PLA filament is a type of plastic that breaks down naturally. It is made from plants like corn and sugarcane. Because it is good for the environment, many people use it for 3D printing. It is easy to work with since it needs low heat to print and doesn’t bend much. This makes it great for beginners.

More people want eco-friendly materials, so PLA is popular. For example:

- The PLA filament market was worth about $600 million in 2023. It might grow to $1.8 billion by 2032.

- People care more about the planet, so they use PLA.

PLA is cheap and can be used in many ways. It’s perfect for fun and creative projects.

Key Takeaways

- PLA filament is good for the planet. It is made from plants like corn and sugarcane, so it’s great for eco-friendly projects.

- Beginners like PLA because it melts easily. You don’t need special tools or high heat to print with it.

- PLA prints look smooth and neat. They are perfect for making detailed models and cool decorations.

- PLA can break easily and doesn’t handle heat well. It’s not good for outdoor stuff or things that need to be very strong.

- To get the best prints, set your printer right. Use the correct temperature and speed for strong and lasting results.

What is PLA Filament Made Of?

Composition and Sources of PLA

PLA filament comes from natural and renewable plants. It is made using corn starch, sugarcane, or cassava roots. These plants have lots of carbohydrates, which are used to make PLA. First, starch is taken from the plants. Then, it is turned into glucose. This glucose is fermented to create lactic acid. Finally, the lactic acid is processed to make polylactic acid, which is the main part of PLA filament.

PLA is special because it is good for the environment. Unlike plastics made from oil, PLA is made from sustainable plants. It can break down naturally over time. This makes it a great choice for people who care about the planet. As more people want eco-friendly materials, PLA is becoming more popular in 3D printing.

Here’s a simple look at where PLA comes from:

- Made from plants like corn starch, sugarcane, and cassava roots.

- A green option compared to regular plastics.

- Gaining popularity as people focus on saving the environment.

Key Properties of PLA as a 3D Printing Material

PLA filament has features that make it great for 3D printing. It melts at a low temperature, between 130–180 °C. This means you can print with it using less heat than other materials. It softens at 60–65 °C, so it’s easy to handle, especially for beginners.

PLA is strong but can break easily. Its strength is similar to PET, but it doesn’t stretch much before snapping. PLA’s stiffness, called Young’s modulus, is between 2.7–16 GPa. These traits make it good for projects that need to be firm but not bendable.

Some types of PLA can handle heat up to 110 °C, making them tougher for certain uses. Regular PLA, however, may lose its shape in high heat. It’s best for indoor items or things that won’t get too hot.

Here’s a quick list of PLA’s properties:

- Melting temperature: 130–180 °C

- Glass transition temperature: 60–65 °C

- Young’s modulus: 2.7–16 GPa

- Tensile strength: Strong like PET but breaks easily

- Heat resistance: Up to 110 °C for special PLA types

These features make PLA filament a flexible choice for 3D printing. Whether you’re making models, decorations, or school projects, PLA is easy to use and works well.

How is PLA Filament Made?

How PLA is Produced

PLA starts with plants like corn or sugarcane. These plants have carbohydrates that turn into glucose. Glucose is fermented to make lactic acid. Then, lactic acid is processed to create polylactic acid. This polylactic acid becomes the base for PLA filament, a biodegradable plastic.

Making PLA focuses on being eco-friendly. Unlike oil-based plastics, PLA uses renewable plants. It breaks down naturally, so it’s great for the environment. PLA is popular because it works for many uses, like DIY projects and prototypes.

The quality of PLA depends on how it’s made. Machines and settings are very important. Things like nozzle heat, build temperature, and feed rate matter. These settings help make PLA strong and good for 3D printing.

Important Settings:

- Nozzle size and heat

- Air gaps and angles

- Layer thickness and infill

These settings affect how strong and durable the PLA filament will be.

Making PLA Filament for 3D Printing

After PLA is made, it’s turned into filament for 3D printing. The process melts PLA pellets and pushes them through a nozzle. This creates a long strand, which is cooled and rolled into spools.

The process needs careful control to keep the filament high-quality. Melt Flow Index (MFI) tests check if the extrusion is smooth. For example, an MFI of 5g/10min at 80 °C shows good consistency. Cooling times depend on the machine used.

|

Metric |

Filament Maker ONE |

Filament Maker TWO |

|---|---|---|

|

Cooling Time (to 170 °C) |

14 minutes |

9 minutes |

|

Cooling Time (to 60 °C) |

3.5 hours |

2 hours 45 mins |

|

Filament Diameter Consistency |

Moderate to high variations |

High consistency |

Different machines work in different ways. Some need manual changes, while others adjust automatically. By cooling properly and keeping the diameter steady, you can make great PLA filament for 3D printing.

