When you choose PETG filament for 3D printing, you get an impressive mix of strength and ease of use. PETG softens at 80°C and fails at 85°C, outperforming PLA’s limits of 60°C and 65°C. It’s less brittle than PLA and offers better impact resistance. With PETG, you can print durable, functional parts effortlessly.

Key Takeaways

- PETG filament is strong and easy to print with. It works well for beginners and experts alike.

- It resists impacts and bends without breaking, making it great for useful parts.

- PETG sticks well to the print bed and doesn’t warp much. This helps create good prints and lowers the chance of mistakes.

Strength and Durability of PETG Filament

Choosing the right material for 3D printing is important. The strength and durability of your filament can affect your project’s success. PETG filament is a strong and dependable choice. It has great mechanical properties for both beginners and experts. Let’s see why PETG is tough and long-lasting.

Impact Resistance and Toughness

PETG is very good at handling impacts. It’s perfect for parts that might be dropped or hit. Tests show PETG filaments, like Radiospares Pro PETG and Colorfabb PETG Economy, have XY impact resistance between 7-14 kJ/m². This is as good as or better than PLA, which breaks more easily. However, Z-axis resistance for PETG is 2-7 kJ/m². This can be lower than PLA, depending on the brand and moisture level.

What does this mean? PETG is strong in horizontal directions, making it great for brackets or enclosures. Its toughness keeps prints from cracking or breaking under pressure. For example, PETG can hold 15-20kg even with small parts, showing its strength for heavy use.

Tip: Don’t use too much cooling when printing with PETG. This improves layer bonding and keeps your prints strong.

Flexibility and Stress Resistance

Unlike fragile materials, PETG is both flexible and sturdy. It resists bending and breaking under pressure. Tests show PETG can handle up to 485 lbf (2160 Newtons), beating ABS, which handles 472 lbf (2100 Newtons). This flexibility helps PETG absorb stress without snapping. It’s great for parts that bend or twist.

For example, hinges or clips made with PETG stay strong over time. Its ability to bend without breaking makes it safer for parts under repeated stress.

|

Material |

Maximum Load (lbf) |

Maximum Load (Newton) |

|---|---|---|

|

PETG |

485 |

2160 |

|

ABS |

472 |

2100 |

Heat and UV Resistance

PETG is not just strong—it also handles tough environments. Its chemical makeup protects it from UV rays, so it doesn’t break down in sunlight. PLA, on the other hand, becomes brittle and fades in the sun. PETG also resists heat better, keeping its strength at higher temperatures.

For outdoor projects, PETG is a smart pick. It won’t crack, fade, or weaken in sunlight. Whether you’re making garden tools, outdoor fixtures, or heat-resistant parts, PETG performs well.

Note: PETG’s heat and UV resistance make it ideal for long-lasting projects in tough conditions.

