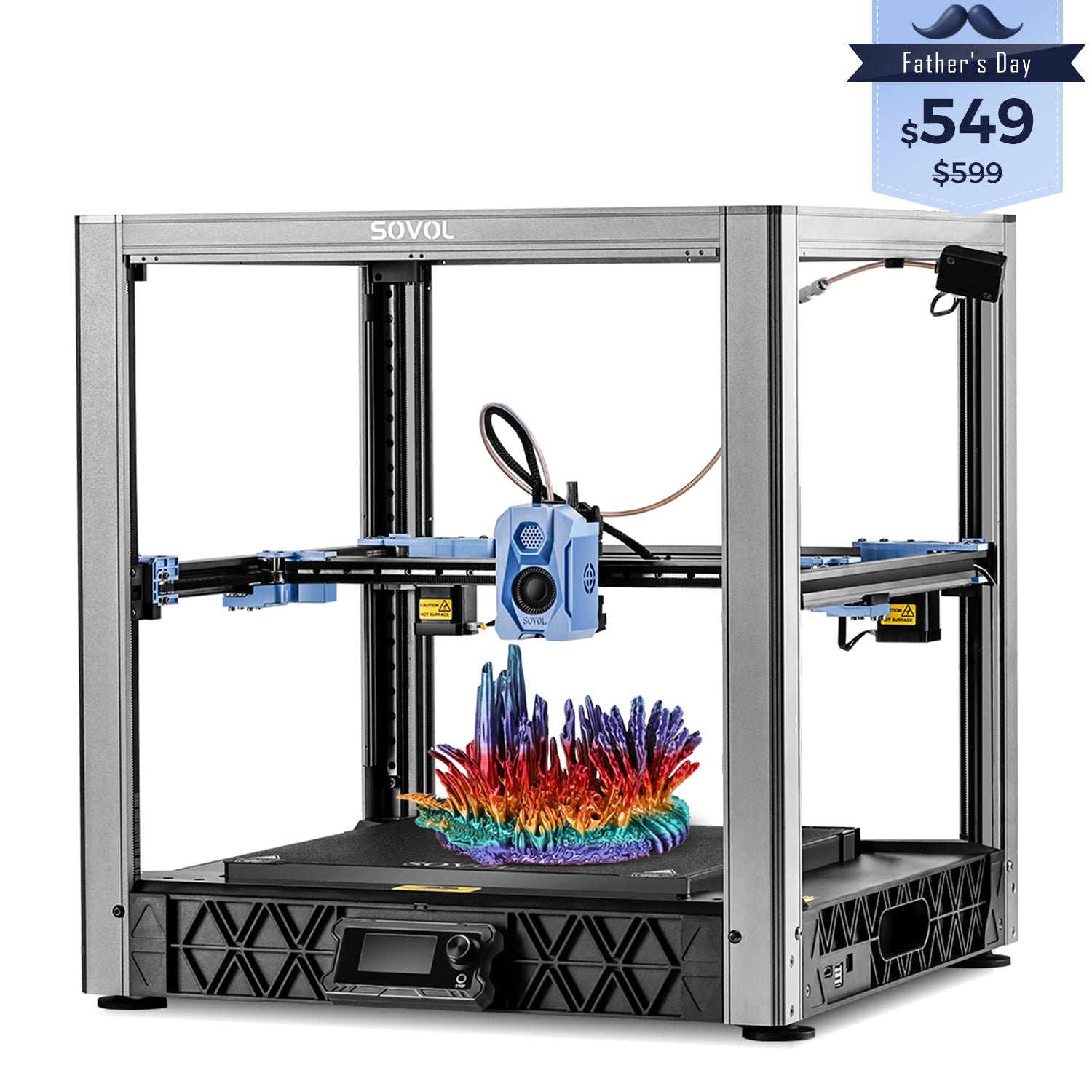

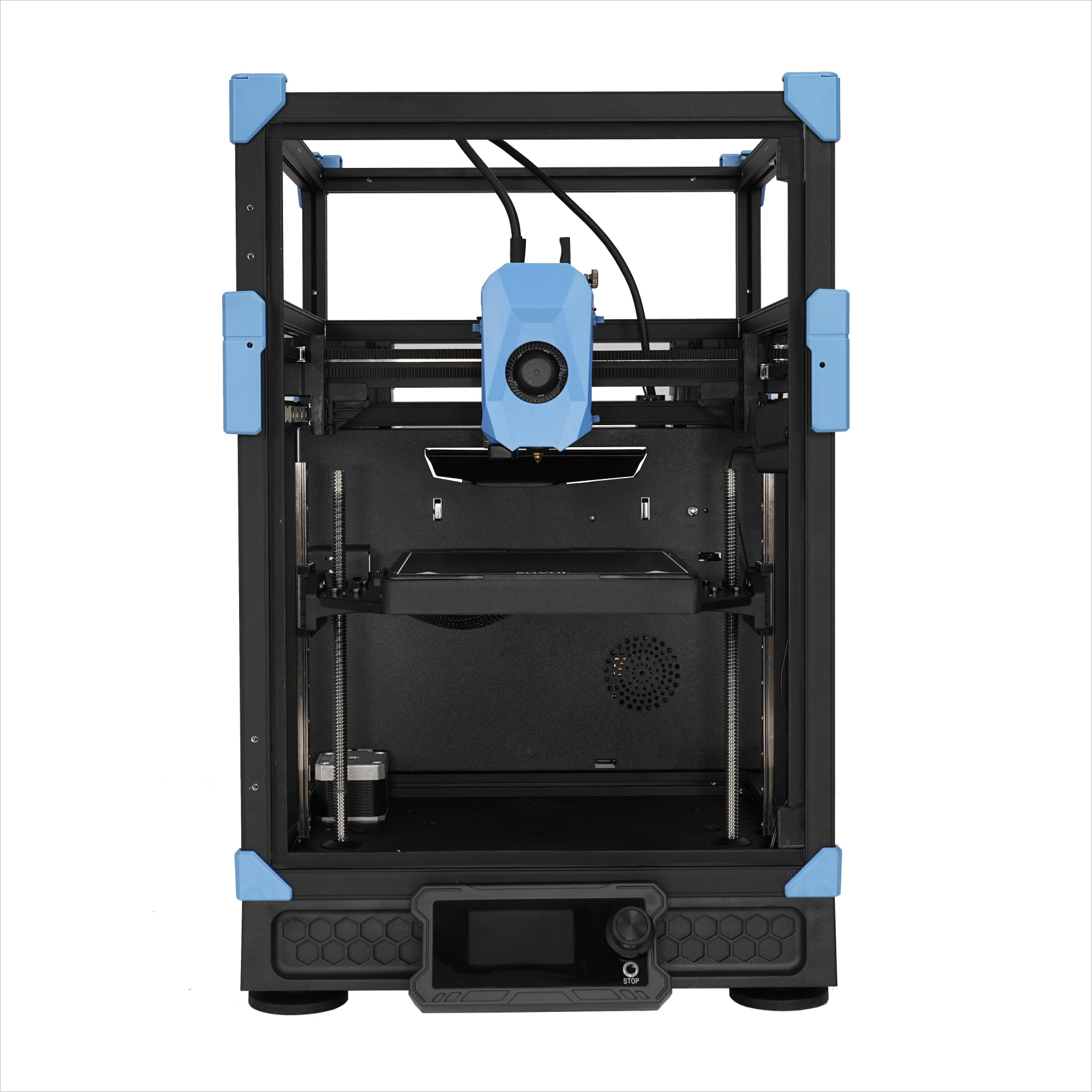

Reimagine 3D printing with SV08 Max's eddy current scanning, a breakthrough technology that ensures precision and speed like never before. This contactless system detects even the tiniest surface irregularities, delivering flawless bed leveling in seconds. Whether you're a hobbyist or a professional, the SV08 Max empowers you to achieve exceptional results effortlessly.

Key Takeaways

- SV08 Max's scanning tech helps level beds by finding tiny bumps, even as small as 0.5 mm. This makes prints look great.

- It scans a 500×500 mm bed in 80 seconds. This saves time and lets you work on fun projects faster.

- Its no-touch design means less fixing is needed. This makes it easy to use for both new and experienced 3D printers.

