When you choose the right 3D printer, size plays a critical role in determining what you can create. A compact printer works well for smaller objects, while larger models accommodate more ambitious projects. Consider your workspace, as a bulky 3D printer might overwhelm it. Start by evaluating your available space and project goals.

Key Takeaways

- Begin with a small 3D printer (6x6x6 to 8x8x8 inches). It’s cheaper and easier for beginners to use.

- Think about what you want to make later. A flexible printer can stop you from upgrading quickly.

- Match your budget to your project goals. Small printers cost less, but big ones do more and cost more.

Understand How to Choose the Right 3D Printer Size

Assessing Your Project Needs

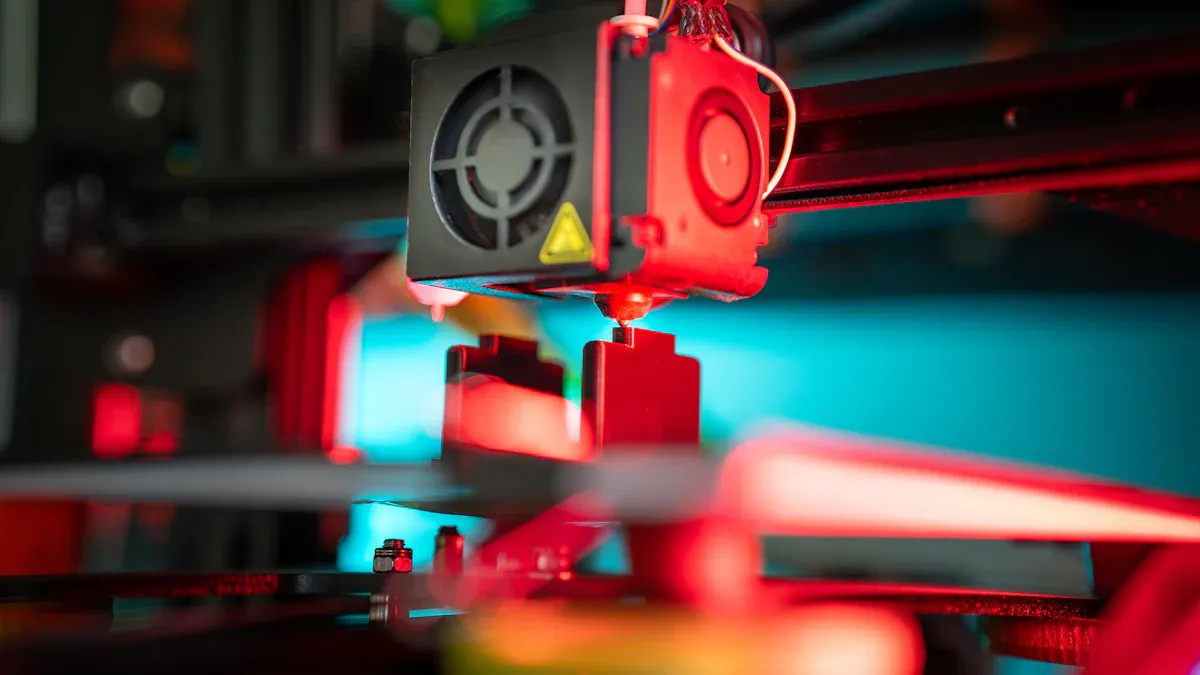

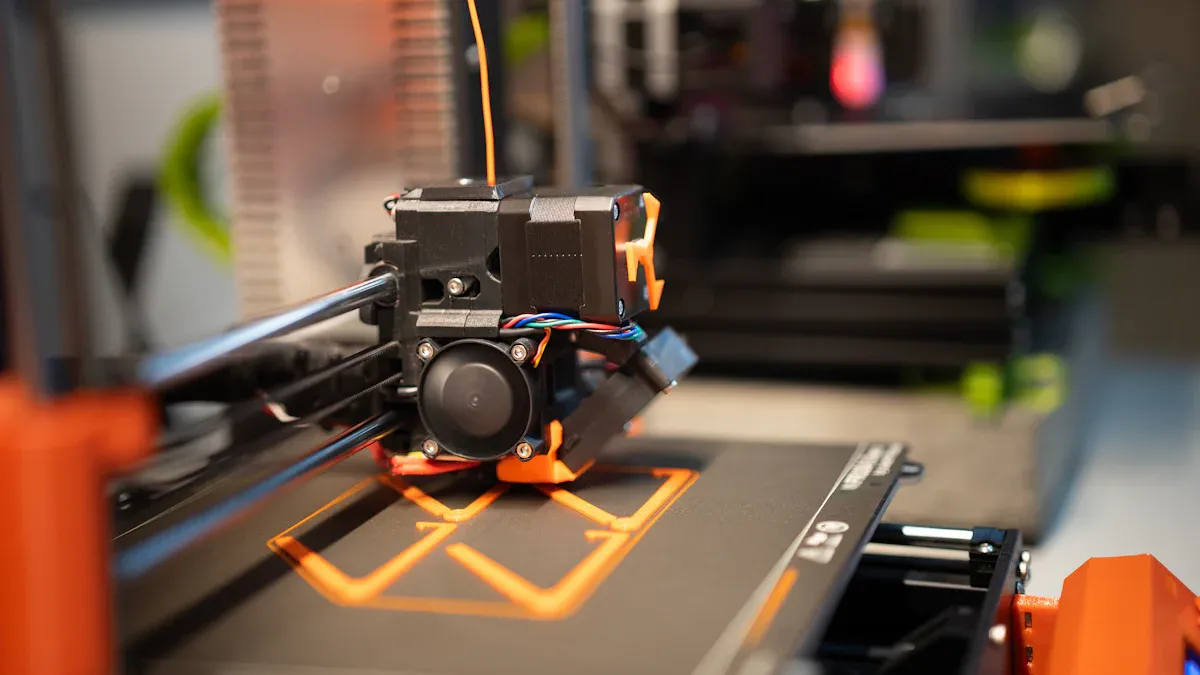

When choosing the right 3D printer, start by evaluating the types of projects you plan to undertake. If you aim to create small, intricate objects like jewelry or miniatures, a compact printer with a smaller build volume may suffice. These printers often provide higher resolution and better detail quality, making them ideal for precision work. On the other hand, if your projects involve larger models or multiple parts, a printer with a larger build volume will better suit your needs.

Tip: Think about potential future projects. Even if you’re starting small, you might want to explore larger or more complex designs later. A versatile printer can save you from needing an upgrade too soon.

