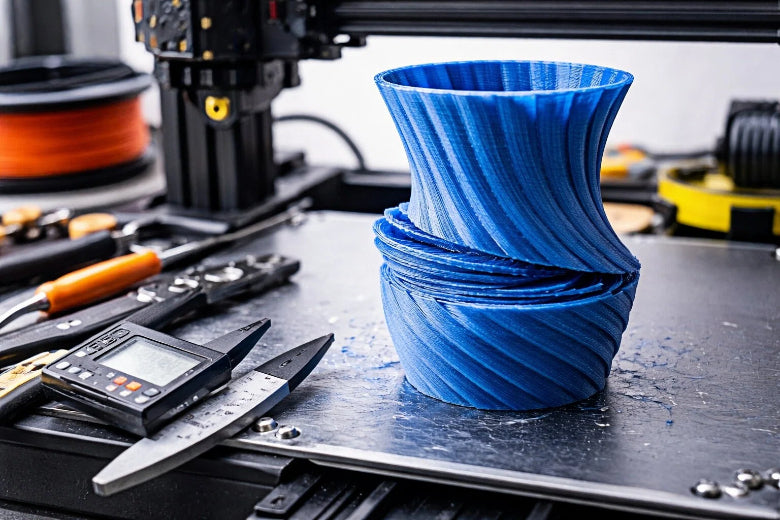

Intelligent slicing software plays a critical role in optimizing 3D printing + AI processes by converting 3D models into precise instructions for printers. AI has revolutionized slicing algorithms, boosting manufacturing efficiency and print quality. By leveraging machine learning and data analysis, AI-enabled 3D printing + AI systems can adjust parameters in real-time, ensuring smart optimization features and reduced errors. Industries like healthcare and aerospace are adopting AI-driven 3D printing + AI services to create high-performance products. AI-powered monitoring tools and AI-driven design tools further enhance process optimization, making artificial intelligence indispensable in modern 3D printing + AI technologies.

The global 3D printing + AI slicing software market was valued at USD 540 million in 2023 and is projected to grow at a CAGR of 9.6%, reaching USD 1.23 billion by 2032.

Key Takeaways

- AI slicing software helps 3D printing by changing settings quickly. This improves print quality and lowers mistakes.

- Fields like healthcare and aerospace use AI in 3D printing. It helps make custom prosthetics and lighter parts.

- Generative AI makes design and slicing easier. It creates automatic workflows that boost creativity and save time in manufacturing.

- AI improves material use, cutting waste and saving money. This makes 3D printing greener and more affordable.

- Even with high costs and setup problems, open-source AI tools can help small users access advanced slicing software.

Current Status of AI-Enhanced Slicing

Features of AI-powered slicing tools

AI-powered slicing tools have transformed how you approach 3D printing. These tools analyze your 3D models and automatically adjust parameters to optimize the printing process. Unlike traditional slicing methods, AI tools use machine learning to predict potential issues and make real-time adjustments. This ensures better print quality and reduces the likelihood of errors.

Key features include:

- Adaptive Layering: AI dynamically adjusts layer thickness based on the complexity of the model, improving detail without wasting material.

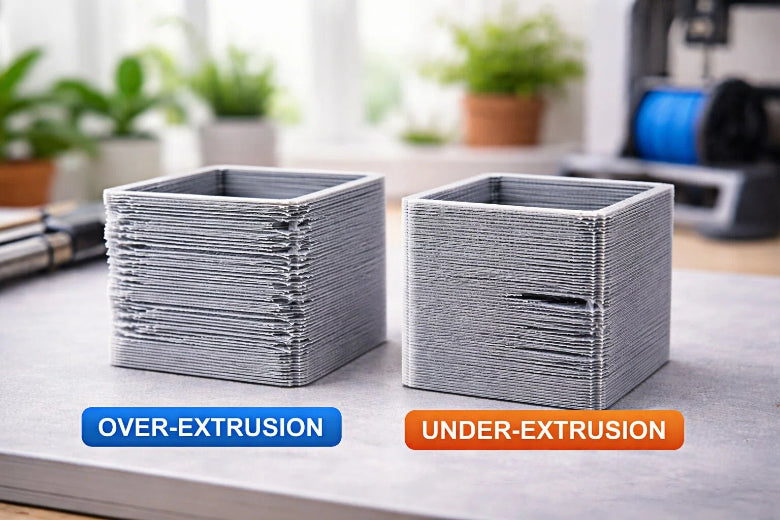

- Error Detection: AI algorithms identify weak points in your design and suggest modifications to enhance structural integrity.