Advantages and Disadvantages of PLA Filament

Benefits of PLA for 3D Printing

PLA filament has many good points for 3D printing fans. It is biodegradable and made from plants like corn and sugarcane. This makes it a better choice for the planet than regular plastics. If you care about the environment, PLA is a smart pick for your projects.

Another great thing about PLA is how easy it is to use. It melts at lower temperatures, around 130–180 °C, so it uses less energy. It also doesn’t smell much while printing, which is nice for indoor use. Beginners like PLA because it sticks well to surfaces and doesn’t need a heated bed.

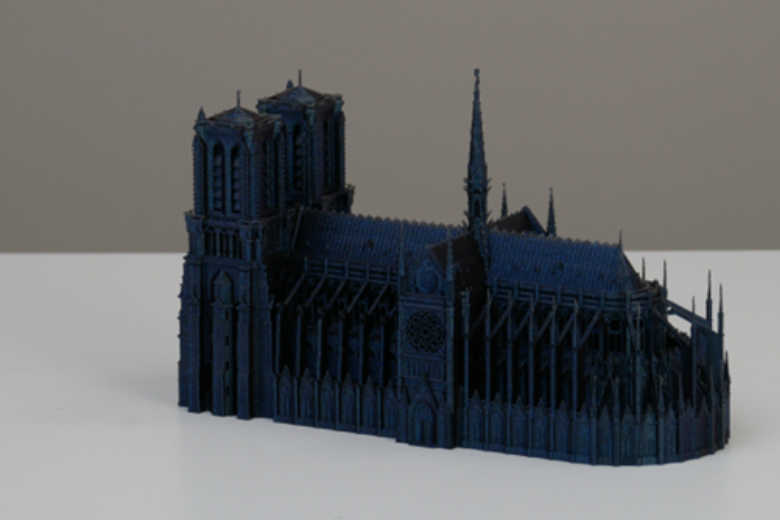

PLA prints have smooth surfaces, perfect for detailed models and decorations. Changing the infill density can make PLA prints stronger. For example, using 60% infill makes prints tougher and less likely to break.

Here are the main benefits of PLA:

- Eco-friendly: Breaks down naturally and comes from renewable plants.

- Easy to print: Needs less heat and works without special equipment.

- Smooth finish: Great for detailed and neat prints.

- Beginner-friendly: Simple to use and widely available.

