The need for big 3D printers has grown significantly in 2025, leading to the emergence of the Best Large Format 3D Printer 2025. This surge is attributed to advancements in technology and an increase in industrial applications. These printers are revolutionizing industries by producing items faster, larger, and with greater reliability. Consider these market facts:

- Big 3D printers were valued at $2.5 billion in 2023.

- They are projected to reach $12.3 billion by 2032.

- The market is expanding rapidly at a rate of 19.8% each year.

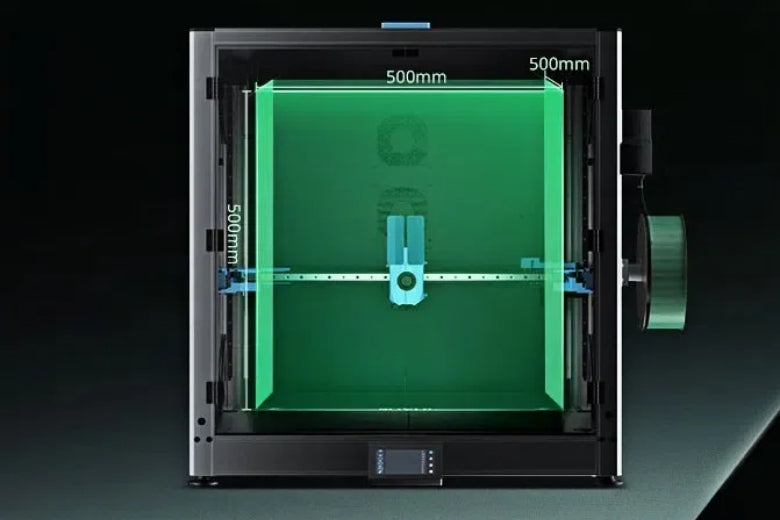

A size of 500x500x500mm has become standard for contemporary use, allowing for the creation of large, intricate designs in a single print. Whether for prototyping or producing final components, the Best Large Format 3D Printer 2025 offers the ideal combination of size, speed, and reliability for your projects.

Key Takeaways

- Big 3D printers make large items in one piece. This saves time and makes items stronger. Pick a printer with a size of at least 500x500x500mm for most tasks.

- These printers can boost work speed by up to 60% in factories. Look for features like auto-bed leveling and filament sensors to work faster.

- Using different materials is important. Make sure the printer works with materials like PLA, ABS, and mixes for various projects.

- Think about the motion system. CoreXY systems are fast and accurate. Cartesian systems are simpler to fix. Pick what fits your project best.

- Spend money wisely. Big 3D printers cost a lot but save money later. Check how much you’ll use it to see if it’s worth it.

What Is a Large Format 3D Printer?

Definition and Characteristics of Large-Format 3D Printers

A large-format 3D printer is made to print bigger items or many small parts at once. These printers have large build spaces, starting at 500x500x500mm and sometimes going over 2000mm. They are built with strong materials like steel or aluminum, making them last longer and stay steady during long prints.

Unlike regular 3D printers, large-format ones have extra features. These include auto-bed leveling, filament sensors, and power recovery systems. These tools help with tough and long projects. The table below shows how standard and large-format 3D printers differ:

|

Specification |

Standard 3D Printers |

Large-Format 3D Printers |

|---|---|---|

|

Build Volume |

~200×200×200mm |

500mm to over 2000mm |

|

Frame Structure |

Basic materials |

Strong steel/aluminum, enclosed frames |

|

Print Technology |

FDM/FFF |

FDM/FFF, SLA/LCD, Binder Jetting, SLS |

|

Bed Leveling System |

Manual |

Auto-bed leveling |

|

Power Recovery |

Rare |

Needed for long prints |

|

Filament Sensors |

Uncommon |

Common for big models |

These features make large-format 3D printers great for professionals needing accuracy and flexibility.

Differences Between Large Format and Standard 3D Printers

How are large-format 3D printers different from regular ones? The biggest difference is their size. Regular printers make small items, but large-format printers can create huge parts or many pieces at once. This saves time and reduces the need to put parts together.

