Keeping your 3D printer in top shape starts with clean printer heads. Residue buildup or clogged printheads can ruin your prints and frustrate your efforts. Don’t worry—it’s easy to fix! With the right tools and a bit of care, you’ll restore your printer’s performance in no time.

Key Takeaways

- Use proper tools to clean your 3D printer head. Important tools are cleaning needles, brass brushes, and cleaning filament. These help remove leftover material and blockages.

- Stay safe while cleaning. Wear gloves to protect your hands. Let the nozzle cool to avoid burns. Work in a space with fresh air to avoid breathing bad fumes.

- Regular care is important. Clean the printer head after 10-15 prints. Do a deeper cleaning every three months to stop clogs and keep prints looking good.

Tools and Materials Needed

Cleaning your 3D printer head doesn’t have to be complicated, but having the right tools on hand makes all the difference. Let’s break down what you’ll need to get started.

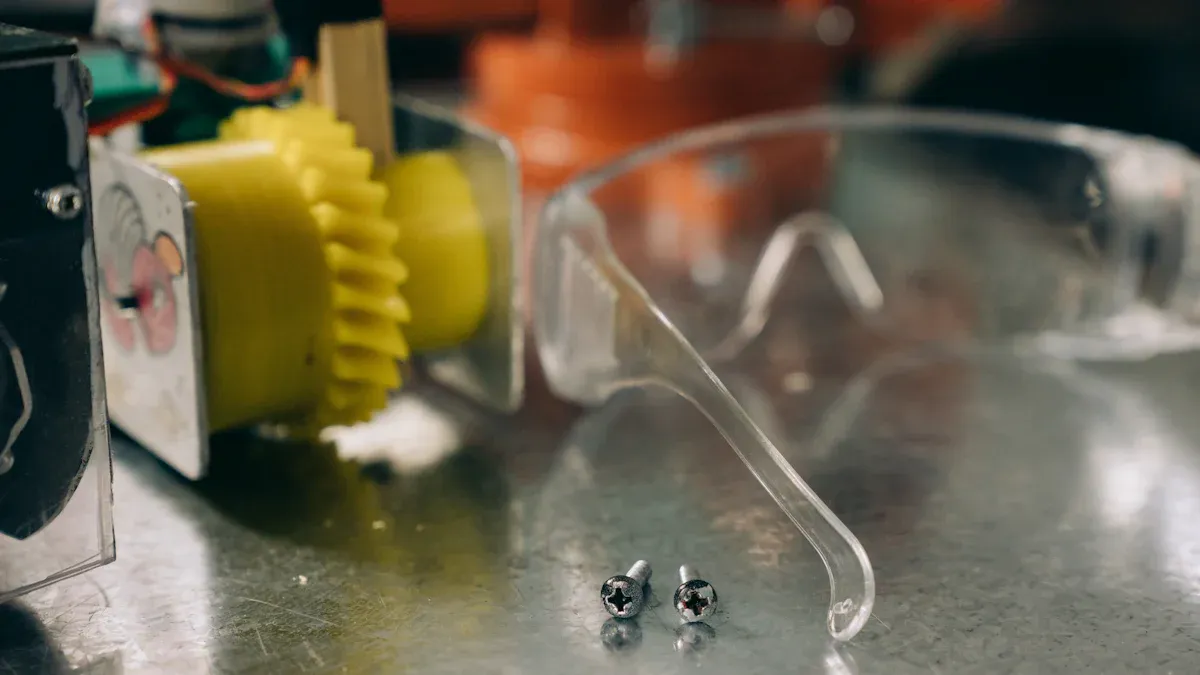

Essential tools for cleaning

To tackle residue and clogs effectively, you’ll need a few basic tools. These are must-haves for any 3D printing enthusiast:

- Cleaning needles: These thin, precise tools help you clear out nozzle blockages without damaging the printhead.

