PLA filament dominates the 3D printing world for good reason. You’ll find it easy to use, versatile, and affordable. Its popularity keeps growing, with the global market projected to reach $1.2 billion by 2032. PLA stands out because it’s biodegradable, renewable, and ideal for beginners refining their skills or professionals creating eco-friendly prototypes.

Key Takeaways

-

PLA filament is good for the environment and breaks down naturally.

-

It melts at a low temperature and is easy to use, perfect for new users and hobbyists.

-

Adjusting printer settings like heat and speed improves PLA print quality.

What is PLA Filament?

Definition and Composition of PLA

PLA, or polylactic acid, is a biodegradable thermoplastic derived from renewable resources. Manufacturers produce it using fermented plant starches such as corn, cassava, sugarcane, and sugar beet pulp. This makes PLA an eco-friendly alternative to petroleum-based plastics. Its chemical composition includes long chains of lactic acid molecules, which give it unique properties like low melting temperatures and ease of processing.

Several methods enhance PLA's performance. For example, annealing increases its crystallinity, improving thermal conductivity and rigidity. Adding nucleating agents or forming composites also boosts its mechanical properties. These enhancements make PLA suitable for a wide range of applications, from prototyping to creating functional parts.

|

Property |

Value Range |

|---|---|

|

Glass Transition Temperature |

60–65 °C |

|

Melting Temperature |

130-180 °C |

|

Young's Modulus |

2.7–16 GPa |

|

Heat Resistance |

Up to 110 °C |

|

Flexural Modulus |

Higher than polystyrene |

|

Crystallinity Improvement |

Enhanced by PDLA blending |

Key Properties of PLA Filament

PLA filament stands out due to its unique properties, making it one of the best 3D printing filament options available. Its low melting temperature (200–220°C) allows for easy processing, even on entry-level 3D printers. PLA also has excellent dimensional stability, ensuring your prints maintain their shape during and after printing.

Here are some measurable properties of PLA:

|

Property |

Description |

|---|---|

|

Young's Modulus |

A measure of stiffness, influenced by the material's composition. |

|

The maximum stress PLA can withstand while being stretched or pulled. |

|

|

Strain at UTS |

The percentage elongation at the point of UTS, varying with infill patterns. |

|

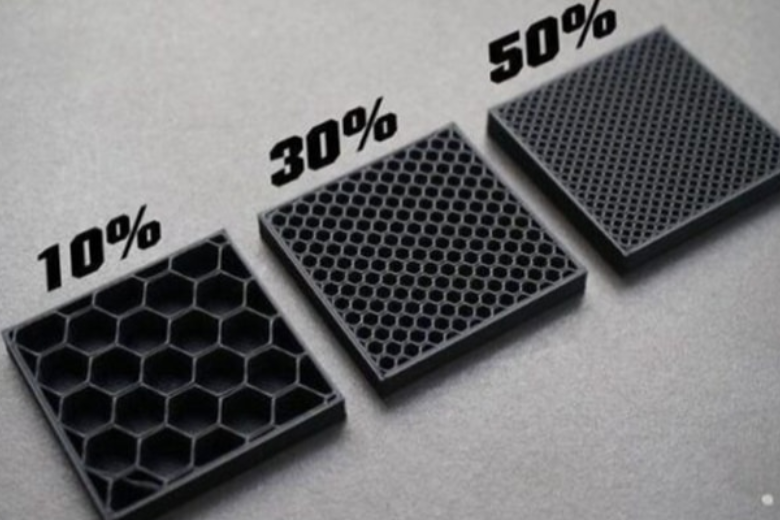

Infill Patterns |

Patterns like grid, triangle, or tri-hexagon affect mechanical properties. |

|

Infill Densities |

Higher infill densities (e.g., 70% or 90%) improve strength but increase material usage. |

These properties make PLA easy to print and ideal for beginners. Its stiffness and tensile strength are comparable to other materials, but its brittleness limits its use in applications requiring high impact resistance.