- Material Optimization: These tools calculate the exact amount of material needed, minimizing waste and lowering costs.

- Speed Optimization: AI reduces slicing time by analyzing data patterns and streamlining the process.

By integrating intelligence into slicing, these tools enhance efficiency and make additive manufacturing more accessible to users like you.

Examples of AI-driven slicing software

Several AI-driven slicing software solutions are leading the way in the 3D printing industry. These tools showcase how artificial intelligence can revolutionize additive manufacturing workflows.

- Ultimaker Cura: This popular software incorporates AI to recommend optimal print settings based on your model's geometry. It also offers material profiles for precise results.

- Simplify3D: Known for its advanced customization options, this software uses AI to simulate the printing process, helping you identify and resolve potential issues before printing.

- Autodesk Netfabb: This tool leverages AI to optimize designs for additive manufacturing, ensuring efficient material usage and faster production times.

- Materialise Magics: With AI-powered features, this software excels in error detection and repair, making it ideal for industries requiring high precision, such as aerospace and healthcare.

These examples highlight how AI integration in slicing software is driving innovation in 3D printing technologies.

Applications of AI in 3D printing industries

AI has unlocked new possibilities across various industries by enhancing 3D printing applications. Its ability to improve accuracy, reduce costs, and streamline workflows has made it indispensable in additive manufacturing.

- Aerospace: AI enables the creation of lightweight, durable components with minimal waste. Real-time monitoring ensures precision, reducing production costs.

- Healthcare: AI-driven 3D printing applications include custom prosthetics, implants, and surgical tools. These innovations improve patient outcomes and reduce manufacturing time.

- Automotive: AI optimizes the design and production of complex parts, enhancing vehicle performance while cutting material costs.

- Consumer Goods: AI allows for mass customization, enabling you to create personalized products like footwear and eyewear with ease.

- Education and Research: AI-powered 3D printing tools help students and researchers prototype ideas quickly, fostering innovation.

The global 3D printing market, valued at USD 15.10 billion in 2021, is projected to grow at a CAGR of 24.3%, reaching USD 83.90 billion by 2029. Similarly, the automated 3D printing market is expected to expand from $706.69 million in 2021 to $5,878.56 million by 2027, reflecting the growing impact of AI in this field.

By integrating AI into 3D printing, industries can achieve unprecedented levels of efficiency, accuracy, and customization, paving the way for a more innovative future.

Benefits of AI in 3D Printing Slicing

Enhanced print quality and reduced errors

AI has significantly improved the quality of 3D printing by reducing errors during the slicing process. You can rely on AI-powered tools to analyze your designs and detect potential flaws before printing begins. These tools use machine learning to predict issues like weak structural points or uneven layering, ensuring your final product meets high standards.

Studies confirm the accuracy of AI in error detection. For example, neural networks achieve up to 98.4% accuracy in identifying defects in gravure cylinders, as shown in research by Villalba-Diez et al. (2019) and Valente et al. (2020a). Similarly, optimization approaches reduce banding and streaks in electrophotographic presses, enhancing print quality.

|

Study |

Methodology |

Accuracy Rate |

Focus Area |

|---|---|---|---|

|

Lundström & Verikas (2010) |

Fuzzy Hough Transform and k-means clustering |

High accuracy |

Halftone dot distortions in offset printing |

|

Villalba-Diez et al. (2019) |

Neural networks |

Up to 98.4% |

Defects in gravure cylinders |

|

Valente et al. (2020a) |

Neural networks |

Up to 98.4% |

Defects in gravure cylinders |

|

C. Kuo (2014) |

Optimization approach |

Dependent on conditions |

Reducing banding and streaks in electrophotographic presses |

These benchmarks highlight how AI enhances print quality and minimizes errors, making additive manufacturing more reliable for your applications.

Faster slicing and improved efficiency

AI accelerates the slicing process, saving you valuable time. Traditional slicing methods often require manual adjustments, but AI automates these tasks by analyzing data patterns and optimizing workflows. This reduces slicing time and ensures efficient resource allocation.

AI-assisted slicing platforms improve performance in dynamic environments. For instance, automated slice management systems integrated with AI enhance decision-making and resource management. These systems also forecast slicing capacity, maximizing economic benefits and ensuring service assurance.

You can experience faster slicing speeds and improved efficiency, especially in industries like aerospace and healthcare, where time-sensitive production is critical. AI’s ability to streamline processes makes it an indispensable tool for modern 3D printing technologies.