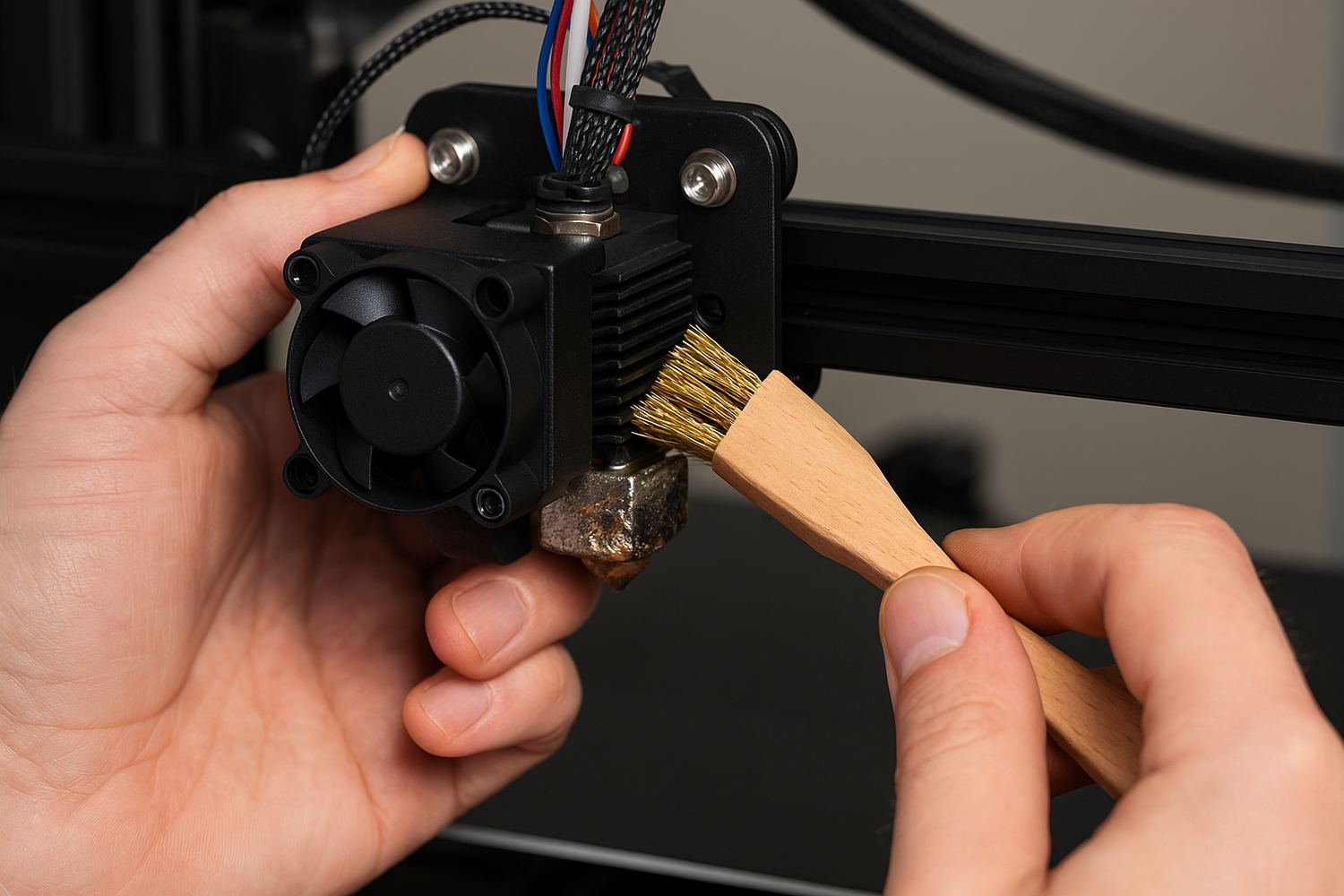

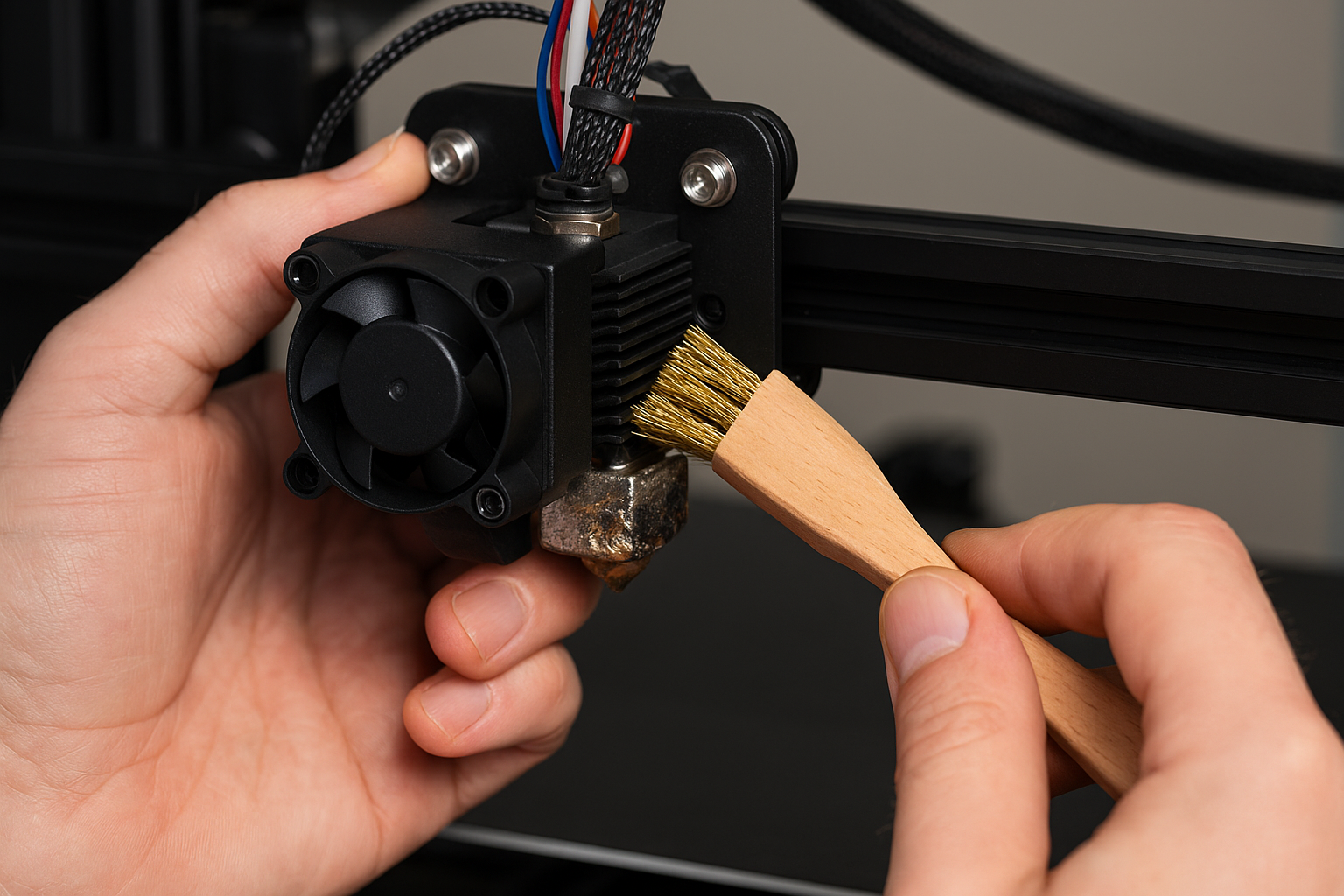

- Brass brushes: Perfect for scrubbing away stubborn filament residue while being gentle on the nozzle.

- Cleaning filament: This specialized filament is designed to remove leftover material from inside the nozzle. Simply load it into your printer and let it do the work.

