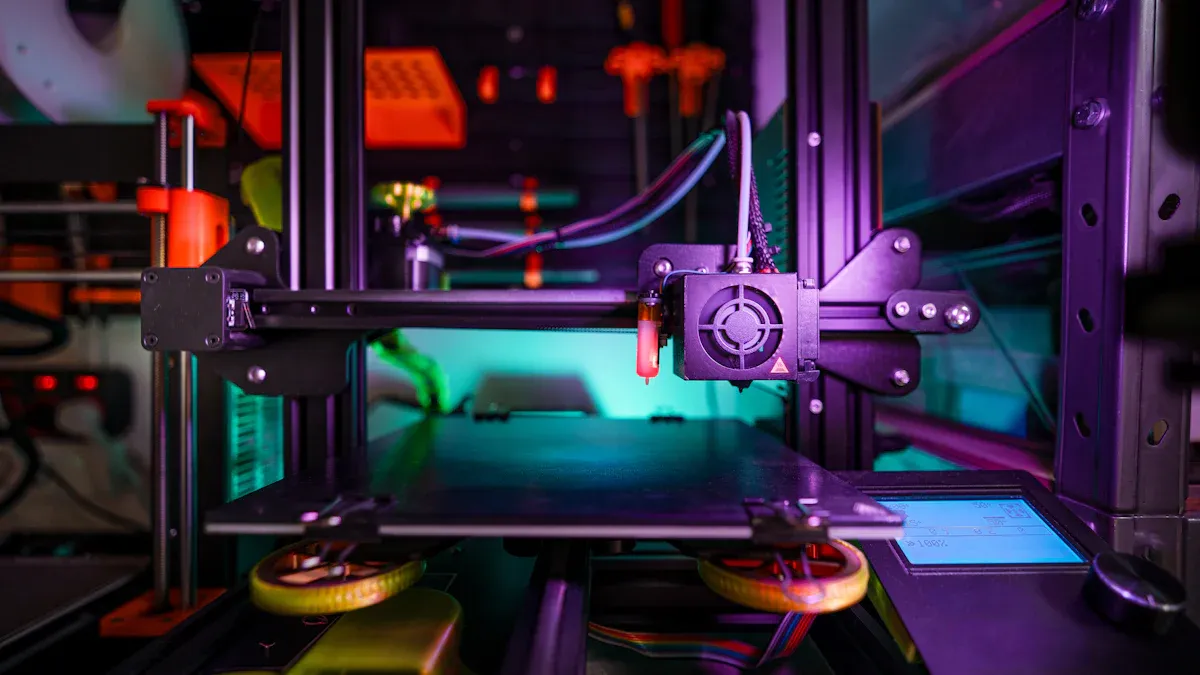

You may have seen more closed-source 3D printers lately. These printers focus on controlling design and technology. This helps companies protect their new ideas. By limiting access to their software and hardware, they control quality better. It also helps them stand out in the 3D printing world. Closed-source printers often have special systems. These systems make it easy to use matching tools and materials. As 3D printing improves, this plan changes how you use 3D printers.

Key Takeaways

- Closed-source 3D printers keep company ideas safe by limiting access. This helps them stay ahead of competitors.

- These printers give great quality and reliable results. They are perfect for users who want easy and consistent printing.

- Fixing and support are easier with closed-source printers. Companies offer expert help and special parts, so repairs are faster.

- Closed-source printers have fewer customization options. This might not work for users who like more freedom and creativity.

- Closed-source printers can cost more because of special parts. But they work well together and make fewer printing errors.

Why Manufacturers Pick Closed-Source Systems

Keeping Ideas Safe

Making new 3D printers takes time and money. Closed-source systems keep designs and technology private. This stops others from copying their ideas. By locking software and hardware, companies protect their work. This helps them stay ahead in the 3D printing race.

Closed systems also inspire new ideas. When companies feel safe, they try better designs. For example, 3D printing helps make products faster. Protecting these steps keeps companies strong in the market.

Creating a Money-Making System

Closed systems build special setups around their printers. These printers work best with certain tools and materials. This makes printing easier and reduces mistakes.

This setup helps companies earn more money. You might need to buy special parts or filaments from them. This keeps printers working well and boosts profits. Custom options also help companies stand out, like in electronics.

Closed systems also help small businesses and inventors. They make it easier for beginners to start. This supports new ideas while keeping quality high.

How Closed-Source Systems Improve User Experience

Keeping Quality High and Reliable

Closed-source 3D printers focus on making high-quality prints. These printers give accurate and reliable results every time. Companies test their printers carefully to meet strict standards. For instance, Formlabs tested their Form 3 and Form 3B printers. They used a test called the Formtest to check accuracy. This test measured 160 prints and found small errors of 0 to 100 microns. This shows these printers work well for things like medical tools.

These systems also prevent mistakes from using the wrong parts or materials. By controlling both hardware and software, they work smoothly together. This makes sure every print is high quality. Even for hard projects, closed-source printers stay dependable.