Another difference is the materials they use. Large-format printers can handle more types of materials, like strong plastics and composites. They also have advanced systems, such as CoreXY or Cartesian setups, for better speed and precision. Plus, they include helpful features like auto-bed leveling and filament runout detection, making them easier to use for big projects.

Applications Where Large-Format 3D Printing Excels

Large-format 3D printing is best for industries needing big, fast, and custom designs. For example:

- Architecture and Construction: These printers can make detailed building models, parts, or even walls. They are very useful for architects and builders.

- Healthcare: Large-format printers help create custom medical models and implants. This improves surgeries and saves time.

- Aerospace and Automotive: These printers make lightweight prototypes and working parts. Over 72% of aerospace prototypes now use 3D printing because it’s so efficient.

- Sustainability: With eco-friendly materials, large-format 3D printing helps reduce waste and pollution. This supports greener manufacturing.

New hardware and software have made large-format 3D printers even better. Automation, material options, and AI tools make them faster and more effective. Industries like automotive, aerospace, and healthcare are using these printers more, pushing the market to grow to $2.5 billion by 2025.

Tip: When choosing a large-format 3D printer, think about what you need it for. Whether it’s for prototypes, production, or custom designs, these printers are very flexible.

Advantages of Large Format 3D Printers

Printing Larger Objects in a Single Piece

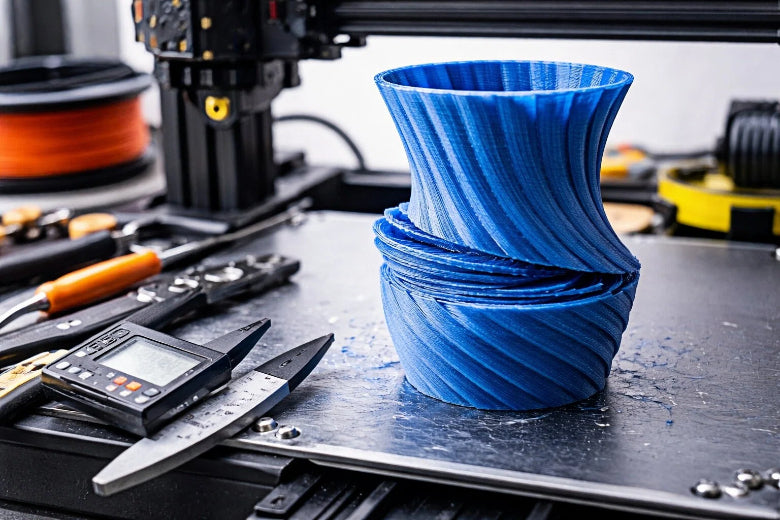

Large-format 3D printers are great for making big items in one go. They can print things like furniture, building models, or machine parts without needing to join smaller pieces. This saves time and keeps the object strong. For instance, a printer with a 500x500x500mm size can create detailed prototypes or finished products with high accuracy.

These printers also handle tricky shapes easily. Whether it's curved designs or detailed patterns, the large space lets you create without losing quality. This makes them perfect for industries like construction and car-making, where strength and precision matter most.

Tip: Pick a sturdy 3D printer with advanced motion systems for better results on big projects.

Improved Productivity for Industrial and Professional Use

Large-format 3D printers help industries work faster and better. They can improve efficiency by up to 60% for tasks like making tools, molds, and patterns. These printers also cut costs for small-batch manufacturing by a lot.

|

Improvement Type |

Measurable Outcome |

|---|---|

|

Process Efficiency |

Up to 60% faster for tools, molds, and patterns. |

|

Cost Reduction |

Big savings in small-batch production. |

|

Quality Consistency |

Reliable, high-quality parts for industrial use. |

Companies like GE Aviation use these printers to make thousands of parts, proving their dependability. Whether you're testing ideas or making final products, these printers give steady, high-quality results that meet industry needs.

Note: Look for a 3D printer with features like auto-bed leveling and filament sensors to save time and improve productivity.

