Making a full-size helmet with a print full-size helmet 3D printer is exciting. You can turn your creative ideas into real objects. Whether it's for cosplay or a cool prop, the right printer matters. Big print areas let you make helmets in one piece. Materials like PLA and ABS make them strong and long-lasting. These printers also work fast and with great detail. This helps you create pro-level helmets at home.

Key Takeaways

- Pick a 3D printer with a big build space (300mm³ or more). This lets you print helmets in one piece without gluing. The result looks smoother and more professional.

- Find printers with CoreXY or sturdy frame designs. These make prints more accurate and stop shaking. This is great for detailed helmet designs.

- Choose a printer that works with materials like PLA, PETG, and ABS. These materials make helmets strong and long-lasting for different projects.

- Get printers with fast printing speeds and smart software. This helps finish projects quickly while keeping good quality. You can test and improve designs easily.

- Look for easy-to-use features like auto bed leveling and touchscreens. These make printing simpler for beginners and experts. They also lower the chance of mistakes.

Key Features of a 3D Printer for Full-Size Helmets

Large Build Volume for Full-Size Helmets

To print a full-size helmet, you need a big build area. A larger space lets you print helmets in one piece. This means no gluing or attaching separate parts. It’s especially useful for designs like Mandalorian helmets or Iron Man masks. A seamless look makes the helmet appear more professional.

Modern printers with at least 300mm³, or better yet 500mm³, work great. For example, the Riddell Speedflex football helmet uses a custom 3D-printed liner. This shows how big build areas help create detailed and functional helmets.

If you want to print helmets easily, pick a printer with a large build space. This ensures your design fits well and prints without stopping.

CoreXY or Stable Frame Design for Precision

Accuracy is very important when making helmets. A strong frame or CoreXY system keeps prints precise, even at fast speeds. CoreXY printers use belts to reduce shaking and improve alignment. This gives smoother surfaces and sharper details, perfect for helmets with patterns or logos.

Stable frames also stop problems like layers shifting or wobbling. Whether it’s for cosplay or a prototype, a sturdy printer ensures reliable results.

Material Compatibility: PLA, PETG, ABS, and More

The material you use affects how strong and flexible your helmet is. Different filaments work better for different designs. Here’s a simple comparison of popular materials:

|

Material |

Bending Modulus (MPa) |

Impact Strength (kJ/m²) |

Softening Temp (°C) |

|

|---|---|---|---|---|

|

PLA |

40 |

3300 |

5 |

60 |

|

PETG |

25 |

1900 |

8.6 |

80 |

|

ASA |

17 |

2300 |

18 |

110 |

PLA is easy to use and cheap, great for beginners. PETG is tougher, so it’s good for durable helmets. ABS and ASA are stronger and handle heat better, ideal for advanced projects.

Choose a printer that works with many materials. This lets you try different filaments to make helmets that are both strong and good-looking.

High-Speed Printing with Advanced Firmware

Printing a full-size helmet quickly is very important. Waiting too long for one print can be annoying. This is especially true if you have deadlines or many designs. New 3D printers with smart firmware, like Klipper or Marlin, help a lot. They make the printer move faster without losing quality.

For instance, the Sovol SV08 MAX uses Klipper firmware and CoreXY design. It can print at speeds up to 700mm/s. This lets you finish a helmet much faster than older printers. Faster printing also helps you test and improve your designs quickly. You can make changes and get a polished helmet faster.

Fast printing doesn’t just save time; it’s more efficient. Advanced firmware has tools like input shaping and pressure advance. These reduce shaking and keep the print smooth and steady. This is great for helmets with fine details, like Iron Man grooves or Mandalorian textures.

When picking a 3D printer, choose one with high-speed firmware. This way, you can finish projects faster while keeping them high-quality.

Reliability and Ease of Use for Beginners and Experts

A reliable printer is key for making big things like helmets. Failed prints waste time, materials, and effort. To avoid this, pick a printer with strong parts and easy features. A sturdy frame, like CoreXY, keeps prints steady during long jobs. This stops problems like layers shifting or warping.

