When it comes to large-format 3D printing, precision isn’t just a feature—it’s a necessity. As print beds scale up to 400mm, 500mm, or even more, maintaining a perfectly level surface becomes increasingly difficult. Traditional leveling methods struggle with the heat-induced warping, mechanical inconsistencies, and surface deviations common in big builds. That’s where Eddy Current Bed Leveling steps in—a non-contact, high-precision solution that’s revolutionizing large-scale 3D printing.

What Is Eddy Current Bed Leveling?

Eddy Current Bed Leveling uses electromagnetic sensors to detect even the slightest variations in distance between the nozzle and the metal bed surface. The sensor emits a magnetic field, and as it approaches a conductive surface, it induces eddy currents. The strength of these currents varies depending on the distance, allowing the system to precisely measure the bed profile—without ever making physical contact.

This method is faster, more reliable, and more durable than traditional mechanical probes (like BLTouch) or capacitive sensors.

Why It Matters in Large-Format Printing

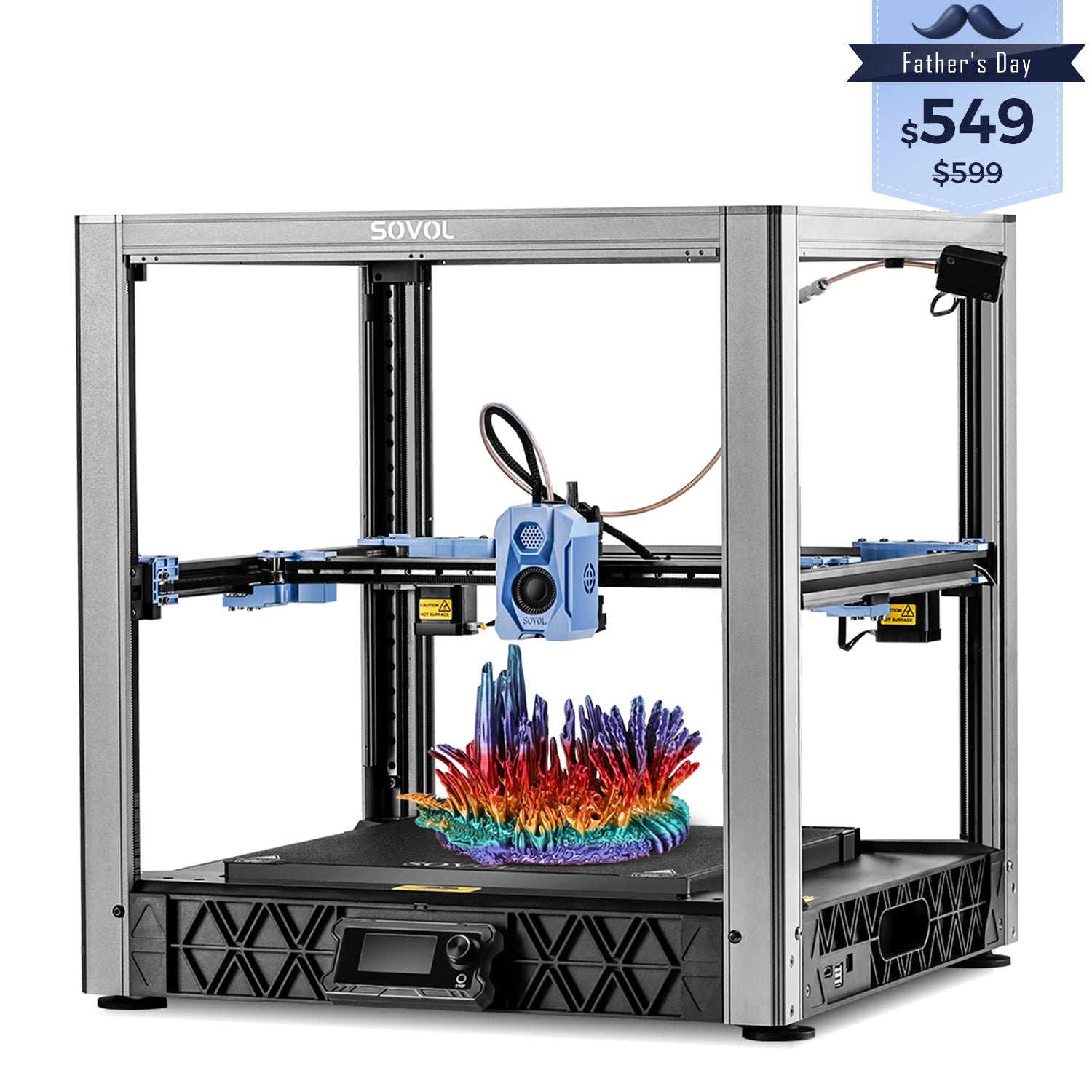

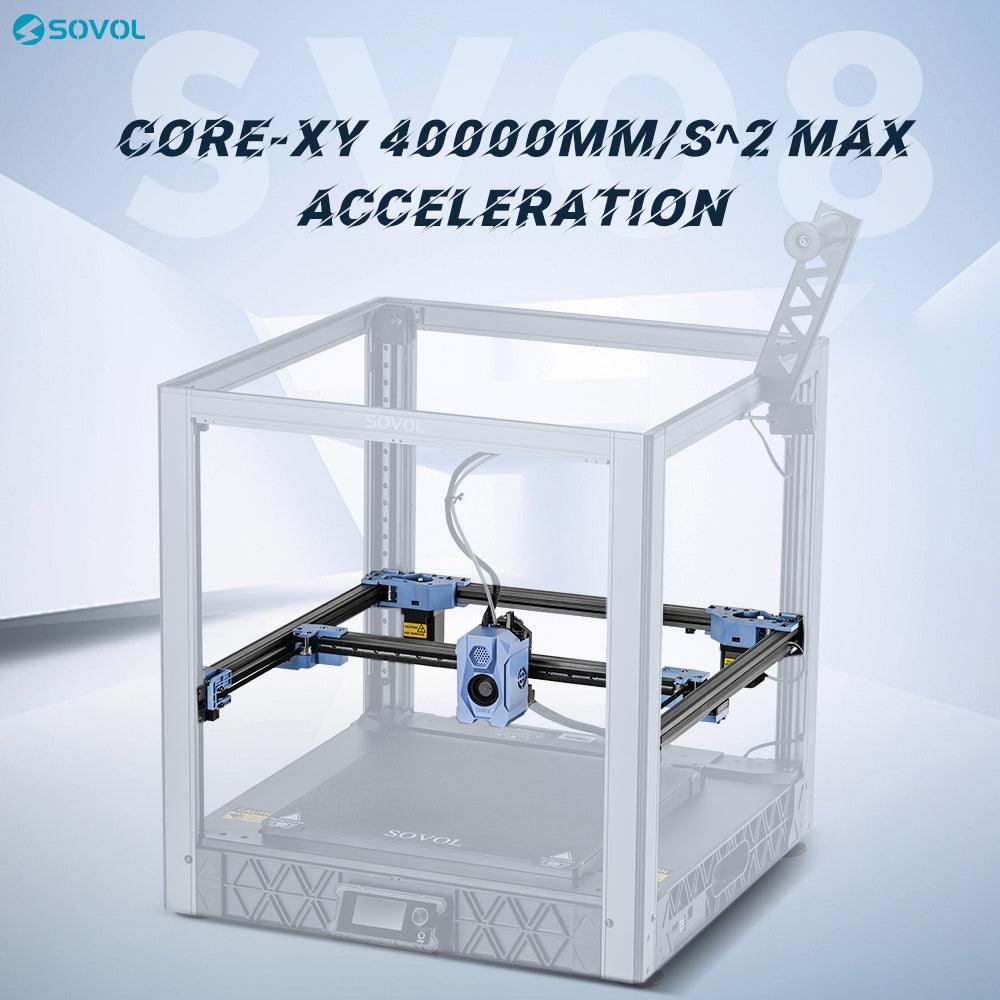

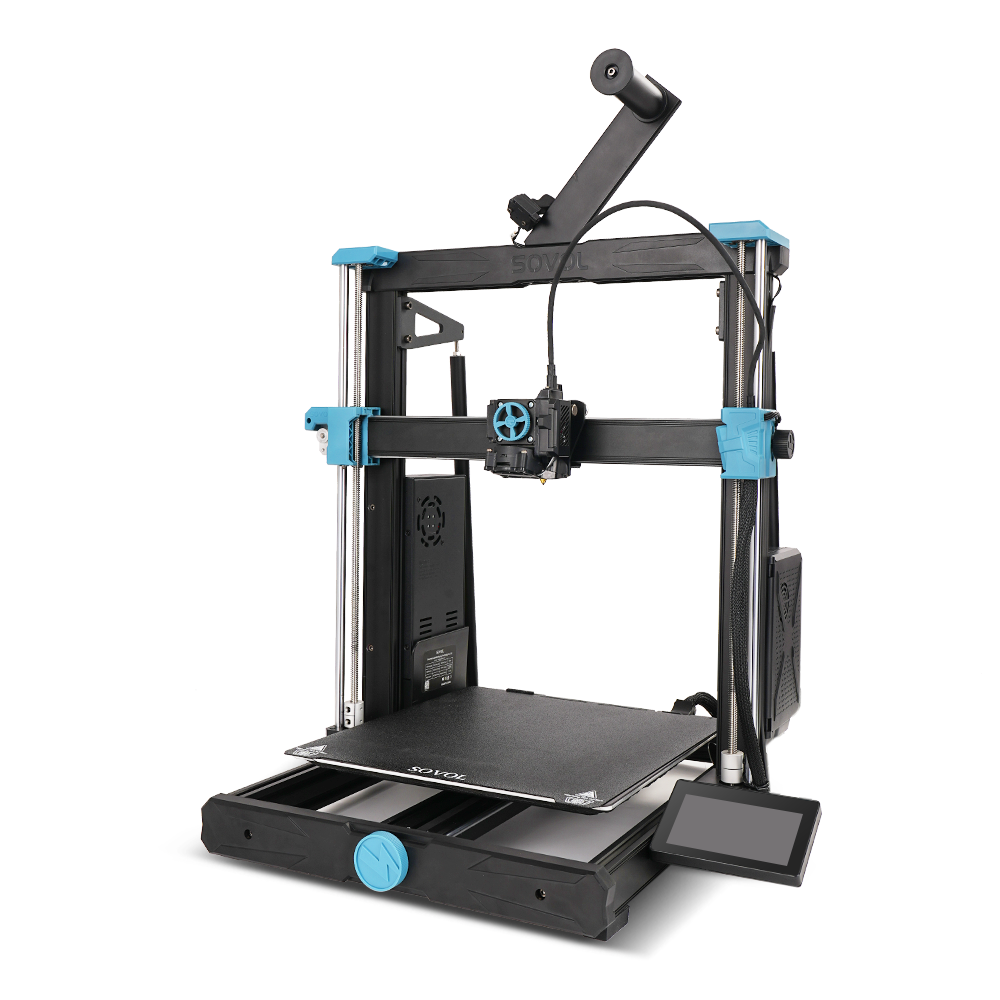

