A large FDM 3D printer, such as the SV08 Max 3D printer, enables you to create oversized and intricate models with ease. These machines are becoming indispensable as FDM technology captures over 44.8% of the market. Industries like aerospace and automotive increasingly rely on their large build volumes to produce high-precision parts with excellent mechanical properties.

Key Takeaways

- Big FDM printers, like the Sovol SV08 Max, can print large models in one go. This saves time and makes prints more accurate.

- FDM printing is cheap for making big items. It uses less material and costs less to run while staying precise.

- Check the printer's size and materials it can use. Make sure it fits your project needs.

How Large FDM 3D Printers Work

Understanding FDM Printing Technology

Fused deposition modeling (FDM) is one of the most widely used 3D printing technologies. It operates by melting thermoplastic filament through an extrusion process. The filament passes through a heated nozzle, where it becomes molten and is deposited layer by layer onto a build platform. This method allows you to create complex geometries with remarkable precision. The process relies on a three-axis system to ensure accurate layer deposition, making it suitable for applications ranging from prototyping to manufacturing.

Key parameters like layer height, temperature, and speed play a crucial role in determining the print quality and resolution. For instance, a smaller layer height improves surface smoothness but increases print time. Similarly, maintaining optimal temperature ensures proper adhesion between layers, reducing the risk of warping or delamination. Despite its simplicity, FDM printing offers versatility in materials, allowing you to work with options like PLA, PETG, and ABS.

|

Aspect |

Description |

|---|---|

|

Principles |

FDM technology involves depositing melted filament material layer by layer to create a 3D object. |

|

Process Parameters |

Key parameters include layer height, temperature, speed, infill density, and build orientation. |

|

Quality Challenges |

Common issues include adhesion problems and high surface roughness due to the stair-stepping effect. |

Scaling FDM for Large-Format 3D Printing

Scaling FDM technology for large-format printing introduces unique challenges and opportunities. Larger build volumes, like the 500×500×500mm capacity of the SV08 Max 3D printer, allow you to create oversized models in a single print. However, achieving consistent print quality across such dimensions requires advanced engineering. Factors like nozzle clogging, layer adhesion, and print accuracy become more critical as the scale increases.

To address these challenges, large-format FDM printers often incorporate features like actively heated build chambers and high-flow nozzles. These components ensure uniform temperature distribution, which is essential for printing high-performance materials like ABS or PEEK. Additionally, CoreXY kinematics, as seen in the SV08 Max, optimize motion paths and reduce vibrations, enabling faster and more precise printing.

|

Factor |

Percentage Effect |

|---|---|

|

Manufacturing Method |

44.2% |

|

Temperature |

47.4% |

|

Young's Modulus Dominance |

82.6% |

Scaling also enhances productivity. Large-format printers can reduce print times by up to 50%, making them ideal for industrial applications. However, you must consider the increased space requirements and operational costs associated with these machines.

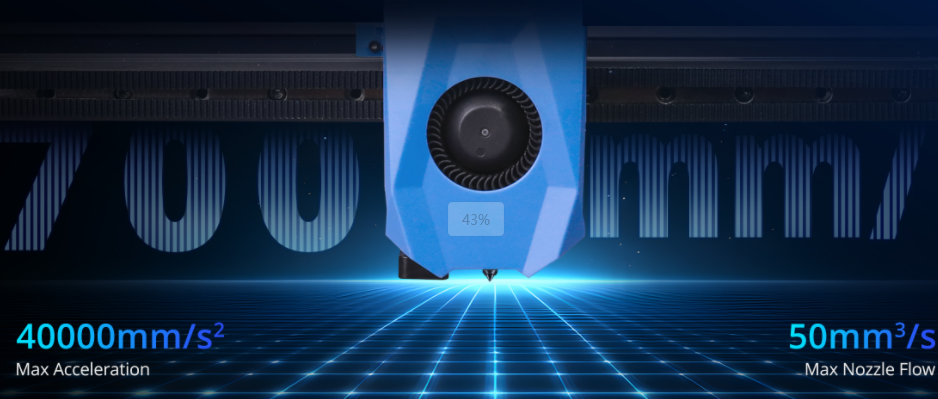

Key Components of Large FDM Printers Like the Sovol SV08 Max

Large FDM printers, such as the Sovol SV08 Max, feature advanced components designed to handle the demands of large-scale printing. These include:

- CoreXY Kinematics: This system minimizes moving mass, allowing for higher acceleration and reduced vibrations. It ensures smoother motion, which directly improves print quality.