Ease of use is also very important, especially for beginners. Many new printers have features that make printing simple. Auto bed leveling makes sure the print surface is even. This lowers the chance of mistakes. Touchscreens and pre-set material settings help new users get started easily.

For experts, advanced tools like filament sensors and resume functions are helpful. These let you pause prints or change filaments without starting over. Whether you’re new or experienced, these features let you focus on creating instead of fixing problems.

A good printer makes the whole process easier and smoother. From setting up your design to finishing the print, it helps you succeed. Whether you’re making a cosplay helmet or testing new ideas, the right printer ensures great results.

Top 3D Printers for Printing Full-Size Helmets in 2025

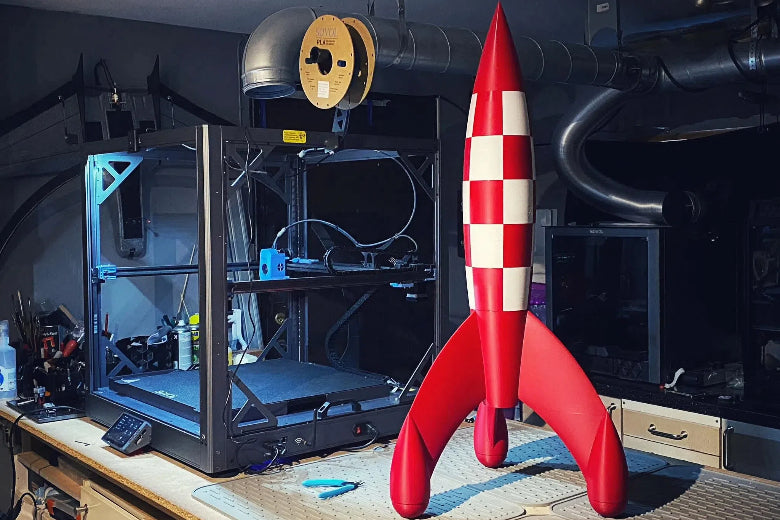

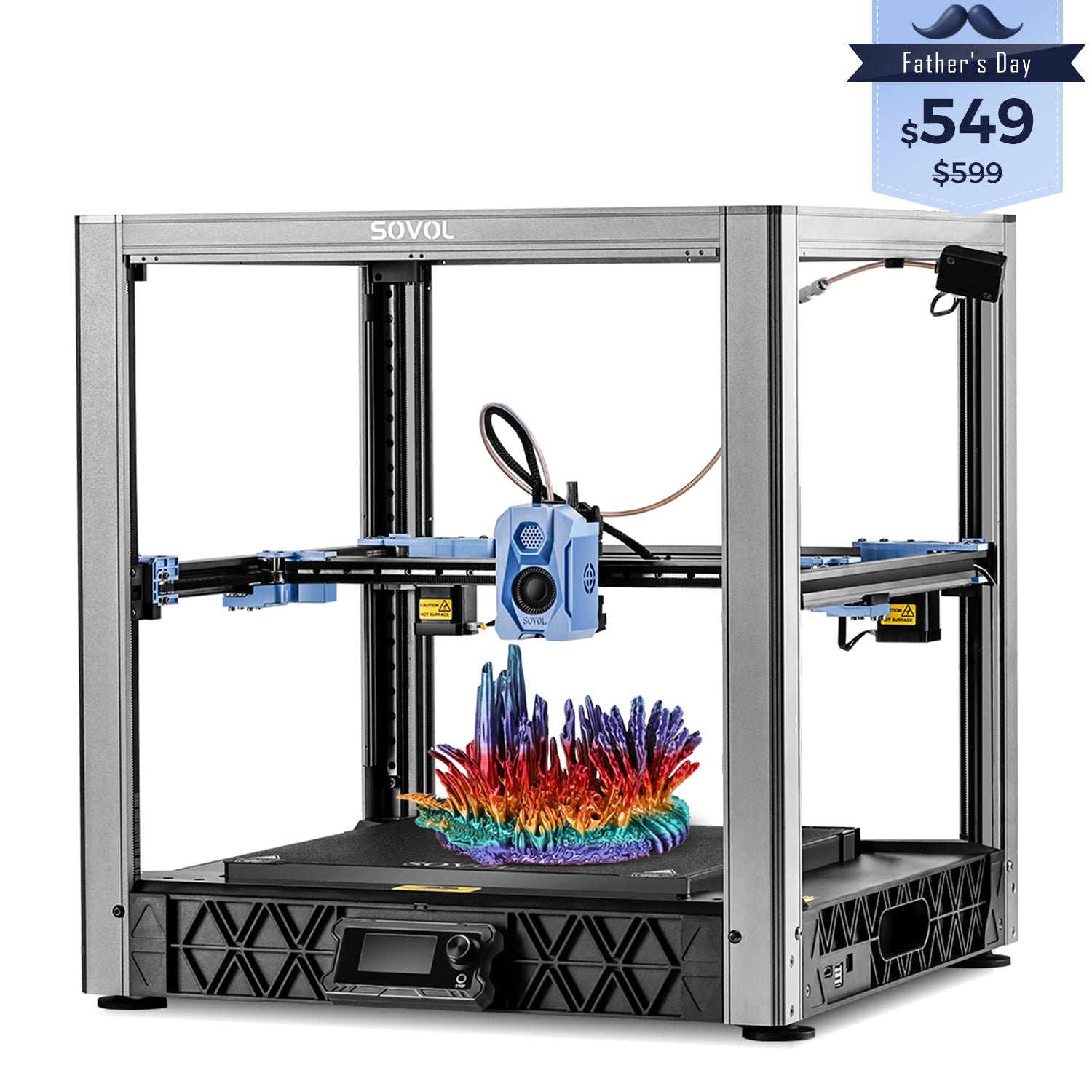

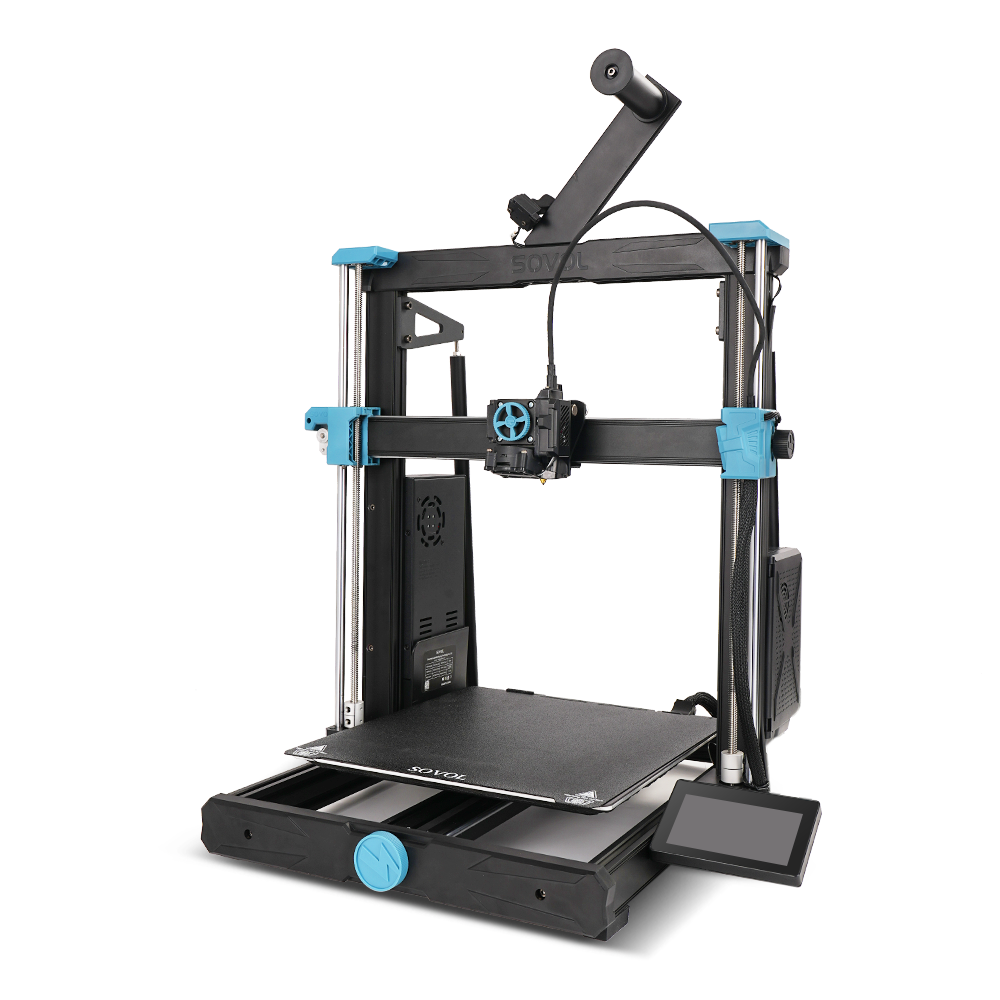

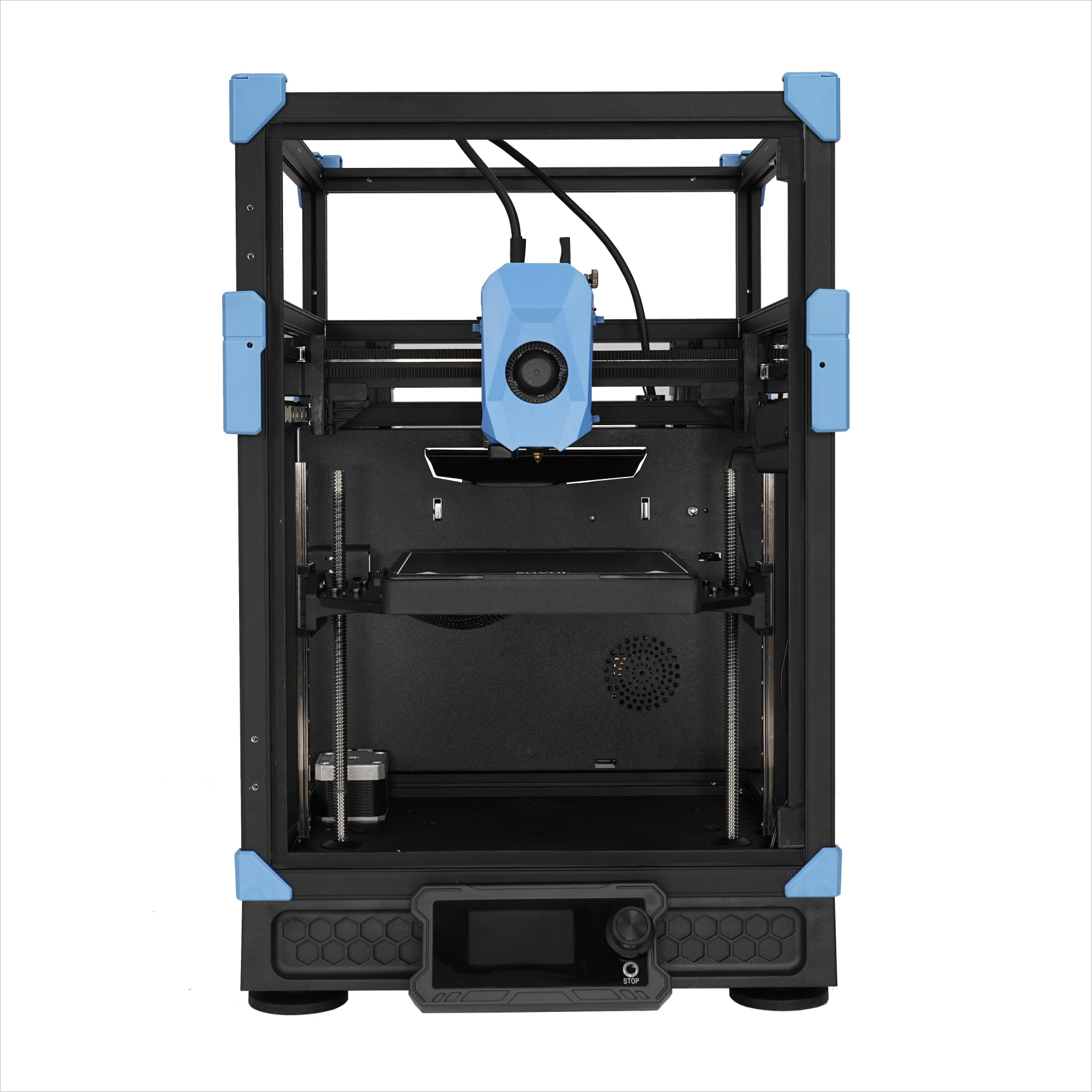

Sovol SV08 MAX

The Sovol SV08 MAX is great for printing helmets. Its large build space of 500×500×500mm lets you print helmets in one piece. You won’t need to glue or attach parts. This is helpful for designs like Mandalorian helmets or Iron Man masks. A seamless helmet looks more professional.

It uses a CoreXY system for accurate printing, even at fast speeds. The Klipper firmware helps it print up to 700mm/s. This means you can finish big projects faster without losing quality. Features like input shaping and pressure advance make prints smoother. This is perfect for helmets with small details.

