each, offering a cost-effective solution for affordable housing.

5. What role does AI play in 3D printed architecture?

AI optimizes designs, enabling complex and customized structures. It accelerates the design phase by 25% and reduces errors during construction, ensuring precision and efficiency.

Note: Use AI tools to explore innovative designs and streamline workflows.

Αφήστε ένα σχόλιο

Όλα τα σχόλια συντονίζονται πριν δημοσιευθούν.

Αυτή η τοποθεσία προστατεύεται από το hCAPTCHA και ισχύουν η Πολιτική απορρήτου και οι Όροι Παροχής Υπηρεσιών του hCaptcha.