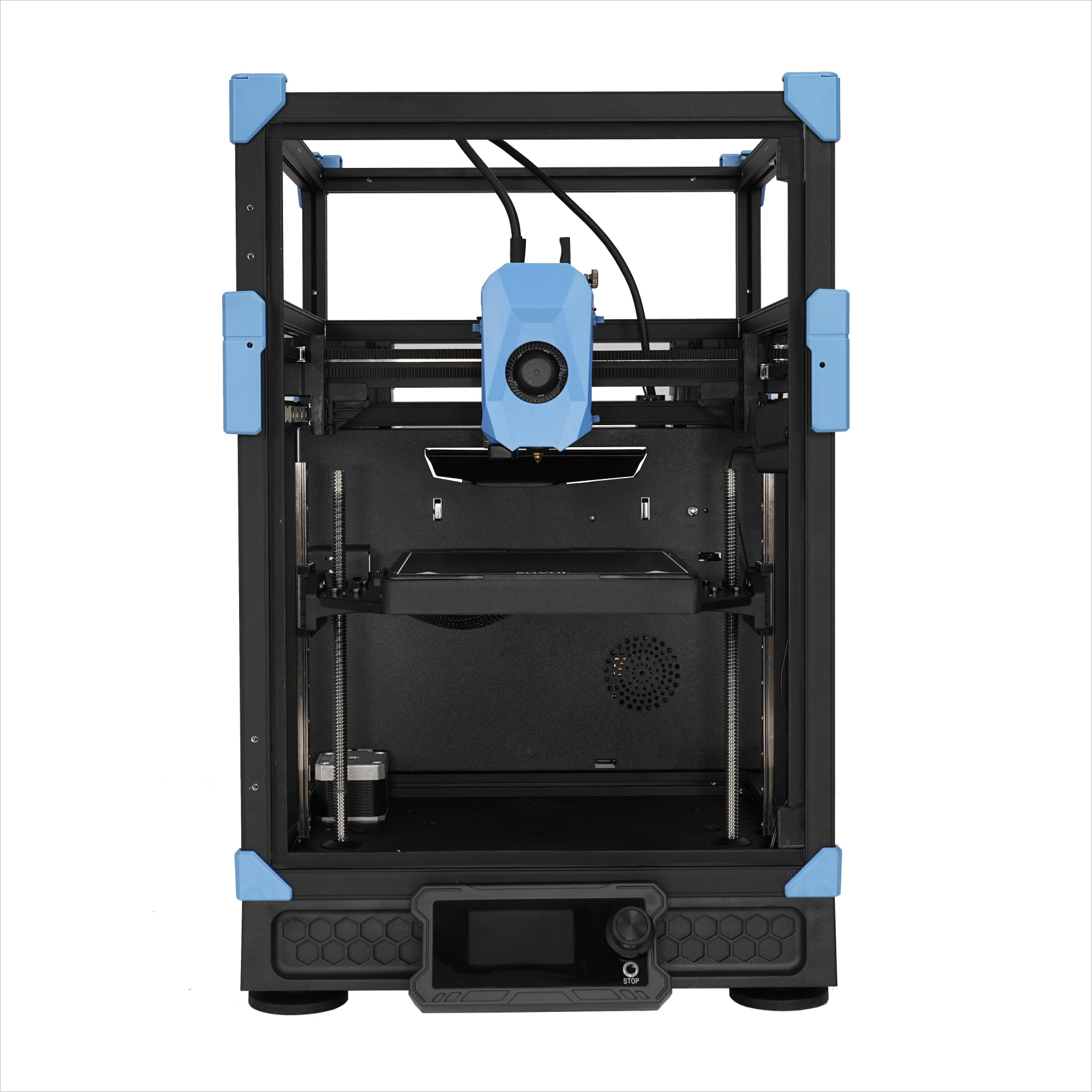

Large-format FDM printers—like the Sovol SV08 Max with its 500×500×500mm build volume—demand a leveling system that’s accurate and robust. Minor bed warping or leveling inconsistencies over such a wide area can lead to failed first layers, poor adhesion, and inconsistent results.

Eddy Current Scanning solves this with:

- Contactless measurement: No risk of probe drag or mechanical wear.

- High speed: Can scan a 500mm bed in ~80 seconds.

- Thermal resistance: Not affected by heated beds like some capacitive sensors.

- Exceptional repeatability: Ensures your first layer sticks every time, even after long prints.

Comparison: Eddy Current vs. Other Leveling Methods

|

Method |

Contactless |

Speed |

Precision |

Durability |

Ideal For |

|---|---|---|---|---|---|

|

Eddy Current |

✅ Yes |

🚀 Fast |

🎯 High |

💪 Very High |

Large-format/industrial |

|

BLTouch |

❌ No |

⚙️ Medium |

👍 Good |

⚠️ Moderate |

Desktop printers |

|

Capacitive |

✅ Yes |

⚙️ Medium |

👌 Moderate |

⚠️ Sensitive |

Smooth non-metal beds |

|

Manual |

❌ No |

🐢 Slow |

🤷♂️ Variable |

🧰 N/A |

Entry-level users |

Real-World Benefits for Creators and Professionals

Whether you're printing:

- Full-size cosplay props

- Industrial jigs or fixtures

- Architectural models

- Multi-part batch runs

...Eddy Current leveling dramatically improves first-layer success rates and overall reliability—saving you time, filament, and frustration.

It’s especially powerful in production environments or print farms where consistent results are critical across multiple machines.

Sovol SV08 Max: Built-In Precision

One standout example is the Sovol SV08 Max, which integrates Eddy Current Scanning into its high-speed CoreXY system. Users can scan a full 500×500mm bed in ~80 seconds with sub-millimeter accuracy—no touching, no adjusting, just precision from the start.

Combined with its 700mm/s max speed, Klipper firmware, and robust aluminum frame, the SV08 Max is a flagship-level machine designed for serious makers and professionals.

Conclusion: The Future Is Magnetic

Eddy Current Bed Leveling is more than a convenience—it's a key enabler for reliable large-scale 3D printing. As printers grow in size and speed, contactless precision leveling is quickly becoming the gold standard.

If you’re serious about getting high-quality prints at scale, it might be time to move beyond probes and step into the future—with Eddy Current technology.

💬 Want to Learn More?

- Explore the Sovol SV08 Max

- Learn about Klipper’s integration with Eddy Current sensors

- Join the Sovol user community on Facebook

FAQ

What is eddy current bed leveling, and how does it work?

Eddy current bed leveling uses magnets to measure gaps. Sensors find small height changes by checking coil resistance. This creates a detailed map for accurate leveling.

Can eddy current bed leveling work with non-metal beds?

No, it only works on metal or conductive materials. Non-metal surfaces, like glass or plastic, don’t have the needed electrical traits.

Is eddy current bed leveling suitable for small 3D printers?

Yes, but it’s better for large printers. Small printers may not need this high level of precision. Hobbyists might prefer simpler, cheaper options.

How often does the system need calibration?

You need to calibrate it sometimes to keep it accurate. How often depends on how much you use it and the environment. Regular checks help it work well.

Does eddy current bed leveling increase print quality?

Yes! It makes the bed even, reducing mistakes like uneven layers. This gives smoother prints and fewer failed projects, especially for big designs.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.