Starting 3D printing can seem confusing at first, especially when considering the common 3D printing beginner mistakes. New users often struggle with picking materials, setting up printers, and learning settings. Surveys say 45% of beginners question if 3D printing can grow. By avoiding these common beginner mistakes, you can achieve better results and experience less frustration.

Key Takeaways

- Make sure the printer bed is flat before printing. A flat bed helps prints stick and look better.

- Change the Z-offset for each filament type. This makes the first layer stick well and keeps prints steady.

- Use good-quality, dry filament. Bad filament can cause weak prints and jams, so keep it stored safely.

Top 10 Common 3D Printing Beginner Mistakes

Skipping Bed Leveling

Leveling the bed is very important in 3D printing. If you skip it, prints might not stick well. This can cause warping or prints falling off during printing. Uneven beds also make layers uneven, ruining print quality.

To fix this, check and adjust your bed often. Use tools like auto-leveling sensors or screws to make the bed flat. A level bed helps prints stick and improves results.

Tip: Always level the bed before printing, especially after moving the printer.

Incorrect Z-Offset Setup

The Z-offset sets the gap between the nozzle and bed. If it’s wrong, the first layer won’t stick well. This can cause bad dimensions or uneven prints.

Different filaments need different Z-offsets because of their properties. For example, filament size and speed affect the setup. Adjust the Z-offset for each filament and test with a small print.

Best Practice: Use a test print to check Z-offset before big projects. This ensures the first layer sticks and prints stay stable.

Ignoring Nozzle Temperature Calibration

Nozzle temperature is key for good filament flow. If it’s too low, the filament won’t melt well, causing gaps. If it’s too high, the filament can burn or create blobs.

Set the nozzle temperature for each filament type. Materials like PLA need lower heat, while PEEK needs higher heat. Follow the filament’s temperature guide and watch for smooth extrusion.

Note: Correct temperatures improve prints and keep the nozzle lasting longer.

Using Wet or Poor-Quality Filament

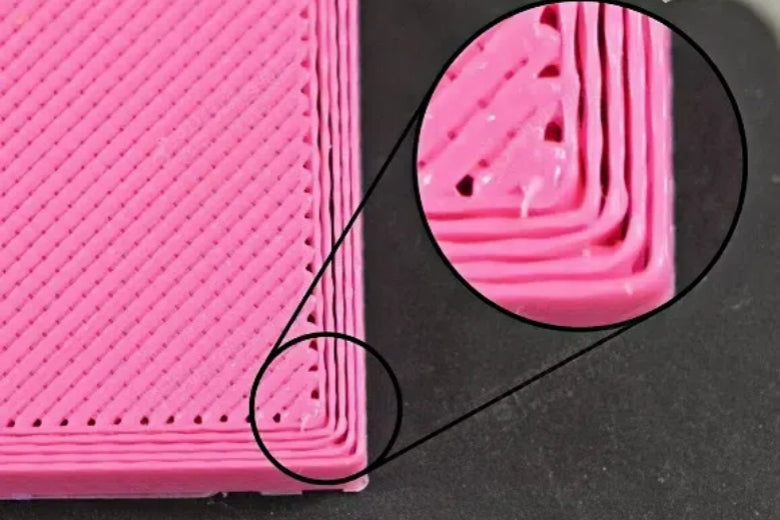

Bad filament can ruin prints. Wet filament absorbs water, causing bubbles and weak layers. Cheap filament can clog nozzles and make messy prints.

Keep filament in airtight boxes with moisture removers. Buy good-quality filament from trusted brands. Check for damage or moisture before using it.

Pro Tip: If filament feels wet, dry it with a filament dryer or low-heat oven.

Printing Too Fast or Too Hot

Printing too quickly or at high heat causes problems. It can make blobs, strings, or rough surfaces. Overheating can also weaken the print.

Match speed and heat to the filament and design. Adjust slicer settings to avoid defects. For special materials like PEEK, follow specific heat rules.

