You may ask if you need a filament dryer for your 3D printer. The answer depends on a few things. The kind of filament you use is important. Humidity in your area can change how much water your filament takes in. More humidity can make the filament swell. It can block the nozzle and make prints weaker. Look at the table below to see how humidity changes printing:

|

Finding |

Description |

|---|---|

|

Increased Humidity |

When humidity goes up, filament takes in more moisture. |

|

Diameter Increase |

Filament can get 5% thicker in wet places. |

|

Filament Swelling |

Too much water can block the nozzle. |

If you want strong and accurate prints or print a lot, think about your space and needs before you choose.

Key Takeaways

-

Filament dryers keep your 3D printing filament dry. This stops problems like weak prints and nozzle clogs from moisture.

-

Humidity can change filament quality. High humidity makes filament swell. This can cause printing problems. Check your room to keep humidity just right.

-

Use a filament dryer if you print a lot. It is also good for materials like nylon, PETG, or PLA. This helps your prints stay strong and accurate.

-

You can dry filament with a food dehydrator or oven. These DIY ways work, but store-bought dryers are easier and work better.

-

Always keep dried filament in airtight containers. Add desiccants to keep out moisture. This helps your prints stay good.

What Is a Filament Dryer

A filament dryer keeps your filament dry. It gets rid of water in the filament before you print. Water can make bubbles and weak prints. It can also clog the nozzle. Many people use a filament dryer box to stop humidity from hurting their filament. There are different filament dryer boxes. Each one has its own features.

How a Filament Dryer Works

A filament dryer uses heat and air to dry filament. You put the spool inside the dryer box. The box gets warm and blows dry air on the filament. This helps water leave the filament. The dryer keeps the filament warm for a set time. Some dryers let you change the heat and time. Look at the table to see the main ideas:

|

Principle |

Explanation |

|---|---|

|

Drying Temperature |

Heat helps water leave the filament. |

|

Moisture Concentration |

Dry air pulls water out of the filament. |

|

Drying Time |

Filament needs time for water to move out. |

|

Air Flow |

Moving air helps get rid of water fast. |

Some filament dryer boxes, like the FD5, get very hot. They can reach 150 °C and use many drying steps. You can dry lots of filament types, like PLA, ABS, nylon, and PETG. Some dryers have remote controls and safety features.

Filament Dryer Box vs. Other Devices

You have a few ways to dry filament. The filament dryer box is the most popular. It works for most filaments and lets you change settings. You can use a food dehydrator too. Food dehydrators cost less and dry PLA and PETG well. They lower humidity and fit at least one spool. Some people use vacuum-sealed boxes, but heat drying works better. If you use a special filament dryer, you get the best results for tough filaments like nylon or PEEK.

Tip: Pick a filament dryer box for easy use and good drying for many filaments. Food dehydrators are fine for simple needs. Tough filaments need a special filament dryer.

Moisture Problems in 3D Printing

Effects on Print Quality

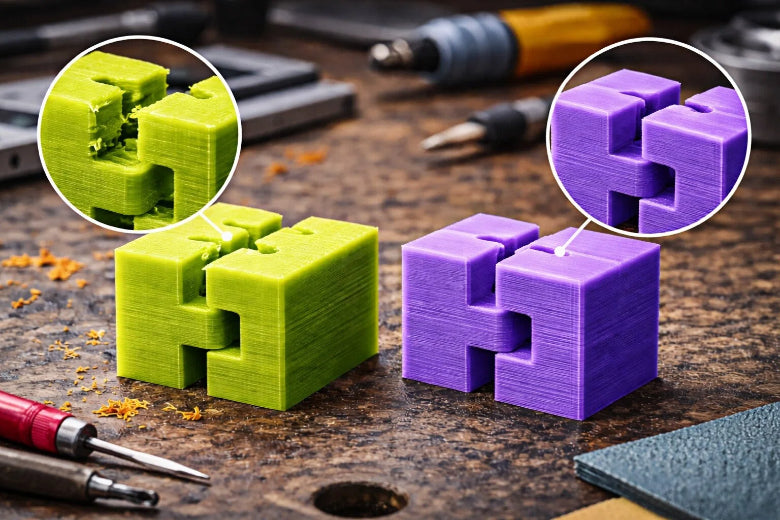

Moisture can cause lots of trouble when you print. Wet filament can make bubbles inside during printing. These bubbles can block the nozzle. If the nozzle gets blocked, you might hear pops. You may also see the material come out uneven. Sometimes, the extruder gets too hot and breaks. PETG can show more stringing when wet. Steam from wet filament can make blobs and oozing. Your prints might look rough or have pits. Layers may not stick together well. Weak layers can split apart. Wet ABS can make prints much weaker, even by 25%. To get good prints, you must keep filament dry.