Easier Support and Repairs

Closed-source systems make fixing problems simpler. If something goes wrong, you can ask the company for help. They have trained teams who know their products well. This means faster fixes and less waiting time. You don’t need to find outside help or solve problems alone.

Taking care of these printers is also easier. Companies design them to use specific parts and materials. This avoids problems with mismatched items and keeps them working longer. You can get official parts and updates directly from the company. This makes the printer last longer and stay reliable.

Choosing a closed-source printer gives you a helpful system. It makes 3D printing easier and more fun to use.

Trade-Offs of Closed-Source 3D Printers

Limited Customization Options

Closed-source 3D printers restrict how much you can change their systems. You cannot adjust the firmware or modify the hardware for special needs. This can upset users who want more control over their printers. Many people prefer open-source systems because they allow creativity and changes.

Tip: If you need flexibility, open-source printers might suit your projects better.

Closed-source systems often lack detailed guides, making changes harder. Without clear instructions, it’s tough to adjust the printer. This can slow you down, especially if you need custom solutions for specific tasks.

Also, while 3D printing saves on tools and materials, closed systems cost more to run. For instance, plastic for digital printers costs about 84 cents per cubic inch. This is much pricier than materials used in older manufacturing methods. Limited customization stops you from finding cheaper options, making these systems less affordable for some uses.

Higher Costs for Proprietary Components

Closed-source 3D printers need special parts, which can raise costs. These printers only work with certain materials and parts from the maker. While this ensures everything fits, it also limits choices and increases expenses.

|

Cost Type |

Closed Systems |

Open Systems |

|---|---|---|

|

Upfront Cost |

Fixed, predictable costs |

Varies, includes unlock fees |

|

Long-Term Costs |

Limited to initial investment |

Can accumulate hidden costs |

|

Material Costs |

Proprietary materials required |

Broader compatibility, but may incur fees |

The table shows how closed systems have higher material costs due to special requirements. Open-source systems let you use cheaper materials, offering more options.

Over time, closed systems can cost more than their starting price. You might need to buy parts or upgrades only from the maker. This reliance can stretch your budget, especially if you use your printer a lot for big projects.

Note: Proprietary parts are reliable but may not be the cheapest choice for everyone.