The Role of Eddy Current Scanning in 3D Printing

What Makes Eddy Current Scanning Unique?

Eddy current scanning stands out as a game-changing technology in 3D printing. Unlike traditional methods, this system uses an alternating magnetic field to induce eddy currents in conductive materials. These currents provide real-time data on material properties, enabling precise analysis without physical contact. This makes it ideal for monitoring temperature variations and detecting surface defects during the printing process.

The versatility of the eddy current scanning system extends to a wide range of materials, including stainless steel, carbon steel, and titanium. Its depth-dependent monitoring ensures accuracy while avoiding interference with the printing process. For validation, advanced techniques like 3D finite element modeling (FEM) simulate thermal and electromagnetic properties, ensuring reliable results.

|

Aspect |

Description |

|---|---|

|

Application |

In-situ monitoring for temperature variations and defect detection. |

|

Principle |

Induction of eddy currents through an alternating magnetic field. |

|

Materials |

Stainless steel, carbon steel, titanium, and other conductive materials. |

|

Monitoring Technique |

Depth-dependent temperature monitoring beneath the build plate. |

|

Validation Method |

Analytical solutions and FEM simulations for thermal and electromagnetic analysis. |

Benefits of the Eddy Current Scanning System in Precision and Efficiency

The eddy current scanning system offers unmatched precision and efficiency in 3D printing. Its ability to detect surface defects as small as 0.5 mm ensures flawless bed leveling, a critical factor for high-quality prints. The system’s high-speed scanning capability reduces inspection time to just a few minutes, outperforming conventional methods.

With multiple coils working simultaneously, the system covers larger areas in a single pass, eliminating the need for repeated scans. This not only saves time but also enhances reliability by increasing the probability of defect detection. Its sensitivity to surface irregularities ensures consistent first-layer adhesion, a cornerstone of successful 3D printing.

|

Performance Metric |

Description |

|---|---|

|

Faster inspection time |

Scans in minutes, faster than traditional methods. |

|

Larger area coverage |

Inspects wide areas in one pass with multiple coils. |

|

Increased accuracy |

High reliability and defect detection probability. |

|

Sensitivity to surface defects |

Detects defects as small as 0.5 mm. |

|

Quick and simple |

Ideal for regular, high-speed inspections. |

By integrating this advanced system, the Sovol SV08 Max ensures that every print begins with a perfectly leveled bed, saving you time and enhancing your overall experience.

Advantages of SV08 Max's Eddy Current Scanning

Superior Accuracy for Bed Leveling

Achieving a perfectly leveled print bed is crucial for producing accurate prints. With SV08 Max's eddy current scanning, you can rely on its advanced technology to deliver great accuracy every time. This contactless system detects even the smallest surface irregularities, ensuring consistent first layers and reducing the risk of print failures. Unlike traditional systems that rely on physical probes, the eddy current scanning method eliminates wear and tear, providing long-term reliability.

Recent calibration tests highlight the precision of this system:

|

Evidence Description |

Details |

|---|---|

|

Simplifies achieving a perfectly leveled print bed for consistent results. |

|

|

Eddy Current Scanning |

Detects small surface irregularities without physical contact. |

|

Consistent First Layers |

Automatically compensates for deviations, saving setup time. |

This level of precision makes the Sovol SV08 Max a standout choice for both beginners and professionals. Whether you're printing intricate prototypes or large-scale models, you can trust this system to deliver accurate prints with ease.

High-Speed Scanning for Reduced Setup Time

Time is a valuable resource, and SV08 Max's eddy current scanning ensures you spend less of it on setup. The system scans a 500×500 mm print bed in just 80 seconds, significantly faster than traditional methods. This high-speed printing capability allows you to focus more on your creative projects and less on tedious adjustments.

A comparison of SV08 Max's scanning system with traditional systems underscores its efficiency:

|

Feature |

SV08 Max |

Traditional Systems |

|---|---|---|

|

Bed Leveling Method |

Eddy Current Scanning |

Physical Probes |

|

Detection Speed |

Varies, often slower |

|

|

Maintenance Needs |

Minimal due to contactless design |

Higher due to wear and tear |

|

Accuracy |

High, detects small irregularities |

Lower, dependent on manual setup |

|

Setup Complexity |

Automatic |

Manual |

By reducing setup time, the Sovol SV08 Max empowers you to achieve fast printing without compromising on quality. This makes it an ideal choice for high-speed printing projects where efficiency is key.

