Nozzle temperature is crucial for ensuring your 3D prints adhere properly and results in strong finished parts. To help you find the optimal settings, refer to this 3D print nozzle temperature guide, which outlines the best temperatures for various materials:

|

Filament |

|

|---|---|

|

PLA |

190–220 |

|

PETG |

230–250 |

|

ABS |

220–250 |

|

TPU / TPE |

210–230 |

|

Nylon (PA) |

240–270 |

|

Polycarbonate (PC) |

260–310 |

|

PVA |

180–210 |

|

Carbon Fiber Reinforced |

230–270 |

Start with the highest temperature in the specified range, then decrease it by 5°C. Continue to lower the temperature until your prints achieve the desired quality. Adjust the temperature for different brands or environmental conditions. Utilize this 3D print nozzle temperature guide to troubleshoot issues and enhance your printing results.

Key Takeaways

- Nozzle temperature helps make strong 3D prints. Change it for each filament type to get good results.

- Begin with the highest temperature your material needs. If you see stringing or blobs, lower the temperature by 5°C.

- Look at your printer's settings often. The first layer must stick well for a good print.

- Try a temperature tower test to find the best nozzle temperature. This test shows how different temperatures change print quality.

- Always keep filaments like PVA in a dry spot. Wet filaments do not work well.

Why Nozzle Temperature Matters

Print Quality and Adhesion

You can change how good your 3D prints look by setting the nozzle temperature. The right temperature helps the filament melt and move easily. This makes the first layer stick better and stops warping or gaps. If you use higher nozzle temperatures, the layers bond more and the print gets stronger. When you increase the temperature, the layers hold together well. Your print will be tougher.

- Park and Lee found that using 230°C for PLA made prints stronger and more dependable.

- Bergonzi et al. said that 235°C made prints stretch more and become stiffer because the filament flowed better and the layers joined tightly.

You should always check your 3D printing settings to make sure the first layer sticks. Good first-layer adhesion helps the whole print turn out better.

Material Properties and Strength

The temperature you pick changes how strong your printed parts are. If you use the best nozzle temperature, your prints will be tough and bend easily.

- PLA can be as strong as 56 MPa at higher temperatures, which is almost like injection-molded parts.

- The table below shows how different temperature settings change the properties:

|

Parameter |

Optimal Temperature Range (°C) |

Observations |

|---|---|---|

|

Tensile Strength |

200–240 |

Highest values in the range of 57–59 MPa. |

|

Flexural Strength |

260 |

Maximum value of 92.8 MPa at 260°C. |

|

Compressive Yield Strength |

220–260 |

Maximum value in the range of 92.7–93 MPa. |

You should change your 3D printing settings for each material to get the best results. Good temperature settings help you avoid weak prints and rough surfaces.

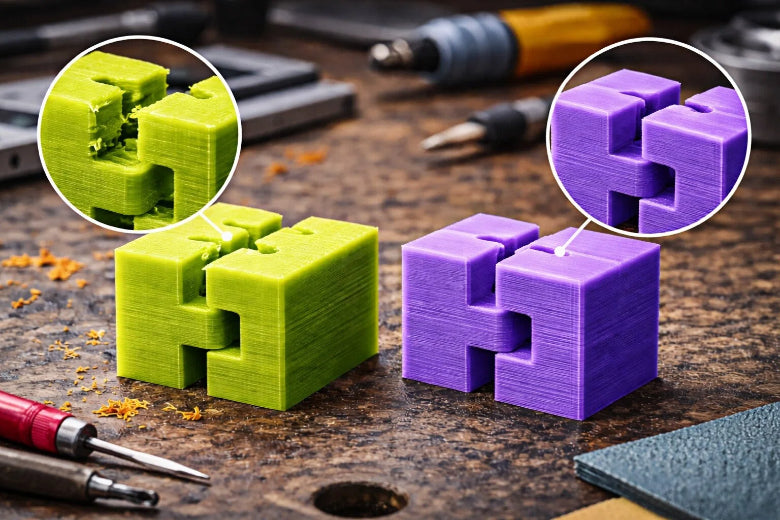

Common Issues from Incorrect Temperature

If you use the wrong temperature, you might have problems:

- Filament does not melt enough, so layers do not stick and the first layer does not hold.

