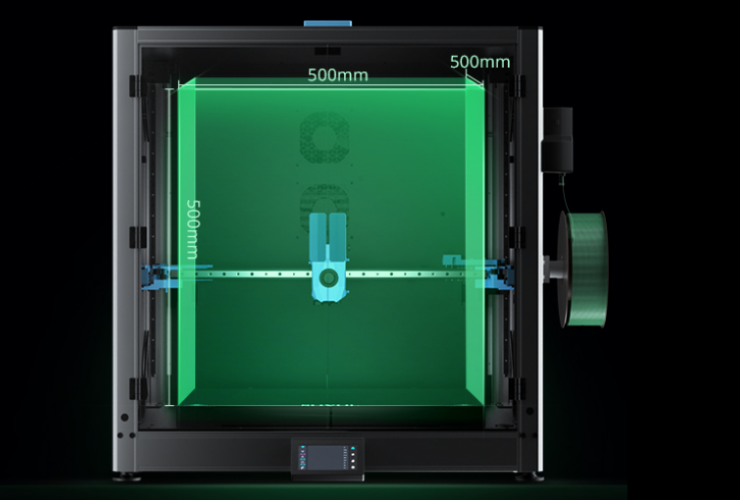

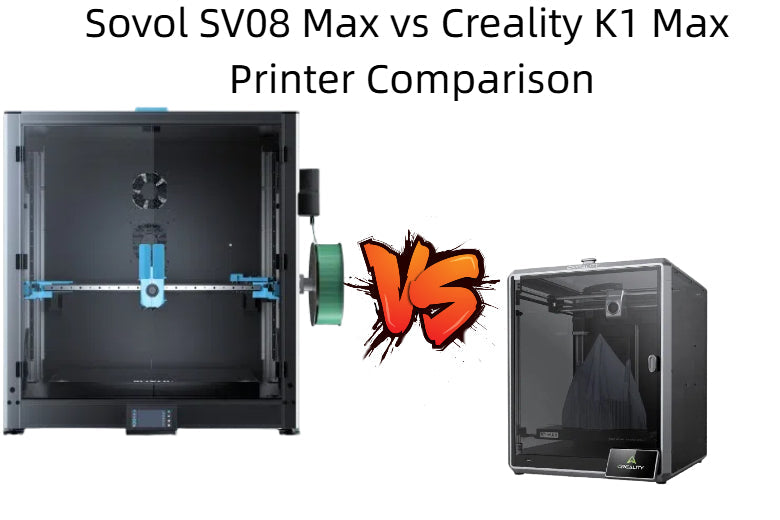

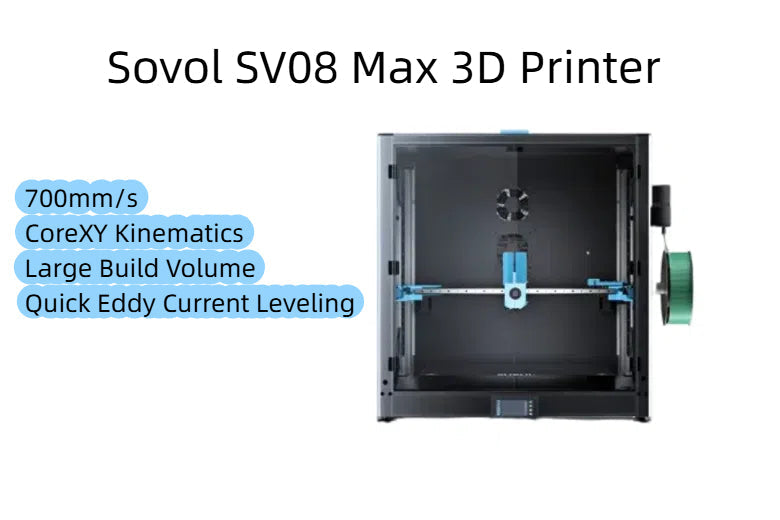

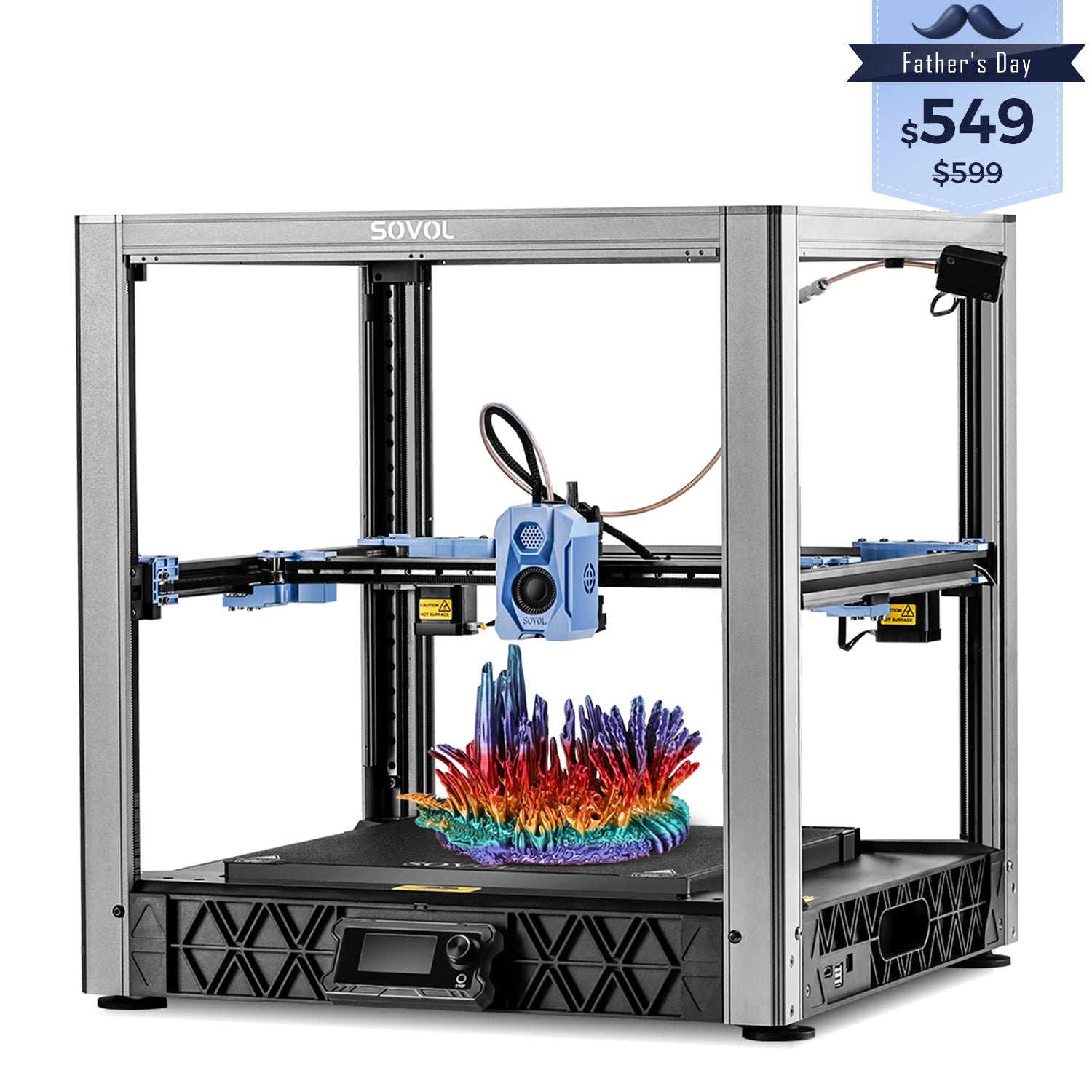

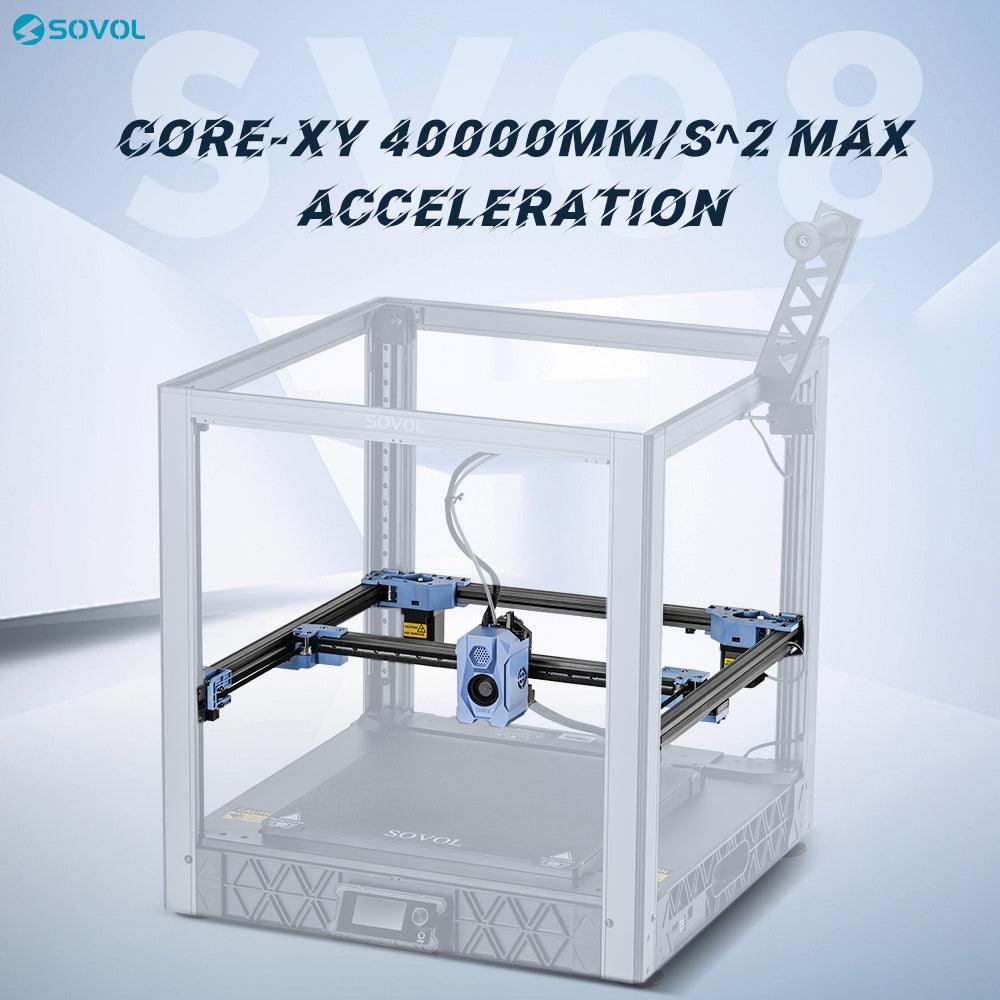

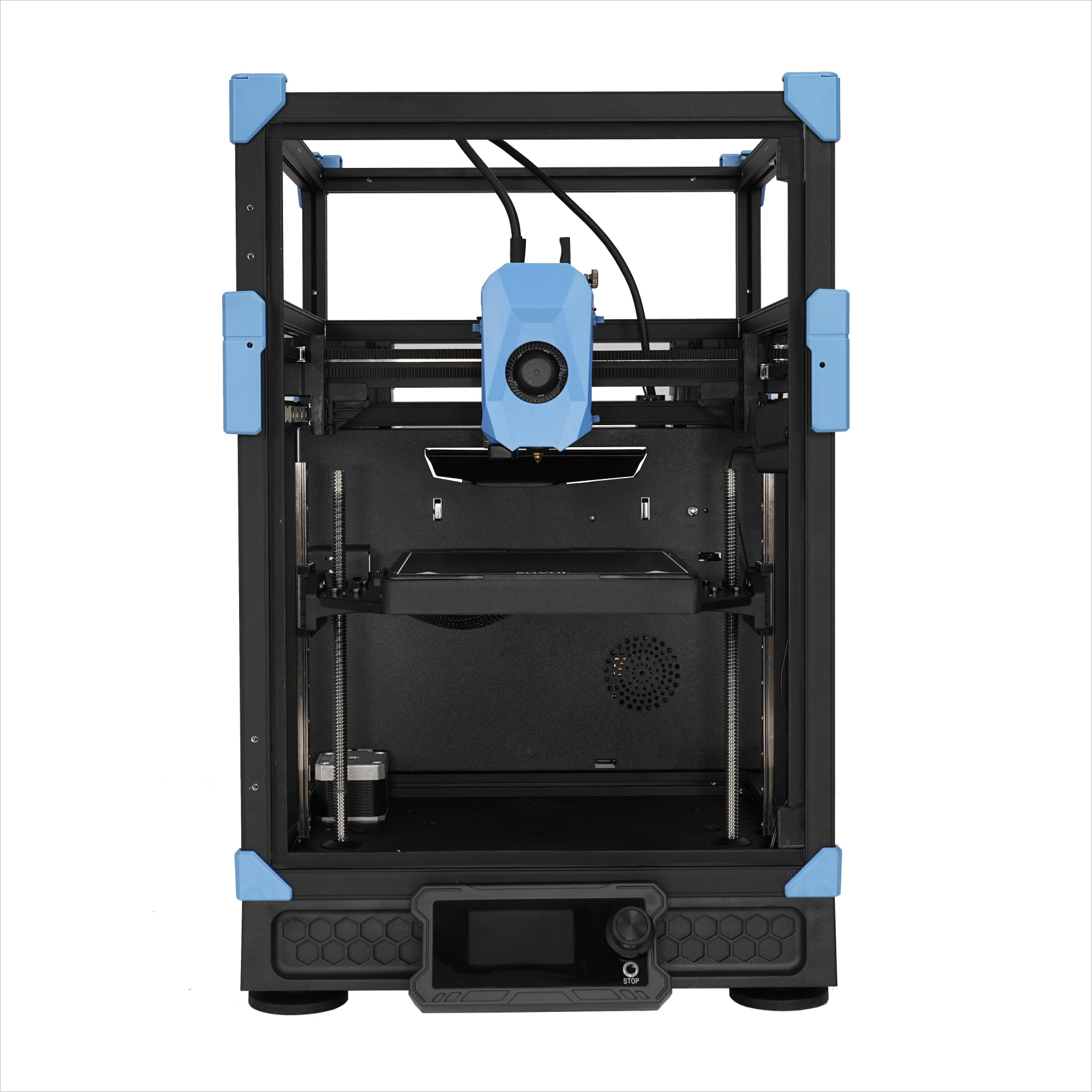

The Sovol SV08 Max 3D printer helps you make unique stools with great accuracy and speed. Its smart tools, like Adaptive Area Detection and Pressure Advance, make sure every detail is perfect. With a build size of 500 x 500 x 500 mm and printing accuracy of ±0.1 mm, this printer turns your ideas into strong, useful furniture.

Key Takeaways

- Make sure your Sovol SV08 Max printer is clean and ready. Keeping it in good shape helps it work well and print better.

- Pick the right material for your stool. NylonX is strong and long-lasting, perfect for making sturdy furniture.

- Change printer settings like layer thickness and speed for better results. Thin layers show more detail, and 50 mm/s is a good speed for both accuracy and speed.