-

Common moisture problems in 3D printing materials:

-

Bubbles and empty spots in filament

-

Nozzle gets blocked

-

More stringing and oozing

-

Layers do not stick well

-

Rough or fuzzy surfaces

-

A filament dryer keeps filament dry. This helps you get strong and smooth prints.

Filaments Most Affected

Some filaments soak up water more than others. PLA, ABS, PETG, and nylon all take in moisture. Some types are more sensitive than others. PLA 4043D can lose 20% strength and melt faster after getting wet. PLA/PBS blends and other PLA types also get weaker. PVA is a filament that dissolves in water and gets wet fast. Flexible filaments also soak up water and need extra care.

|

Filament Type |

Impact on Mechanical Properties |

|

|---|---|---|

|

PLA 4043D |

Most moisture-sensitive |

20% less strength, 50% more MFI |

|

PLA/PBS 75/25 Blends |

Big drop in strength |

10% less strength |

|

Other PLA Grades |

Changes by type |

24% to 36% less strength after 3 months wet |

You should use a filament dryer for filaments that soak up water. If you want good prints, keep filament dry and store it well. This helps you get strong prints and stops problems.

Filament Drying Needs

When to Use a Filament Dryer

It is important to know when to dry filament. Some filaments soak up water from the air very fast. Nylon, PETG, and PLA are examples of these filaments. Nylon is the most sensitive to water. It can cause printing problems after only a short time in humid air. PETG and PLA also take in water, but not as quickly as nylon.

If you live where it is humid, you need to watch your filament. Keeping the air dry helps your filament stay good. The table below shows the best humidity for each filament:

|

Filament |

Recommended Humidity Range |

|---|---|

|

PLA |

<= 50% |

|

PETG |

5%-10% |

|

Nylon |

N/A |

|

General |

30-50% is acceptable |

You should use a filament dryer if you see these signs:

-

Prints look rough or have a bad finish

-

You hear bubbling or popping from the extruder

-

Prints are stringy or ooze a lot

-

Layers are weak or break easily

Tip: Always check your filament before you print. If you see any of these problems, dry your filament right away.

You should dry filament before you use it for the first time. You should also dry it after each use, especially for filaments that soak up water fast. If you keep filament in a humid room, you may need to dry it more often. Nylon can get wet in just a few hours. PETG and PLA take longer, but they still need drying sometimes.

You can check if your filament needs drying by:

-

Looking for print problems like bubbles or rough spots.

-

Weighing the spool before and after drying. If it is lighter, water is gone.

-

Using a humidity sensor in your storage box.

If you want strong prints, always use dry filament. Drying your filament helps you avoid problems and get better prints.

Best Way to Dry Filaments

You can find the best way to dry filament by following simple steps. A filament dryer is the best choice for most people. It uses heat and moving air to take out water. The dryer makes the filament dry and ready to print.

Here are some good tips for drying filament:

-

Set the right temperature and time for each filament. This stops the filament from melting and makes sure it is dry.

-

Check the instructions from the maker before you start drying.

-

Keep the filament in a dry place for one or two days after drying.

-

Use vacuum dryers for faster and better drying.

-

Do not go over the glass reflow temperature, which is usually 70ºC for most filaments.

-

Change the desiccant in your storage box often.

-

Check the wires and plugs on your filament dryer to stay safe.