- Nozzle clogs because the filament melts too slowly.

- Prints lean or lines look messy because extrusion is bad.

- High temperatures can cause under-extrusion and make prints worse.

- Old or broken hot ends may show wrong temperatures, which can ruin prints.

You can fix many problems by checking your 3D printing settings and changing the nozzle temperature. Always look for signs like a bad first layer or nozzle clogs. These issues usually mean you need to adjust your temperature settings.

Nozzle Temperature by Material

PLA Print Temperature

You will find PLA one of the easiest filaments to print. The pla print temperature usually falls between 190°C and 220°C. Lower settings, such as 190°C to 200°C, help you get crisp details and smooth surfaces. Higher settings, from 210°C to 220°C, improve layer bonding and strength, especially for larger models. You should always check the manufacturer's label for the best pla print temperature for your specific brand.

Tip: Start at the highest recommended pla print temperature and lower it by 5°C if you see stringing or blobs.

The recommended bed temperature for PLA is 50°C to 60°C. You can print small parts without a heated bed if you use glue stick or hairspray for adhesion. On PEI plates, some users succeed with 45°C to 50°C.

|

Bed Temperature (°C) |

Description |

|---|---|

|

50–60 |

Good for most prints, especially on glass or PEI. |

|

None |

Possible for small prints with adhesives. |

|

45–50 |

Works for some PEI plates and printers. |

You should adjust your temperature settings if you see poor adhesion or rough surfaces.

ABS Temperature Range

ABS is strong and heat-resistant, but it can warp if you do not use the right 3d printing temperature. The ideal nozzle temperature for ABS is 240°C to 270°C. Some brands suggest starting at 230°C for new filament. If layers peel off, increase the temperature by 5°C. If you see blobs or strings, lower it by 5°C. Never go below 210°C.

A heated bed is important for ABS. The optimal temperature is 95°C to 110°C. This helps prevent warping and keeps the print stuck to the bed.

|

Manufacturer |

Nozzle Temperature (°C) |

Heated Bed Temperature (°C) |

|---|---|---|

|

Snapmaker |

210 - 250 |

N/A |

|

Siraya Tech |

240 - 270 |

100 - 110 |

|

Source |

Recommended Bed Temperature Range |

|---|---|

|

Wevolver |

95-110°C |

|

Anycubic Wiki |

90-100°C |

You should use an enclosure for ABS to keep the heat even and reduce cracking.

PETG Temperature Range

PETG is tough and flexible. The best 3d printing temperature for PETG is 220°C to 250°C. Most users start at 230°C for the first layer and 240°C for the rest. You should adjust your temperature settings if you see stringing or poor layer bonding.

|

Source |

Recommended Nozzle Temperature Range |

|---|---|

|

JLC3D |

220°C to 250°C |

|

Prusa |

230°C (first layer), 240°C (others) |

|

Siraya |

230°C to 250°C |

The optimal temperature for the bed is 70°C to 90°C. Most people find 80°C works well. On glass beds, try 85°C to 90°C. On PEI sheets, use around 70°C.

- PETG sticks well, so let the bed cool before removing prints.

- If you see too much stringing, lower the nozzle temperature by 5°C.

