Moisture can mess up your 3D printing. It gets into filaments, making them weaker and prints look bad. For example, if filament moisture is over 0.4%, prints have rough surfaces with gaps. After 72 hours in moisture, filament strength drops to 94%. This makes prints weaker. A filament dryer, such as the Sovol SH01 filament dryer or the Sovol SH02 filament dryer, effectively removes this moisture. Drying your filament with a Sovol SH01 filament dryer or a Sovol SH02 filament dryer makes it strong again, improves its appearance, and helps prints turn out better and more accurate.

Key Takeaways

- Water ruins 3D print quality. Drying filament makes prints stronger and nicer.

- Check for moisture signs, like breaking easily or crackling sounds, to know when drying is needed.

- Use a filament dryer to remove water. This helps make smoother and better prints.

- Keep filament in sealed boxes with silica gel to stay dry and ready.

- Check your filament often for water. Weighing it helps you see its condition.

Why Moisture Affects 3D Printing Quality

How Moisture Gets into Filament

Water gets into 3D printing filament in many ways. Most filaments are hygroscopic, meaning they soak up water from the air. This happens faster in places with high humidity. Over time, the water changes the filament, causing printing problems.

|

Mechanism/Process |

Description |

|---|---|

|

Filaments soak up water from the air, raising water levels. |

|

|

Plasticization |

Water makes the filament softer but also weaker. |

|

Swelling |

Filament grows bigger as it absorbs water, changing its size. |

|

Matrix Hydrolysis |

Water breaks down the filament chemically, making it weaker. |

|

Interfacial Debonding |

Water loosens the bond between parts of the filament. |

|

Osmotic Process |

Water messes up the filament's inside structure, lowering its quality. |

To stop water absorption, keep filaments in a dry place. Filament dryers can also remove water already inside the filament.

Signs Your Filament Needs Drying

Knowing when to dry your filament helps keep prints good. Look for these signs:

- Brittle Filament: If it breaks easily, it has too much water.

- Popping or Hissing Sounds: These sounds during printing mean water is escaping.

- Stringy or Blobby Prints: Too much water causes uneven extrusion, making strings or blobs.

- Rough or Bubbly Surfaces: Water creates bubbles, making prints rough or uneven.

If you see these signs, drying the filament can fix it and improve prints.

Tip: Check your filament often, especially in humid areas.

Impact of Moisture on Print Quality

Water harms print quality and weakens filament strength. It messes up material flow during printing. This causes bad layer sticking, rough prints, or even cracks. Water also makes the filament less strong and durable.

Drying filament before printing gives better results. Studies show drying loose filament works better than drying it on spools. This removes water faster and improves print looks and strength. Keeping filament dry at all times is key for great prints.

How Filament Dryers Remove Moisture

The Science Behind Filament Drying

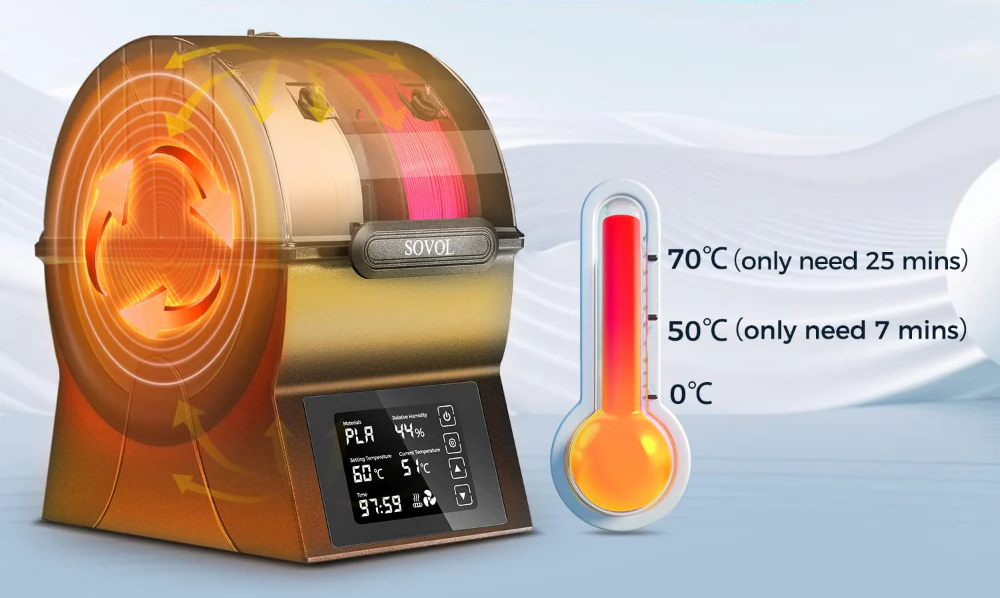

Filament dryers use heat and air to take out moisture. Heating makes water inside the filament move and expand. This creates a pressure difference, pushing water out of the filament. Warmer air holds more water, so higher heat dries faster.

Many dryers also use desiccants like silica gel to soak up water. Desiccants work better in cooler places, so check humidity while drying. Weigh the filament spool to track progress. If the weight stays the same, the filament is dry.

Note: Absolute humidity, not relative humidity, affects drying. Temperature changes this, so adjustable dryers give the best results.

Benefits of Using a Filament Dryer

Using a filament dryer helps your 3D printing in many ways:

- Better Print Quality: Dry filament makes smoother, shinier, and cleaner prints. Problems like bubbles or rough spots are reduced.

- Steady Results: Drying filament ensures smooth extrusion. This avoids blobs or strings and improves layer sticking.

- Works with All Materials: Whether using PLA, ABS, or TPU, dryers keep filament strong and reliable.