Comparison with Other 3D Printing Filaments

When comparing PLA to other 3D printing filaments like ABS and PETG, you’ll notice distinct advantages and limitations. PLA offers high tensile strength and is easy to print, but it is more brittle than ABS and PETG. ABS provides better impact resistance and durability, making it suitable for functional parts. PETG combines the strengths of PLA and ABS, offering flexibility, durability, and ease of use.

|

|

PLA |

ABS |

PETG |

|---|---|---|---|

|

Tensile strength |

7,250 psi |

4,600 psi |

7,250 psi |

|

Elongation at break |

6% |

20% |

20-30% |

|

Glass transition temperature |

60-65°C |

~105°C |

85°C |

|

Printing temperature |

200-220°C |

220-250°C |

220-260°C |

PLA is the best overall PLA filament for beginners due to its low printing temperature and minimal warping. However, if you need a material for outdoor use or high-stress applications, ABS or PETG might be better options. For creative projects, you can explore the best exotic PLA or even the best glow-in-the-dark PLA to add unique effects to your prints.

Why is PLA Filament Popular?

Beginner-Friendly and Easy to Print

PLA is one of the easiest materials to work with in 3D printing. Its low melting temperature (200–220°C) ensures smooth extrusion, even on entry-level printers. You don’t need a heated bed, as PLA adheres well to most surfaces, including painter’s tape or glass. This makes it ideal for beginners who want to focus on learning the basics of 3D printing without worrying about complex settings. Additionally, PLA produces minimal warping, so your prints maintain their shape and quality.

Environmental Benefits of PLA

PLA stands out as an eco-friendly option in the world of 3D printing filament. It is made from renewable resources like corn starch and sugarcane, reducing reliance on petroleum-based plastics. Unlike traditional plastics, PLA is biodegradable under industrial composting conditions. This makes it a sustainable choice for environmentally conscious makers. By using PLA, you contribute to reducing plastic waste and promoting greener manufacturing practices.