Experts also recommend keeping a few additional items nearby for better visibility and precision during cleaning. Here’s a quick reference table:

|

Cleaning Tool/Material |

Purpose |

|---|---|

|

Mirror |

To view the print head and roller clearly |

|

Isopropyl alcohol (90%-95%) |

For effective cleaning of print heads |

|

Lint-free cloth |

To avoid leaving fibers on the print heads |

|

Glove |

To protect hands during cleaning |

|

Flashlight |

To illuminate the cleaning area |

These tools ensure you can clean your printer head thoroughly and safely, even in hard-to-reach spots.

Safety precautions to follow during the cleaning process

Safety should always come first when working with heated components and cleaning solutions. Here are some precautions to keep in mind:

- Wear gloves: Protect your hands from burns, sharp tools, and cleaning chemicals. Studies show that gloves can reduce exposure to harmful materials and lower the risk of injuries by up to 86%.

- Avoid burns: Always let the nozzle cool slightly before handling it. While cleaning, use tools like tweezers or pliers to avoid direct contact with hot surfaces.

- Work in a well-ventilated area: Some cleaning solutions, like isopropyl alcohol, release fumes. Proper ventilation keeps you safe from inhaling harmful substances.

By following these steps, you’ll minimize risks and make the cleaning process much smoother.

Optional tools for advanced cleaning

For tougher clogs or more advanced maintenance, you might need additional tools. These aren’t essential for everyday cleaning but can come in handy for stubborn issues:

- Heat guns: These can soften hardened filament, making it easier to remove.

- Ultrasonic cleaners: Ideal for cleaning small parts like nozzles. They use sound waves to dislodge debris without damaging the components.

- Isopropyl alcohol: A versatile cleaning solution that works wonders on build plates and nozzles. It’s especially effective for removing sticky residue from filaments like PETG.

Other options include specialized cleaning agents like Mean Green or denatured alcohol. These can provide an extra level of cleaning power when needed.

Pro Tip: Always test any cleaning solution on a small, inconspicuous area first to ensure it doesn’t damage your printer components.

With these tools and tips, you’ll be well-equipped to handle any cleaning challenge your 3D printer throws your way.

Step-by-Step Cleaning Methods by Filament Type

Cleaning PLA filament residue

PLA is one of the most commonly used filaments, but it can leave behind residue that clogs your nozzle. Here’s how you can clean it effectively:

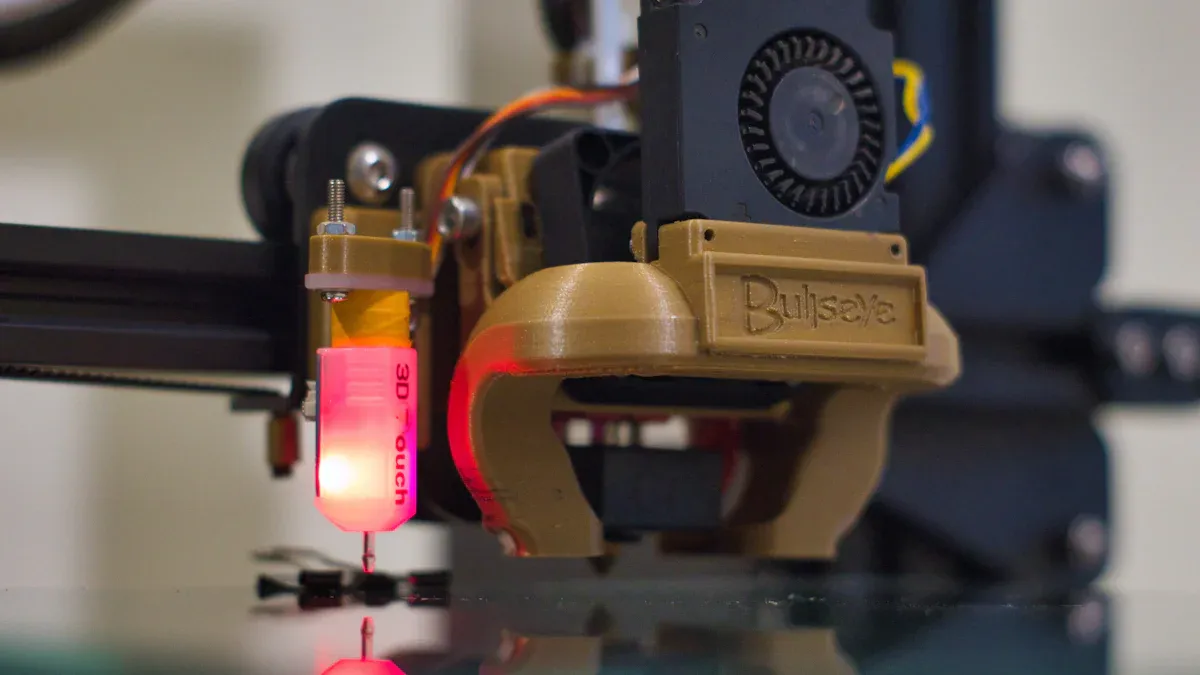

- Heat the nozzle: Set your printer to the recommended PLA printing temperature (around 200°C). This softens the filament, making it easier to remove.

- Use a cleaning filament: Load a cleaning filament into the printer. Push it through the nozzle to clear out any leftover PLA.

- Apply a cleaning needle: If the nozzle remains clogged, gently insert a cleaning needle to dislodge the residue. Be careful not to damage the nozzle.

- Brush the exterior: Use a brass brush to clean the outside of the nozzle. This removes any burnt filament stuck to the surface.

Tip: Avoid letting PLA sit in the nozzle for too long after printing. It hardens quickly and becomes harder to clean.

Cleaning ABS filament residue

ABS filament can be tricky to clean because it tends to leave behind sticky residue. Follow these steps to tackle it:

- Heat the nozzle slightly higher: ABS requires a higher temperature (around 230°C) to soften. Heat the nozzle to this range.

- Perform a cold pull: Once the nozzle is heated, insert a cleaning filament or a piece of nylon filament. Let it cool slightly, then pull it out. This method removes stubborn ABS residue.

- Use isopropyl alcohol: Dampen a lint-free cloth with isopropyl alcohol and wipe the nozzle’s exterior. This helps dissolve any sticky residue.

- Inspect for clogs: If the nozzle is still clogged, repeat the process or use a cleaning needle to clear the blockage.

Pro Tip: Store ABS filament in a dry, airtight container. Moisture can make it more prone to clogging.

Cleaning PETG filament residue

PETG is durable and versatile, but it can leave behind stringy residue that’s tough to clean. Here’s how you can handle it:

- Heat the nozzle to PETG’s range: Set the temperature to around 240°C. This ensures the filament softens enough for removal.

- Use a cleaning filament: Run a cleaning filament through the nozzle to push out any PETG remnants.

- Scrape gently with a brass brush: PETG can stick to the nozzle’s exterior. Use a brass brush to scrape it off without scratching the nozzle.

- Apply isopropyl alcohol: For stubborn residue, soak a lint-free cloth in isopropyl alcohol and clean the nozzle.

Note: PETG tends to stick to the nozzle more than other filaments. Regular cleaning after each print helps prevent buildup.

Cleaning printheads manually for other filament types (e.g., TPU, Nylon)

Some specialty filaments like TPU and Nylon require extra care. Cleaning printheads manually is often the best approach for these materials:

- Heat the nozzle to the filament’s temperature: TPU typically requires 220°C, while Nylon needs around 250°C. Adjust the temperature based on the filament type.

- Perform a manual cold pull: Insert a piece of cleaning filament or Nylon filament into the nozzle. Let it cool slightly, then pull it out to remove debris.

- Disassemble the nozzle if needed: For stubborn clogs, remove the nozzle and soak it in isopropyl alcohol. Use a cleaning needle to clear out any remaining residue.