- Less Waste: Wet filament causes failed prints. Drying saves time and reduces wasted material.

For example, users say Sovol SH01 and Sovol SH02 dryers improve print quality and strength. These dryers remove moisture well, making prints look professional and last longer.

Types of Filament Dryers to Consider

Pick a filament dryer based on your needs. Here’s a comparison of popular ones:

|

Filament Dryer |

Drying Method |

Key Features |

Performance Characteristics |

|---|---|---|---|

|

FilaDryer S2 |

Active |

Holds 1 spool, adjustable settings |

Great for common materials |

|

FilaDryer S4 |

Active |

Holds 4 spools, strong heating |

Dries faster than S2 |

|

D1 Filament Dryer |

Active |

Heats all around, can be wall-mounted |

Lowers filament breaking risk |

|

PrintDry Pro3 |

Active |

Heats up to 85 °C, six preset options |

Works for many materials |

|

Drywise Filament Dryer |

Active, Desiccant |

Dries engineering filaments inline, updated material list |

Good for industrial use |

|

FD1 Filament Dryer |

Active |

Dries, conditions, and feeds filament |

Works with many materials |

For hobbyists, the Sovol SH01 filament dryer (available here) is great for one spool. If you need to dry more spools at once, try the Sovol SH02 filament dryer (available here) for faster drying and advanced features.

Best Practices for Filament Drying

Getting Filament Ready for Drying

Check your filament for signs of water damage. Look for brittleness or bubbles. Clean off any dust or dirt before drying. If the filament is on a spool, loosen it a bit for better airflow. For loose filament, spread it out evenly on a tray.

Here’s a simple guide for drying different filaments:

|

Filament Type |

Suggested Drying Time |

|

|---|---|---|

|

PLA |

40–50 |

4–6 hours |

|

PETG |

60–70 |

4–6 hours |

|

ABS |

70–80 |

8–12 hours |

|

Nylon |

70–90 |

Overnight |

|

TPU |

40–50 |

4–6 hours |

Tip: Always follow the manufacturer’s drying instructions for best results.

Choosing the Right Temperature and Time

Using the right heat and time is important. This removes water without harming the filament. For example, drying nylon at 85°C overnight works well. A food dehydrator is good for PLA and PETG but may not work for tougher materials like nylon.

Steps to dry filament properly:

- Set the dryer to the correct temperature for your filament.

- Watch the process to prevent overheating.

- Weigh the filament before and after drying. If the weight stays the same, it’s dry.

If you use desiccants, dry them in an oven at 110°C for two hours when they’re full of moisture.

Drying Tips for Different Filaments

Each filament type needs special care. PLA and TPU need lower heat, while ABS and nylon need higher temperatures. Nylon absorbs water fast, so drying it overnight is often needed. For TPU, don’t use too much heat to avoid damage.

Pro Tip: After drying, store filament in vacuum-sealed bags with desiccants to keep it dry.

By following these tips, your filament will stay dry and ready for great prints.

Maintaining Filament Quality After Drying

Storing Filament the Right Way

Keep your 3D filament in a dry, safe place. Filaments soak up water from the air, which can ruin prints. Wet filament causes rough surfaces and weak prints. Use airtight containers to stop moisture from getting in.

Vacuum-sealed bags are also a great choice. They are cheap, come in many sizes, and block water from reaching the filament. Add silica gel packets to these bags to absorb extra moisture. This keeps your filament dry and ready to use.

Tip: Write the filament type and drying date on the container. This helps you track its condition easily.

Using Silica Gel and Vacuum Bags

Silica gel packets are great for keeping filament dry. These packets soak up water and keep the storage space moisture-free. Put them in airtight containers or vacuum-sealed bags with your filament.

Vacuum-sealed bags give extra protection. They remove air, lowering the chance of water getting in. This simple method works well to keep filament in good shape.

Using both silica gel and vacuum bags keeps filament dry. This avoids problems like popping sounds or uneven printing.

Checking Filament for Moisture

Check your filament often to spot problems early. Look for brittleness, bubbles, or mold. These signs mean the filament has absorbed water and needs fixing.

Filaments pull in water from the air, which causes issues. Wet filament can make popping noises, stringy prints, or weak results. Regular checks help you fix these problems before printing.

Pro Tip: Weigh your filament spool now and then. If it’s heavier, it may have absorbed water. Dry it again to fix this.

Follow these steps to keep your filament in top shape and get better prints every time.

Water can mess up your 3D printing, but filament dryers fix this. Using the right drying methods and tools makes prints better and filaments last longer. Keeping filament dry after drying helps it stay in great shape. These easy steps give you smoother, stronger, and more accurate prints. Try these tips now to improve your 3D printing results.

Pro Tip: Always dry and store filament properly for better, lasting prints.

FAQ

How should you store filament after drying?

Keep it in a sealed container with silica gel packs. Vacuum-sealed bags are also a good option. These stop water from getting back into the filament, keeping it dry and ready to use.

When should you dry your filament?

Dry it if you see signs of moisture, like brittleness or popping sounds while printing. In humid places, check and dry it more often to keep prints looking good.

Can a food dehydrator dry filament?

Yes, you can use a food dehydrator for some filaments like PLA or PETG. But it might not get hot enough for materials like nylon. Always check the drying temperature for your filament type.

Does drying filament make prints stronger?

Yes, drying removes water that makes filament weak. This makes prints stronger and last longer. Dry filament also helps layers stick better and gives smoother results.

Why does filament soak up water?

Most 3D printing filaments absorb water because they are hygroscopic. This happens faster in wet air. Storing and drying them properly stops water problems.