Why PETG is Easy to Print With

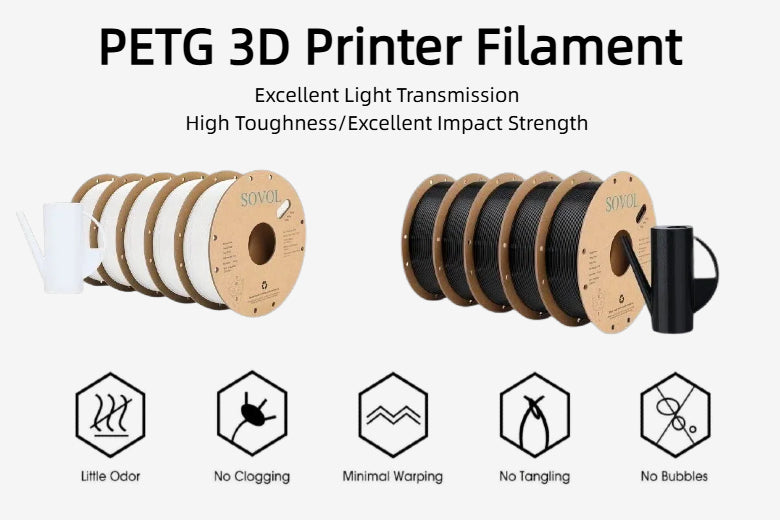

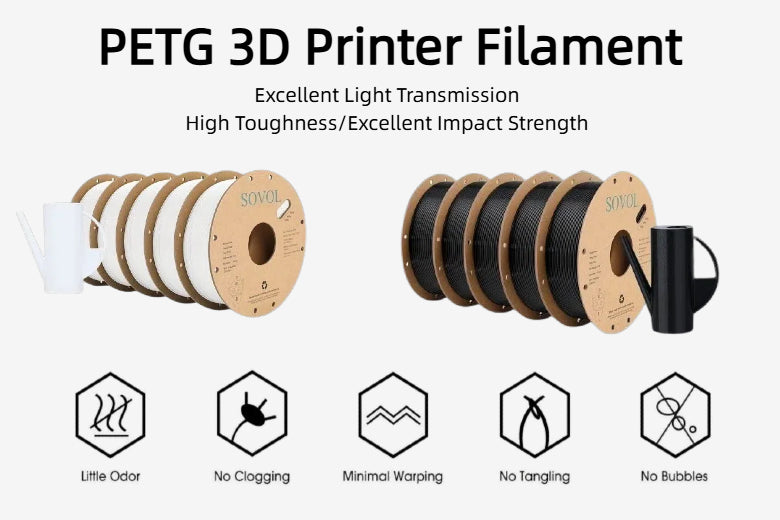

Less Warping and Shrinkage

Printing with PETG filament is simple because it avoids warping. Unlike ABS, PETG shrinks very little when cooling. This keeps your prints accurate in size and shape. Warping, a common problem in 3D printing, is much less likely with PETG.

- PETG filament reduces warping due to its low shrinkage.

- It sticks layers together well, keeping prints strong and stable.

- Printing at 220°C to 260°C helps prevent warping even more.

This makes PETG great for projects needing exact sizes, like prototypes or functional parts. You can print big models without worrying about corners lifting or layers splitting.

Tip: Level your print bed and heat it to 70°C-90°C to avoid warping.

Strong Bed Adhesion

PETG naturally sticks well to the print bed. This keeps your prints in place during printing, lowering the chance of failure. Whether you use a glass bed, PEI sheet, or textured surface, PETG stays firmly attached.

Good bed adhesion also makes PETG prints stronger. Parts won’t move or detach while printing, keeping the final product high-quality. This is especially helpful for tall or detailed designs that need a steady base.

Note: Use a glue stick or adhesive sheet to improve bed adhesion for tricky prints.

Smooth Extrusion and Strong Layers

PETG filament flows smoothly through the nozzle, creating clean and precise prints. Its strong layer bonding makes your models durable and long-lasting.

Adjusting the temperature can improve your prints. Lower temperatures (around 220°C) make smoother surfaces. Higher temperatures (up to 260°C) improve layer bonding for stronger parts. This lets you customize settings for your project’s needs.

For example, PETG Economy filament provides reliable extrusion and strong layers. It reduces problems like warping and stringing, making it a good choice for beginners and experts alike.

Tip: Keep your nozzle clean to ensure smooth extrusion. Regular printer maintenance improves print quality.

Versatility of PETG in 3D Printing

Moisture Resistance for Outdoor Use

PETG filament is great at resisting moisture. This makes it perfect for outdoor use. Unlike PLA, which absorbs water and weakens, PETG stays strong. Even in wet or humid weather, it keeps its durability.

You can use PETG for outdoor items like garden tools or signs. It won’t warp or crack from moisture, so your projects last longer. This makes PETG a reliable choice for tough outdoor conditions.

Tip: Keep PETG filament in a dry container to protect its quality.

Food Safety and Non-Toxicity

PETG is safe for food-related projects. It’s approved by the U.S. FDA as food-grade plastic. It doesn’t have harmful chemicals, so it’s good for food containers or utensils. But, you must use food-safe colors and keep your printer clean.

Clean your printer’s nozzle and bed before printing food items. A separate nozzle for food projects is even better. PETG’s smooth surface and non-toxic nature make it ideal for kitchen tools.

Note: Check if your PETG filament is labeled food-safe by the maker.

Chemical Resistance for Functional Parts

PETG resists many chemicals like acids, oils, and alkalis. This makes it great for parts used in harsh environments. It’s perfect for mechanical parts, industrial tools, or chemical storage containers.

Tests show PETG has strong tensile strength and flexibility. It handles stress well and doesn’t break down from chemicals. This makes it a smart choice for durable and functional parts.

Tip: Use PETG for strong, chemical-resistant items like machine covers or lab tools.

Comparing PETG with PLA and ABS

Strength Comparison: PETG vs. PLA

PETG and PLA can handle similar weight limits. But PETG is tougher and less likely to crack. PLA is easier to print but breaks more easily under pressure. PETG bends without breaking, making it better for strong parts.

|

Property |

PLA |

PETG |

|---|---|---|

|

Similar |

Similar |

|

|

Impact Resistance |

Low |

High |

|

Longevity and Durability |

Not very durable |

Very durable |

For parts that need to last or handle stress, PETG is better than PLA.

Ease of Printing: PETG vs. ABS

PETG is simpler to print than ABS. ABS often warps and needs a heated enclosure. PETG doesn’t shrink much and sticks well to the print bed. It also flows smoothly and bonds layers strongly, making prints look great.

- PETG doesn’t warp and stays stuck to the bed.

- ABS is strong but harder to print due to temperature issues.

If you want a filament that’s easy to use and strong, PETG is a good pick.

Versatility: PETG as a Middle Ground

PETG mixes the best parts of PLA and ABS. It prints easily like PLA and is strong like ABS. Unlike PLA, PETG resists water and sunlight, so it works well outdoors. It also avoids ABS’s warping problems, making it reliable for many uses.