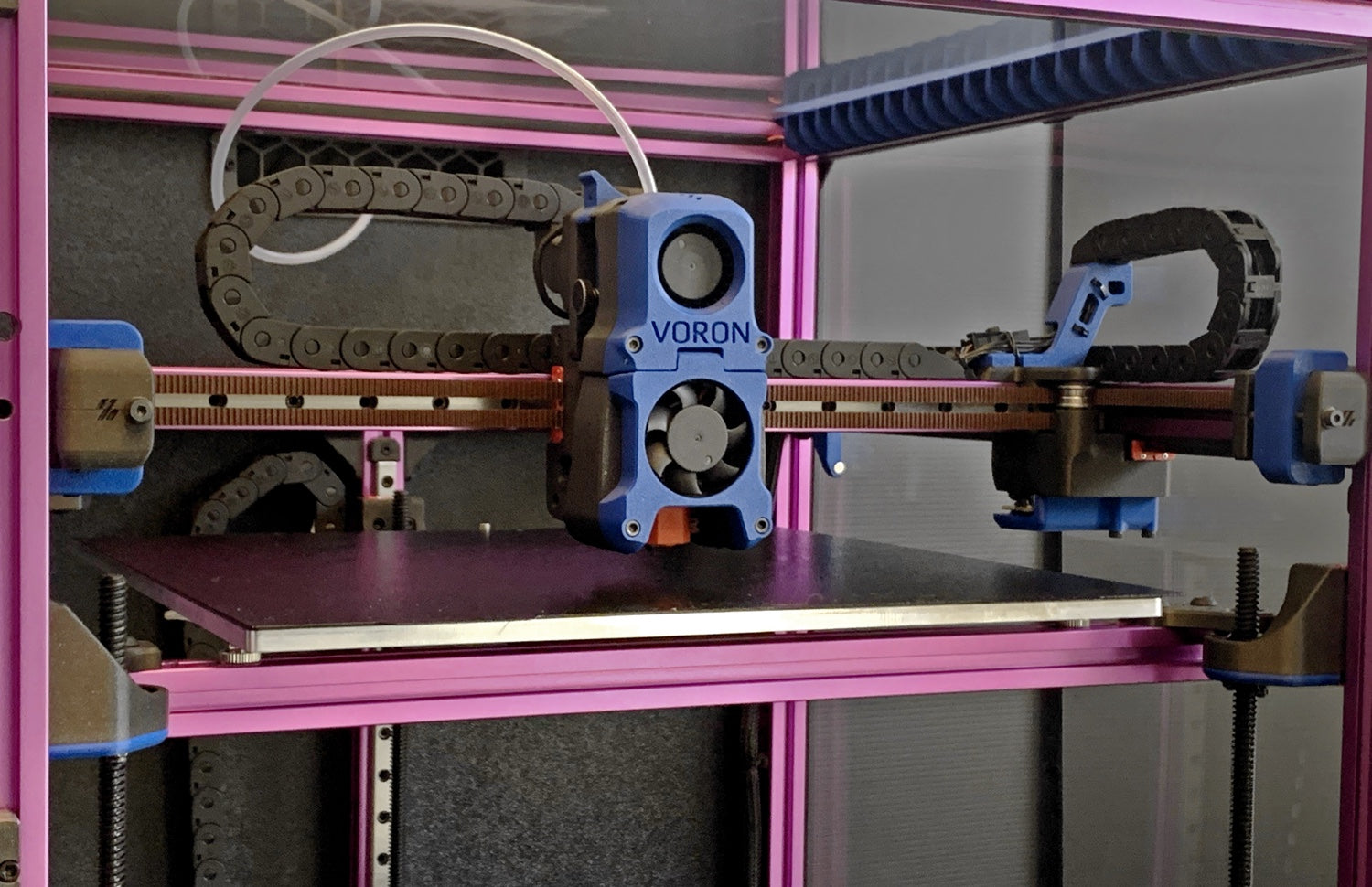

If you use a Sovol 3D printer, PLA works really well. Sovol printers handle PLA’s low melting point easily, giving you great results every time.

Limitations of PLA as a Material

PLA has some downsides you should know about. One big problem is its low heat resistance. It softens at 60–65 °C, so it’s not good for hot places. For example, a PLA item left in a hot car might bend or lose its shape.

PLA is also brittle, meaning it can snap under pressure. This makes it less useful for parts that need to bend or handle impacts. It also absorbs water from the air, which can hurt its quality over time.

Using PLA outdoors isn’t ideal. It breaks down when exposed to sunlight and rain, so it’s not great for outside projects. Materials like PETG or ABS work better for outdoor use.

Here are some common drawbacks of PLA:

- Low heat resistance: Can’t handle high temperatures.

- Brittleness: Breaks easily under stress.

- Moisture issues: Loses quality when exposed to water.

- Not for outdoor use: Damaged by sunlight and rain.

Studies compare PLA with other materials. ABS is stronger and handles heat better, while PETG resists chemicals and bends more easily. But both are less eco-friendly than PLA.

If you’re printing big items, PLA might shrink or misalign. Dense infill can also take longer to dry, slowing your work. Picking the right material for your project is important.

Tips for PLA 3D Printing

Best Settings for PLA Filament

To get good results with PLA printing, adjust your printer settings. Set the hot-end temperature between 180°C and 220°C. If layers don’t stick, raise the temperature slightly. But too much heat can cause stringy or messy prints. Keep the print bed temperature between 55°C and 70°C. A cold bed can make prints not stick, while too much heat can warp the base.

Print speed is also important. Slower speeds give better details, especially for complex designs. Test different speeds to balance quality and time. Check the filament size too. For 1.75mm PLA, use around 185°C. For 2.85mm PLA, aim for about 205°C.

|

Setting Type |

Recommended Range |

Notes |

|---|---|---|

|

Hot End Temp |

180-220°C |

Raise temp if layers don’t stick; too hot causes mess. |

|

Print Bed Temp |

55-70°C |

Cold bed = poor stick; too hot = warped base layers. |

|

Print Speed |

Slower speeds = better quality; test for balance. |

Adjust to match design needs and time. |

How to Improve Bed Adhesion

Good adhesion starts with a clean print bed. Wipe the bed to remove dirt or grease. Use isopropyl alcohol for glass beds or a damp cloth for others. Adding glue stick or painter’s tape helps PLA stick better. If your printer has a heated bed, set it to 60°C for best results.