Beginners often overlook the importance of aligning the printer size with their specific needs. For example, a company like Geo Globe Poland uses 3D printers to prototype transportation trays, reducing production time significantly. Similarly, AMS-systems crafts sensor casings to optimize assembly, showcasing how the right printer size can enhance efficiency. These examples highlight the importance of matching your printer’s capabilities to your project requirements.

Typical Print Sizes for Beginners

For beginners, the ideal size of a 3D printer often falls within a build volume of 6x6x6 inches to 8x8x8 inches. This range provides enough flexibility to experiment with various designs without overwhelming you with complexity. Smaller printers in this category are also more budget-friendly and easier to manage in limited spaces. They allow you to focus on learning the basics of 3D printing without the added challenges of handling larger machines.

Here’s a quick comparison of typical printer sizes and their benefits:

|

Printer Size |

Best For |

Benefits |

|---|---|---|

|

Small (6x6x6 in) |

Miniatures, small prototypes |

High resolution, lower cost, compact design |

|

Medium (8x8x8 in) |

Functional parts, medium projects |

Balance between size and versatility, suitable for most beginner needs |

|

Large (10x10x10 in) |

Larger models, multiple parts |

Greater flexibility, supports ambitious projects |

Smaller printers often come with higher pixel-density screens, which enhance the quality of intricate designs. However, larger printers provide the advantage of printing multiple items simultaneously, saving time for batch production.