Optimized material usage and cost savings

AI helps you optimize material usage, reducing waste and lowering costs. By analyzing your designs, AI calculates the exact amount of material needed for each print. This ensures you use resources efficiently without compromising quality.

A study by the Institute for Supply Management (ISM) reveals that AI-enhanced cartonization can save up to 15% in logistics operations. This demonstrates how AI improves material usage and reduces waste, leading to significant cost savings in manufacturing and transportation.

In additive manufacturing, optimized material usage not only cuts costs but also supports sustainable practices. You can achieve better results while minimizing environmental impact, making AI a valuable asset for process optimization.

Increased customization and design flexibility

AI has transformed how you approach customization in 3D printing. It allows you to create designs tailored to specific needs, whether for personal use or industrial applications. By analyzing data, AI enables you to adjust parameters and produce unique products with precision. This level of intelligence ensures that every design meets your exact requirements.

In manufacturing, AI-powered 3D printing tools offer unmatched flexibility. You can modify designs quickly without starting from scratch. This adaptability is especially useful in industries like healthcare, where custom prosthetics and implants must fit individual patients perfectly. AI also supports design optimization, ensuring that your creations are both functional and aesthetically pleasing.

You can explore endless possibilities with AI-driven 3D printing. For example, AI helps you experiment with complex geometries that traditional methods cannot achieve. It also simplifies the process of testing multiple iterations, saving time and resources. This efficiency makes it easier for you to innovate and bring your ideas to life.

AI enhances process optimization by streamlining workflows. It automates repetitive tasks, allowing you to focus on creativity. This combination of intelligence and automation ensures that your designs are not only unique but also produced efficiently. Whether you are creating prototypes or final products, AI and 3D printing empower you to push the boundaries of design.

The applications of AI in 3D printing extend beyond customization. It enables scalable manufacturing, making it possible to produce personalized items on a large scale. This capability bridges the gap between mass production and individualization, offering you the best of both worlds.

With AI and 3D printing, you can achieve a new level of creativity and flexibility. These technologies redefine what is possible in design and manufacturing.

Challenges in AI-Enhanced Slicing

Computational and hardware demands

AI-enhanced slicing requires significant computational power. You need advanced processors and GPUs to handle the complex algorithms that drive AI in 3D printing. These systems analyze large amounts of data to optimize designs and improve manufacturing efficiency. However, not all users have access to such high-performance hardware.

The demands of AI can also strain your existing infrastructure. For example, running AI-powered slicing software on older computers may lead to slower processing times or system crashes. This can disrupt your workflow and reduce the efficiency of additive manufacturing applications.

To overcome these challenges, you might need to invest in upgraded hardware or cloud-based solutions. While these options can improve performance, they also add to your overall costs.

Cost barriers for small-scale users

The cost of implementing AI in 3D printing can be a significant barrier, especially for small-scale users. AI-powered slicing software often comes with high licensing fees. Additionally, the need for specialized hardware increases your expenses.

If you run a small business or work as an independent creator, these costs can limit your ability to adopt AI-enhanced tools. The upfront investment may outweigh the immediate benefits, making it harder for you to compete with larger manufacturers.

Despite these challenges, some affordable options are emerging. Open-source AI tools and pay-as-you-go cloud services can help you access advanced features without breaking the bank. Exploring these alternatives can make AI more accessible for smaller operations.

Integration challenges with existing 3D printers

Integrating AI-powered slicing software with your existing 3D printers can be complex. Many printers are not designed to support advanced AI features. This can lead to compatibility issues, requiring you to modify your equipment or purchase new models.

You may also face challenges in syncing AI software with your printer's firmware. This can result in errors during the printing process, reducing the quality of your final product. Additionally, the lack of standardized protocols in additive manufacturing makes integration even more difficult.

To address these issues, you can work with manufacturers that offer AI-compatible printers. Some companies also provide software updates to improve compatibility. By staying informed about the latest advancements, you can ensure smoother integration and better results.

Limited AI training data for niche applications

AI relies heavily on large datasets to function effectively, but niche applications in 3D printing often lack sufficient data. When you work with specialized industries like healthcare or aerospace, the available datasets may not cover unique requirements. This limitation reduces the accuracy of AI predictions and impacts the efficiency of your manufacturing processes.