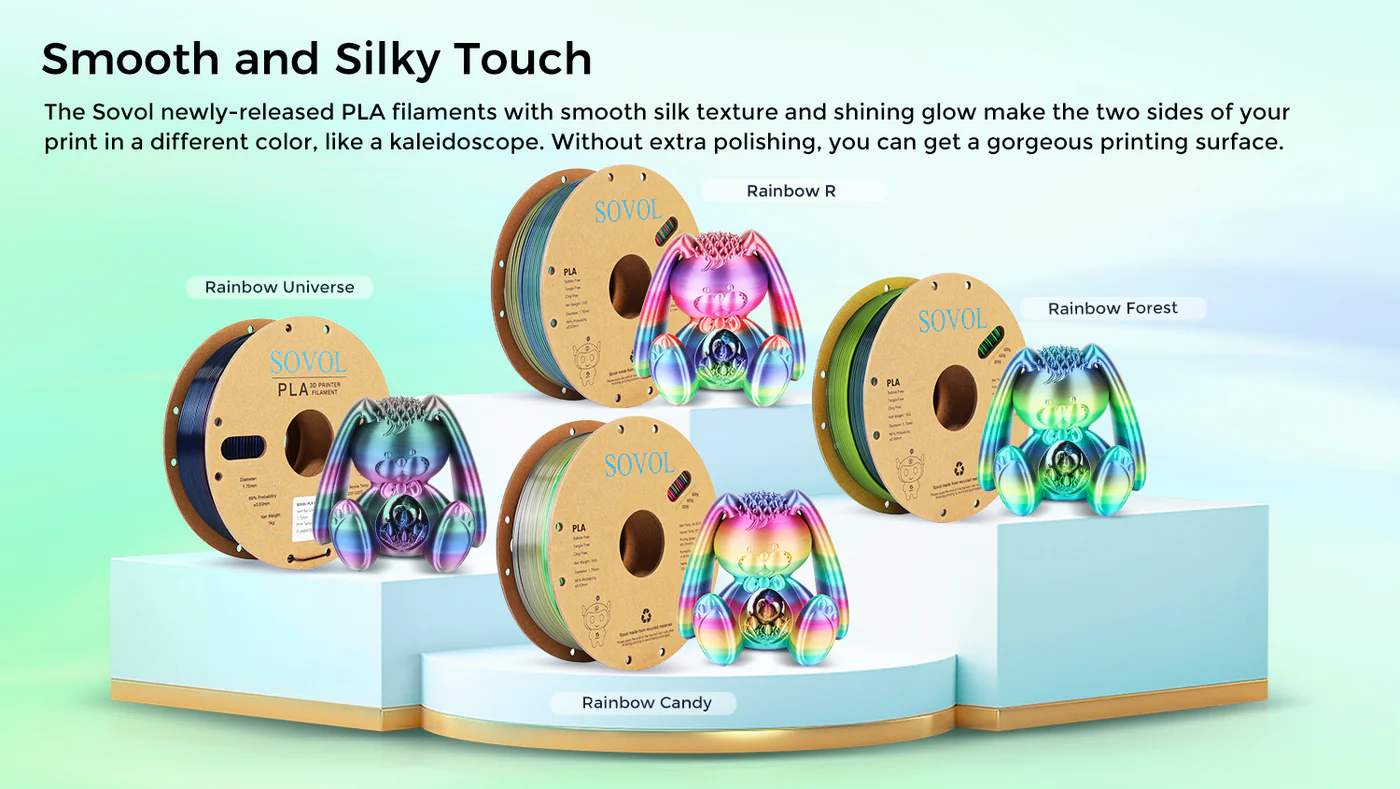

Affordable and Widely Available

PLA filament is one of the most affordable options for 3D printing. Its cost-effectiveness makes it accessible to hobbyists, students, and professionals alike. The market for PLA continues to grow due to its popularity and eco-friendly properties. You’ll find it widely available in various colors, finishes, and blends.

-

PLA is recognized as the best overall PLA filament for budget-conscious users.

-

Its affordability and versatility drive its adoption in industries like healthcare, automotive, and packaging.

-

The rise of additive manufacturing technologies has further boosted the demand for PLA.

-

Versatility for Different Applications

PLA’s versatility makes it suitable for a wide range of applications. You can use it to create prototypes, decorative items, and even functional parts. For example, Volkswagen Autoeuropa uses 3D printing with PLA to manufacture custom tools and prototypes in the automotive sector. PLA also finds applications in healthcare for creating medical models and in packaging for eco-friendly solutions. Its adaptability and ease of use make it the best PLA for 3D printing across various industries.

How to Use PLA Filament Effectively

Step-by-Step Guide for Beginners

Getting started with PLA filament is straightforward if you follow a structured approach. Here’s a step-by-step guide to help you achieve successful prints:

-

Understand PLA Basics

Learn what PLA is and why it’s ideal for beginners. PLA filament comes in standard diameters like 1.75mm and 2.85mm. Choosing the right diameter for your printer ensures optimal extrusion and print quality. -

Prepare Your Hardware

Check your printer’s hotend and bed requirements. PLA works well with most printers, but setting the hotend temperature to 200°C and the bed temperature to 65°C improves adhesion. If your printer doesn’t have a heated bed, use painter’s tape or glue stick for better results. -

Load the Filament

Insert the PLA filament into the extruder and ensure it feeds smoothly. If you’re switching from another filament, purge the old material by extruding a small amount before starting your print. -

Calibrate the First Layer

The first layer is crucial for print success. Adjust the bed leveling and nozzle height to ensure the PLA adheres properly. A clean and well-leveled bed prevents warping and improves dimensional accuracy. -

Monitor the Print

Keep an eye on the initial layers to ensure proper adhesion and extrusion. If issues arise, pause the print and troubleshoot before continuing.

PLA is favored for its ease of use, affordability, and dimensional accuracy. Following these steps will help you master the basics and achieve consistent results.

Best Printer Settings for PLA

Optimizing your printer settings for PLA filament ensures high-quality prints. Here are the recommended settings:

-

Extruder Temperature: Set the hotend temperature between 200°C and 220°C. Lower temperatures reduce stringing, while higher temperatures improve layer bonding.

-

Bed Temperature: PLA doesn’t require a heated bed, but setting it to 65°C enhances adhesion.

-

Print Speed: Use a speed of 40–60 mm/s for detailed prints. Increase to 80–100 mm/s for faster results without compromising quality.

-

Cooling Fan: Enable the cooling fan to run at 100% after the first few layers. This prevents overheating and improves surface finish.

-

Layer Height: For fine details, use a layer height of 0.1mm. For faster prints, increase to 0.2mm or 0.3mm.

Adjusting these settings based on your specific printer and project requirements will help you achieve the best results with PLA.