- High-Flow Nozzle: Capable of extruding up to 50mm³/s, this nozzle significantly reduces print times while maintaining accuracy.

- Smart Auxiliary Feeder System: This feature ensures smooth filament feeding and actively monitors for tangles or clogs, preventing interruptions during printing.

- Eddy Current Scanning System: This advanced bed leveling technology scans the entire build platform in just 80 seconds, ensuring a perfectly leveled surface for optimal first-layer adhesion.

- Thickened Hotbed: The 8mm aluminum hotbed, powered by 1300W, provides rapid and even heating. This minimizes warping and ensures consistent adhesion, even for large models.

|

Metric |

CoreXY Printer Performance |

|---|---|

|

Frame Rigidity |

180% increase compared to MK4S aluminum extrusions |

|

Positional Deviation |

≤0.02 mm during 500 mm/s² acceleration tests |

|

Print Speed |

120% faster than MK4S, achieving 450 mm/s travel moves |

|

Extrusion Rate |

35 mm³/s across all layer heights |

|

Ringing Artifacts Reduction |

92% reduction compared to disabled configurations |

The SV08 Max 3D printer combines these features to deliver exceptional performance. Its large build volume, high-speed capabilities, and advanced components make it a top choice for professionals and hobbyists alike.

Benefits of Large FDM 3D Printers

Advantages of Large Build Volumes for 3D Printing

Large build volumes open up new possibilities for creating oversized prototypes and intricate designs in a single process. With a printer like the Sovol SV08 Max 3D Printer, you can produce complex parts without splitting them into smaller sections. This capability reduces post-processing time and ensures seamless results. The thickened 8mm aluminum hotbed, powered by 1300W, provides rapid and even heating across the entire surface, minimizing warping and enhancing reliability for large-scale models.

In industries like architecture and construction, large-format FDM printing technology enables the production of full-scale models and structural components. You can also use it for creative projects, such as cosplay props or art installations, where size and detail matter. The ability to print large objects in one go not only saves time but also improves print quality by eliminating assembly errors.

Cost-Effectiveness of FDM Printing for Large-Scale Projects

FDM printing stands out as one of the most cost-effective methods for large-scale production. Unlike traditional manufacturing techniques, which require expensive molds or tooling, FDM printers allow you to create parts directly from digital designs. This reduces upfront costs and makes the technology accessible for small businesses and hobbyists.

The Sovol SV08 Max 3D Printer further enhances cost efficiency with its high-speed capabilities. By slashing print times by up to 50%, it lowers energy consumption and operational expenses. Its Smart Auxiliary Feeder System ensures smooth filament feeding, reducing material waste and preventing costly interruptions. Whether you're prototyping industrial components or producing custom designs, FDM printing offers an economical solution without compromising accuracy or resolution.

Versatility in Materials and Applications with the Sovol SV08 Max

Large FDM printers excel in their ability to work with a wide range of materials. The Sovol SV08 Max supports filaments like PLA, PETG, ABS, and TPU, making it suitable for diverse applications. You can use flexible materials for wearable designs or durable ones for functional prototypes. Its high-temperature hotend and heated bed also accommodate advanced engineering materials, expanding your options for specialized projects.

In the medical field, large FDM printers are used to create customized models and drug delivery systems. Their flexibility allows you to produce patient-specific designs, which are invaluable for surgical planning and neuroscience experiments. The Sovol SV08 Max's advanced features, such as CoreXY kinematics and adaptive area detection, ensure consistent print quality across large dimensions, making it ideal for scientific and industrial applications.

Tip: Leverage the SV08 Max's large build volume and material compatibility to explore creative and professional opportunities.

