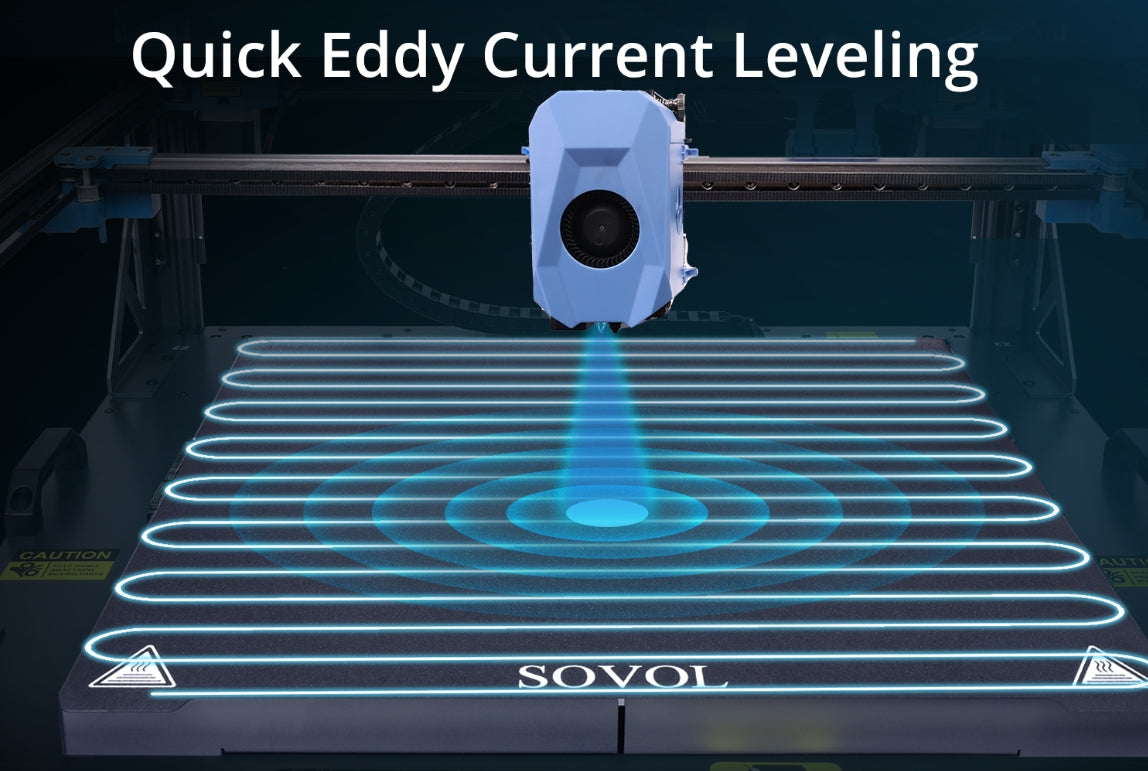

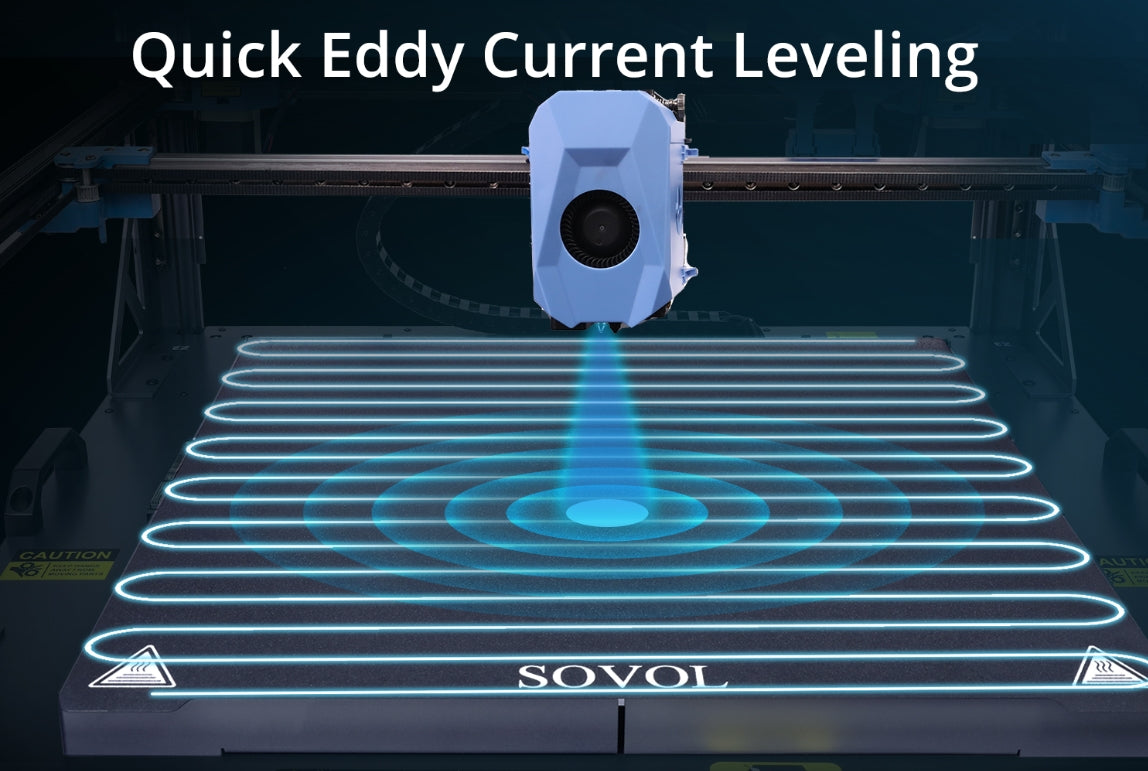

You can enhance your 3D printing experience with Eddy Current Scanning 3D Printer technology. This innovative method utilizes an eddy current scanning system to thoroughly inspect the bed surface. You achieve quick and consistent leveling every time. Eddy current bed leveling is particularly advantageous because it is fast and operates reliably. This feature helps you avoid common printing issues. Large eddy current scanning 3D printer setups enable both hobbyists and professionals to produce high-quality prints.

Key Takeaways

-

Eddy current scanning helps level the bed quickly and correctly. This saves you time and makes your prints look better.

-

The non-contact method does not touch the printer bed. This keeps the bed safe and clean.

-

This technology finds small bumps or dips on the bed. It helps stop print mistakes and makes the first layer better.

-

Eddy current scanning works with many bed materials and different temperatures. This makes it useful for many printing jobs.

-

Using this system makes 3D printing easier and more fun. You get more good prints and do not have to work as hard.

Eddy Current Scanning System for 3D Printer Leveling

How Eddy Current Bed Leveling Works

You use an eddy current scanning system to level your 3D printer bed very accurately. The system sends high-frequency magnetic fields with a probe. When the probe moves over the bed, the magnetic field meets the metal surface. This makes tiny electrical currents called eddy currents. The system checks how these currents change to find the bed’s height and bumps. The probe does not touch the bed, so it is a non-contact method. This keeps the bed clean and safe from damage. Eddy current bed leveling gives you the same good results, even after many prints.

Detecting Surface Irregularities

Eddy current scanning 3D printer technology helps you find very small bumps or dips on your bed. You can see defects as tiny as 30 µm. The scanning system works even if the bed is dirty or wet. Capacitive sensors need a clean surface, but this system does not. You do not have to worry about hurting the bed when scanning. The system works best with some bed materials. Strong magnets in the bed can change probe readings. Temperature changes can also make the system less accurate. Hotter beds lower the electrical conductivity of the material. You should think about these things for the best results.

Tip: If you print with metal powders or use heated beds, watch the temperature closely to keep leveling accurate.