Whether you’re making prototypes, tools, or gadgets, PETG is strong, flexible, and easy to print.

Use Cases for PETG Filament

Functional Parts and Prototypes

PETG is great for making strong, useful 3D prints. It handles stress, impacts, and tough conditions well. PETG resists oils, acids, and alkalis, making it good for tools. It also works better than PLA in hot environments.

|

Attribute |

Description |

|---|---|

|

Strength and Durability |

PETG prints are strong, resist impacts, and handle stress well. |

|

Chemical and Heat Resistance |

Stands up to oils, acids, and heat better than PLA. |

|

Weather Resistance |

Resists UV rays and moisture, perfect for outdoor projects. |

|

Consistent Print Quality |

Prints smoothly with strong layers and little warping. |

|

Cost-Effectiveness |

Affordable for large projects and prototypes. |

You can use PETG for brackets, enclosures, or prototypes. Its smooth printing and strong layers make every print high quality.

Hobbyist Projects and Decorative Items

Hobbyists love PETG for its mix of strength and flexibility. You can make cool designs like puzzles or decorations easily. PETG lasts longer, even with frequent use. For example, a puzzle printed with PETG shows its toughness and flexibility.

- PETG combines the best of PLA and ABS for strong prints.

- A puzzle printed with PETG took 6 to 8 hours to finish.

- PETG’s smooth finish is great for vases, figurines, or ornaments.

Its versatility lets you try creative ideas while keeping prints durable and attractive.

Professional Applications in Engineering

Professionals use PETG for engineering tasks. Car makers create custom tools with it. Electronics designers use it for strong cases. Its toughness and chemical resistance work well in harsh conditions.

New PETG types allow faster printing without losing quality. This helps meet tight deadlines for projects. Whether in aerospace, defense, or cars, PETG is reliable for tough jobs.

PETG’s strength, chemical resistance, and easy printing make it a top pick for professionals needing dependable material.

Troubleshooting PETG Printing Challenges

Fixing Stringing and Oozing

Stringing and oozing happen when extra filament leaks out. This leaves thin strands or blobs on your print. You can fix this by changing some settings:

- Increase retraction distance and speed in your slicer. This pulls filament back during moves.

- Lower the nozzle temperature to around 220°C. This makes the filament less runny.

- Dry your filament before printing. PETG absorbs water, which makes stringing worse.

Tip: Keep PETG filament in a sealed container with desiccant to stay dry.

Adjusting Print Settings

Good print settings make PETG prints look better. Use this table for the best settings:

|

Setting Type |

Recommended Value |

|---|---|

|

Nozzle Temperature |

220-250°C |

|

Heated Bed Temperature |

70-80°C |

|

Cooling Fan Settings |

Medium cooling |

|

Retraction Settings |

Adjust as needed |

Medium cooling keeps layers strong and avoids overheating. Change retraction settings based on your printer and filament to stop oozing and improve prints.

Note: Always adjust your printer when using new materials like PETG.

Avoiding Overheating and Burn Marks

Overheating can cause blobs, burn marks, or color changes. To stop this, control the nozzle temperature and speed:

- Keep the nozzle temperature between 220°C and 260°C. This helps the filament flow well without overheating.

- Slow the print speed to about 60 mm/s. Slower speeds improve layer bonding and reduce blobs or burns.

- Use medium cooling to harden layers fast without weakening them.

Tip: Clean your nozzle often to remove burnt filament and improve prints.

PETG filament is a great choice for 3D printing. It’s strong and durable, making it perfect for useful parts. At the same time, it’s easy to print, which helps both beginners and experts. PETG works well in many industries, as global data shows:

|

Region |

Key Facts |

|---|---|

|

North America |

35% of polymer filament sales in 2023; Boeing increased PETG use by 40% for non-critical parts. |

|

Europe |

Germany recycles 67% of PETG; food packaging prototypes grew 41% from 2021 to 2023. |

|

Middle East |

15% of Saudi Arabia's NEOM models used PETG; UAE’s sector grew by 27%. |

|

Latin America |

Brazil approved 14 PETG medical products; 65% of Colombia’s school models use PETG. |

From creative designs to tough prototypes, PETG is reliable and flexible for any project.

FAQ

Why is PETG better than PLA for outdoor use?

PETG handles sunlight and water well, so it’s great outdoors. PLA, however, breaks easily and fades in sunlight or damp places.

How do you stop stringing with PETG?

Change retraction settings, lower the nozzle to 220°C, and keep filament dry. These steps help avoid extra strands during printing.

Can PETG be used for food-related items?

Yes, PETG is safe for food. It’s FDA-approved. Use clean tools and food-safe colors for making kitchen items or containers.

Lämna en kommentar

Alla kommentarer modereras innan de publiceras.

Denna webbplats är skyddad av hCaptcha och hCaptchas integritetspolicy . Användarvillkor gäller.