Key Features to Consider in Large FDM 3D Printers

Build Volume and Dimensions (e.g., SV08 Max's 500×500×500mm capacity)

When evaluating large FDM printers, build volume is one of the most critical factors. It determines the maximum size of the object you can create in a single print. For instance, the Sovol SV08 Max 3D Printer offers an impressive build volume of 500×500×500mm, enabling you to produce oversized models, industrial parts, or full-scale prototypes without splitting them into smaller sections. This capability not only saves time but also ensures seamless results by eliminating assembly errors.

Larger build volumes provide greater freedom in design and production. However, they also demand advanced engineering to maintain consistent print quality across the entire print area. The SV08 Max addresses this with features like a thickened 8mm aluminum hotbed, which ensures even heating and minimizes warping.

|

Metric |

Description |

Importance |

|---|---|---|

|

Build Volume |

The maximum size of the object that can be printed. |

Larger volumes allow for more complex designs and projects. |

|

Manufacturer Claims |

Comparison of real-world print dimensions to the manufacturer's specifications. |

Ensures that the printer meets advertised capabilities, affecting scores. |

Tip: Always verify that the printer's real-world performance aligns with its advertised specifications to avoid unexpected limitations.

Material Compatibility and Extrusion Systems

Material compatibility is another essential feature to consider. Large FDM printers like the SV08 Max support a wide range of materials, including PLA, PETG, ABS, and TPU. This versatility allows you to tackle diverse projects, from flexible wearable designs to durable industrial components. The printer's high-temperature hotend and heated bed also accommodate advanced engineering materials like carbon-fiber-reinforced filaments, expanding your creative possibilities.

The extrusion system plays a pivotal role in ensuring smooth material flow and consistent print quality. The SV08 Max features a Smart Auxiliary Feeder System that actively monitors filament feeding, preventing tangles and clogs. This system ensures uninterrupted printing, even during long and complex projects.

|

Feature |

F770 |

F900 |

|---|---|---|

|

Materials |

ASA, ABS-M30 |

ABS-ESD7, ABS-M30, ULTEM 9085, Nylon 12, etc. |

Precision and speed are vital for achieving high-quality results in large-scale 3D printing. The SV08 Max leverages CoreXY kinematics, a unique design that minimizes moving mass and optimizes motion paths. This system enhances print speed and dimensional accuracy, making it ideal for complex geometries and large models.

|

Evidence Description |

Key Points |

|---|---|

|

Unique kinematic design with dual linear actuators |

Enhances print speed and dimensional precision, distinguishing it in additive manufacturing. |

|

Architecture enables faster printing speeds |

Improved stability and reduced inertia, ideal for complex geometries. |

|

Simultaneous axis driving |

Enhances overall print speeds significantly with minimal inertia. |

The SV08 Max achieves an acceleration of 40,000 mm/s² and a high-flow nozzle capable of extruding up to 50mm³/s. These features reduce print times by up to 50%, allowing you to complete projects faster without compromising accuracy.

Software and User Interface for Seamless 3D Printing

A user-friendly software and interface can significantly enhance your 3D printing experience. The SV08 Max supports open-source slicers like Cura and PrusaSlicer, giving you the flexibility to customize settings for optimal results. Its intuitive touchscreen interface simplifies operation, making it accessible even for beginners.

Advanced software features, such as adaptive area detection and pressure advance, further improve print quality by optimizing extrusion and motion control. These tools ensure consistent results, even for intricate designs.

Callout: Look for printers that offer compatibility with multiple slicers and provide advanced software features to maximize your printing efficiency.

Additional Features Like Auto-Leveling and Filament Monitoring

Modern large FDM printers come equipped with features that enhance convenience and reliability. The SV08 Max includes an Eddy Current Scanning system for auto-leveling, which scans the entire build platform in just 80 seconds. This ensures a perfectly leveled bed, improving first-layer adhesion and overall print success rates.

Filament monitoring is another crucial feature. The SV08 Max's Smart Auxiliary Feeder System not only ensures smooth feeding but also detects filament runouts or clogs. This prevents interruptions and material waste, allowing you to focus on your projects.

|

Parameter |

|

|---|---|

|

Prototyping (desktop) |

± 0.5% (lower limit: ± 0.5 mm) |

|

Industrial |

± 0.15% (lower limit: ± 0.2 mm) |

Reminder: Features like auto-leveling and filament monitoring can save you time and reduce the risk of failed prints, especially for large-scale projects.