- Eddy current scanning finds very small bumps or dips.

- The system works even if there are liquids or dirt.

- The probe does not touch the bed, so it stays clean.

Rapid Bed Mesh Generation

You get fast mesh generation with eddy current bed leveling. The scanning system quickly checks the whole bed before printing. This saves you time and makes setup easier. The system can adjust to changes in bed material and temperature. You get good results every time. The mesh helps you get a perfect first layer, so your prints look better and fail less. Eddy current scanning 3D printer setups make leveling simple and quick for everyone.

Key Benefits of Eddy Current Bed Leveling

Precision and Consistency

You want your 3d prints to look neat and nice. Eddy current bed leveling helps you get the right results for every print. The eddy current scanning system checks your bed without touching it. It finds even tiny problems on the surface. This way, you do not get scratches or dents like with other sensors. You get good bed leveling each time, so your prints start well. This means fewer mistakes and better quality.

Note: Eddy current scanning 3d printer technology gives you steady results every time you print.

- You get very accurate prints.

- You avoid damage to your bed.

- You see good results with every print.

Speed and Efficiency

Eddy current bed leveling saves you time. The scanning is quick, so you can start printing faster. The system makes a map of your bed and finds bumps or dips. You spend less time setting up and more time printing. Eddy current scanning makes leveling easy and works well. At home or in a factory, you print more and waste less. You finish more prints with less work.

|

Feature |

Traditional Leveling |

Eddy Current Bed Leveling |

|---|---|---|

|

Speed |

Slow |

Fast |

|

Accuracy |

Medium |

High |

|

Repeatability |

Low |

High |

|

Contactless |

No |

Yes |

- You stop print problems from bed warping.

- You print faster and easier.

- You get better results with less effort.

Durability and Low Maintenance

You want a leveling system that lasts a long time. Eddy current scanning does not touch your bed or sensor, so nothing wears out. You do not need to fix things often and can print more. The system works well for many prints, so you do not change parts much. You avoid problems from old sensors or broken beds. Your 3d printer stays in good shape, and your prints look nice.

Tip: Non-contact scanning helps your printer last longer and keeps your bed smooth.

- You fix things less and save money.