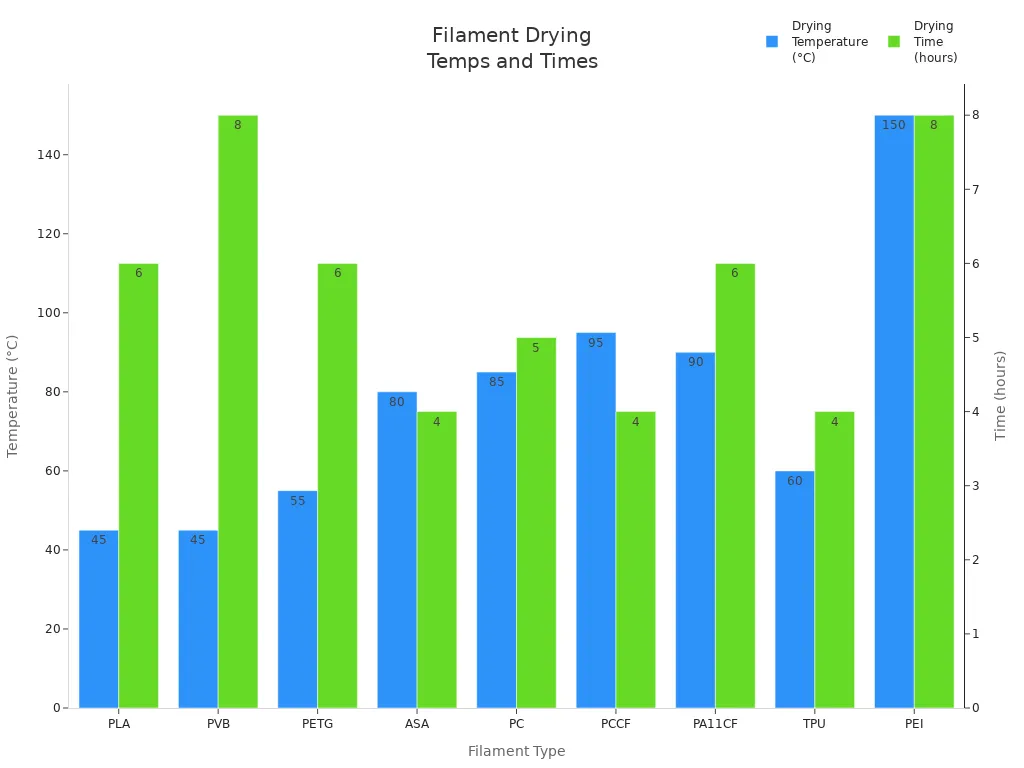

The table below shows how long and how hot to dry each filament:

|

Material |

Max Drying Temp (°C) |

Duration (Hours) |

|---|---|---|

|

PLA |

65 |

4 |

|

PETG |

65 |

4 |

|

Nylon |

90 |

4 |

|

ABS |

80 |

4 |

|

ASA |

80 |

4 |

|

TPU |

60 |

4 |

|

PEI |

150 |

8 |

You can also see how to dry different filaments in the chart below:

If you want the best results, use a filament dryer with the right settings. This works for most filaments and gives you good prints. For filaments like nylon that soak up water fast, use a vacuum dryer or a dryer with special heat control.

Note: If you dry filament too many times and do not use it soon, it can get brittle. Keep your dry filament in a sealed box with desiccant to keep it good.

Drying filament helps you stop bubbles, weak layers, and bad prints. Taking out water is important for strong and smooth models. If you follow these steps, your prints will look better and have fewer problems.

Alternatives to Filament Dryers

DIY Filament Drying Methods

You can dry filament at home with easy tools. Many people use their kitchen oven for this. Set the oven to a low heat and watch the filament. This works well if you control the heat. A food dehydrator is another good choice. It dries filament slowly and safely. Some people say these ways work better than some commercial dryers. You can also make a dry box from an IKEA container. You can use filament storage bags with desiccant packs too. These choices help you save money and keep filament ready for printing.

|

Method |

Effectiveness |

Limitations |

|---|---|---|

|

Oven |

Can dry filament without changing its shape. |

Needs careful heat control. |

|

Food Dehydrator |

Modified ones dry filament well. |

May not get hot enough. |

|

Commercial Dryers |

Made for filament drying, best results. |

Cost more than DIY ways. |

Storage After Drying

After drying filament, you need good storage. Use airtight bins or vacuum bags to keep water out. Put silica gel packs or reusable desiccant beads inside the box. These beads change color when they soak up water. This helps you know when to replace them. You can use the original packaging with extra desiccant too. Always take filament out of your printer after use. Store it in a sealed box. Some people make custom spool holders to protect filament from wet air. Keeping humidity under 25% helps filament stay dry.

-

Put gel packs in sealed bags or boxes.

-

Use airtight bins or vacuum bags for many spools.

-

Recharge silica gel beads often.

-

Make your own dry box with online guides.