Applications of Large FDM 3D Printers

Industrial and Manufacturing Applications

Large FDM printers play a pivotal role in industrial and manufacturing sectors. You can use them to produce durable components, tooling, and jigs with high precision. Their ability to handle engineering-grade materials like ABS and PEEK makes them ideal for creating parts that require excellent mechanical properties. For example, studies have shown that optimizing parameters such as nozzle temperature and layer thickness can significantly enhance tensile strength in materials like PLA and PETG.

|

Study |

Methodology |

Findings |

|---|---|---|

|

Pernica et al. |

ANOVA, Tukey test |

Investigated the effect of nozzle temperature on tensile strength of PLA, PETG, and ABS. |

|

Jiang et al. |

L9 orthogonal array |

Found optimal parameters for PEEK parts, increasing tensile strength from 91.48 to 98.85 MPa. |

The Sovol SV08 Max 3D printer, with its high-flow nozzle and CoreXY kinematics, ensures consistent print quality across large dimensions. This makes it a reliable choice for industries requiring high-performance parts and prototypes.

Prototyping and Product Development

Prototyping becomes faster and more efficient with large FDM printers. You can create full-scale prototypes without splitting them into smaller sections, saving time and improving accuracy. The SV08 Max’s advanced features, such as its Smart Auxiliary Feeder System, ensure smooth filament feeding, reducing interruptions during long prints. This capability is invaluable for product development, where rapid iterations are essential.

FDM printing also allows you to experiment with different materials, enabling you to test prototypes under various conditions. Whether you need flexible filaments for wearable designs or rigid ones for structural components, the versatility of FDM printers ensures you can meet diverse project requirements.

Architecture, Construction, and Oversized Models

In architecture and construction, large FDM printers enable the creation of scaled fabrication models and full-scale components. You can use them to produce intricate designs and sustainable structures. For instance, the Institute for Advanced Architecture of Catalonia successfully assembled a 3D-printed house in just one week using 35 different parts. This project highlights the efficiency and innovation that FDM printing brings to modern architectural practices.

Rapid design iterations are another advantage. Scaled models allow architects and engineers to refine their designs and communicate effectively with clients. The Sovol SV08 Max’s large build volume and precise motion control make it ideal for producing oversized models and structural elements with exceptional resolution.

Creative Projects Like Art, Design, and Cosplay

Large FDM printers open up endless possibilities for creative projects. You can use them to craft intricate art installations, detailed cosplay props, and custom designs. The SV08 Max’s ability to handle flexible and rigid materials ensures you can bring your creative visions to life. Its high-speed capabilities reduce production time, allowing you to focus on refining your designs.

Artists and designers benefit from the printer’s advanced features, such as its Eddy Current Scanning system for auto-leveling. This ensures consistent first-layer adhesion, improving overall print quality. Whether you’re creating wearable costumes or oversized sculptures, the SV08 Max empowers you to achieve professional-grade results.

Tip: Leverage the versatility of large FDM printers to explore creative opportunities across art, design, and cosplay.

Challenges and Limitations of Large FDM 3D Printers

Space and Size Requirements for Large Printers

Large FDM 3D printers demand significant space due to their oversized build volumes and robust frames. For instance, the Sovol SV08 Max, with its 500×500×500mm capacity, requires a dedicated area for operation. You must also account for ventilation and accessibility, as these printers often generate heat and fumes during printing. The need for additional storage for materials and tools further increases spatial requirements. This makes large FFF printers more suitable for workshops or industrial environments rather than small offices or homes.