The printer works with PLA, PETG, and ABS materials. You can pick the best filament for your helmet. It’s easy to use, even for beginners. Auto bed leveling and a touchscreen make setup simple. Filament sensors stop interruptions during long prints.

If you want a fast, precise, and flexible printer, the Sovol SV08 MAX is a great choice.

Creality CR-M4

The Creality CR-M4 is a good option for beginners or simple designs. Its build space of 450×450×470mm is big enough for most helmets. You can print helmets in one go without spending too much money.

It has a strong frame that reduces shaking during printing. This keeps layers aligned and surfaces smooth. While it’s not as fast as the Sovol SV08 MAX, its speed works well for most projects.

The printer supports PLA, PETG, and TPU materials. These give you choices for strength and flexibility. It also has updated firmware with helpful features. Resume printing and filament runout detection make long prints easier.

For a budget-friendly way to print helmets, the Creality CR-M4 is a solid pick.

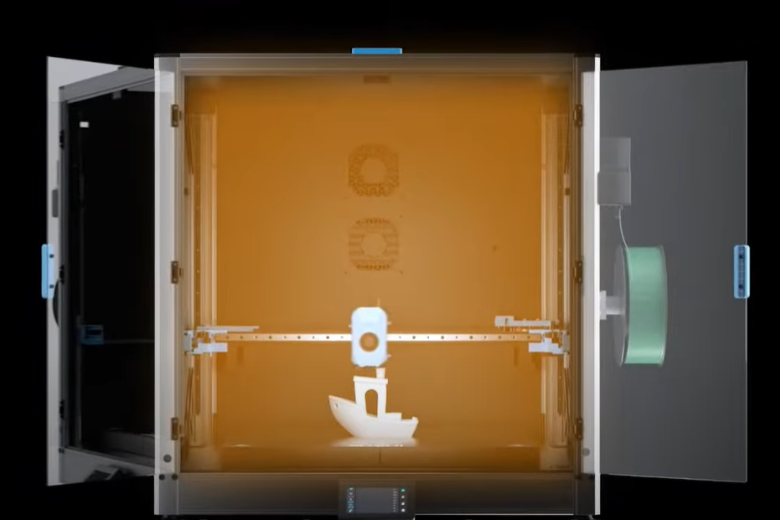

Bambu Lab X1 Carbon

The Bambu Lab X1 Carbon is made for advanced users and professionals. Its build space of 256×256×256mm is smaller but packed with smart features. It’s great for printing helmets with high detail and quality.

This printer is fast and precise. It scans up to 400 in./s (10 m/s) and prints layers as thin as 50 μm. It supports many materials, letting you try different textures and finishes.

AI-powered tools make printing easier. They monitor prints and fix problems like warping or layer shifts. You can also use multiple materials or colors in one print. This adds a polished look to your helmet designs.

If you want top-notch precision and advanced features, the Bambu Lab X1 Carbon is a powerful choice.