Enhanced User Experience with Contactless Technology

SV08 Max's eddy current scanning system not only enhances performance but also improves your overall user experience. Its contactless design minimizes maintenance needs, as there are no physical components to wear out over time. This ensures a hassle-free printing process, allowing you to focus on bringing your ideas to life.

Key benefits of this contactless technology include:

- Quick detection of surface irregularities for stable prints.

- Reduced maintenance needs due to the absence of physical probes.

- Enhanced accuracy, making it suitable for both beginners and professionals.

The advanced eddy current scanning system simplifies the printing process, making it more accessible and enjoyable. Whether you're a hobbyist exploring creative projects or a professional tackling large-scale tasks, the Sovol SV08 Max ensures a seamless experience from start to finish.

Practical Applications of Sovol SV08 Max

Ideal for Large-Scale Printing Projects

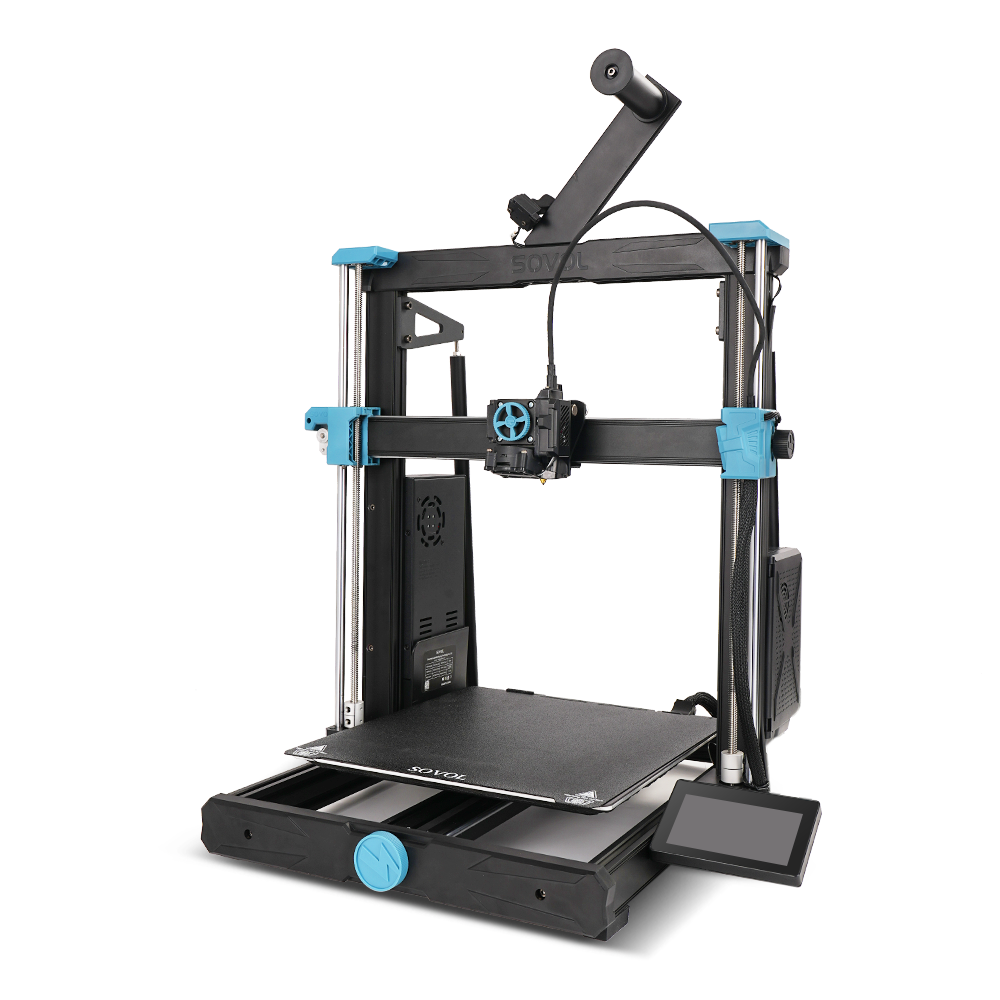

The Sovol SV08 Max excels in large-scale printing projects, thanks to its massive build volume of 500×500×500 mm. This feature allows you to create large-scale prototypes and full models without splitting them into smaller parts. Whether you're working on intricate sculptures or industrial components, the printer's expansive capacity ensures seamless production.