- You keep your 3d printer working well.

- You trust your leveling system to work every time.

Eddy current scanning gives you accuracy, speed, and strength. You get better prints, fewer mistakes, and an easier printing process. This technology helps you do 3d printing better and get great results every time.

Real-World Impact of Eddy Current Scanning 3D Printer Technology

Enhanced Print Quality

You want your 3d prints to look smooth and professional. The eddy current scanning system helps you reach high precision and accuracy. When you use eddy current bed leveling, you scan the bed before every print. This process finds surface flaws and tiny bumps. You avoid common flaws that ruin the first layer. Non-contact scanning keeps the bed clean and safe. You see better quality in your finished prints. The scanning system works fast, so you do not waste time. You get sharp details and strong layers in every 3d print.

Tip: Scan your bed before each print to catch any surface flaws early.

Fewer Print Failures

You know how frustrating failed prints can be. Eddy current scanning 3d printer technology reduces mistakes. The scanning system checks the bed for dips or bumps. You get accurate leveling every time. This means your prints stick well and do not peel off. You avoid wasted material and save time. Eddy current bed leveling finds problems before you start printing. You see fewer failed prints and more successful projects.

- Scan the bed to spot issues early.

- Use accurate leveling for better results.

- Save time and materials with fewer failures.

Scalability for Large-Scale Printing

You may want to print big objects or run many printers at once. Eddy current scanning makes scaling up easy. The scanning system works fast, even on large beds. You get the same precision and accuracy on every printer. Eddy current bed leveling helps you keep quality high, no matter the size. You do not need to adjust settings for each printer. The system handles different bed materials and sizes. You can trust your prints to come out right, even in large-scale printing.

|

Benefit |

Small Prints |

Large Prints |

|---|---|---|

|

Precision |

High |

High |

|

Accuracy |

High |

High |

|

Speed |

Fast |

Fast |

|

Quality |

Consistent |

Consistent |

Note: Eddy current scanning 3d printer setups help you grow your printing projects without losing quality.

Why Choose Eddy Current Scanning for Leveling

Practical Reasons for Adoption

You want your 3d printer to work well every time. The eddy current scanning system gives you a strong reason to upgrade your leveling process. You do not need to touch the bed, so you avoid scratches and dents. Non-contact scanning keeps your equipment in good shape. You get fast results because the scanning happens quickly. You do not waste time waiting for the printer to check the bed. The system works with many types of beds, so you can use it for different 3d printing projects.

Note: You can trust the scanning to find small bumps or dips that other systems might miss.

You also get better accuracy and precision. The scanning system checks the bed in detail. You see fewer print failures and better first layers. You do not need to adjust the system often. This makes your 3d printing easier and more reliable.

Direct User Benefits

You see many benefits when you use eddy current bed leveling. Your prints look better because the scanning finds problems before you start. You save time and materials by avoiding failed prints. The system works fast, so you spend more time printing and less time setting up.

Here are some key benefits you get:

- Consistent leveling for every print

- Less wear on your bed and printer parts

- High accuracy for detailed 3d prints

- Easy setup for new printing jobs

|

Feature |

Benefit to You |

|---|---|

|

Fast scanning |

Quicker print starts |

|

Non-contact |

Longer bed life |

|

High precision |

Better print quality |

You can use the system for small or large beds. The scanning adapts to your needs. You get great results whether you print at home or in a workshop. Eddy current scanning helps you enjoy 3d printing with less stress and more success.

You can see how eddy current bed leveling helps your 3d printing. The scanning does not touch the bed. It finds tiny bumps and keeps prints accurate. Experts say scanning the whole bed is fast. This helps the nozzle stay at the right spot. You get better accuracy and reliable prints. You spend less time fixing problems. Scanning makes leveling simple for everyone. If you want smoother prints and fewer mistakes, try eddy current scanning.

Eddy current scanning gives you quick, steady, and exact results every time you print.

- Scanning makes prints look better.

- Scanning helps prints work well.

- Scanning makes printing simple.

FAQ

What makes eddy current scanning better than other methods?

You get faster and more accurate results with eddy current scanning. This method does not touch the bed. You avoid damage and keep your 3d printer working well. Scanning finds small bumps that other systems might miss.

Can eddy current scanning work with all 3d printer beds?

You can use scanning with most metal beds. Some materials with strong magnets may affect scanning accuracy. Always check your printer’s manual before starting scanning. This helps you get the best results for your printing projects.

How does scanning improve my 3d printing quality?

Scanning checks the bed surface before every print. You find and fix small problems early. This gives you better first layers and fewer failed prints. Your printing becomes more reliable and your finished objects look smoother.

Is scanning hard to set up for beginners?

You can set up scanning easily. Most systems come with clear instructions. You follow simple steps to start scanning. The process does not take long. You spend less time on leveling and more time enjoying printing.

Does scanning save time during printing?

You save time because scanning works quickly. The system creates a map of the bed in seconds. You start printing sooner and avoid delays. Scanning helps you finish more projects without waiting.