Comparing Closed-Source and Open-Source 3D Printers

Flexibility and Innovation in Open-Source Systems

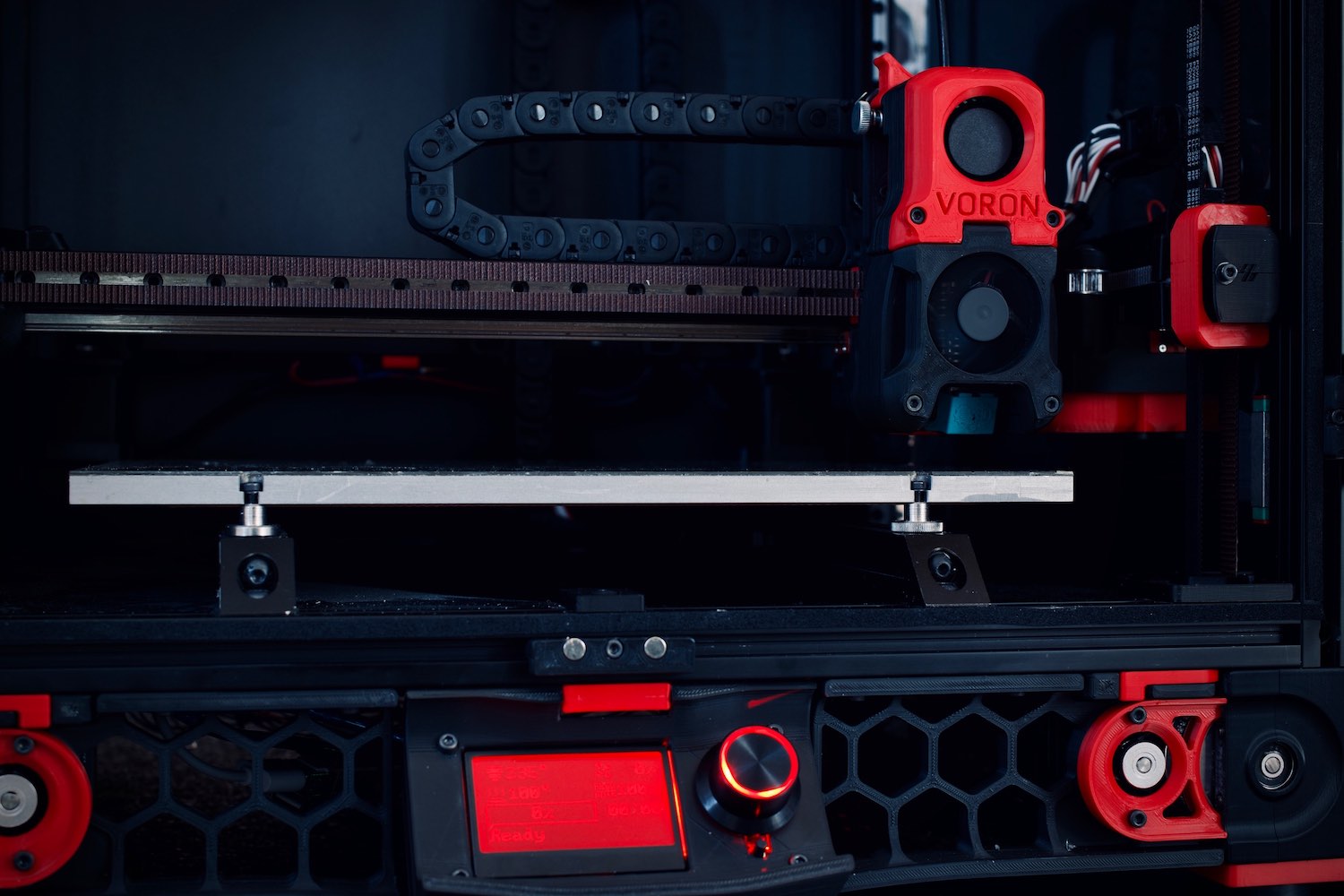

Open-source 3D printers let you change hardware and software freely. You can adjust them to fit your needs or try new designs. Unlike closed-source systems, they allow creativity and new ideas. Users worldwide share tips, fixes, and upgrades to improve printers.

Brands like Sovol and Voron show the benefits of open-source systems. Sovol printers are simple and affordable, great for beginners. Voron is for skilled users who want to build advanced printers. Both brands prove open-source systems encourage teamwork and fresh ideas.

Open-source printers also work with many materials. You can use cheaper or reused options to save money. This helps the environment and lowers costs. Closed-source systems only allow materials from the maker. While this is easier, it limits your choices.

Cost and Accessibility Differences

Open-source printers usually cost less upfront. They save money by using non-proprietary materials. For example, materials can cost as little as $0.025 per kilogram. Closed-source printers need special parts, which cost more over time.

|

Aspect |

Closed-Source Systems |

Open-Source Systems |

|---|---|---|

|

Cost |

High initial investment, limited customization options |

Lower costs, customizable, accessible to wider audience |

|

Accessibility |

Limited to well-funded labs, proprietary software |

Democratized access, community-driven improvements |

|

Modification Difficulty |

Difficult to modify for custom applications |

Easier to modify, fostering innovation and adaptation |

Accessibility is another big difference. Closed-source printers are often used in labs or businesses. They depend on special software and hardware, making them harder for hobbyists to use. Open-source systems are made for everyone. They let you control your projects without spending too much.

Community vs. Manufacturer Support

Open-source printers come with active user communities. These groups share guides, fixes, and ideas to help each other. Ultimaker’s community shows how teamwork leads to better designs. The more you join in, the more you learn and grow.

Closed-source systems rely on company support. This gives expert help but can feel less personal. You might wait for updates or repairs, slowing your work. Open-source communities often solve problems faster. They offer creative fixes and a sense of belonging.

Tip: Open-source systems are great if you enjoy learning and sharing ideas.

Closed-source 3D printers are gaining popularity for protecting ideas. They ensure quality by controlling how hardware and software work together. These systems give reliable results and simple support. But there are downsides to consider. You can’t customize much, and special parts cost more. Open-source printers are cheaper and flexible but need more work. Picking between closed and open-source depends on your goals and needs.

FAQ

What makes closed-source 3D printers easy to use?

Closed-source printers are simple and beginner-friendly. They combine hardware and software to work smoothly together. You don’t need special skills to use them. This makes them great for people new to 3D printing.

How is community support different in open and closed systems?

Open-source printers have active user groups. People share tips, fixes, and ideas to help each other. Closed-source printers depend on company support. While helpful, it doesn’t offer the same freedom or teamwork as open-source groups.

Are closed-source printers good for hobbyists?

Closed-source printers are easy to use and reliable. But they don’t allow much customization. Hobbyists who like to tinker may prefer open-source printers. If you want simple and consistent results, closed-source printers are a good choice.

Why do closed-source printers cost more?

Closed-source printers need special parts and materials. These increase costs but ensure everything works well together. Open-source printers let you use cheaper materials, saving money over time.

Can closed-source printers handle tough projects?

Yes, closed-source printers make high-quality, accurate prints. They are reliable for hard tasks and easy to use. But they might not offer the flexibility needed for very custom projects.

Yorum bırak

Tüm yorumlar yayınlanmadan önce denetlenir.

Bu site hCaptcha ile korunuyor. Ayrıca bu site için hCaptcha Gizlilik Politikası ve Hizmet Şartları geçerlidir.