TPU Temperature Range

TPU is a flexible filament. The best pla print temperature for TPU is 210°C to 250°C, depending on the brand. NinjaTek recommends 225°C to 250°C, MatterHackers suggests 220°C to 240°C, and Polymaker lists 210°C to 230°C. Most users find 230°C works well.

|

Manufacturer |

Recommended Temperature Range |

|---|---|

|

NinjaTek |

225–250°C |

|

MatterHackers |

220–240°C |

|

Polymaker |

210–230°C |

The optimal temperature for the bed is 40°C to 60°C. Start at 50°C and adjust by 5°C if you have adhesion problems.

|

Bed Temperature (°C) |

Description |

|---|---|

|

40–60 |

Maintains optimal adhesion for TPU printing. |

|

50 |

Good starting point. Adjust if needed. |

|

Room Temperature |

Possible, but heated bed improves results. |

You should print TPU slowly to avoid jams and get smooth results.

Nylon Temperature Range

Nylon is strong and flexible, but it absorbs moisture. The best 3d printing temperature for Nylon is 250°C to 255°C. You should dry your filament before printing to avoid bubbles and weak spots.

|

Recommended Nozzle Temperature |

Range |

|---|---|

|

Nylon Filament |

250°C - 255°C |

The optimal temperature for the bed is 70°C to 90°C. Some types, like NylonX and NylonG, work at 60°C to 65°C.

|

Nylon Type |

Recommended Bed Temperature (°C) |

|---|---|

|

NylonX |

60 |

|

NylonG |

65 |

|

Nylon |

70-90 |

You should use an enclosure to keep the temperature steady and reduce warping.

Polycarbonate (PC) Temperature

Polycarbonate is very strong and heat-resistant. The best nozzle temperature for PC is 260°C to 310°C. Sales Plastics recommends 250°C to 300°C, Top 3D Shop suggests 260°C to 310°C, and MatterHackers lists 290°C to 310°C.

|

Source |

Nozzle Temperature Range |

|---|---|

|

Sales Plastics |

250–300°C |

|

Top 3D Shop |

260–310°C |

|

MatterHackers |

290–310°C |

The optimal temperature for the bed is 145°C to 150°C. You need at least 135°C for good adhesion.

- Use an enclosure to keep the print warm and reduce warping.

- PC needs a high-temperature hot end and bed.

PVA Temperature

PVA is a water-soluble support material. The best pla print temperature for PVA is 190°C to 240°C. Most users print at 200°C to 220°C for good results.

|

Filament Type |

Recommended Nozzle Temperature (°C) |

|---|---|

|

PVA |

190 - 240 |

The optimal temperature for the bed is 45°C to 60°C.

|

Temperature Type |

Optimal Range |

|---|---|

|

Printing |

180-230°C |

|

Bed |

45-60°C |

|

Heat Bed |

0-60°C |

You should store PVA in a dry box to keep it from absorbing water.

Carbon Fiber Reinforced Temperature

Carbon fiber reinforced filaments are strong and stiff. The best nozzle temperature is 260°C to 285°C. The optimal temperature for the bed is 100°C to 110°C.

|

Parameter |

Recommended Range |

|---|---|

|

Extruder Temperature |

260 - 285°C |

|

Heated Print Bed |

>100°C (optimum 110°C) |

|

Filament Type |

Optimal Bed Temperature (°C) |

|---|---|

|

Siraya Tech Fibreheart ABS-CF |

100-110 |

|

STYX PA6-CF15 |

90-110 |

You should use a hardened steel nozzle because carbon fiber is abrasive.

Note: Always check the manufacturer's recommendations. Adjust your temperature settings for your printer and environment. Try different settings to find the optimal temperature for your material.

Signs of Incorrect Nozzle Temperature

When you set the wrong temperature settings, your 3D prints can show many problems. You need to know these signs to fix your prints and get better results.

Low Temperature Symptoms

If you set the extrusion temperature too low, the filament does not melt well. This causes weak prints and poor surface quality. Look for these signs:

- Weak Layers: Layers do not stick together. You can break the print easily.

- Under-Extrusion: The printer does not push out enough plastic. You see gaps or missing lines in your print.

- Poor Adhesion: The first layer does not stick to the bed. Prints may peel off or warp.

- Nozzle Clogs: The filament jams in the nozzle. Printing stops or skips layers.

- Rough or Grainy Surface: The print feels rough. The layers look uneven.