Versatility in Materials and Applications

Large-format 3D printers are very flexible in what they can do and the materials they use. You can make prototypes, finished items, or even creative designs. They work with many materials, like strong plastics, composites, and eco-friendly options. This lets you customize projects, whether you're building models or making lightweight car parts.

- Big 3D printers can create detailed and complex designs.

- They help the environment by reducing waste and using green materials.

- Fields like architecture, art, and furniture design benefit from their creativity.

FDM technology, common in industries, makes these printers easy to use and versatile. You can design detailed prototypes or make strong, lasting parts. In architecture, they help by creating accurate models and structural pieces for better project outcomes.

Tip: Choose a 3D printer that works with different materials to get the most out of it for various projects.

Comparing Large Format Printers to Other Types

Large Format vs. Large Bed Printers

Large-format and large bed 3D printers both have big build areas. However, they are used for different purposes. Large-format printers are made for printing big objects or many parts at once. They often come with strong frames and auto-bed leveling for long prints without stopping.

Large bed printers focus on having a wide print surface. But they may not offer the same precision or material options. These printers are better for making several smaller items in one go. If your work needs detailed designs or high accuracy, a large-format printer is the smarter choice.

Tip: Think about your project needs. For large, detailed prints, pick a large-format printer.

Build Volume and Intended Use Differences

The size of the build area affects what you can make. Large-format printers start at 500x500x500mm and can go over 2000mm in one direction. This makes them great for industries like architecture, where big models or prototypes are needed.

Smaller printers are better for hobbies or schools. They are good for small, detailed items but may need assembly for bigger projects. Always choose a printer that fits your needs. For example, in car design, a large-format printer can make full-size prototypes, saving time and effort.

Cost and Performance Comparisons

The price of a 3D printer shows what it can do. Large-format printers, like the BigRep ONE, cost $50,000 to $100,000. They are perfect for industrial tasks. Desktop printers, such as the Ender-3 V2, cost $200 to $500. These are great for beginners but not for big projects.

Here’s a simple comparison of 3D printer types:

|

Type of 3D Printer |

Example Model |

Price Range (USD) |

|---|---|---|

|

Desktop 3D Printer |

Ender-3 V2 |

200 – 500 |

|

Educational 3D Printer |

MakerBot Replicator+ |

1,000 – 2,000 |

|

Industrial 3D Printer |

Stratasys Fortus 450mc |

50,000 – 100,000 |

|

Resin/SLA 3D Printer |

Formlabs Form 3 |

3,000 – 5,000 |

|

Metal 3D Printer |

Markforged Metal X |

100,000 – 200,000 |

|

Large-scale 3D Printer |

BigRep ONE |

50,000 – 100,000 |

Material costs are also important. For example, SLA resins cost $50 to $200 per liter. Metal powders for DMLS can cost over $500 per kilogram. These costs add up, so include them in your budget when picking a printer.

Note: Large-format printers cost more upfront, but they save time and handle big projects well, making them worth the price.

Industries and Applications for Large Format 3D Printers

Architecture and Construction

Large-format 3D printers are changing how buildings are made. They can create detailed models, housing parts, or even full walls. These printers save materials and cut labor costs, making them great for eco-friendly projects.

Smart cities and fast construction needs are boosting this technology. For example, in 2024, the 3D printing construction market was worth $53.9 million. It grew at an amazing rate of 111.3% each year. By 2030, modular homes and energy-saving materials will lead the industry.

In 2023, the market was valued at $1.5 billion, growing at 59.6% yearly. This shows the rising need for green building solutions. By 2032, these printers will lower costs and waste even more, becoming key to modern construction.

Tip: If you work in construction, a large-format printer can save time and money.

Automotive and Aerospace Industries

Large-format 3D printers are great for cars and planes. They make strong, lightweight parts with complex shapes. These printers also use tough materials to meet strict standards.

|

Industry |

What They Do |

|---|---|

|

Automotive |

Make lightweight, strong car parts designed for specific models. |

|

Aerospace |

Build aircraft parts with high-strength materials. |

For cars, these printers create parts that lower weight and improve fuel use. In planes, they make strong, light components that save time and boost accuracy. This makes them essential for modern factories.