Getting the Sovol SV08 Max 3D Printer Ready

Cleaning and Setting Up the Printer

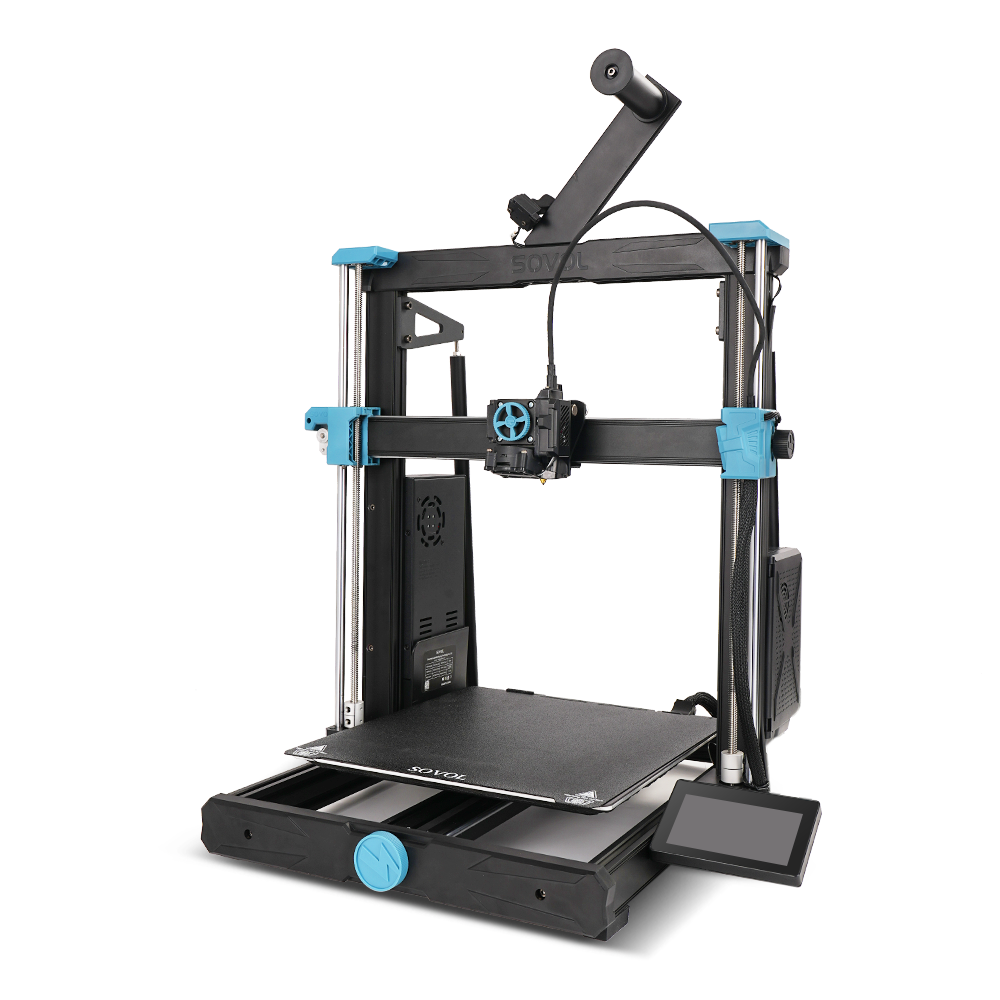

Before you start, clean and set up your printer. Dust can cause problems, so wipe the nozzle and build plate with a soft cloth. Level the bed using the Eddy Current Scanning system. This tool checks the surface in 80 seconds for small bumps. Regular checks help layers stick well and avoid printing mistakes. Look for clogs in the nozzle and make sure the filament moves smoothly.

Creating a Good Workspace

A steady workspace helps your printer work better. Place it on a flat table that doesn’t shake. Keep it away from windows or vents to avoid drafts or temperature changes. If using hot filaments like ABS, keep the room warm to stop warping. Store tools and supplies in labeled boxes for easy access. A neat area makes printing easier and safer.

Keeping the Area Safe and Ventilated

3D printing can release harmful fumes. Set up your printer in a room with good airflow. Use fans or air filters to remove bad particles from the air. Check the air often to make sure it’s clean. Wear gloves and goggles when touching hot parts or chemicals. A safe space lets you focus on printing without worrying about health risks.