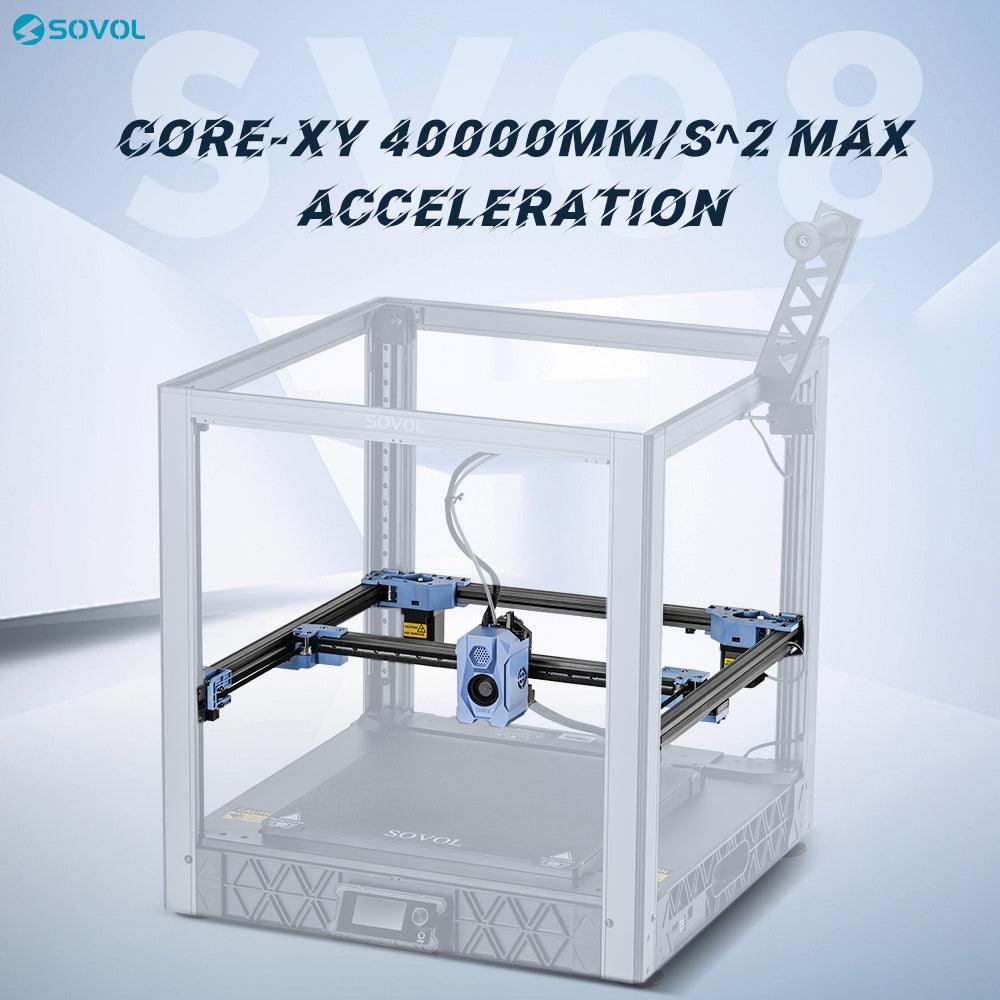

Its CoreXY system enhances precision and stability, even for complex designs. Operating at speeds of up to 450 mm/s, the SV08 Max boosts productivity while maintaining high accuracy. This combination of speed and precision makes it ideal for projects that demand both efficiency and quality.

Real-world applications highlight the printer's versatility:

- Engineers have used it to produce large prototypes for all-electric concept cars, meeting tight deadlines and design specifications.

