Wet filament can ruin your 3D printing projects. When filament absorbs water, it becomes weaker and prints badly. Nylon can take in up to 7% of its weight in water. This can cause bubbling or weak layers in your prints. Even PLA, which absorbs less water, can still mess up your print quality.

Drying filament is very important. If you hear popping sounds while printing, it means there’s moisture in the filament. Dry filament is stronger and prints better. It helps you make smooth and durable prints. Keeping filament dry prevents problems and keeps your projects successful.

Key Takeaways

- Keeping filament dry is important for good 3D prints. Wet filament can make layers weak and prints look bad.

- Try oven drying, silica gel, or filament dryers to remove water from filament.

- Store filament in sealed containers with drying packs to stop it from getting wet and keep prints looking great.

- Use hygrometers to check humidity and keep filament dry for printing.

- Do not use microwaves to dry filament. They heat unevenly and can ruin it.

Why Wet Filament is a Problem

How moisture changes filament

When filament gets wet, it can ruin your prints. Water gets inside the material, making it weak and hard to use. Wet PLA becomes soft and loses strength. Nylon can swell and change shape. Moisture also lowers the melting point, causing uneven printing. If you see bubbles or steam from the nozzle, that’s water turning into vapor. These problems make it tough to get smooth, good-quality prints.

Signs your filament is wet

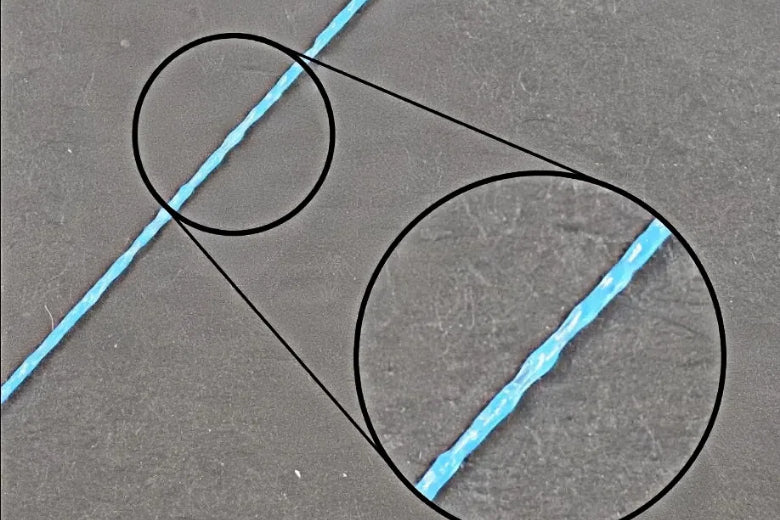

How do you know if filament is wet? There are some easy clues. First, listen for popping or crackling sounds while printing. This happens when water in the filament turns to steam. Second, check for stringy or messy plastic on your prints. Wet PLA often leaves thin strands behind. Third, look at your print’s surface. If it’s rough, bubbly, or uneven, moisture is likely the problem. These signs can be annoying but show your filament needs drying.

How wet filament affects prints

Wet filament makes printing harder and weakens your prints. Prints made with wet filament often break easily because of weak layers. The quality also drops, with rough textures and flaws. A study by Hadi et al. (2023) found drying nylon makes prints stronger and last longer. Some manufacturers warn that PLA can become unusable after just one hour in humid air. Here’s a simple table showing how moisture affects filament:

|

Problem Type |

What Happens |

|---|---|

|

Absorbing Moisture |

Filament absorbs water, making printing harder. |

|

Strength and Durability |

Drying nylon makes prints stronger and tougher. |

|

Printing Settings |

Adjusting settings can help with wet filament. |

|

Manufacturer Warnings |

Wet PLA may not work after 1 hour in humid air. |

|

Moisture Effects |

More moisture means worse prints and weaker filament. |

By knowing these problems, you can stop wet filament from ruining your 3D prints.

5 Proven Methods to Dry Wet Filament

Oven Drying

Drying filament in an oven is simple and effective. Preheat your oven to 150°F to 180°F (65°C to 82°C). Put the filament spool on a tray and heat it for 2 to 6 hours. This works well for PLA, ABS, and nylon. Watch the temperature carefully. Too much heat can ruin the filament by melting or warping it.

Here’s a helpful chart for oven drying:

|

Drying Time (hours) |

|

|---|---|

|

75 - 85 |

8 |

|

90 - 100 |

12 |

|

100 - 130 |

8 - 12 |

|

110 - 140 |

8 - 12 |

|

80 |

4 |

|

85 - 95 |

6 |

Drying single filaments instead of spools works better. Single filaments dry faster because more surface is exposed to heat. If your PLA filament is wet, oven drying can fix it and improve your prints.