For example, if you design custom prosthetics or implants, AI needs detailed data about patient-specific anatomy. Without enough examples, the intelligence behind the software struggles to optimize designs. Similarly, in aerospace, creating lightweight components requires data on specific materials and stress factors. Limited datasets make it harder for AI to deliver precise results.

You might notice that AI performs better in general applications like consumer goods or education. These fields have broader datasets, allowing AI to adapt and improve. However, niche applications demand tailored solutions, and the lack of data creates challenges. This gap slows down innovation and limits the potential of 3D printing in specialized industries.

To address this issue, you can contribute to building better datasets. Sharing your designs and manufacturing outcomes helps expand the pool of information available for AI training. Collaboration between industries also plays a key role. When companies share data, AI becomes smarter and more capable of handling niche applications.

AI has the power to transform 3D printing, but its success depends on the quality of data. By focusing on data collection and sharing, you can unlock new possibilities for specialized manufacturing. This approach ensures that AI continues to evolve and meet the demands of unique applications.

Limited data is a hurdle, but it’s also an opportunity. By working together, industries can overcome this challenge and drive innovation in 3D printing.

Future of AI in 3D Printing Slicing

Generative AI for automated design and slicing

Generative AI is reshaping how you approach design and slicing in 3D printing. This technology uses advanced algorithms to create designs automatically, reducing the need for manual intervention. You can input basic parameters, and generative AI will produce optimized models tailored to your specifications. This capability streamlines workflows and enhances creativity, allowing you to focus on innovation rather than repetitive tasks.

Generative AI also simplifies slicing by automating the process. It analyzes your 3D models and adjusts slicing parameters to ensure precision and efficiency. This reduces errors and improves the quality of your final product. For example, AI can dynamically adjust layer thickness based on the complexity of your design, ensuring optimal material usage and structural integrity.

Industry forecasts highlight the growing impact of generative AI in 3D printing. The rise of tools like ChatGPT demonstrates increasing demand for AI solutions in design and automation. By 2025, enterprise-grade AI models will become more specialized, enhancing their application in automated design workflows. New turnkey AI platforms will simplify deployment, making it easier for you to integrate AI into your processes.

|

Aspect |

Details |

|---|---|

|

Generative AI Tipping Point |

The rise of ChatGPT indicates a growing demand for AI solutions in design and automation. |

|

Enterprise-Grade AI |

By 2025, AI models will be more specialized, enhancing their application in automated design. |

|

AI Platforms |

New turnkey AI platforms simplify deployment, crucial for integrating AI into design workflows. |

Generative AI is not just a tool; it’s a transformative force in additive manufacturing. It empowers you to explore complex geometries, optimize designs, and achieve higher levels of customization.

Predictive analytics for error prevention

Predictive analytics is revolutionizing error prevention in 3D printing. This AI-driven approach uses historical data and real-time inputs to forecast potential issues before they occur. You can rely on predictive analytics to identify weak points in your designs, ensuring your final product meets high standards.

For example, AI can analyze stress factors in aerospace components or anatomical details in healthcare applications. It uses this intelligence to suggest modifications that enhance structural integrity and functionality. Predictive analytics also improves process optimization by automating quality checks, reducing the need for manual inspections.

This technology enhances efficiency by minimizing downtime caused by errors. You can achieve faster production cycles and lower costs, making predictive analytics a valuable asset for additive manufacturing. As AI continues to evolve, its ability to prevent errors will become even more sophisticated, ensuring reliable and high-quality results in your applications.

Autonomous 3D printing workflows

Autonomous workflows represent the future of AI in 3D printing. These systems use AI to manage the entire printing process, from design to production. You can experience seamless automation, where AI handles tedious aspects like slicing, material selection, and quality control.

AI-driven workflows allow you to focus on creativity while the technology takes care of the technical details. For instance, AI 3D object generators accelerate the design cycle, enabling you to explore complex designs that were previously impractical. This approach enhances efficiency and opens new possibilities for innovation.

- AI is utilized to manage tedious aspects of 3D modeling, allowing designers to focus on creativity.

- The use of AI 3D object generators has accelerated the design cycle significantly.

- This approach has enabled exploration of complex designs that were previously impractical.

Autonomous workflows also improve scalability in additive manufacturing. You can produce customized items on a large scale without compromising quality. This capability bridges the gap between mass production and individualization, offering you the best of both worlds.

The future of AI in 3D printing lies in fully autonomous systems that integrate design, slicing, and production into a single workflow. These innovations will redefine how you approach manufacturing, making it faster, more efficient, and highly adaptable to your needs.