Picking the Best Design and Materials for Stool Printing

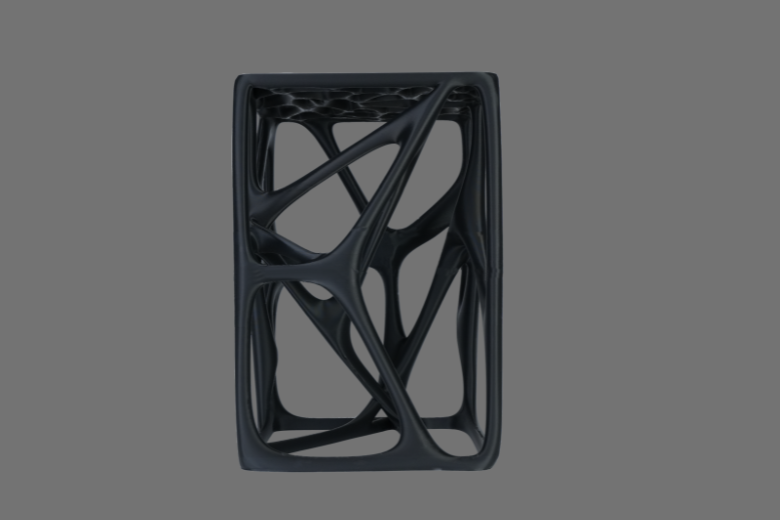

Choosing a Stool Design

Picking a good stool design is the first step. It helps you make furniture that looks nice and works well. You can get ideas from cool 3D printing trends. For example:

- Hempla uses hemp to make eco-friendly meditation stools.

- Studio TOOJ mixes art and tech, like the Contourage Blue Sand Table.

- Some designers use recycled stuff, like coffee grounds, to cut waste.

Think about what the stool is for. A home stool might need to look pretty. A work stool should be strong and last long. Pick designs that are creative but also useful.

Best Filament Choices

The filament you pick changes how strong your stool is. Here’s a table of good filament options:

|

Filament Type |

Features |

Best Uses |

|---|---|---|

|

NylonX |

Tough, durable, no extra finishing needed |

Strong parts, ready-to-use prints |

|

NylonG |

Stiff, impact-resistant, colorful |

Strong parts, handles sudden impacts |

|

Nylon |

Flexible, strong, absorbs moisture |

Hinges, strong working parts |

For furniture, NylonX is the best choice. It’s strong and looks great. It can handle daily use without breaking.

Making Sure It’s Strong

Your stool needs to be safe and sturdy. Follow these tips to make it strong:

- Make sure it can hold at least 180 lbs.

- Use 1.75mm PLA filament for better strength.

- Use good joinery for stools with many parts.

- Check sizes so parts fit together perfectly.

- Print parts in ways that make them stable.

By following these steps, your stool will look good and stay strong.

Configuring Sovol SV08 Max 3D Printer Settings

Adjusting Layer Height and Print Speed

Changing layer height and print speed helps make better prints. Layer height controls how thick each layer is. Thinner layers make smoother surfaces and clearer details. For detailed prints, use a layer height of 0.1 mm to 0.15 mm. For regular prints, 0.2 mm works well for speed and quality.

Print speed affects how accurate the size of your print is. A speed of 50 mm/s reduces mistakes in length, width, and depth. Slower speeds give better detail but take longer. Faster speeds save time but may lose precision. Start at 50 mm/s and change it based on your design.

Tip: Test your printer after changing these settings to check results. Regularly calibrate the Sovol SV08 Max to keep it working well.

Setting Infill Density

Infill density changes how strong and heavy your print is. For stools that need to be strong, use infill densities between 50% and 100%. For stools that are just for decoration, lower densities like 0% to 15% save material and time.

Pick an infill pattern that spreads weight evenly. Gyroid and triangular patterns make parts stronger and less likely to bend. Concentric patterns at 80% density stick layers together better and fill gaps, making prints last longer.

Note: Start with infill density between 20% and 50%, then adjust for the stool’s purpose. Higher densities may need extra tuning for good layer bonding.

