If you’re new to FDM 3d printing, start with PLA. You’ll find it easy to work with because it prints at lower temperatures, sticks well, and comes in many colors. Material choice affects your results. For example, PLA and PETG both offer good strength for 3d printing:

|

Material |

Tensile Strength (MPa) |

|---|---|

|

PLA-F |

53 |

|

PETG-F |

50 |

Learning these basics helps you avoid common mistakes. This guide will boost your confidence with every filament you try.

Key Takeaways

- Begin your 3D printing with PLA filament. It is simple to use. Most printers can use it. PLA gives nice results for models and prototypes. - Pick your filament by what your project needs. Also, check what your printer can do. PETG is strong and bends a little. ABS can take heat but is harder to use. TPU is good for parts that need to bend. - Keep your filament dry and stored well. This helps stop printing problems. Use airtight boxes with silica gel. Make sure the filament spool does not get tangled.

FDM 3D Printing Filament Basics

What Is FDM?

You might hear people talk about FDM when they mention 3d printing. FDM stands for fused deposition modeling. This is the most common way people do 3d printing at home and in many industries. In FDM, your printer heats up a 3d printing filament and pushes it through a nozzle. The printer lays down the melted filament layer by layer to build your object.

Here are some cool facts about FDM 3d printing:

- FDM printers come in desktop and industrial sizes. Desktop ones are great for home use, while industrial ones handle bigger jobs.

- FDM 3d printing keeps getting better with faster speeds, higher precision, and stronger printed parts.

- The global FDM 3d printing market was worth about $1.7 billion in 2023 and keeps growing fast.

- FDM works with many materials, so you can pick the right 3d printing filament for your project.

- Big companies like Stratasys and Markforged lead the way in FDM technology.

You can use FDM 3d printing for making prototypes, tools, and even real parts for cars or medical devices.

What Is Filament?

Filament is the main material you use in FDM 3d printing. It looks like a long plastic string wound on a spool. When you start printing, your FDM printer pulls the filament into the hot end, melts it, and lays it down to create your 3d object.

Here’s why filament matters:

- The type of filament you choose affects how strong, flexible, or detailed your 3d prints turn out.

- PLA is the most popular 3d printing filament because it’s easy to print and biodegradable. The Sovol Filaments Blind Box is a fun and practical option that satisfies both your curiosity and 3D printing needs.

- Other filaments, like ABS and PETG, offer different strengths and uses.

- Some filaments, like carbon fiber blends, give extra strength and are used in cars and airplanes.

- Companies keep making new filaments with better properties, like toughness and heat resistance.

You should always match your filament to your project and printer. The right filament makes 3d printing easier and gives you better results.

Main Filament Materials

Choosing the right filament can make your 3d printing journey much smoother. In this part of the 3d printing materials guide, you’ll learn about the four most popular 3d printing materials: PLA, ABS, PETG, and TPU. Each one has its own strengths and best uses. Let’s break them down so you can pick the best option for your next project.

PLA

PLA, or polylactic acid, is the top choice for beginners in 3d printing. You’ll find it easy to use because it prints at lower temperatures (about 200-220°C) and sticks well to most print beds. PLA gives you smooth surfaces and sharp details, which is great for models, toys, and prototypes.

Here’s why PLA stands out:

- You don’t need a heated bed, but if you use one, set it around 60°C.

- PLA warps less than other 3d printing materials, so your prints stay flat.

- It comes in many colors and even special blends like wood or glow-in-the-dark.

Tip: If you want the best results, keep your filament dry and store it in a sealed bag with a desiccant. Moisture can ruin your print quality.

PLA is stiff but brittle. It works well for display pieces and low-stress parts. You shouldn’t use it for outdoor items or anything that needs to handle heat or impact. Studies show clear PLA has a tensile strength of about 51 MPa, while wood-filled PLA is much weaker. Printing direction also matters—a part printed flat can be much weaker than one printed upright. PLA’s stiffness comes from its strong layer bonding, but it can snap if you bend it too far.

You’ll love PLA if you want easy, reliable prints. It’s the star of any ultimate 3d printing materials guide for beginners.

ABS

ABS is another classic 3d printing filament. You might know it from LEGO bricks. ABS is tougher than PLA and handles heat better, with a glass transition temperature of about 105°C. This makes it a good pick for parts that need to survive in hot places, like car interiors.