Note: Pick a printer that works with strong materials for these industries.

Prototyping and Manufacturing

Large-format 3D printers make prototyping and manufacturing easier. They create prototypes that look and work like final products. This lowers costs and speeds up design changes.

- Make prototypes that act like finished products.

- Skip expensive tools, saving money on prototypes.

- Speed up design and production times.

- Test many designs quickly for better results.

- Create shapes that are hard to make with old methods.

- Adjust designs to fit specific needs.

- Use many materials for different projects.

These printers also let you pick materials to match your project. Whether for detailed prototypes or tricky parts, they offer great flexibility.

Tip: For fast prototyping, choose a printer with good precision and material options.

Key Features to Consider When Choosing the Best Large Format 3D Printer 2025

Build Volume and Frame Structure

The build volume decides how big your printed items can be. It’s crucial for handling large projects. For most professional uses, a size of 500x500x500mm works well. Some printers go beyond this, with sizes over 2000mm in one direction. This lets you print big items like furniture or building models in one piece.

The frame structure keeps the printer steady during long prints. Strong frames made of steel or aluminum reduce shaking and improve accuracy. For example, stainless steel frames with auto-leveling systems are durable and easy to use. Features like air filters also improve the workspace, especially for industrial jobs.

Tip: Pick a printer with a strong frame and a build size that fits your needs. Bigger build volumes give more options but need more room.

Motion Systems: CoreXY vs Cartesian

The motion system affects how fast and accurate your printer works. Two common systems are CoreXY and Cartesian, each with pros and cons.

|

Feature |

CoreXY |

Cartesian |

|---|---|---|

|

Print Speed |

Fast and smooth prints |

Slower for bigger items |

|

Accuracy |

Very precise movements |

Good accuracy but slower |

|

Design Efficiency |

Compact design for larger builds |

Takes up more space |

|

Maintenance |

Harder to fix |

Easier to maintain |

|

Advantages |

High speed, less shaking |

Simple design, reliable quality |

|

Disadvantages |

Costs more, harder to learn |

Slower speed, bigger footprint |

CoreXY systems are compact and fast, reducing vibrations for smoother prints. But they cost more and need more upkeep. Cartesian systems are simpler and easier to fix. They may be slower but still produce good-quality prints.

Note: Choose CoreXY for speed and precision. Pick Cartesian for simpler tasks or smaller budgets.

Firmware: Klipper vs Marlin

Firmware controls how your printer works. Two popular options are Klipper and Marlin, each offering unique benefits.

- Klipper: This firmware is fast and advanced. It uses extra hardware to process tasks, boosting speed and accuracy. Features like input shaping reduce shaking for better prints. However, it’s harder to set up and takes time to learn.

- Marlin: This firmware is simple and reliable. It works with many printers and is easy to customize. While it’s not as fast as Klipper, it’s stable and great for beginners.

Tip: Use Klipper for speed and advanced features. Choose Marlin for simplicity and ease of use.

Print speed and reliability

When picking a large-format 3D printer, speed and reliability are key. A faster printer helps finish jobs quickly, but it must stay accurate. Advanced systems like CoreXY keep prints precise by reducing shaking, even at high speeds. This mix of speed and accuracy is vital for industries like cars and planes, where details and deadlines matter.

Reliability means the printer works well over time. Long prints, especially for big items, need a machine that won’t stop halfway. Features like filament sensors and power recovery systems prevent mistakes during long jobs. For instance, a strong frame and advanced firmware, like Klipper, help handle tough tasks with less downtime.

Tip: Pick a printer that balances speed and accuracy. A sturdy, reliable machine with advanced systems saves time and avoids errors.