Anycubic Kobra Max

The Anycubic Kobra Max is a good pick for hobbyists. It’s affordable and can print full-size helmets easily. Its large build space of 400×400×450mm fits helmets in one piece. You won’t need to glue parts together, making your helmet look smooth.

This printer is simple to use, even for beginners. The auto bed leveling keeps the print surface flat. This helps avoid mistakes and failed prints. The touchscreen is easy to use and lets you change settings fast.

It works with materials like PLA, PETG, and TPU. These let you try different strengths and finishes for your helmets. While it’s not as fast as expensive printers, it’s steady for big projects.

This printer is great for cosplay fans and hobbyists. It’s reliable, easy to use, and budget-friendly. It’s a good way to start printing full-size helmets.

Prusa XL

The Prusa XL is a top choice for pros and advanced users. Its big build space of 360×360×360mm is perfect for large models. You can print detailed helmets like Mandalorian masks with ease.

It has a modular toolhead system for swapping extruders. This lets you use different materials or nozzle sizes. It supports many filaments like PLA, PETG, ABS, and composites. You can make helmets strong, flexible, or unique in appearance.

The printer has smart firmware for better quality and speed. Input shaping reduces shaking, giving smooth surfaces and sharp edges. It also has a filament sensor and power recovery to avoid interruptions.

If you’re serious about 3D printing, the Prusa XL is a great choice. It’s perfect for making high-quality helmets for cosplay or movies.

Why the Sovol SV08 MAX is Great for Full-Size Helmets

Large Build Space: 500x500x500mm

The Sovol SV08 MAX has a huge print area. Its 500x500x500mm size lets you print helmets in one piece. You won’t need to cut and glue parts together. A single-piece helmet looks smooth and feels stronger. Whether it’s a Mandalorian or Iron Man helmet, this printer gives you enough space to create without limits.