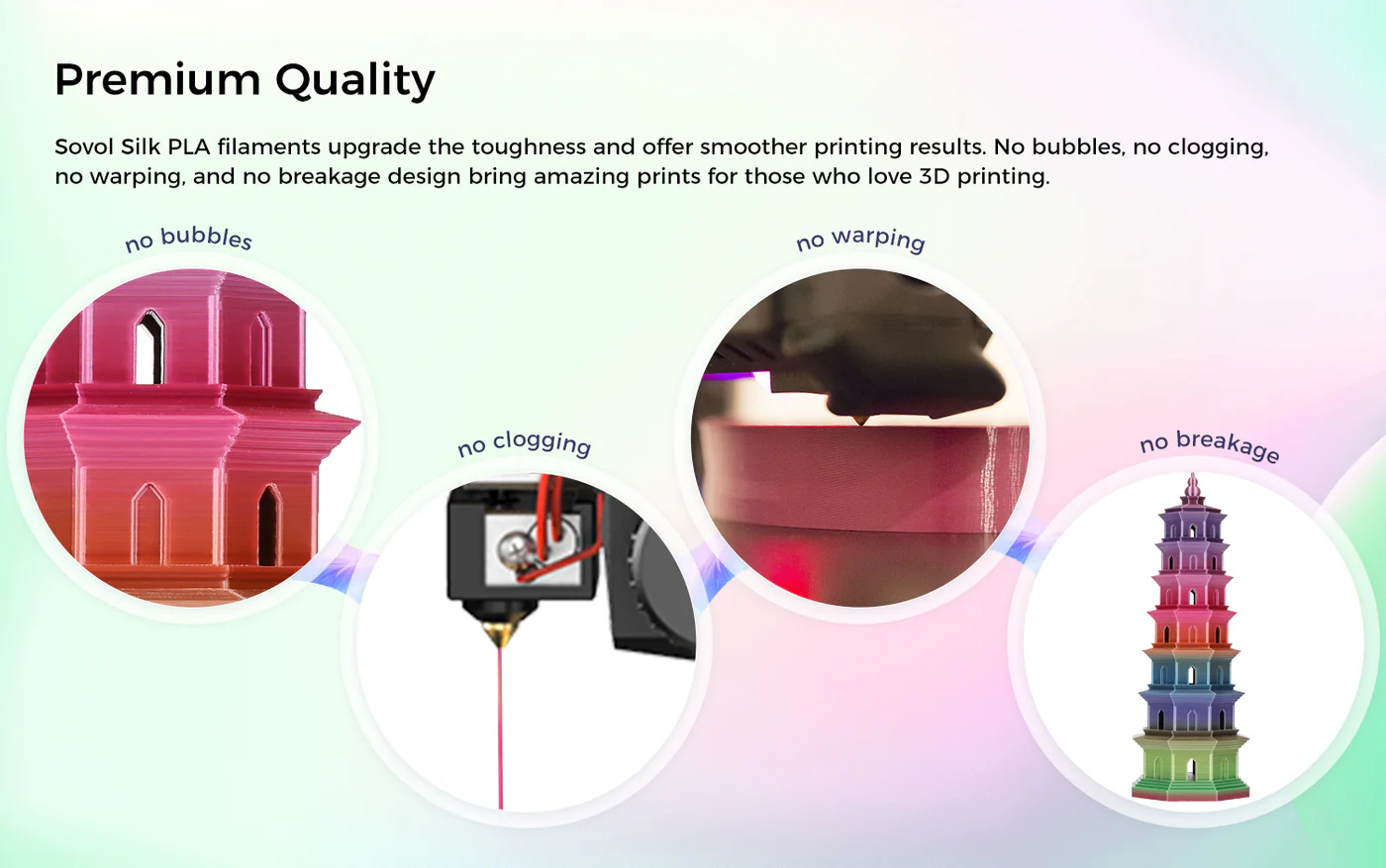

Troubleshooting Common PLA Issues

Even though PLA is easy to print, you may encounter occasional challenges. Here’s how to address common problems:

-

Poor Adhesion to the Print Bed

Ensure the bed is clean and free of debris. Scrape off residue and wipe it down before printing. Applying a layer of adhesive like Monocure3D Platebond can improve adhesion. -

Stringing or Oozing

Reduce the extruder temperature or increase retraction settings to minimize stringing. Lowering the print speed can also help. -

Warping

Warping is rare with PLA, but if it occurs, check the bed leveling and ensure the first layer adheres properly. Using a heated bed or adhesive can prevent this issue. -

Clogged Nozzle

If the nozzle clogs, heat it to 220°C and manually extrude filament to clear the blockage. Regular maintenance prevents clogs and ensures smooth extrusion.