Tip: If you see these problems, increase your temperature settings by 5°C and try again.

High Temperature Symptoms

If you set the nozzle temperature too high, the filament gets too runny. This can damage your print and your printer. Watch for these signs:

- Stringing: Thin threads appear between parts of your print.

- Blobs and Oozing: Extra plastic forms blobs or drips from the nozzle.

- Surface Defects: The print looks shiny, saggy, or has bubbles.

- Loss of Detail: Small features melt or lose shape.

- Odor or Smoke: You smell burning plastic or see smoke. This means the extrusion temperature is much too high.

Note: Lower your temperature settings by 5°C if you notice these issues. Always check your printer’s display to confirm the right temperature.

You can solve most print problems by adjusting your temperature settings. Watch your prints closely and make small changes for the best results.

3D Print Nozzle Temperature Guide: Calibration and Optimization

Temperature Tower Test

A temperature tower helps you find the best nozzle temperature for your filament. This test print has different sections, each with a different temperature. The temperature changes as the tower gets taller. You can see how each temperature affects your print.

- Print a temperature tower using your filament.

- Change the temperature by 5°C for each part.

- Start with the lowest temperature at the bottom. Go higher as you move up.

- Check each section for smoothness, strong layers, and nice surfaces.

Some parts of the tower will look better than others. The best-looking part shows the right temperature for your filament. This test makes it easy to change your 3d printing settings. Use the 3d print nozzle temperature guide to compare and choose the best setting.

Tip: Always set your nozzle and bed temperature before printing a temperature tower. Good temperature control gives you better results.

Step-by-Step Calibration

You can use these steps to set your nozzle temperature and make your prints better:

- Heat your printer’s hot end and bed to the right temperatures for your filament.

- Use an IR thermometer to check the real temperature. Compare it to what your printer shows.

- If the difference is more than 1°C, fix it in your printer’s software or firmware.

- Check the temperature again to make sure it matches.

- Print a temperature tower with five parts. Start with the lowest temperature and go up by 5°C for each part.

- Look at each part for strong layers and a smooth surface.

- Choose the temperature that works best. Write down your final settings for later.

This way, you get the most from your 3d print nozzle temperature guide. You can adjust your 3d printing settings and get better prints every time.

Note: Always test new filament with a temperature tower. Different brands and colors might need different temperature control.

Troubleshooting Tips

You might have problems when you use your 3d print nozzle temperature guide. Here are some easy ways to fix common problems:

- If you see weak layers or gaps, raise the temperature by 5°C.

- If you see stringing or blobs, lower the temperature by 5°C.

- If the first layer does not stick, check your bed temperature and clean the bed.

- If the nozzle clogs, make sure your filament is dry and your temperature is right.

- If your prints look shiny or saggy, the temperature is too high. Lower it and try again.

You can fix most problems by making small changes to your 3d printing settings. Watch your prints closely and use the temperature tower to test new changes. Good temperature control helps you get strong, smooth, and reliable prints.

Tip: Write down your best settings for each filament. This will help you save time and get good results next time.

If you follow this 3d print nozzle temperature guide, you can learn to control temperature and get better at 3D printing. Practice and patience will help you get the best results from your printer.

Advanced 3D Printing Settings

Print Speed and Layer Height

You can change how your prints look and feel by changing print speed and layer height. If you want to make a model fast, use a higher print speed and thicker layers. This will save time but might make your print less strong and less detailed. If you want your print to be strong and look nice, slow down the print speed and use thinner layers. When you print faster, you need a higher nozzle temperature. This helps melt more filament quickly. If you print slower, the filament melts better. You might need to lower the nozzle temperature to stop stringing or blobs. Changing these 3d printer settings helps you get the results you want.

Tip: Start with a medium speed and layer height. Change them for your project and see how they change your print.