Comparing Filament Dryer Box and Other Solutions

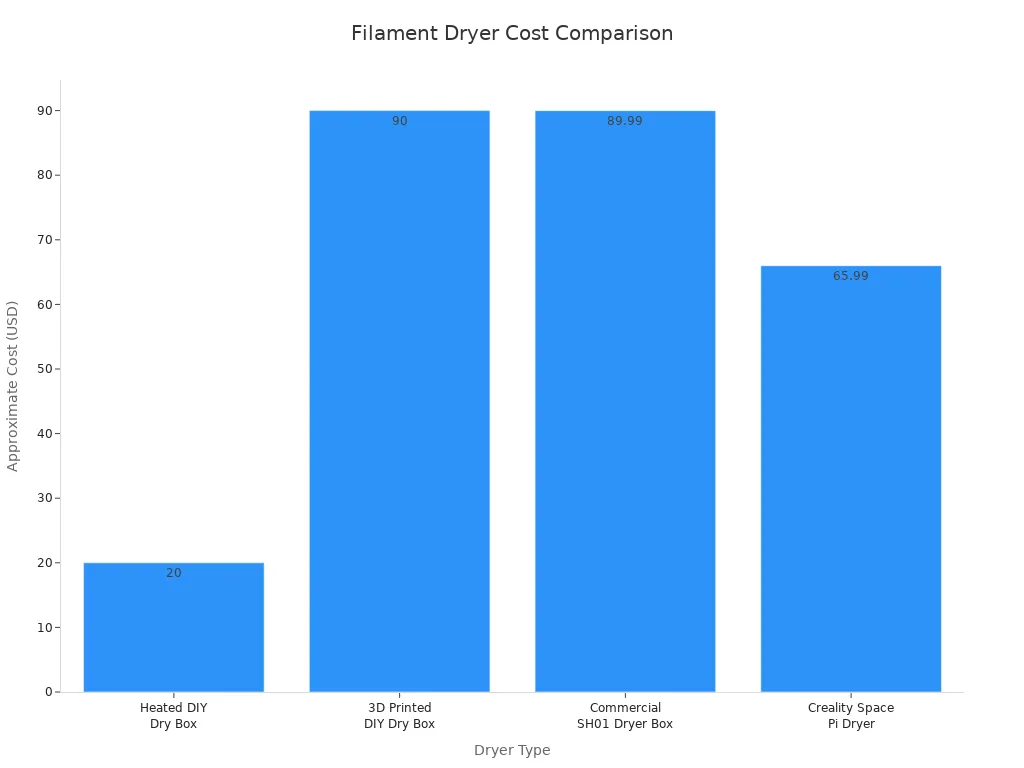

You have many ways to keep filament dry. A commercial filament dryer is easy to use and dries well, but it costs more. DIY dry boxes are cheap and work well if you build them right. Vacuum storage bags are simple and protect filament for a short time. The chart below shows how much each way costs:

User reviews are mixed. Some people say commercial dryers do not get hot enough for tough filaments. Others think ovens and food dehydrators work better and cost less. Dry boxes slow down water getting in, but do not stop it. For filaments like nylon, you need direct drying. Desiccants help with storage, but cannot remove water deep inside filament. Pick the way that fits your budget, printing needs, and local humidity.

Tip: Try different ways and see which keeps your filament dry and your prints strong.

You should think about what you want to print. Check how humid it is where you live. This helps you decide if you need a filament dryer. Many people get better prints when their filament is dry. Their models are stronger and do not fail as much.

-

Buying a dryer can make your setup cost more. It may go up by 12-15%.

-

Some companies say they have 28% fewer failed prints with dryers.

-

Most rejected parts, over 70%, happen because of moisture.

Here are some filament dryer choices for your 3D printer:

|

Filament Dryer Model |

Key Features |

ROI Potential |

|---|---|---|

|

SUNLU S4 |

Dries fast, controls humidity, holds four spools |

2-3 months |

|

Creality’s Space Pi Plus |

Has lab temperature, twelve settings |

Not specified |

|

eSUN eBOX Lite |

Saves money, PI heating, small size |

Not specified |

Pick the dryer that matches your budget and what you want to print.

FAQ

How do you know if your filament needs drying?

You can check for signs like popping sounds, rough surfaces, or weak layers in your prints. If you see these problems, your filament likely has moisture. Weighing the spool before and after drying also helps you spot water loss.

Can you use a regular oven to dry filament?

You can use a kitchen oven if you set it to a low temperature. Watch the filament closely to avoid melting. Many people use ovens for PLA and PETG, but always check the recommended drying temperature for your filament.

What happens if you print with wet filament?

Wet filament can cause bubbles, stringing, and weak prints. You may see rough surfaces or hear popping noises. Your model might break easily. Dry filament helps you get strong and smooth results.

Do all filaments need a dryer?

Not all filaments need a dryer. Nylon and PETG soak up water quickly, so they need drying more often. PLA and ABS can stay dry longer if you store them well. Use a dryer for sensitive filaments or in humid places.