By addressing these issues promptly, you’ll maintain print quality and avoid unnecessary delays.

Post-Processing Techniques for PLA Prints

Post-processing enhances the appearance and functionality of PLA prints. Here are some effective techniques:

|

Technique |

Description |

|---|---|

|

Sanding |

Use sandpaper to smooth rough edges and surfaces. Start with coarse grit and finish with fine grit. |

|

Painting |

Apply acrylic paints for vibrant finishes. Use a primer to improve paint adhesion. |

|

Polishing |

Buff the surface with a polishing compound for a glossy finish. |

|

Annealing |

Heat the print in an oven at 80–120°C to improve strength and heat resistance. |

|

Assembly |

Combine multiple parts using adhesives or screws for complex models. |

While post-processing adds time and cost, it significantly improves the final product’s quality. For professional-grade results, invest in tools and materials that streamline these processes.

Advanced Tips for Professionals

Multi-Material Printing with PLA

Multi-material printing opens up new possibilities for combining PLA with other filaments. You can use dual-extrusion printers to create objects with different properties, such as combining PLA with flexible or conductive materials. For example, pairing PLA with TPU (thermoplastic polyurethane) allows you to produce parts that are both rigid and flexible. To achieve seamless transitions between materials, ensure your printer’s extruder is calibrated for each filament type. Adjust the retraction settings to prevent oozing or mixing at the boundaries. Multi-material printing with PLA is ideal for creating functional prototypes, multi-color models, or objects with varying textures.

Optimizing PLA for Specific Applications

PLA can be tailored to meet the demands of specific projects. For professional applications, you should focus on optimizing performance through careful material selection and process adjustments. For instance, annealing PLA improves its heat resistance and mechanical strength, making it suitable for high-stress environments. Additionally, using specialized tools can help you analyze and refine your printing process.

|

Tool |

Best For |

|---|---|

|

General performance analysis during development |

|

|

line_profiler |

Line-by-line analysis to find bottlenecks |

|

memory_profiler |

Monitoring memory usage and spotting leaks |

|

py-spy |

Low-overhead, real-time profiling in production |

|

Scalene |

Analyzing both CPU and memory usage |

|

Pyinstrument |

Visualizing call stacks for function tracking |

|

Intel Tiber |

Real-time monitoring in live environments |

Expert knowledge is crucial for selecting the appropriate profiling tool, interpreting profiling data, and implementing optimizations. Understanding the strengths and limitations of each tool ensures you choose the right one for your needs.

Achieving High-Quality Finishes with PLA

Achieving a professional finish with PLA requires attention to detail during post-processing. Sanding is a simple yet effective way to smooth surfaces. Start with coarse-grit sandpaper and gradually move to finer grits for a polished look. Painting can add vibrant colors to your prints. Use acrylic paints and apply a primer for better adhesion. For a glossy finish, consider polishing your PLA prints with a buffing compound. Annealing can also enhance the appearance and durability of your models. By refining these techniques, you can elevate the quality of your PLA prints to a professional level.

Experimenting with PLA Blends and Additives

PLA blends and additives expand the possibilities of 3D printing. You can experiment with wood-filled PLA to create prints with a natural, grainy texture. Metal-infused PLA adds weight and a metallic sheen, making it perfect for decorative items. Conductive PLA enables the creation of functional electronic components. When working with these blends, adjust your printer settings to accommodate the unique properties of each material. For example, wood-filled PLA may require a larger nozzle diameter to prevent clogging. Experimenting with these options allows you to push the boundaries of what PLA can achieve.