Using Supports and Adhesion Techniques

Supports and adhesion methods help print tricky stool designs. Supports stop overhangs from falling, and adhesion keeps prints stuck to the build plate. The Sovol SV08 Max has smart features to improve these steps.

E-stage supports work best with little bending but use more material. Dendritic supports also reduce stress and improve molding. Avoid gradient supports, as they don’t improve print quality much.

For adhesion, use a heated bed and apply glue sticks or painter’s tape. The Sovol SV08 Max’s hotbed heats evenly, stopping warping and keeping prints stuck to the surface.

Pro Tip: Use the Eddy Current Scanning system before printing to level the bed. This improves first-layer sticking and lowers the chance of failed prints.

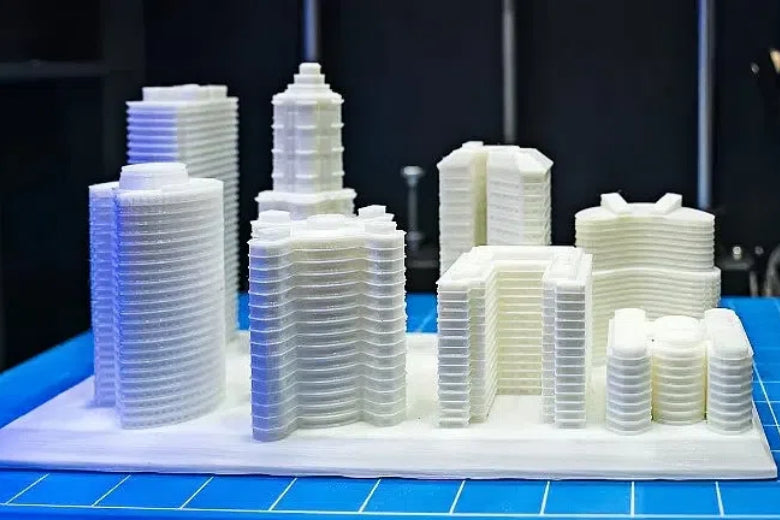

Printing the Stool: Step-by-Step Process

Loading Filament and Starting the Print

Get the Sovol SV08 Max 3D printer ready to print. Place the filament into the Smart Auxiliary Feeder System. This system keeps the filament feeding smoothly and avoids tangles. Cut the filament tip at an angle to make it easier to insert. Use the touchscreen to heat the nozzle and bed to the right temperatures for your filament. For example, NylonX needs a nozzle at 250°C and a bed at 60°C.

After loading the filament, start the print using the printer’s controls. Choose your stool design file from the memory or upload it with USB or Wi-Fi. The Eddy Current Scanning system will level the bed automatically. This helps the first layer stick well. Check the first bit of filament to ensure it flows properly before printing begins.

Tip: Test small models first to check settings like temperature and speed. This saves time before printing the full stool.

Monitoring the Print Progress

Watch the printing process to make sure it goes smoothly. The Sovol SV08 Max shows real-time progress on its screen. Look out for problems like uneven layers, filament tangles, or misaligned prints.

You can also use advanced tools like terahertz (THz) waves or optical microscopes. These tools help you see how the material is being placed without touching the print. This is especially helpful for big projects like stools.

Monitoring Tip: THz waves let you check the print without stopping it. This ensures accuracy and reduces mistakes.

Handling Mid-Print Issues

Sometimes, problems happen during printing. Fix them quickly to save time and materials. Common issues include filament jams, clogged nozzles, or warping. If the filament stops moving, pause the print and check for tangles or dirt in the feeder. Use the Sovol SV08 Max’s clog detection to find and fix nozzle blockages.

Warping happens when the bed temperature changes too much. Make sure the hotbed stays evenly heated. If warping continues, use glue sticks or painter’s tape to help the print stick better. For layers that separate, raise the nozzle temperature slightly to improve bonding.

Pro Tip: Regularly test and adjust the Sovol SV08 Max to avoid problems. Keep extra nozzles and filaments nearby for quick fixes.