- Inspect and reassemble: Once clean, reattach the nozzle and test it with a small print to ensure smooth extrusion.

Did you know? Automated cleaning methods, like ultrasonic cleaners, can save time and effort. Studies show they’re often more effective than manual methods for removing stubborn residue.

By following these steps, you’ll keep your printer running smoothly, no matter what filament you use. Regular cleaning prevents clogged printheads and ensures consistent print quality.

Maintenance and Prevention Tips

Keeping your 3D printer in great shape doesn’t stop at cleaning. Regular maintenance and smart habits can prevent clogs and keep your printer running smoothly for years.

How to prevent clogs in the future

Preventing clogs starts with using high-quality filament. Cheap filaments often contain impurities that can block your nozzle. Always check the filament diameter to ensure it matches your printer’s specifications. Storing filament properly is just as important. Moisture can ruin filament, causing bubbles and clogs during printing. Use airtight containers or filament dryers to keep it dry.

Routine checks also help. Make sure your printer’s extrusion temperature is set correctly for the filament type. Incorrect temperatures can create back pressure, leading to clogged printheads. Cleaning your nozzle regularly with a cleaning filament or cleaning solution removes buildup before it becomes a problem.

Regular maintenance schedule for your 3D printer head

A maintenance schedule keeps your printer in top condition. Start with daily inspections. Look for signs of wear or residue on the nozzle. Every two weeks, clean printer heads thoroughly using a cleaning solution or cleaning filament. For deeper maintenance, disassemble the nozzle every three months to remove stubborn debris. Studies show that routine cleaning can eliminate up to 90% of contaminants, reducing the risk of clogs significantly.

Here’s how regular maintenance benefits your printer:

|

Benefit |

Description |

|---|---|

|

Enhanced print quality |

Consistent maintenance improves print quality. |

|

Prolonged lifespan of components |

Regular care extends the life of nozzles and extruders. |

|

Reduced risk of breakdowns |

Fewer unexpected failures mean less downtime. |

|

Improved energy efficiency |

Optimized settings save energy during printing. |

|

Increased productivity |

A well-maintained printer works more efficiently. |

Best practices for filament storage and handling

Proper filament storage is key to avoiding clogs. Always store filament in a cool, dry place. Airtight containers with silica gel packets work well to keep moisture out. If you live in a humid area, consider investing in a filament dryer.

When handling filament, avoid touching it with bare hands. Oils from your skin can transfer to the filament, affecting print quality. Before loading filament, inspect it for dust or damage. These small steps can make a big difference in preventing clogs and ensuring smooth prints.

Pro Tip: Label your filament spools with the type and date of purchase. This helps you track usage and avoid using old or degraded filament.

By following these tips, you’ll save time, reduce frustration, and enjoy better results from your 3D printer.

Keeping your 3D printer head clean is the key to better prints and fewer headaches. By matching your cleaning methods to the filament type, you’ll get smoother results every time. Don’t forget regular maintenance—it’s the secret to a long-lasting printer.

Remember: A little care now saves you from costly repairs later!

FAQ

What should I do if my nozzle is completely clogged?

If your nozzle is fully clogged, remove it and soak it in isopropyl alcohol. Use a cleaning needle to gently clear the blockage.

Can I use any filament for cleaning my nozzle?

No, you should use cleaning filament specifically designed for nozzle maintenance. It’s more effective at removing residue without causing damage.

How often should I clean my 3D printer head?

Clean your printer head after every 10-15 prints or whenever you notice print quality issues. Regular cleaning prevents clogs and keeps your printer running smoothly.

Tip: Keep a maintenance log to track your cleaning schedule and filament usage. It’ll help you stay organized and avoid unexpected issues.

Lämna en kommentar

Alla kommentarer modereras innan de publiceras.

Denna webbplats är skyddad av hCaptcha och hCaptchas integritetspolicy . Användarvillkor gäller.