Common Mistakes and How to Avoid Them

Incorrect Printer Settings for PLA

Incorrect printer settings can lead to poor print quality and wasted filament. You should pay close attention to key settings like layer height, print speed, and temperature. For example, using a layer height that is too thick sacrifices detail, while thinner layers take longer to print. High print speeds often result in poor layer adhesion and stringing. Temperature settings also play a crucial role. Low temperatures can cause clogs, while high temperatures lead to oozing and stringing.

To avoid these issues, start with a layer height of 0.2mm for balanced detail and speed. Set the extruder temperature to around 210°C, as recommended for PLA filament. Use moderate print speeds of 40–60 mm/s to ensure smooth extrusion and proper bonding between layers. Cooling settings are equally important. Insufficient cooling can cause stringing and poor adhesion, so set the fan speed to 100% after the first few layers.

|

Setting Type |

Consequence of Incorrect Setting |

Recommended Action |

|---|---|---|

|

Layer Height |

Thicker layers may sacrifice detail; thinner layers take longer to print. |

Start with a layer height of 0.2mm; adjust for detail as needed. |

|

Print Speed |

High speeds can lead to poor layer adhesion and stringing. |

Start with moderate speeds (40-60 mm/s) and adjust based on material and complexity. |

|

Temperature Settings |

Low temperature can cause clogs; high temperature can lead to oozing and stringing. |

Consult filament manufacturer for optimal temperature; typically around 210°C for PLA. |

|

Cooling Settings |

Insufficient cooling can lead to stringing and poor layer adhesion. |

Use 100% fan speed for PLA after the first few layers. |

Poor Adhesion to the Print Bed

Poor adhesion between PLA prints and the print bed is a common challenge. You may notice prints lifting or warping during the process. This often happens due to an uneven bed surface or unsuitable environmental conditions. Certain substrates, like hairy textiles or acrylated-coated cotton, can deform PLA during printing, making adhesion impossible.

To improve adhesion, ensure the print bed is clean and level. Use painter’s tape, glue stick, or a specialized adhesive like Monocure3D Platebond to enhance grip. If your printer has a heated bed, set it to 65°C for optimal results. Environmental factors also matter. Printing in a stable temperature environment prevents warping and ensures consistent adhesion.

Overheating or Underheating Problems

Temperature issues can ruin your prints. Overheating causes oozing and stringing, while underheating leads to clogs and poor extrusion. You should always consult the filament manufacturer’s guidelines for the recommended temperature range. For PLA, this is typically between 200°C and 220°C.

To avoid overheating, monitor the extruder temperature closely and reduce it if you notice excessive stringing. If underheating occurs, increase the temperature gradually until the filament extrudes smoothly. Retraction settings also help minimize oozing. Start with a retraction distance of 0.5–2mm and adjust as needed.

Neglecting Post-Processing Steps

Skipping post-processing steps can leave your PLA prints looking unfinished. Sanding, painting, and polishing improve the appearance and functionality of your models. Neglecting these steps can result in rough edges, dull surfaces, or weak parts.

To achieve professional results, sand your prints with coarse-grit sandpaper first, then finish with finer grits. Apply acrylic paints for vibrant colors and use a primer for better adhesion. Polishing with a buffing compound adds a glossy finish. For added strength, anneal your prints by heating them in an oven at 80–120°C. These steps elevate your prints and make them suitable for display or functional use.

PLA filament offers unmatched benefits for both beginners and professionals. It is eco-friendly, easy to print, and safe for indoor use due to its low gas emissions. You can experiment with its versatility to create prototypes, decorative items, or functional parts. By mastering PLA, you build a strong foundation for exploring advanced 3D printing materials and techniques.

FAQ

What makes PLA great for fast 3D printers?

PLA’s low melting temperature and excellent flow properties make it ideal for fast 3D printers. It extrudes smoothly, ensuring consistent results even at higher speeds.

How can you improve printing quality with PLA?

To enhance printing quality, optimize your printer settings. Adjust the temperature, print speed, and cooling fan settings for better layer adhesion and surface finish.

Is PLA safe for indoor use?

Yes, PLA is safe for indoor use. It emits minimal fumes during printing, making it a preferred choice for home and educational environments.

Zostaw komentarz

Wszystkie komentarze są moderowane przed opublikowaniem.

Ta strona jest chroniona przez hCaptcha i obowiązują na niej Polityka prywatności i Warunki korzystania z usługi serwisu hCaptcha.