ABS can be tricky for beginners. It needs a heated bed (100-110°C) and prints at higher temperatures (220-250°C). ABS likes a warm, draft-free space, so an enclosed printer helps a lot. If you skip these steps, your prints might warp or crack.

Here’s a quick look at ABS:

- Strong and impact-resistant, perfect for tools and functional parts.

- Prints slower than PLA, usually at 30-60 mm/s.

- Releases fumes, so always print in a well-ventilated area.

ABS is great for making things you’ll use every day, but it’s not as easy as PLA. If you want to try ABS, start with small projects and make sure your printer can handle the heat.

PETG

PETG is a favorite for people who want something between PLA and ABS. It’s strong, flexible, and resists impact. PETG prints at 220-260°C and likes a bed temperature of 70-90°C. You’ll notice PETG sticks well to the bed and gives you tough, clear prints.

PETG stands out because:

- It has excellent layer adhesion, so your prints won’t split apart.

- It bends more before breaking, with an elongation at break of 20-30%.

- It’s food-safe if you use the right filament and keep things clean.

PETG can string more than PLA, so you might need to tweak your retraction settings. It’s a good choice for water bottles, mechanical parts, and anything that needs to handle stress. If you want to boost strength, you can even find PETG mixed with carbon fiber.

TPU

TPU is the go-to filament for flexible 3d prints. It feels rubbery and can stretch a lot—up to 500% before breaking! TPU prints at 210-240°C and works best at slower speeds (20-30 mm/s). You’ll want to use a direct drive extruder for the smoothest experience.

TPU is perfect for:

- Phone cases, shoe insoles, and gaskets.

- Parts that need to bend, squish, or absorb shock.

- Projects where you want a soft touch or impact resistance.

TPU can be tricky to feed through your printer, so keep your filament path short and straight. It’s more rigid than some other flexible filaments, but still much softer than PLA or ABS.

Note: TPU’s Shore hardness ranges from 60A to 98A, so you can pick how soft or firm you want your print.

Filament Properties Table

Here’s a handy filament properties table to help you compare these 3d printing materials:

|

Material |

Print Temp (°C) |

Bed Temp (°C) |

Tensile Strength (MPa) |

Flexibility |

Best For |

|---|---|---|---|---|---|

|

PLA |

200-220 |

0-60 |

51 (clear PLA) |

Low |

Models, prototypes, easy prints |

|

ABS |

220-250 |

100-110 |

40-50 |

Medium |

Functional parts, tools, heat-resistant items |

|

PETG |

220-260 |

70-90 |

50-55 |

Medium-High |

Bottles, mechanical parts, food-safe prints |

|

TPU |

210-240 |

20-60 |

Very High |

Flexible parts, phone cases, insoles |

This table gives you a quick look at the most important 3d printing filament properties. You can see how each material fits different needs in your 3d printing projects.

If you’re just starting out, stick with PLA. As you get more comfortable, try PETG for tougher prints or TPU for flexible ones. ABS is great for advanced users who want strong, heat-resistant parts. This 3d printing materials guide and the ultimate 3d printing materials guide will help you pick the right filament every time.

Filament Guide for Beginners

Picking the right filament can seem hard at first. This guide will help you step by step. You will learn how to choose the best filament for your needs. You will also match it to your printer and your skill level. Let’s begin!

How to Choose

You want your 3d printing to go well and be fun. The filament you pick is very important. Here is an easy guide to help you choose:

-

Start with PLA

PLA is great for beginners. It prints easily and does not need a heated bed. You can find it in many colors. It works for most projects, like toys and models. -

Think About Your Project

What do you want to make? If you need something strong or bendy, try PETG or TPU after you learn PLA. For parts that need heat resistance, ABS is good but harder to use. -

Check Your Printer

Not all printers work with every filament. Make sure your printer can reach the right temperatures. Check if it has the features needed for your filament. -

Match Your Skill Level

If you are new, use PLA. When you get better, try ABS, PETG, or special blends. -

Consider Post-Processing

Some filaments need extra steps after printing. PLA needs little work. ABS can be smoothed with acetone vapor.