Planning for Future 3D Printing Projects

As you gain experience, your 3D printing ambitions may grow. The industry is expanding rapidly, with the market size projected to reach $19.9 billion in 2023. This growth reflects increasing adoption and innovation in home 3D printing. Planning for future needs ensures that your investment remains valuable over time.

Consider whether your current printer can handle more complex or larger projects down the line. For instance, companies like Bocar and AGH Racing have used 3D printers to create life-size models and advanced prototypes, respectively. These examples demonstrate how a larger build volume can accommodate ambitious designs and improve functionality.

Note: If you’re unsure about your long-term needs, start with a smaller, reliable printer. You can always upgrade to a larger model as your skills and project requirements evolve.

By thinking ahead, you can choose the right 3D printer that balances your current needs with future possibilities. This approach minimizes the risk of outgrowing your equipment too quickly, saving you time and money in the long run.

Key Specifications to Evaluate for 3D Printer Size

Build Volume and Its Impact on Project Size

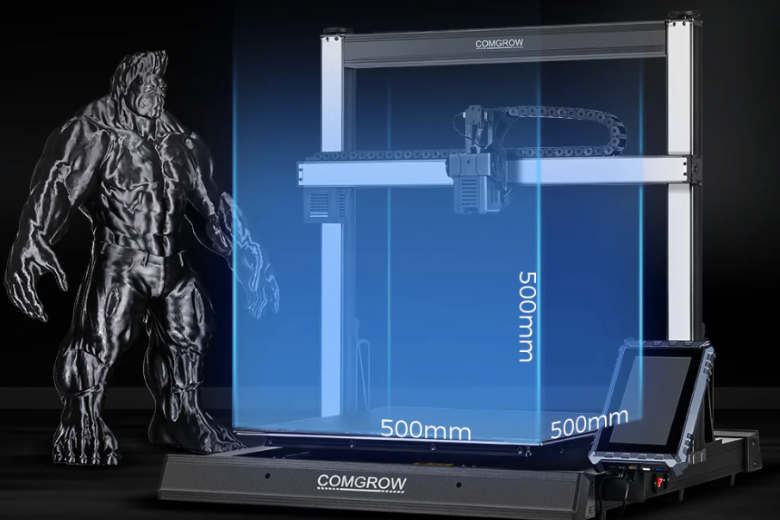

The build volume is one of the most critical factors when selecting a 3D printer. It defines the maximum dimensions of the objects you can create. For beginners, understanding how build volume affects project size is essential. A smaller build volume, such as 6x6x6 inches, works well for compact designs like figurines or small prototypes. However, if you plan to work on larger or more complex projects, you’ll need a printer with a bigger build volume.

A large 3D printer offers the flexibility to create bigger models or multiple parts in one go. For instance, a printer with a mega build area can handle ambitious projects like architectural models or functional prototypes. Keep in mind that larger build volumes often require more space and may increase the overall cost of the printer. Balancing your project needs with the available build volume ensures you choose the right 3D printer for your goals.

Tip: Always consider the print volume in relation to your workspace. A big 3D printer might not fit comfortably in a small area, so plan accordingly.

Material Compatibility and Printer Dimensions

The materials you plan to use can influence the size and type of 3D printer you need. Different materials, such as PLA, ABS, or PETG, have specific requirements for temperature and printer design. Some materials may require an enclosed build area to maintain consistent temperatures and improve print quality. If you’re working with advanced materials like nylon or carbon fiber, you may need a larger, more specialized printer.

Printer dimensions also play a role in material compatibility. Compact printers are often limited to basic materials, while larger models can accommodate a wider range of options. For example, a reliable large 3D printer might include features like a heated bed or dual extruders, allowing you to experiment with multiple materials. Understanding the relationship between material compatibility and printer dimensions helps you make an informed decision.

Note: Check the manufacturer’s specifications to ensure the printer supports the materials you want to use. This step can save you from unexpected limitations.

Balancing Resolution, Precision, and Size

Resolution and precision are key factors that affect the quality of your 3D prints. Higher resolution allows for finer details, which is crucial for intricate designs like jewelry or small mechanical parts. However, as resolution increases, the printing process may take longer. Balancing resolution with the size of your 3D printer is important to achieve the desired print quality without unnecessary delays.