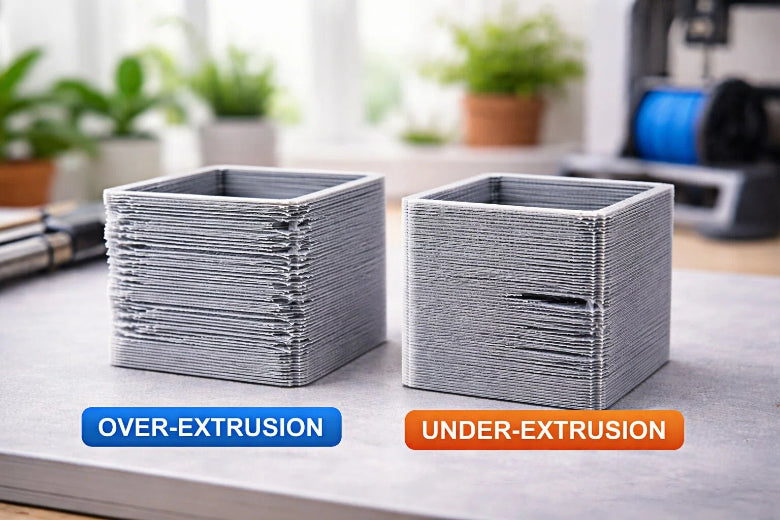

Supported materials and extrusion systems

The materials a printer can use decide how flexible it is. Large-format 3D printers work with many materials like PLA, ABS, PETG, and carbon fiber. This lets you do different projects, from light prototypes to strong parts. For example, architects may use eco-friendly materials, while aerospace needs tough composites for strength.

Extrusion systems manage these materials. Direct-drive extruders control soft filaments better, while Bowden extruders are faster with hard materials. Dual extruders let you print with two materials or colors at once. This is great for making complex designs or working prototypes.

Note: Choose a printer with an extrusion system that fits your materials. A flexible system gives you more options for creative projects.

Bed leveling systems and ease of use

Bed leveling affects how well prints stick to the surface. If the bed isn’t level, prints can warp or fail. Many large-format 3D printers now have automatic bed leveling. These systems use sensors to adjust the bed height, ensuring the first layer sticks well, even for big prints.

Ease of use is also important. Touchscreens, pre-set profiles, and simple software make printing easier. These tools help beginners start quickly and save time for professionals. They improve the overall printing experience.

Tip: Get a printer with automatic bed leveling and easy controls. These features make printing simpler and ensure great results every time.

Challenges and Considerations in Large-Format 3D Printing

Cost and Budget Constraints

Large-format 3D printing needs smart money planning. Costs include buying the printer, yearly fees, and materials. A good large-format printer costs $50,000 to $100,000. Material prices depend on the type of filament or resin used.

These printers can save money in certain areas, like healthcare. For example, 3D models help surgeons work faster and more accurately. This saves money per surgery. But savings depend on how often the printer is used. If usage is low (5%), costs may be too high. Higher usage (20%) makes the investment worth it.

Tip: Think about how much you’ll use the printer before buying. This helps you save money.

Maintenance and Durability

Large-format 3D printers need regular care and repairs. Long print jobs can wear out parts like extruders and motion systems. Materials like nylon and PLA absorb moisture, which makes them weaker.

Studies show common problems with durability:

|

Study |

Findings |

|---|---|

|

Celestine et al. |

|

|

Cormier and Poddar |

Voids and weak layers lower strength. |

|

Banjo et al. |

Nylon and PLA weaken from water absorption. |

|

Kaknuru and Pochiraju |

Moisture affects ABS and PLA strength. |

|

Xiao et al. |

UV light reduces polyethylene strength. |

|

Dizon et al. |

Post-processing improves composite durability. |

|

Afshar and Mihut |

Metallic films make parts stronger. |

|

Glowacki et al. |

Freeze-thaw cycles change material properties. |

|

Grassi et al. |

Heat and UV light affect big structures. |

To make parts last longer, use UV-safe materials or add metallic coatings. Regular care keeps the printer working well and lasting longer.

Note: Check your printer often and store materials safely to avoid damage.

Space Requirements and Setup

Large-format 3D printers need a lot of room. Their big build sizes, like 500x500x500mm, need strong setups and special areas. A stable surface stops shaking during prints. Some printers need enclosures to control heat and air.