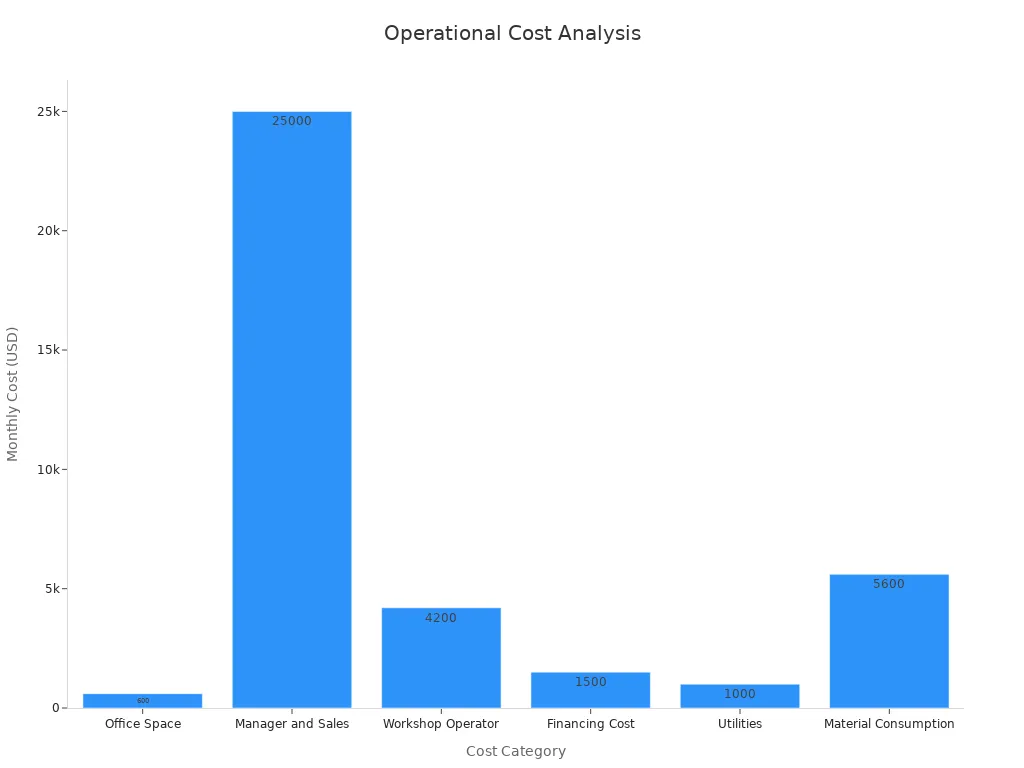

Initial Investment and Operational Costs

The initial investment for large FDM printers can be substantial. Beyond the purchase price, operational costs such as utilities, labor, and material consumption add to the financial burden. A cost breakdown reveals monthly expenses like $5,600 for materials and $1,000 for utilities, totaling $37,900, including other operational costs.

While these costs may seem high, the long-term benefits of reduced waste and faster production often justify the investment. However, you must carefully evaluate your budget and expected returns before committing.

Maintenance and Troubleshooting for Optimal Performance

Maintaining large FDM printers involves regular checks and troubleshooting to ensure consistent print quality. Common issues include filament runout, blocked nozzles, and improper nozzle positioning. For example, a nozzle too close to the print bed can hinder filament extrusion, affecting part accuracy. Regular maintenance, such as cleaning the nozzle and calibrating the bed, is essential to avoid these problems. Investing in a printer with advanced features like filament monitoring can help minimize downtime and improve efficiency.

Limitations in Precision Compared to Other 3D Printing Technologies

While large FDM printers excel in speed and versatility, they often lag behind other technologies in precision. Layer-by-layer production can lead to dimensional inaccuracies and mechanical weaknesses. For instance, FDM print quality may suffer from inconsistent strength across different directions, making it less reliable for critical applications like aerospace or medical devices. Traditional manufacturing methods or alternative 3D technologies often provide better resolution and isotropic properties, making them more suitable for high-precision requirements.

|

Aspect |

Traditional Manufacturing Advantages |

|

|---|---|---|

|

Batch Quality Testing |

Difficult due to layer-by-layer production leading to individual differences in prints. |

Consistent production allows effective batch quality testing. |

|

Material Selection |

Limited to certain materials; high-performance materials face technical challenges. |

Wide range of high-performance materials available. |

|

Mechanical Properties |

Inconsistent strength in different directions; weaker under lateral stress. |

Isotropic parts with consistent strength across all directions. |

|

Application in Industries |

Less reliable for demanding applications like aerospace and medical devices. |

Proven reliability and durability in critical applications. |

How to Choose the Right Large FDM 3D Printer

Assessing Your Project Needs and Goals

Choosing the right 3D printer begins with understanding your project requirements. Consider the size, complexity, and materials needed for your designs. If you plan to create oversized prototypes or industrial parts, a large-format FDM printer like the Sovol SV08 Max 3D Printer offers the capacity and precision required. Evaluate whether your projects demand high-speed production or specialized materials, as these factors influence the printer's suitability.