Innovations in materials and techniques

AI is transforming the way you approach materials and techniques in 3D printing. By integrating advanced algorithms and machine learning, AI accelerates the discovery of new materials and enhances the efficiency of additive manufacturing processes. These innovations are paving the way for groundbreaking applications across industries.

AI-Driven Materials Discovery

AI is revolutionizing materials science by enabling faster and more precise discoveries. Automated systems and deep generative models now play a critical role in designing materials tailored for specific applications. For instance:

- Laboratory automation, such as the A-Lab, uses high-throughput synthesis and characterization to speed up materials discovery.

- AI helps overcome data challenges in materials science, ensuring that you can develop materials for technologies like sustainable energy.

- Conferences like the Nature Conference emphasize the synergy between AI and materials science, introducing the concept of a 'fourth paradigm' driven by big data and AI.

These advancements allow you to explore materials with unique properties, such as higher strength-to-weight ratios or improved thermal resistance, which are essential for industries like aerospace and healthcare.

Innovations in Slicing Techniques

AI is also redefining slicing techniques in 3D printing. Traditional slicing methods often rely on static parameters, but AI introduces dynamic adjustments that optimize the process. Here’s how:

- Real-Time Adaptation: AI analyzes your 3D models and adjusts slicing parameters in real-time, ensuring precision and reducing material waste.

- Multi-Material Printing: AI enables seamless transitions between different materials during printing, expanding the possibilities for complex designs.

- High-Resolution Slicing: Advanced algorithms allow for ultra-thin layers, enhancing the detail and quality of your prints.

These techniques not only improve the quality of your final product but also make additive manufacturing more sustainable by minimizing resource consumption.

The Future of Materials and Techniques

The future of 3D printing lies in the continued integration of AI into materials and techniques. You can expect innovations such as:

- Self-Healing Materials: AI will help design materials that can repair themselves, extending the lifespan of printed objects.

- Smart Materials: These materials will respond to environmental stimuli, opening new possibilities for applications in robotics and wearable technology.

- AI-Optimized Composites: By analyzing vast datasets, AI will create composites with unparalleled strength and flexibility, ideal for demanding manufacturing environments.

These advancements will redefine what is possible in additive manufacturing, offering you tools to create more efficient, sustainable, and innovative products.

AI is not just a tool for optimization; it is a catalyst for innovation. By embracing these advancements, you can unlock the full potential of 3D printing and lead the way in modern manufacturing.

AI has transformed 3D printing workflows, making slicing software smarter and more efficient. You can now rely on AI to optimize designs, reduce errors, and improve material usage. These advancements have made additive manufacturing faster and more reliable across industries like healthcare and aerospace.

However, challenges remain. High computational demands and integration issues with existing printers limit accessibility. Small-scale users often face cost barriers, while niche applications struggle with limited data for AI training. Addressing these hurdles will require collaboration and innovation.

The future of AI in 3D printing holds immense promise. Generative design will enable you to create structures that traditional methods cannot achieve. Predictive analytics will prevent errors and minimize downtime. Full automation of print farms and smarter production processes will redefine manufacturing efficiency. With AI, you can expect higher precision, enhanced intelligence, and groundbreaking possibilities in 3D printing workflows.

AI is not just improving 3D printing; it is revolutionizing how you approach manufacturing. By embracing these advancements, you can unlock the full potential of intelligent slicing software.

FAQ

What is intelligent slicing software?

Intelligent slicing software converts 3D models into instructions for printers. It uses AI to optimize parameters like layer thickness, material usage, and print speed. This ensures better quality and efficiency in 3D printing.

How does AI improve 3D printing slicing?

AI analyzes your designs, predicts potential issues, and adjusts settings automatically. It reduces errors, speeds up slicing, and optimizes material usage. This makes the process faster, more accurate, and cost-effective.

Can AI-powered slicing software work with all 3D printers?

Not all printers support AI features. Compatibility depends on your printer's firmware and hardware. Some manufacturers offer updates or AI-compatible models to help you integrate advanced slicing tools.

Is AI-enhanced slicing affordable for small businesses?

AI tools can be expensive due to licensing fees and hardware requirements. However, open-source software and cloud-based solutions provide affordable options for small-scale users.

What industries benefit most from AI in 3D printing?

Industries like aerospace, healthcare, and automotive gain the most. AI helps create lightweight components, custom prosthetics, and complex parts with precision. It also supports mass customization in consumer goods.

💡 Tip: Explore open-source AI tools to start optimizing your 3D printing processes without high upfront costs.