Setting up these printers also needs good airflow. Some materials release fumes, so ventilation is important. Electrical needs vary, and some printers use more power.

Tip: Plan your workspace carefully. Make sure there’s enough room for the printer, tools, and materials.

Common Buyer Mistakes to Avoid

Forgetting About Build Volume

Some buyers don’t think about build volume when picking a printer. They focus on speed or materials but forget if the printer fits their project size. A small build volume means you can’t print big items or many parts at once.

Measure the size of what you want to print first. Compare it to the printer’s build volume. For example, furniture prototypes or building models need at least 500x500x500mm.

Tip: Pick a printer with the right build volume for your needs. Bigger isn’t always better, but too small limits your options.

Not Checking Material Compatibility

Material compatibility is very important for good printing results. Some buyers skip this step and get printers that don’t work with their materials. If you need strong composites like carbon fiber or flexible filaments like TPU, make sure the printer supports them.

Different extruders handle materials differently. Direct-drive extruders are great for soft filaments, while Bowden extruders work better with hard ones. Check the printer’s specs to match your material needs.

Note: Always check if the printer works with your materials. This avoids problems later.

Choosing Speed Over Quality

Fast printers sound great, but they might lower print quality. This can lead to rough surfaces or wrong sizes. For industries like healthcare or aerospace, accuracy is very important.

Look for printers that balance speed and quality. Features like advanced motion systems help with both. Slower printers often give better results for professional projects.

Reminder: Don’t pick speed over quality. Accurate prints save time and money in the end.

Skipping Firmware and Software Features

Not paying attention to firmware and software can cause problems. These tools control how your 3D printer works and how easy it is to use. If you ignore them, you might get a printer that feels old or lacks important features for your projects.

Modern firmware, like Klipper and Marlin, has useful features. Klipper makes printing faster and more accurate by using extra hardware. Marlin is stable and works with many printers. Picking the right firmware helps your printer work better and fit your needs.

Software is just as important. Large-format printers need slicing software to prepare models for printing. Programs like Cura, PrusaSlicer, and Simplify3D let you change settings like layer height and print speed. Without good software, it’s harder to fix problems or improve your prints.

Tip: Make sure the printer works with popular slicing software. This makes it easier to adjust settings and get help from others.

Firmware updates are also important. Companies release updates to fix bugs, add features, or improve performance. If your printer doesn’t get updates, it might not keep up with new technology. This could stop you from using new materials or advanced printing methods.

|

Feature |

Klipper |

Marlin |

|---|---|---|

|

Speed |

Very fast |

Moderate |

|

Accuracy |

Excellent |

Good |

|

Ease of Use |

Needs setup |

Easy for beginners |

|

Update Frequency |

Regular |

Frequent |

Skipping these features can lead to bad prints or fewer options. Always check firmware and software before buying a large-format 3D printer.

Reminder: Firmware and software are like the brain of your printer. Choose carefully to get the best results.

Top Large Format 3D Printers in 2025

Sovol SV08 MAX: Features, Benefits, and Performance

The Sovol SV08 MAX is a top pick for 2025. It works well for both professionals and hobbyists. With a build size of 500x500x500mm, it can print large, detailed designs in one go. Its strong aluminum frame keeps it steady during long prints. The Klipper firmware makes it faster and more accurate.

This printer is very flexible, working with materials like PLA, ABS, and PETG. Its direct-drive system handles soft filaments easily, making it useful for many projects. Features like auto bed leveling and filament sensors make printing easier and reduce mistakes.

People love the Sovol SV08 MAX for its steady performance and great print quality. Whether you’re testing ideas or making final products, it gives professional results. Its mix of advanced features and fair price makes it a great choice for large-format 3D printing in 2025.

Tip: If you need speed and accuracy, the Sovol SV08 MAX is a smart buy.

Other Leading Models in the Market

Other printers also stand out in 2025. The Elegoo Neptune 4 Max has a 420x420x480mm build size and is known for speed and quality. The Anycubic Kobra 2 Max, with a slightly bigger size of 420x420x500mm, offers good quality but mixed reviews on speed.