Tip: Define your goals clearly to ensure the printer aligns with your creative or professional objectives.

Comparing Build Volumes and Material Compatibility

Build volume determines the maximum size of objects you can print. For hobbyists, smaller printers with volumes under 10"x10"x10" may suffice. Professionals often require larger capacities, such as the SV08 Max's 500×500×500mm build volume, which accommodates oversized models without splitting them into sections.

Material compatibility is equally important. Large FDM printers like the SV08 Max support a wide range of materials, including PLA, PETG, ABS, and TPU. Advanced features like high-temperature hotends expand options for engineering-grade materials.

|

Criteria |

Details |

|---|---|

|

Hobby printers: < 10"x10"x10"; Professional printers: up to 22" height |

|

|

Materials |

PLA, PETG, ABS, TPU; advanced options like carbon-fiber composites |

Evaluating Budget and Long-Term Value

Budget plays a critical role in selecting a 3D printer. Hobby printers typically cost up to $6,000, while professional models range from $8,000 to $12,000. The Sovol SV08 Max offers exceptional value at $1299, combining advanced features with affordability. Its open-source design allows for upgrades, ensuring long-term usability.

Reminder: Factor in operational costs like materials and maintenance when evaluating the printer's overall value.

Why Sovol SV08 Max Is a Top Choice for Large-Scale 3D Printing

The Sovol SV08 Max stands out for its generous build volume, high-speed capabilities, and precision-enhancing features. Its CoreXY kinematics reduce vibrations, while adaptive area detection optimizes bed leveling. The high-flow nozzle ensures faster production without compromising print quality.

|

Feature |

Specification |

|---|---|

|

Printing Volume |

500×500×500mm |

|

700mm/s |

|

|

Acceleration |

40,000mm/s² |

|

Adaptive Area Detection |

Yes |

|

Pressure Advance |

Yes |

These features make the SV08 Max ideal for industrial applications, creative projects, and prototyping.

Researching Brand Reputation and Customer Support

A reliable brand ensures consistent performance and support. Sovol has earned a reputation for innovation and affordability, backed by a strong commitment to open-source principles. Resources like the Sovol Wiki provide comprehensive guides, while customer support ensures smooth operation.

Callout: Prioritize brands with proven expertise and accessible support systems to enhance your printing experience.

Large FDM 3D printers offer unmatched versatility, speed, and precision. With 71% of businesses using FDM internally and 69% citing the ability to produce complex shapes, their value is undeniable. Sovol’s SV08 Max, featuring a 500×500×500 mm build volume, Eddy Current Scanning, and high-flow nozzles, exemplifies innovation. Explore Sovol’s range to elevate your projects.

|

Statistic |

Value |

|---|---|

|

Businesses using FDM internally |

71% |

|

Businesses citing complex shape production as a benefit |

69% |

|

Businesses satisfied with 3D printing strategies |

81% |

FAQ

What makes the Sovol SV08 Max suitable for large-scale projects?

The Sovol SV08 Max offers a 500×500×500mm build volume, CoreXY kinematics, and high-speed capabilities, making it ideal for oversized models, industrial parts, and intricate designs.

Can the Sovol SV08 Max handle advanced materials like carbon-fiber filaments?

Yes, the SV08 Max supports advanced materials, including carbon-fiber-reinforced filaments, thanks to its high-temperature hotend and heated bed, ensuring compatibility with engineering-grade projects.

How does the Eddy Current Scanning system improve print quality?

The Eddy Current Scanning system ensures precise bed leveling by detecting surface deviations in 80 seconds, enhancing first-layer adhesion and overall print success rates.

Tip: Explore Sovol's Wiki for detailed guides on optimizing your SV08 Max's performance.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.