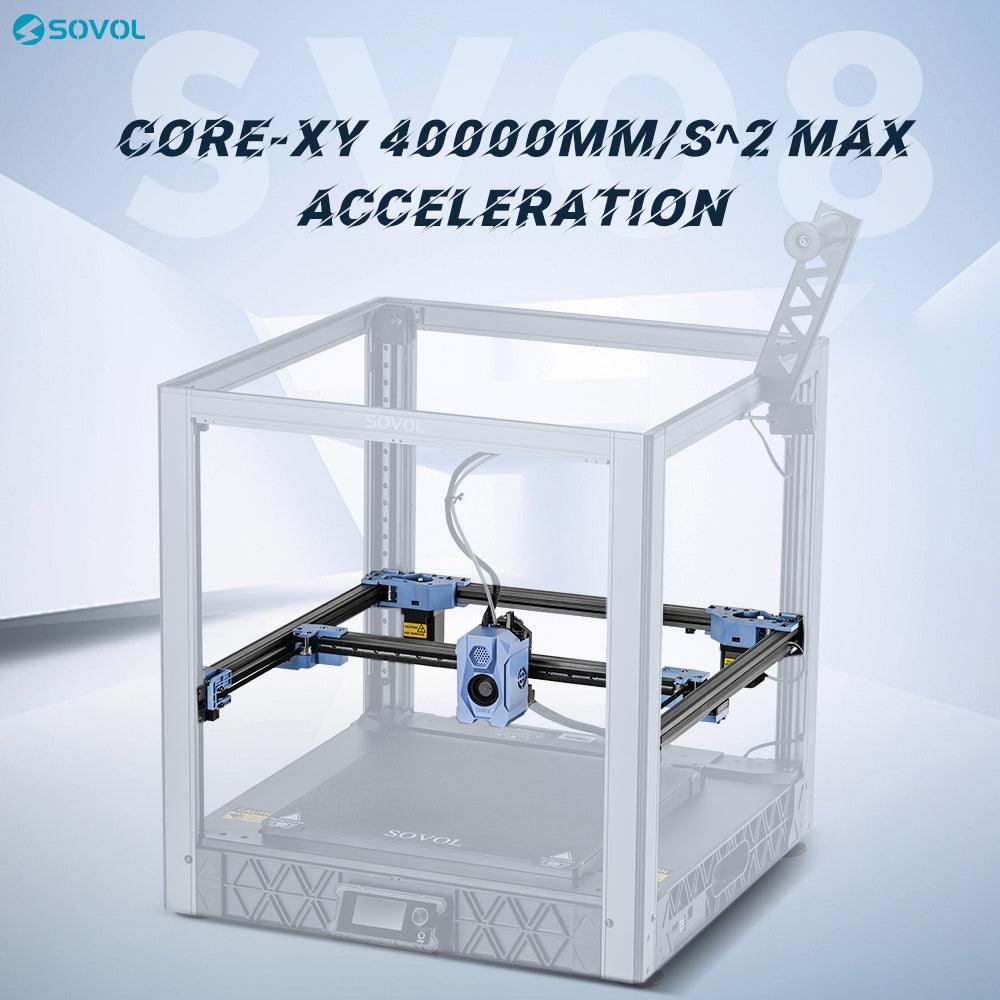

CoreXY System for Speed and Accuracy

The Sovol SV08 MAX uses a CoreXY system for better printing. Belts move the print head, reducing shaking and improving precision. This makes surfaces smooth and details sharp, even on complex designs. The Klipper firmware boosts speed up to 700mm/s. You can finish big prints faster while keeping them high-quality. This mix of speed and accuracy is perfect for helmets with grooves or patterns.

Works with PLA, PETG, and ABS

This printer supports many materials like PLA, PETG, and ABS. PLA is easy to use and great for beginners. PETG is tougher and works well for durable helmets. ABS is strong and heat-resistant, ideal for advanced projects. With this printer, you can try different materials to make helmets that are both strong and good-looking.

Pros and Cons of the Sovol SV08 MAX

When choosing the Sovol SV08 MAX, consider its good and bad points. It has great features but also a few downsides to think about.

Pros:

- Large Build Volume: The 500x500x500mm size lets you print helmets in one piece. This means no gluing parts, giving your helmets a smooth, professional look.

- High-Speed Printing: With Klipper firmware and CoreXY design, it prints up to 700mm/s. You can finish big projects faster without losing quality.

- Material Versatility: It works with PLA, PETG, and ABS. This allows you to try different materials for strong and good-looking helmets.

- User-Friendly Features: Auto bed leveling and a touchscreen make it easy to use. Filament sensors stop interruptions during long prints, helping beginners and experts alike.

- Precision and Stability: The CoreXY system reduces shaking, making surfaces smooth and details sharp. This is great for helmets with grooves or patterns.

Cons:

- Size and Space Needs: Its large size means it takes up a lot of room. You’ll need enough space to set it up.

- Advanced Features Take Time: While easy for beginners, advanced tools like Klipper firmware may take time to learn.

- Noisy Operation: Printing at high speeds can be loud, which might bother you in quiet spaces.

- Limited Material Choices: It doesn’t work with special filaments like carbon fiber without changes.

The Sovol SV08 MAX is fast, precise, and flexible, making it great for printing helmets. But its size and advanced tools might be tricky for some users. Knowing these pros and cons can help you decide if it’s the right printer for you.

Tips for Successful Full-Size Helmet Printing

Adjusting Print Settings for Big Models

Printing large models like helmets needs the right settings. Start by setting the layer height. A 0.2mm height gives good speed and detail. Smaller heights add detail but take longer to print. Use slower speeds for better stickiness and fewer mistakes. Speeds around 50mm/s work well for big prints.

Make sure your print bed is level. An uneven bed can cause prints to warp or fail. If your printer has auto bed leveling, use it. If not, adjust the bed by hand to make it flat. Raising the first-layer temperature by 5-10°C can also help the print stick better.

Lastly, use a brim or raft for big models. These add support and help stop warping.

Picking the Best Filament for Helmets

The filament you pick changes how strong and nice your helmet looks. PLA is great for beginners. It’s easy to use and makes smooth prints. But it’s not very strong or heat-resistant. PETG is stronger and more flexible, making it good for wearable helmets. ABS is even tougher and handles heat well, but it needs a heated enclosure to avoid warping.