Post-Processing and Finishing the Stool

Taking Off Supports and Smoothing Edges

After printing, take off supports to make the stool look neat. Gently remove supports using pliers or a scraper. Be careful not to scratch the stool's surface. If there are deep gaps over 50 mm, add exit holes during design to make support removal easier. Openings in moving parts also help with this process.

To smooth the edges, use fine-grit sandpaper. For a matte look, keep the body thickness at 0.1 mm. Leave a 0.5 mm gap between parts during design for better results. Adding extra parts can save time when removing supports from long, closed sections. These steps improve how the stool looks and works.

Tip: Use bright light to see flaws and fix them easily.

Painting or Coating for Strength

Painting or coating makes the stool stronger and better-looking. First, clean the stool to get rid of dust. Apply a primer so the paint sticks well. Use spray paint or a brush for a smooth finish. For outdoor stools, use weatherproof coatings to protect them from rain and sunlight.

If you like a natural look, use clear coats to show the material’s texture. Apply thin layers and let each one dry before adding another. This makes the stool look nice and last longer.

Pro Tip: Test the paint on a small hidden spot to check if it works well with the material.

Putting Together Multi-Part Stools

If your stool has many parts, put them together carefully. Line up the parts to make sure they fit well. Use strong glue or screws to hold them in place. If the stool has joints that lock together, test them before final assembly. Sand rough edges for a smooth fit.

Follow the design instructions to keep the stool strong. Add extra support to the joints with epoxy or similar materials. This helps the stool stay sturdy and safe for daily use.

Note: Check the stool’s alignment and strength before using it to ensure safety.

Troubleshooting Common Issues with Sovol SV08 Max 3D Printer

Fixing Warping or Adhesion Problems

Warping and sticking issues can ruin your prints. Pre-heating the print bed helps stop warping and improves sticking. The Sovol SV08 Max’s heated bed spreads heat evenly. Check it often to keep it working well.

|

Solution Type |

What It Does |

|---|---|

|

Stops warping and helps prints stick better. |

|

|

Regular Checks & Cleaning |

Prevents layer shifting and keeps the printer running smoothly. |

|

Learning Printer Basics |

Reduces mistakes when fixing problems or changing filament. |

To avoid warping, don’t use too much heat or pressure. This keeps the filament in the right shape and size.

Addressing Layer Separation

Layers may split if they don’t stick together well. Always adjust your printer settings before starting a project. Change the extrusion multiplier between 97% and 105% to spread heat evenly. Printing a temperature tower helps find the best nozzle heat for your filament.

Watch the extrusion rate during test prints to keep it steady. Clean and adjust the Sovol SV08 Max regularly to avoid printing problems like too much or too little filament.

Tip: Write down the best settings for each filament. This saves time and gives better results later.

Preventing Nozzle Clogs

Clogs in the nozzle can stop your print. Use good-quality filament to avoid dirt that blocks the nozzle. Keep filament in sealed containers to stop moisture from causing bubbles or clogs.

Clean the nozzle often to remove leftover material. Don’t switch filaments without cleaning, as this can cause blockages. Adjusting the Sovol SV08 Max correctly helps prevent filament buildup.

Pro Tip: Check the nozzle for clogs before printing. This simple step saves time and materials.

Making a stool with the Sovol SV08 Max 3D printer is fun and useful. Follow the steps to create strong, custom stools that fit your needs.

Tip: Try out various designs and materials. Discover how the Sovol SV08 Max can turn your ideas into reality!

FAQ

What is the maximum weight a 3D-printed stool can support?

The weight capacity depends on the design and material. Using strong filaments like NylonX and proper infill density, your stool can support up to 180 lbs.

How long does it take to print a stool with the Sovol SV08 Max?

Print time varies by size and settings. For a medium-sized stool, expect 8–12 hours using standard speed and layer height configurations.

Can I use the Sovol SV08 Max to print outdoor stools?

Yes, you can. Use weather-resistant filaments like PETG or apply protective coatings to ensure durability against rain and sunlight.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.