Reminder: Slower speeds and moderate heat give better results, especially for detailed designs.

Not Understanding Layer Height and Resolution

Layer height affects how smooth or fast a print is. Beginners often ignore this, leading to rough prints or long print times.

For smooth prints, use smaller heights like 50 microns. For faster prints, use larger heights like 100 microns. Pick a height based on your design and printer.

|

Layer Height (Microns) |

Surface Quality |

Print Speed |

|---|---|---|

|

50 |

Smooth |

Slow |

|

100 |

Rough |

Fast |

Insight: Smaller heights look better but take longer. Choose wisely.

Incorrect Support Settings

Supports help with overhangs or tricky designs. Wrong settings can cause sagging or hard-to-remove supports.

Use slicer software to adjust support settings. Change density, placement, and material for stability. Test settings to find what works best.

Tip: Soluble supports are easier to remove and leave cleaner prints.

Choosing the Wrong Infill Pattern or Density

Infill affects strength, weight, and material use. Beginners often use dense infill, wasting material and money.

Pick patterns based on what you need. For light parts, use low-density honeycomb or gyroid. For strong parts, use higher density grid or solid infill.

Best Practice: Test infill settings to balance strength and save material.

Not Cleaning or Maintaining the Printer

Skipping maintenance can cause bad prints and expensive repairs. Dust and leftover filament can clog nozzles and ruin prints.

Clean the bed, nozzles, and fans often. Check parts to make sure they work well. Maintenance keeps prints good and the printer lasting longer.

Reminder: A clean printer gives better and more reliable prints.

Giving Up Too Early Without Troubleshooting

3D printing takes practice. Many beginners quit after a few failures. They miss chances to learn and get better.

Treat mistakes as lessons. Find the problem, fix settings, and try again. Join online groups to get help and share tips.

Encouragement: Keep trying! Patience and practice lead to success in 3D printing.

Bonus Tips to Avoid 3D Printing Mistakes

Beginner-friendly printers to consider (e.g., Sovol SV06 ACE / SV08)

Picking the right printer makes 3D printing easier. Models like Sovol SV06 ACE and SV08 are great for beginners. The Sovol SV06 ACE has auto-leveling, so you don’t need to level the bed yourself. Its small size fits well in tight spaces. The Sovol SV08, however, has a bigger build area for larger prints. Both printers are simple to use and have beginner-friendly controls.

Tip: Choose a printer that fits your needs. If unsure, go for one that’s easy to use and dependable.

Sovol’s guide pages and user community

Learning from others helps you avoid mistakes. Sovol has helpful guides and a community where users share advice. These guides explain calibration, fixing problems, and updating firmware. You’ll find clear steps for setting up your printer and adjusting it for different materials.

The Sovol community connects you with experienced users. They can answer questions and give tips. Whether it’s nozzle clogs or support settings, the community is there to help.

Note: Save Sovol’s guide links and join forums to learn more.

Sovol’s warranty and customer support

Good customer support can save you trouble. Sovol offers a warranty to help if your printer has issues. Their support team responds quickly and provides useful solutions. Whether you need parts or troubleshooting help, they’ve got you covered.

Reminder: Register your printer to activate the warranty and get support.

Making mistakes in 3D printing helps you learn quickly. Every error shows you more about settings, materials, or methods. Start each project with care and a plan. Sovol printers and tools make things easier for beginners. Check out their easy-to-use printers, helpful guides, and community to build skills and get great prints.

FAQ

What can you do if prints don’t stick?

Make sure the bed is level and clean. Try using glue sticks or painter’s tape to help prints stick better.

Tip: Always check the first layer is set up correctly.

How do you stop nozzle clogs while printing?

Store filament in a dry place and use good-quality brands. Clean the nozzle often and avoid printing at very high heat.

Why do prints curl or warp at the edges?

Warping happens when cooling is uneven. Use a heated bed, add adhesives, and keep the enclosure warm for materials like ABS.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.