Make sure the bed is level. An uneven bed can ruin the first layer. Use a piece of paper to check the nozzle gap. The paper should slide under the nozzle with slight resistance. To stop warping, use a brim or raft. These add more surface area for better stability.

Tip: If the first layer has gaps, raise the bed temperature or adjust the nozzle height.

Finishing PLA Prints

PLA is easy to finish, making it great for detailed projects. Sanding is simple because PLA melts at low heat. Start with rough sandpaper to smooth edges, then use finer sandpaper for a polished look. For painting, use acrylic paints. Apply a primer first so the paint sticks well.

Gluing PLA parts is easy too. Use super glue for strong bonds. To make prints stronger for sanding or assembly, adjust the printer settings before printing.

Note: Don’t use high-speed tools for sanding. Too much friction can melt PLA.

PLA vs. Other 3D Printing Materials

PLA vs. ABS: Key Differences

PLA and ABS are different in many ways. PLA is eco-friendly because it’s made from plants. ABS comes from oil, so it’s less kind to the planet. PLA is easier to print since it needs less heat. It also doesn’t smell bad while printing. ABS needs more heat and gives off fumes, so good airflow is important.

PLA is stiffer and less flexible than ABS. This means PLA can snap under pressure. ABS is stronger and handles impacts better, making it good for tough parts. PLA’s strength changes more with layer thickness. ABS stays strong even with thinner layers.

|

Property |

PLA |

ABS |

|---|---|---|

|

Stiffness (Young's Modulus) |

Lower than PLA |

|

|

Strength by Layer Thickness |

Drops more with thinner layers |

Stays strong with thinner layers |

|

Impact Resistance |

Brittle, breaks easily |

Tough, handles impacts |

PLA works well for indoor or decorative items. ABS is better for outdoor or mechanical parts because it’s durable and heat-resistant.

PLA vs. PETG: Key Differences

PLA and PETG have unique traits. PLA is stiffer and great for detailed models. PETG is more flexible and resists impacts, making it better for functional parts. PLA prints at lower temperatures and is easier to use. PETG needs higher heat and often a heated bed.

Heat resistance is another difference. PLA softens in warm places, so it’s not good for hot areas. PETG can handle higher temperatures, so it’s better for outdoor use. PLA doesn’t resist chemicals well, but PETG can handle some chemicals without breaking down.

If you want something easy and eco-friendly, choose PLA. For stronger, heat-resistant projects, PETG is the better pick. Both are great for 3D printing but suit different needs.

Applications of PLA Filament

Common Uses in 3D Printing Projects

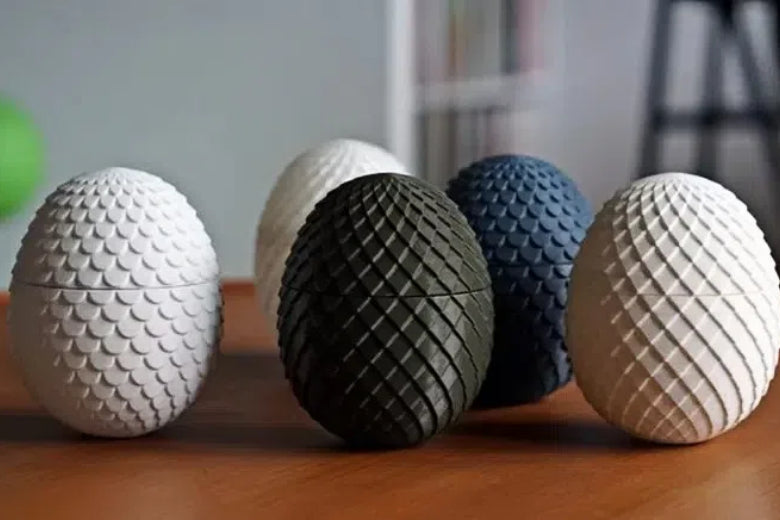

PLA filament is a flexible material for 3D printing. It’s easy to use and eco-friendly, making it popular. People use PLA to make many things, like decorations and prototypes. For example, you can print figurines, jewelry, or home décor. PLA creates smooth surfaces, perfect for creative projects.

If you like crafts or DIY, PLA is great. You can design gifts like keychains or photo frames. Many people also use PLA for cosplay props because it’s light and easy to paint. Teachers use PLA to make models, like shapes or replicas, to help students learn.