- Cosplayers rely on the SV08 Max to create props like helmets in one piece, reducing assembly time and ensuring structural integrity.

- Creative professionals have crafted detailed sculptures and decorations, showcasing the printer's ability to handle intricate designs with ease.

The Sovol SV08 Max empowers you to tackle ambitious projects, whether you're designing functional prototypes or artistic masterpieces. Its advanced features make it a reliable choice for large format printing.

Industries Leveraging SV08 Max's Technology

The Sovol SV08 Max has found applications across various industries, revolutionizing workflows and reducing costs. Its ability to handle large-scale assignments with precision and speed has made it a valuable asset in sectors such as aerospace, construction, and retail.

|

Industry |

Cost Savings (%) |

Description |

|---|---|---|

|

Aerospace |

30-40% |

Reduced material waste and labor expenses through efficient printing. |

|

Construction |

Up to 35% |

Lower labor requirements and minimized material waste for large-scale projects. |

In aerospace, the SV08 Max enables the production of lightweight components with minimal waste, optimizing both cost and performance. Construction professionals use it to create architectural models and structural prototypes, streamlining project timelines and reducing overhead costs.

Retail and creative industries also benefit from the printer's capabilities. For example:

- Adidas customized their Futurecraft 4D shoes, enhancing fit and cushioning for individual wearers.

- A 4m x 1.5m dragon was printed for Sydney Airport, showcasing innovation in retail displays.

- The National Geographic Museum utilized large-scale 3D printing for an immersive exhibit, captivating audiences with intricate designs.

The Sovol SV08 Max's massive build volume and advanced technology make it a versatile tool for industries seeking efficiency and innovation. Whether you're crafting prototypes, creating custom products, or designing immersive experiences, this printer delivers exceptional results.

Troubleshooting and Common Concerns

Addressing Misconceptions About Eddy Current Scanning

Eddy current scanning often faces misconceptions, especially among those new to 3D printing. One common misunderstanding is that this technology only works with specific materials. In reality, the Sovol SV08 Max's system is compatible with a wide range of conductive materials, including aluminum and steel. This versatility ensures reliable performance across various projects.

Another misconception is that eddy current scanning might interfere with the printing process. However, the system operates independently of the printer's mechanical components. Its contactless design ensures seamless integration without disrupting print quality.

Some users also believe that eddy current scanning requires frequent recalibration. On the contrary, the SV08 Max's advanced algorithms maintain accuracy over extended periods, reducing the need for manual adjustments.

Tip: Familiarize yourself with the printer's user manual to better understand how eddy current scanning enhances your workflow.

Solutions for Common Issues with Sovol SV08 Max

Even with advanced technology, occasional issues may arise. Here are solutions to common concerns:

- Uneven Bed Leveling: Ensure the print bed is clean and free of debris. Run the automatic bed leveling process to recalibrate the surface.

- Scanning Errors: Check for firmware updates. Outdated software can affect scanning accuracy. Sovol provides regular updates to optimize performance.

- Material Compatibility: Use recommended materials for best results. While the system supports various metals, non-conductive surfaces may require additional preparation.

Note: Sovol's customer support team is available to assist with troubleshooting. Contact them for expert guidance if issues persist.

By addressing these concerns, you can maximize the potential of the Sovol SV08 Max and enjoy a smoother 3D printing experience.

SV08 Max's eddy current scanning transforms your 3D printing experience. Its precision ensures flawless bed leveling, while its speed reduces setup time. The contactless design enhances reliability and simplifies maintenance.

Unlock Possibilities: Sovol SV08 Max empowers you to create intricate prototypes and large-scale models effortlessly. Explore its advanced features today and elevate your printing projects to new heights.

FAQ

How does eddy current scanning improve print quality?

Eddy current scanning ensures precise bed leveling by detecting surface irregularities. This results in consistent first layers and enhances the overall print quality.

Is the Sovol SV08 Max suitable for beginners?

Yes, its contactless scanning system simplifies setup and reduces maintenance. Beginners can achieve high-speed reliable printing without extensive technical knowledge.

What materials are compatible with eddy current scanning?

The system works with conductive materials like aluminum, steel, and titanium. It ensures accurate monitoring without interfering with the printing process.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.