For a pro finish, try ASA. It’s like ABS but resists sunlight, so it’s great for outdoor helmets. Always check if your printer works with the filament you want to use.

Fixing Common Problems (Warping, Layer Shifts, etc.)

Big prints often have problems like warping or layer shifts. Warping happens when the edges of the print lift off the bed. To fix this, use mesh compensation. This adjusts the z-axis height to improve the first layer’s stickiness.

Layer shifts happen when the print head moves out of place. Updating your printer’s firmware, like Klipper, can help. It lets the printer handle small errors better, reducing failures.

Here’s a quick table to help with these problems:

|

Problem |

How to Fix It |

Result |

|---|---|---|

|

Warping |

Use mesh compensation to adjust z-axis height. |

Better first-layer stickiness and improved print quality. |

|

Layer Shifts |

Update Klipper firmware to handle small errors and avoid print stops. |

More reliable printing with fewer failures from disconnections. |

By solving these problems, you’ll have an easier time printing helmets and get better results.

Post-Processing for a Professional Finish

Making your 3D-printed helmet look great takes a few steps. These steps make the helmet stronger and better-looking. Here are simple ways to improve your helmet:

|

Step |

What It Does |

|---|---|

|

Removing Supports |

Cut leftover supports with tools, then sand smooth. |

|

Fixing Cracks |

Fill small gaps with filler, then sand again. |

|

Sanding |

Smooth the surface using wet sanding for better results. |

|

Vapor Polishing |

Use solvent vapors to make the surface shiny. |

|

Painting |

Prime first, then paint for a bright finish. |

Start by cutting off extra supports from the print. Use flush cutters or a small knife to do this carefully. After cutting, sand the helmet with 200 or 400 grit sandpaper to smooth rough spots.

Check for cracks or gaps in the helmet. Fill these with a special filler made for 3D prints. Once the filler dries, sand the area again to make it even. Wet sanding works best for materials like PLA and ABS. It keeps dust down and makes the surface smoother.

For a shiny look, try vapor polishing. This melts the outer layer slightly using solvent vapors. Be careful and work in a ventilated space when using this method.

Painting is the last step. Start with a primer to make the surface ready for paint. After the primer dries, add thin layers of paint for a bright and lasting finish.

Follow these steps to make your helmet look polished and professional. It will stand out and impress in any situation.

Picking the best 3D printer for full-size helmets depends on what you need. The Sovol SV08 MAX is great for serious makers. It has a big build space, prints fast, and is very accurate.

Suggestions based on your needs:

- Affordable Option: The Creality CR-M4 is cheap and dependable.

- For Hobbyists: The Anycubic Kobra Max is easy to use and works well.

- For Experts: The Prusa XL or Bambu Lab X1 Carbon offers advanced tools and amazing quality.

Choose a printer that fits your budget, skill level, and project plans. The right printer will help you turn your helmet ideas into reality!

FAQ

Can you print a full-size helmet in one piece?

Yes, you can! If your printer has a big build area, like 500x500x500mm, you can print helmets in one go. This means no gluing parts, making your helmet look smooth and professional. Pick a printer with enough space for your design.

What filament works best for helmets?

PLA is simple and great for beginners. PETG is strong and flexible. ABS handles heat but needs a heated space. ASA resists sunlight, so it’s good for outdoor helmets. Choose based on how strong or flexible you want your helmet to be.

How do you prevent warping during helmet printing?

Use a heated bed and make sure it’s level. Add a brim or raft to support the edges. Raise the first-layer temperature a little to help it stick better. These steps keep your helmet’s base steady and stop warping.

Is high-speed printing safe for large models?

Yes, if your printer has smart firmware like Klipper. Features like input shaping reduce shaking, keeping prints smooth. But beginners might want to use slower speeds to avoid mistakes.

Do you need post-processing for 3D-printed helmets?

Yes, it helps your helmet look better and stronger. Sand the surface to smooth it out. Fill gaps and use wet sanding for a clean finish. Vapor polishing adds shine, and painting gives it a pro look. These steps make your helmet stand out.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.