For beginners, PLA is a smart choice. It prints at low heat and sticks well to surfaces. It’s good for trying new ideas without worrying about cracks. Whether for fun or work, PLA lets you create many things.

Industrial and Educational Applications

PLA is used in industries and schools because of its special features. In prototyping, it helps make detailed models to test ideas. Factories use PLA to make parts for cars and planes.

In schools, PLA helps students learn by doing. Teachers use it to print science models, building designs, or history items. It’s safe and easy, so it’s great for classrooms.

PLA is also helpful in healthcare. It’s safe for the body, so it’s used for medical models and prosthetics. Artists and architects use PLA for sculptures and designs. The table below shows how PLA is used in different areas:

|

Sector |

Applications |

|---|---|

|

Prototyping |

Makes detailed models to test ideas before production. |

|

Manufacturing |

Used for car and plane parts. |

|

Education |

Helps students learn with hands-on projects. |

|

Healthcare |

Creates medical models and prosthetics. |

|

Others |

Used in art, architecture, and consumer goods. |

As shown, PLA is not just for hobbies. It’s useful in many fields, showing its value in today’s world.

Environmental Impact of PLA Filament

Biodegradability and Composting

PLA is a greener choice compared to regular plastics. It’s made from plants like corn and sugarcane, not oil. This makes it better for the environment and useful for things like food packaging. PLA can break down into natural parts under the right conditions, helping reduce waste.

Research shows PLA breaks down well in industrial composting. For example, tests show PLA films fully decompose in these setups. But this needs high heat and controlled moisture. At home, PLA takes much longer to break down, making it less practical for everyday composting.

If you want an eco-friendly material, PLA is a good option. It balances being useful and kind to the planet. Its ability to decompose in proper settings makes it great for cutting down plastic waste, especially for single-use items like food containers.

Challenges in Recycling PLA

Recycling PLA is tricky, even though it’s eco-friendly. Over 400 million tons of plastic are made each year, but only 9% gets recycled. PLA adds to this problem because it needs special recycling centers, which are rare.

Here are some reasons why PLA recycling is hard:

- Most recycling centers can’t process PLA, so it ends up in landfills.

- Mixing PLA with other plastics raises costs and lowers recycling success.

- PLA’s plant-based design doesn’t work well with regular recycling systems.

These issues show the need for better recycling systems and education. While PLA is better for the planet, managing its waste is still a challenge. Supporting new composting and recycling methods can make PLA an even better eco-friendly choice.

PLA filament is eco-friendly, affordable, and very useful. It’s made from plants, so it’s better for the planet than regular plastics. Its low melting point makes it easy to use for beginners and experts. You can use PLA to make decorations or test ideas with your 3D printer. It gives good results every time.

But PLA isn’t perfect. It doesn’t handle heat well and isn’t as strong as ABS. A study compared PLA and ABS and found they affect cells differently:

|

Filament Type |

Effects on Cells |

Changed Chemicals |

Pathway Changes |

|---|---|---|---|

|

PLA |

More changed chemicals |

Vitamin metabolism at low dose, sugar metabolism at high dose |

|

|

ABS |

Lower cell health, MDM2, MMP-9 |

Fewer changed chemicals |

Sugar metabolism at low dose, protein metabolism at high dose |

Using PLA helps the environment and is easy for 3D printing. Try it today and see how it improves your projects!

FAQ

Why is PLA good for the environment?

PLA comes from plants like corn and sugarcane. It breaks down naturally in special composting setups. This helps reduce plastic waste and makes it eco-friendly.

Can PLA filament be recycled?

Recycling PLA is hard because it needs special centers. Most places can’t recycle it, so it often goes to landfills. Composting is a better way to get rid of PLA.

Can you use PLA for outdoor projects?

PLA isn’t great for outdoor use. Sunlight and rain can damage it. For outdoor projects, use stronger materials like PETG or ABS instead.

How should you store PLA filament?

Keep PLA in a dry, cool spot to avoid moisture. Use sealed containers with drying packs to protect it. Storing it well keeps it working properly for printing.

What makes PLA a green choice?

PLA is made from plants, not oil, so it’s bio-based. Making PLA uses less energy and creates less pollution than regular plastics. This makes it a smart pick for eco-friendly printing fans.

Zostaw komentarz

Wszystkie komentarze są moderowane przed opublikowaniem.

Ta strona jest chroniona przez hCaptcha i obowiązują na niej Polityka prywatności i Warunki korzystania z usługi serwisu hCaptcha.