Tip: Use an oven thermometer to check the temperature. Some ovens may not heat evenly, which could harm your filament.

Using Silica Gel or Desiccant Packs

Silica gel or desiccant packs are cheap and easy ways to dry filament. These materials soak up moisture from the air. Put your filament spool in a sealed container with silica gel packets. Leave it for 1 to 2 days to dry.

Why silica gel works well:

- It removes moisture from the air, keeping filament dry.

- Filament stored with desiccants stays at 10-20% humidity, ideal for printing.

- Even after months, filament stored this way stays in good shape.

This method is great for long-term storage. For instance, filament stored with desiccants for three months still printed perfectly. While slower than heat methods, silica gel prevents moisture issues reliably.

Note: Use enough desiccant for your container size. Too little won’t keep your filament dry.

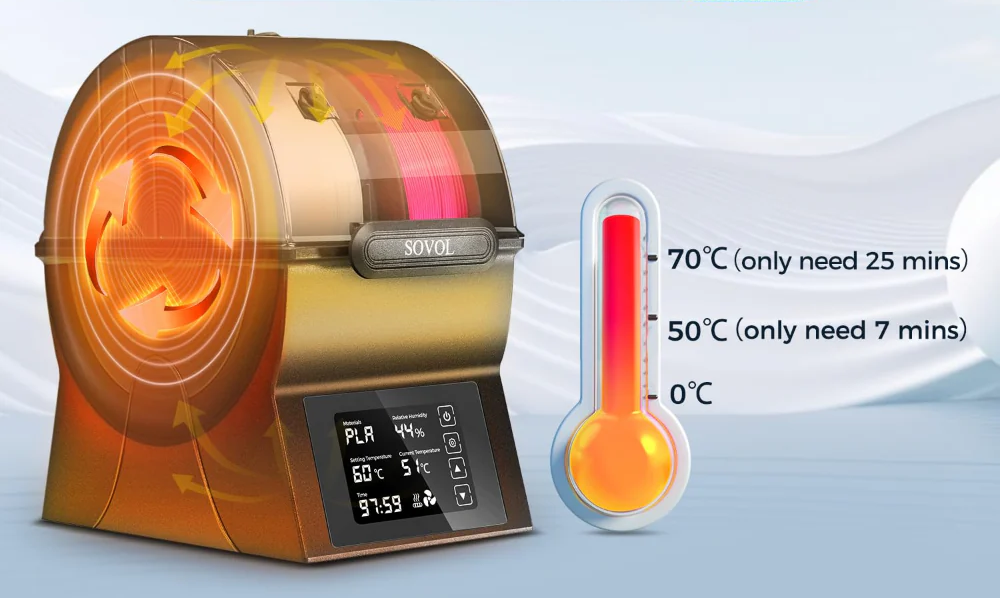

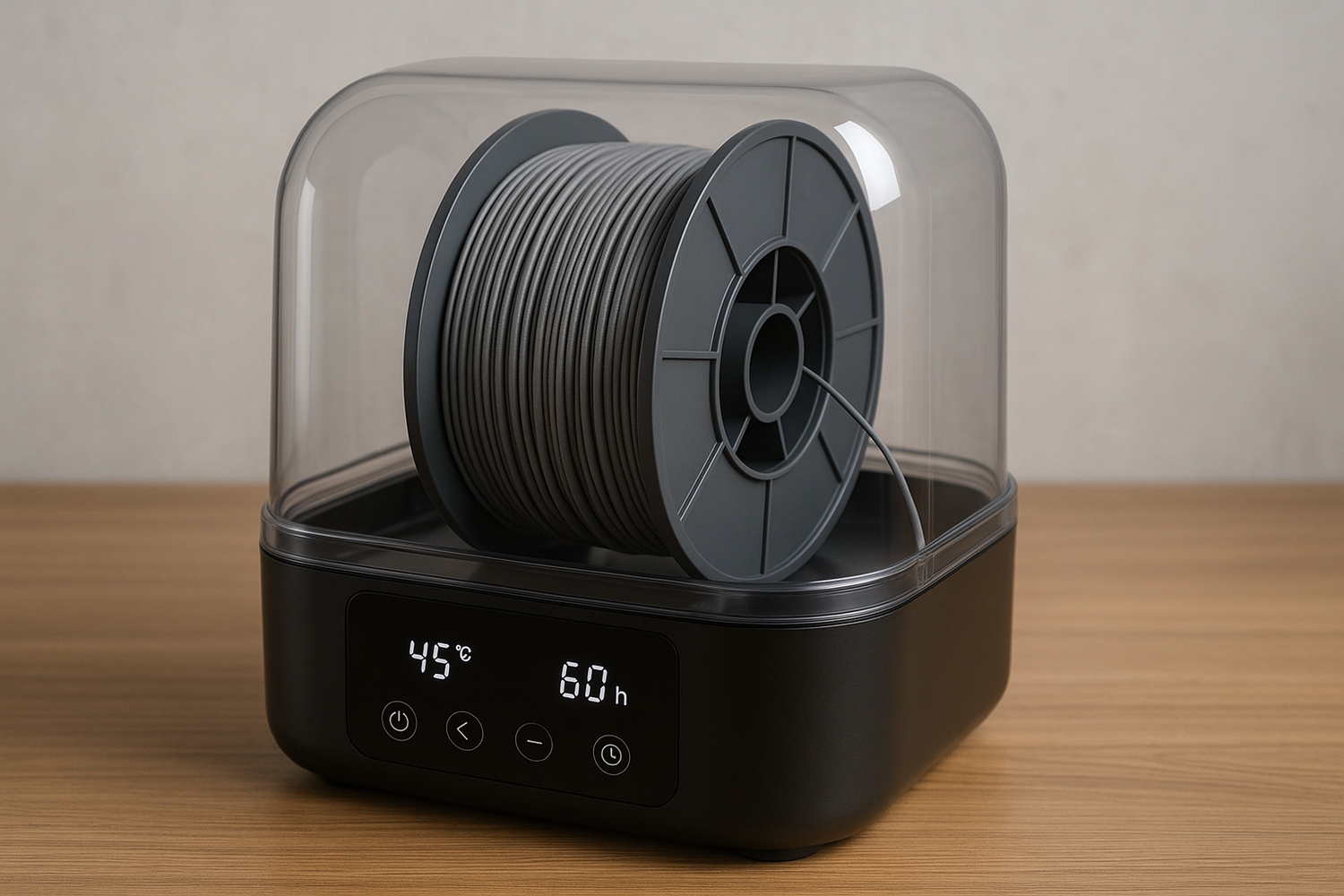

Filament Dryers

Filament dryers are special tools made to dry filament. They use heat and airflow to remove moisture quickly. These devices are easy to use and work well for wet PLA or other sensitive materials.

Why filament dryers are great:

- They keep a steady temperature, drying filament evenly without overheating.

- Airflow speeds up drying, making it faster than silica gel.

- Some dryers let you print directly from them, keeping filament dry while printing.

For example, filament dryers can restore nylon and ABS for better prints. If you print often, a filament dryer can save time and improve results.

Pro Tip: Choose a filament dryer with adjustable temperature settings. This helps you dry different filament types safely.

Food Dehydrators

Food dehydrators are not just for food. They can also dry filament easily. These machines use low heat, which is safe for PLA and other delicate materials.