For a cheaper option, the Artillery Sidewinder X4 Plus is reliable and affordable. The Comgrow T500, with a 500x500x500mm build size, is easy to use and versatile, making it a strong competitor in the market.

Note: Think about your needs, like size and material options, when comparing printers.

Comparison of Price, Reliability, and Print Quality

Picking the right large-format printer means balancing cost, reliability, and quality. The table below compares popular models:

|

Printer Model |

Price |

Build Volume |

Print Quality (Layer Resolution) |

User Feedback |

|---|---|---|---|---|

|

Artillery Sidewinder X4 Plus |

$349.00 |

300 x 300 x 400 mm |

0.1 mm |

Affordable and reliable, but some setup issues reported. |

|

Elegoo Neptune 4 Max |

$430.00 - $665.28 |

420 x 420 x 480 mm |

0.1 mm |

Fast and high-quality, but firmware bugs noted. |

|

Anycubic Kobra 2 Max |

$479.00 |

420 x 420 x 500 mm |

0.1 mm |

Good quality, but speed claims questioned. |

|

Comgrow T500 |

$799.00 |

500 x 500 x 500 mm |

0.1 mm |

Easy to use and versatile, great for many tasks. |

The Sovol SV08 MAX, though not listed here, competes well with its advanced features and strong performance. When choosing a printer, focus on your budget and project needs.

Reminder: Expensive printers often have better features, but cheaper ones can still work well for smaller tasks.

Picking the best large-format 3D printer in 2025 means knowing what you need and finding features that fit. Think about the technology, build size, motion systems, and materials it supports. Different printers have their own strengths and weaknesses.

|

Technology |

Pros |

Cons |

|---|---|---|

|

FDM |

Popular and budget-friendly |

Less precise, basic designs |

|

SLA |

Sharp details, works with many materials |

Costs more, needs extra steps |

|

SLS |

Strong parts with great properties |

Expensive and harder to set up |

Here’s how to choose based on your needs:

- Hobbyists: Go for low-cost printers with easy-to-replace parts. Models between $700 and $1200 are simple and dependable.

- Prosumer Users: Look for flexible printers with better performance. Dual extruders and thin layers (20-25 microns) improve detail for $1800-$2500.

- Industrial Users: Choose scalable machines with advanced tools. Printers with adjustable build sizes and high precision (~20 microns) are best for professional work.

|

User Type |

Price Range |

Smallest Layer Size |

Build Volume |

Key Features |

|---|---|---|---|---|

|

Hobbyist |

100 microns |

0.06 cf |

Replaceable parts |

|

|

Pro |

$1800 - $2500 |

20 - 25 microns |

0.69 cf |

Dual extruders |

|

Industrial |

~$3500 |

20 microns |

Varies |

Advanced tools |

Final Tip: Match your budget and project goals to the printer’s features. Whether you’re a hobbyist trying new ideas or a business scaling up, the right printer will save time and deliver great results.

FAQ

What size should a large-format 3D printer be?

The right size depends on your project. A 500x500x500mm build area is good for most jobs. Bigger sizes, like over 2000mm, are best for industries needing large models, such as construction or car-making.

Do large-format 3D printers give good print quality?

Yes, they produce great quality even for big items. Features like fine resolution and advanced systems help create smooth surfaces and detailed designs. Check the printer’s resolution and sturdy frame for reliable results.

Are large-format 3D printers good for quick prototyping?

Yes, they are great for fast prototyping. Their big build space and ability to use different materials make them ideal for creating working prototypes quickly. This saves time and money in fields like healthcare and aerospace.

What materials work well with large-format 3D printers?

These printers can use materials like PLA, ABS, PETG, and composites. Pick materials based on your needs. For example, PLA is good for eco-friendly projects, while carbon fiber composites are strong and lightweight for tough parts.

How can I get high-quality prints?

To get sharp prints, choose a printer with advanced software and precise systems. Features like auto-bed leveling and filament sensors help improve accuracy. Regular care keeps the printer working well and ensures better results.