Smaller printers often excel in precision due to their compact design. They can produce high-quality prints with minimal layer lines. On the other hand, a large 3D printer may sacrifice some precision for the ability to handle bigger projects. If you’re planning to create large models, focus on finding a printer that offers a good balance between size and print quality.

Tip: Test the printer’s resolution settings before starting a major project. This practice ensures you achieve the best results for your specific design.

By evaluating these key specifications, you can choose the right 3D printer that aligns with your project requirements and long-term goals. Whether you’re starting with a small printer or investing in a large 3D printer, understanding these factors will help you make a confident decision.

Budget and Practical Considerations

Cost vs. Build Volume Trade-offs

When selecting a 3D printer, balancing cost and build volume is crucial. Larger build volumes allow you to create bigger models or multiple parts simultaneously, but they come with higher price tags. For beginners, starting with a smaller printer often provides the best value. These models are affordable and offer sufficient build volume for most entry-level projects.

Here’s a breakdown of typical price ranges based on build volume:

|

Build Volume Category |

Price Range |

Example Printer |

|---|---|---|

|

Small (150x150x150 mm) |

$429 |

|

|

Medium (220x220x250 mm) |

$259 |

|

|

Large (300x300x350 mm) |

$259 |

|

|

Extra Large (500x500x500 mm) |

$829 |

Smaller printers are ideal for compact spaces and provide excellent print quality for intricate designs. However, if your projects require a larger build area, you’ll need to invest more. Choose the right printer by aligning your budget with your project size and long-term goals.

Starting Small and Scaling Up

Starting with a small 3D printer offers several advantages. Compact models are portable, easy to use, and designed for beginners. They also fit well in limited spaces, making them a practical choice for home use. Smaller printers allow you to focus on learning the basics of 3D printing without overwhelming you with complex features.

|

Advantage |

Description |

|---|---|

|

Accessibility |

Smaller 3D printers are portable and easy to transport, making them suitable for users with limited space. |

|

Affordability |

They provide an affordable entry point into 3D printing technology without sacrificing quality. |

|

User Experience |

Compact devices are designed for ease of use, appealing to beginners who may be intimidated by larger models. |

As your skills improve, you can scale up to a larger 3D printer. This approach minimizes initial costs while allowing you to expand your capabilities over time. Investing in a big 3D printer later ensures you’re ready to handle more ambitious projects.

Hidden Costs of Larger 3D Printers

Larger 3D printers often come with hidden expenses that can impact your budget. Maintenance costs, such as lubricants and cleaning supplies, are essential for keeping the printer in good condition. Advanced materials may require additional accessories like heated beds or enclosures, increasing operational costs. Shipping fees for larger models can also be significant.

Design complexity charges and material surcharges further inflate the overall cost. For example, larger printers consume more material, which increases expenses for filament or resin. Planning for these hidden costs ensures you stay within your budget while maintaining print quality.

By understanding these budget considerations, you can make an informed decision when choosing a 3D printer. Whether you start small or invest in a large 3D printer, aligning your budget with your needs will help you achieve your 3D printing goals.

Choosing the right 3d printer size involves balancing your project needs, budget, and workspace. Start small to build your skills and expand as your ambitions grow. Research thoroughly before purchasing. Engage with the 3D printing community to gain insights and avoid common pitfalls. This approach ensures a rewarding and efficient 3D printing experience.

FAQ

What is the best 3D printer size for a beginner?

A small to medium printer (6x6x6 to 8x8x8 inches) works best. It balances affordability, ease of use, and versatility for most beginner projects.

Can I upgrade to a larger printer later?

Yes, you can. Start with a smaller printer to learn the basics. Upgrade when your skills and project requirements grow.

How much space do I need for a 3D printer?

Allocate enough space for the printer, accessories, and ventilation. A small printer typically fits on a standard desk or table.

Tip: Measure your workspace before purchasing to ensure a proper fit.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.