Here’s how to dry filament with a food dehydrator:

- Put the filament spool on a tray inside the dehydrator.

- Set the right temperature. Use 40-45°C for PLA and 80°C for ABS or nylon.

- Let it dry for 4-6 hours.

- Watch the temperature and humidity during drying.

- Cool the filament completely before using it for printing.

Food dehydrators work well because they keep the heat steady. This helps the filament dry evenly without melting or bending. Whether your filament is PLA or nylon, this method can make it print better.

Tip: If you use many filament types, label their drying settings. This will save time and help you get great results every time.

Avoiding Microwaves and Safer Options

Microwaves may seem fast, but they are unsafe for filament. They heat unevenly, which can melt or burn the filament. It’s better to use safer methods.

Here are some good alternatives:

- Airtight Containers with Desiccants: Store filament with silica gel in a sealed box. This keeps it dry over time.

- Oven Drying: Use your oven if you don’t have a dehydrator or filament dryer. Keep an eye on the temperature to avoid damage.

- Filament Dryers: These tools are made for drying filament. They are simple to use and work well for PLA and ABS.

These methods are safe and effective for drying filament. Avoid microwaves to protect your filament and get better printing results.

Note: Always check the drying instructions for your filament type. This helps prevent overheating and ensures the best quality.

Tips for Proper Filament Storage

Using airtight containers

Storing filament in airtight containers keeps it safe from moisture. Sealed containers block humid air that can harm filament quality. Choose containers with tight lids or rubber seals to keep air out. You can use items like plastic bins or food storage boxes. Make sure they are dry before putting filament inside.