Here is a table to compare popular filaments and see which fits your needs:

|

Filament Type |

Key Features |

Applications |

Printer Compatibility |

Skill Level Considerations |

Post-Processing |

|---|---|---|---|---|---|

|

PLA |

Biodegradable, minimal warping, easy to print |

General purpose, beginners, colorful prints |

No heated bed needed; extrusion ~190-220°C |

Beginner-friendly |

Minimal post-processing |

|

ABS |

Strong, flexible, heat resistant; smooth glossy finish |

Durable parts, phone cases, toys, automotive |

Requires heated bed, enclosed print area; extrusion 210-250°C |

Intermediate; needs warping control |

Acetone vapor smoothing |

|

PETG |

Strong, flexible, impact resistant |

Bottles, mechanical parts, food-safe prints |

Heated bed 70-90°C; extrusion 220-260°C |

Beginner to intermediate |

Minimal post-processing |

|

TPU |

Flexible, soft |

Flexible parts, wearables |

Direct-drive extruder preferred; heated bed 30-50°C; extrusion 200-230°C |

Intermediate; flexible filament handling |

Usually no post-processing |

Tip: If you are not sure, start with PLA. It is the easiest filament and helps you learn 3d printing basics.

Project Needs

Every project is different. You should pick your filament based on what you are making. Here is how you can do that:

-

Display Models and Prototypes:

PLA is best for these. It gives smooth prints and bright colors. You do not need much extra work. -

Functional Parts:

PETG or ABS are better if you need strength or heat resistance. PETG is easier to print than ABS and still strong. -

Flexible Items:

TPU is best for things like phone cases or shoe insoles. It bends and stretches without breaking. -

Outdoor or Special Use:

Some filaments, like ASA, resist sunlight and weather. For outdoor signs or car parts, check if your filament can handle the environment.

Studies show picking the right filament saves time and material. For example, a study on 3d printed face shields showed print times and filament use changed a lot with design and settings. One design used 30 grams of filament and took 46 minutes. Another used 50 grams and took over 3 hours. This means you should always think about your project before printing.

Note: If you want to print something for food or medical use, check if your filament is safe for that.

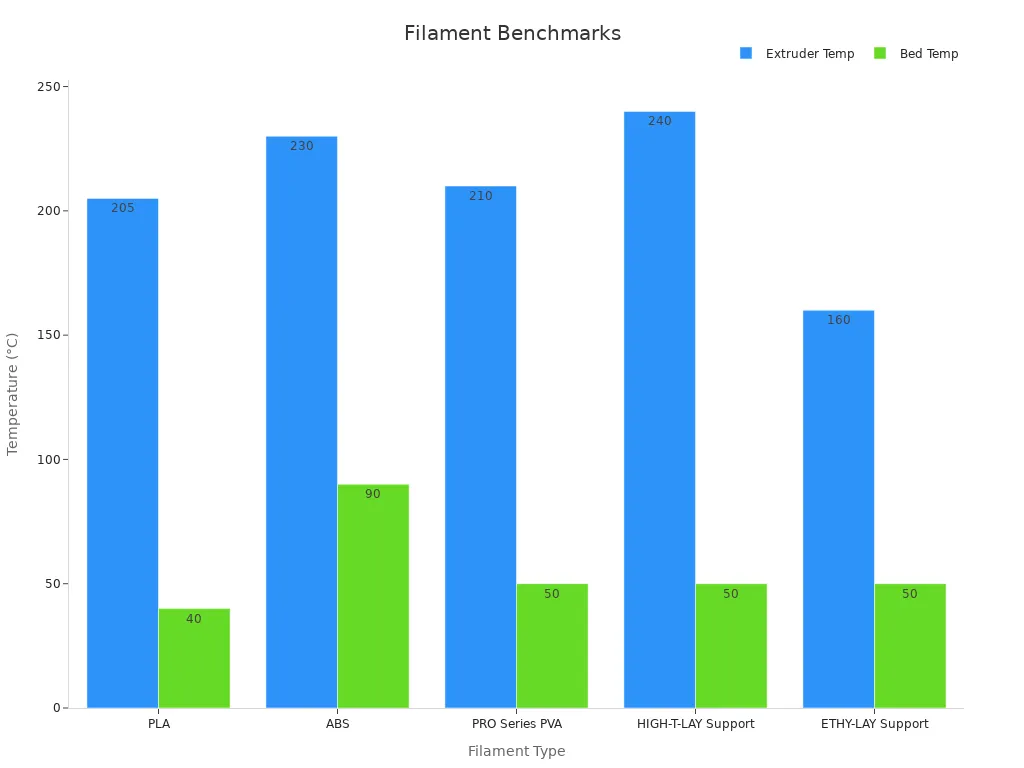

Printer Compatibility

Your printer decides which filaments you can use. Always check your printer’s specs before buying new filament. Here is a quick guide to help you:

|

Filament Type |

Extruder Temperature (°C) |

Bed Temperature (°C) |

Bed Adhesion Method |

Compatible Base Filaments |

|---|---|---|---|---|

|

PLA |

205 ± 15 |

40 ± 15 |

Blue Painters Tape |

- |

|

ABS |

230 ± 10 |

90 ± 10 |

Kapton Tape / Hairspray |

- |

|

PETG |

240 ± 10 |

70 ± 10 |

Kapton Tape / Hairspray |

- |

|

PRO Series PVA |

210 ± 10 |

50 ± 5 |

Kapton Tape / Hairspray |

PLA, Tough PLA, Nylon |

You can see PLA needs the lowest temperatures and works with most printers. ABS and PETG need more heat and sometimes a special bed surface. If your printer has a heated bed and can get hotter, you can try more advanced filaments as you learn.

Pro Tip: Always check your printer manual before using a new filament. Some filaments, like carbon fiber or metal blends, need a hardened nozzle so they do not damage your printer.

This guide helps you match your filament to your printer, your project, and your skill level. PLA is the best starting point for most beginners. As you get better at 3d printing, you can try PETG, ABS, or flexible filaments for harder projects. Remember, every print helps you learn something new!

Storage Tips

Keep Filament Dry

You want your filament to last and print well every time. Moisture is the biggest enemy of good filament. Some types, like Nylon, PETG, and TPU, soak up water from the air very quickly—sometimes in just one day. Even PLA, which resists moisture better, can still get damaged if you leave it out too long.

When filament absorbs water, you might hear popping sounds during printing. Prints can look rough or even break easily. Studies show that wet filament loses up to 25% of its strength. You may also see bubbles or gaps in your prints. To avoid these problems, always store your filament in airtight containers or vacuum-sealed bags. Add silica gel packets to absorb any leftover moisture. A dry box with a hygrometer helps you keep humidity below 20%. For very sensitive filament, like Nylon or PVA, use a filament dryer before printing.

Tip: Store your filament in a cool, dark place. Sunlight and heat can make filament brittle and fade its color.

Prevent Tangles

Tangled filament can ruin your print and waste material. You should always keep your filament spool tidy. When you finish printing, secure the loose end of the filament in the spool’s hole or use a clip. Never let the filament unwind on its own.

Here are some easy ways to prevent tangles:

- Place your filament spool on a holder that lets it spin smoothly.

- Check that the filament feeds straight into your printer.

- Avoid pulling the filament off the spool by hand.

A little care with your filament storage saves you time and trouble. You get better prints and make your filament last longer.

Now you know why PLA is best for beginners. PLA is simple to use and safe indoors. It gives good results for most prints. Experts suggest PLA because it prints at low heat. You do not need a heated bed for PLA. It comes in many bright colors. PLA is biodegradable and made from plants. This makes it a smart and green choice. You can use PLA for models and creative projects. As you get better, try PETG or TPU next. Each new filament has its own fun and challenges. Every print teaches you something new about 3d printing. Start with easy projects and enjoy learning. Let your printing journey help you try new ideas. You have what you need to do well with 3d printing!

FAQ

What filament should you buy first as a beginner?

You should start with PLA filament. This filament prints easily and works with most printers. PLA gives you smooth results and helps you learn the basics of 3D printing.

How do you store filament to keep it in good shape?

Keep your filament dry and away from sunlight. Use airtight containers or bags with silica gel. This simple step keeps your filament ready for your next project.

Can you use any filament with every 3D printer?

Not every printer supports every filament. Always check your printer’s manual or this guide. Some filaments need higher temperatures or special hardware to print well.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.