Cooling and Environment

Cooling and your workspace are important for good prints. If you make the nozzle temperature higher, you might need to slow down the print speed or use more fan. This stops problems like curled edges. If you lower the nozzle temperature, you may need less fan or a faster print speed to help layers stick. Small parts need more air from the fan, but big parts need less. The room’s temperature and how wet the air is also change your printing temperature settings. If your room is cold, prints cool too fast and can warp. Warm rooms help layers stick together.

- Use an enclosure for materials that need heat.

- Change fan speed for different part sizes.

- Keep your workspace dry and warm for the best prints.

Special Filaments and Composites

Special filaments, like carbon fiber or glass-filled ones, need extra care. These filaments often need higher nozzle and bed temperatures. Make sure your printer can use these settings. For heat-resistant materials, set the bed temperature between 90°C and 120°C. Use a hardened steel nozzle for rough filaments. Change cooling and speed to stop problems. If you see rough surfaces or weak layers, change your temperature and fan settings.

|

Filament Type |

Nozzle Temp (°C) |

Bed Temp (°C) |

Notes |

|---|---|---|---|

|

Carbon Fiber Nylon |

260–285 |

100–110 |

Use steel nozzle |

|

Glass-Filled Polyamide |

250–270 |

90–120 |

Reduce fan speed |

Note: Always check if your printer works with special filaments before using them.

3D Printing Temperature Quick Reference Table

You need a quick way to check the best nozzle temperatures for your 3D printing materials. This section gives you a simple guide. You can use it when you set up your printer or when you want to solve a problem with your prints.

Tip: Always start with the highest temperature in the range. Lower it by 5°C if you see stringing, blobs, or other issues.

Summary Table of Optimal Nozzle Temperatures

You can use this table to find the right nozzle temperature for each filament. The table also shows the best bed temperature. These settings help you get strong, smooth, and reliable prints.

|

Material |

Nozzle Temp (°C) |

Bed Temp (°C) |

Notes |

|---|---|---|---|

|

PLA |

190–220 |

50–60 |

Easy to print |

|

PETG |

230–250 |

70–90 |

Good for strong parts |

|

ABS |

220–250 |

95–110 |

Needs enclosure |

|

TPU / TPE |

210–230 |

40–60 |

Print slow for best results |

|

Nylon (PA) |

240–270 |

70–90 |

Keep filament dry |

|

Polycarbonate (PC) |

260–310 |

135–150 |

Use high-temp hot end |

|

PVA |

180–210 |

45–60 |

Store in dry box |

|

Carbon Fiber Reinforced |

230–270 |

100–110 |

Use steel nozzle |

- You should always check the filament label for the best settings.

- If you see weak layers, raise the temperature by 5°C.

- If you see stringing or blobs, lower the temperature by 5°C.

Note: Room temperature and humidity can change how your filament prints. Try small changes to find what works best for you.

You can print this table or save it on your computer. Use it every time you start a new print or try a new material. This will help you get better results and avoid common problems.

You should pick the right nozzle temperature for each material and your workspace. Try out different temperatures to see what works best for your printer. Use calibration tools, like temperature towers, to help you test. If you see problems, make small changes and watch what happens. Look at the quick reference table and material tips when you use a new filament.

Remember: Making careful changes helps you get strong and smooth 3D prints every time.

FAQ

What happens if you print at the wrong nozzle temperature?

You may see weak layers, stringing, or clogs. Prints can look rough or not stick to the bed. Always check your print for these signs and adjust the temperature as needed.

How do you know the best nozzle temperature for a new filament?

Print a temperature tower. This test shows how your filament behaves at different temperatures. Pick the section that looks smooth and strong. Use that temperature for your prints.

Can you use the same nozzle temperature for all brands of filament?

No. Each brand may need a different temperature. Always check the label or the manufacturer’s website. Start with their suggestion, then adjust by 5°C if you see problems.

Why does room temperature affect 3D printing?

Room temperature changes how fast your print cools. Cold rooms can cause warping or poor layer bonding. Warm rooms help layers stick better. Try to print in a stable, warm space for best results.