Vacuum-sealed bags are another great option. These bags remove all air, giving extra protection to your filament. Whether you store PLA or other types, airtight containers help keep filament ready for printing.

Tip: Write the filament type and purchase date on the container. This helps you stay organized and use older filament first.

Adding desiccants to storage

Desiccants are small packets that absorb moisture from the air. Adding them to your storage keeps filament dry and lasts longer. For example, the BigRep SHIELD uses a special chamber with desiccants to keep humidity at 0.01%. This stops moisture damage without drying filament too much.

Why desiccants work well:

- They control moisture for sensitive filaments like PLA and nylon.

- They prevent damage, helping avoid failed prints.

- Using them saves money by reducing waste and repairs.

“The BigRep SHIELD cuts misprints by 20% and repair costs by 50%.”

Check your desiccants often. Replace them when they are full of moisture to keep filament dry and ready to use.

Storing filament in low-humidity environments

Humidity can ruin filament and cause bad prints. Keeping filament in low-humidity areas protects its strength and print quality. Try to keep humidity below 40%, especially for materials like PLA and nylon.

If your area is humid, use a dehumidifier in your storage space. Drying filament before storing it also helps keep it in good condition. Many people use filament dryers to remove moisture quickly before storage.

Pro Tip: Use a hygrometer to check humidity levels in your storage area. This tool helps you spot moisture problems early.

By using airtight containers, desiccants, and low-humidity storage, you can protect your filament. These steps make printing smoother and less frustrating.

Checking filament moisture with hygrometers

Keeping filament dry is key for good 3D prints. But how can you tell if it’s safe from moisture? Hygrometers can help. These tools check humidity levels and show if storage is dry. They are easy to use and prevent problems caused by wet filament.

Put a hygrometer in your filament container. It will display the humidity level. If it’s too high, you can fix it quickly. For PLA, keep humidity under 40%. For materials like nylon, aim for 20% or less. If levels rise, add more desiccant or dry the filament to solve the issue.

Hygrometers remove the need to guess. You’ll know exactly when to take action. This is especially helpful for PLA, which absorbs water fast. Watching humidity protects your filament and improves print quality.

Here’s how dry filament improves prints:

|

Addition (%) |

Flexibility Increase (%) |

Bending Strength Increase (%) |

|---|---|---|

|

1 |

N/A |

|

|

3 |

28.72 |

35.67 |

|

5 |

38.3 |

44.88 |

The table shows that drying filament makes it stronger and more flexible. This leads to smoother prints and tougher parts. Hygrometers help keep these benefits by ensuring dryness.

Tip: Use a digital hygrometer for better accuracy. Some even have alarms to warn you about high humidity.

By tracking moisture, you can avoid issues like bubbling or weak prints. Hygrometers make storing filament easier and improve your 3D printing success.

Dry filament is key for good 3D printing results. Wet filament can cause bad prints, but you can fix it. Use methods like ovens, filament dryers, or silica gel to dry it. Each method works differently, so pick what suits your tools. Storing filament correctly also matters. Use sealed containers, moisture-absorbing packs, and humidity meters to keep it safe. These steps prevent problems and help you make better, stronger prints every time.

FAQ

What’s the best way to dry PETG filament?

The best way is using a filament dryer or food dehydrator. Set it to 65°C (149°F) and dry for 4-6 hours. This method dries evenly without harming the filament.

Can I dry PETG filament in an oven?

Yes, you can dry PETG filament in an oven. Heat the oven to 65°C (149°F) and place the spool inside. Let it dry for 4-6 hours. Use an oven thermometer to check the temperature and avoid overheating.

How can I tell if PETG filament is wet?

Wet PETG makes popping sounds while printing. You may see stringy prints, rough spots, or bubbles in layers. These signs mean the filament has absorbed water and needs drying.

Does drying filament help with the first layer?

Yes, drying filament helps the first layer stick better. Wet filament causes uneven extrusion, making adhesion harder. Dry filament gives smoother extrusion and better first-layer results.

How do I store PETG filament to keep it dry?

Keep PETG filament in a sealed container with silica gel. Store it in a low-humidity area, under 40%. Use a hygrometer to check humidity and keep the filament dry.

Yorum bırak

Tüm yorumlar yayınlanmadan önce denetlenir.

Bu site hCaptcha ile korunuyor. Ayrıca bu site için hCaptcha Gizlilik Politikası ve Hizmet Şartları geçerlidir.