You achieve smooth results when you use at least 3 top layers for your 3D print top layers. Top layers cover inner structures and boost surface quality and strength. The best count depends on layer height, material, and print speed. Adjust slicer settings for your best finish.

Key Takeaways

- Use 3 to 5 top layers for smooth and strong 3D prints. Adding more layers helps cover infill patterns. This also makes the surface look better.

- Change your slicer settings for layer height and infill percentage. More infill gives better support to top layers. This stops gaps from forming.

- Try different layer heights and print speeds. Thin layers make prints smoother. But thin layers take more time to print.

3D Print Top Layers and Surface Smoothing

Top Layer Count for Quality Prints

You create the final surface of your print with the 3d print top layers. These layers cover the infill and give your model its finished look. If you want a smooth and strong top, you need to choose the right number of top layers. Most slicer software lets you set this value. For many prints, using 3 to 5 top layers gives you the best quality.

- More top layers help hide the infill pattern and prevent gaps.

- Fewer top layers can lead to visible lines, holes, or weak spots.

- Increasing the number of top layers improves smoothing and makes the surface look better.

Tip: If you see lines or holes on the top of your print, try adding more top layers in your slicer settings.

You should also think about how the number of 3d print top layers affects print time and material use. More top layers mean longer print times and more filament. However, the extra time and material often lead to much better quality and smoothing.

Smoothing and Preventing Gaps

Smoothing the top of your print depends on both the number of top layers and the support underneath. The infill acts as a base for the 3d print top layers. If you use a low infill percentage, the top layers may sag or show gaps. A higher infill percentage gives better support, which helps the top layer stay flat and smooth.

When you print with enough top layers and proper infill, you prevent holes and gaps. The top layer covers the infill pattern and creates a solid, smooth finish. If you see gaps, increase the infill percentage or add more top layers. This adjustment improves the quality and smoothing of your print.

- Higher infill percentages support the top layer and help with smoothing.

- Lower infill can cause gaps and weak spots in the top surface.

- Always check your slicer preview to see if the top layers cover the infill well.

Layer Height and Top Layer Thickness

The thickness of your 3d print top layers depends on the layer height you choose. Layer height is the thickness of each printed layer. Thinner layers give you better smoothing and higher quality, but they take longer to print. Thicker layers print faster but may show more lines on the top surface.

To get the best quality, you should make the total thickness of your top layers at least 1 to 1.2 mm. You can calculate the number of top layers by dividing this thickness by your chosen layer height. For example:

- If you use a 0.2 mm layer height: 1 mm / 0.2 mm = 5 top layers

- If you use a 0.28 mm layer height: 1 mm / 0.28 mm ≈ 4 top layers

Note: Always round up to the next whole number to make sure you have enough coverage.

Here is a quick reference table for slicer settings:

|

Layer Height (mm) |

Recommended Top Layers |

Total Top Layer Thickness (mm) |

|---|---|---|

|

0.1 |

10-12 |

1.0-1.2 |

|

0.2 |

5-6 |

1.0-1.2 |

|

0.28 |

4-5 |

1.1-1.4 |

Choosing a smaller layer height improves the smoothing of your 3d print top layers. Thinner layers reduce the step effect and make the top surface look more polished. If you use a larger nozzle, you may need to add more top layers to get the same quality.

- Smaller nozzles let you use thinner layers for better smoothing.

- Larger nozzles print faster but may need extra top layers for a smooth finish.

Remember: Wall thickness also affects the strength and quality of your print. Keep it above 0.8 mm for most projects.

You can adjust these settings in your slicer to match your needs. Try different combinations to find the best balance between print time, material use, and surface quality. Always check your print preview to make sure your top layer will cover the infill and give you the smoothing you want.

Top Layer Settings and 3D Printing Troubleshooting

Adjusting Top Layer Settings for Different Materials

You should change top layer settings for each material. PLA prints best at 190°C to 220°C. ABS needs more heat, from 240°C to 270°C, so it does not warp and stays strong. PETG works better if you print slower, under 60 mm/s. This helps the surface look nice and stick together. Lowering the layer height and slowing the speed can make prints smoother. Using a smaller nozzle gives more detail, but takes longer to print. Always check your printer’s shells and top layer thickness to fit your material.

- PLA: Needs lower heat, thin layers, smooth finish.

- ABS: Needs higher heat, thick shells, strong parts.

- PETG: Needs slow speed, steady shells, smooth top.

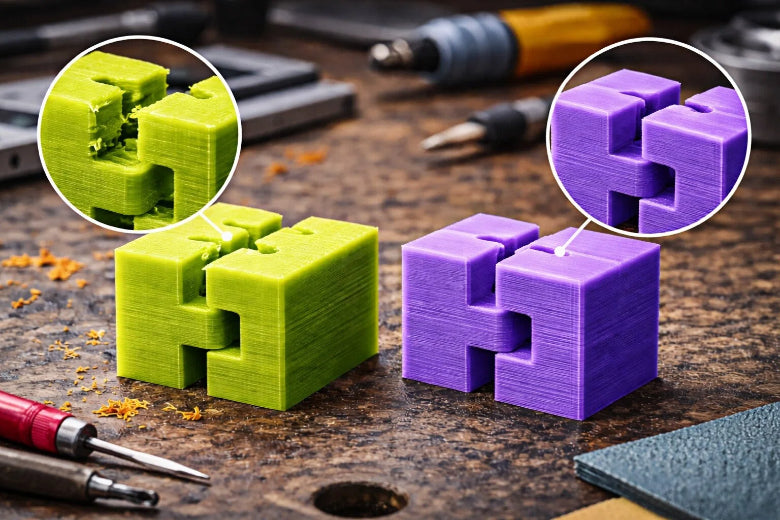

Common Top Layer Problems and Solutions

You might see holes, weak tops, or rough spots. Try these ways to fix them:

- Add more top layers in your slicer. This covers holes and makes the part stronger.

- Use more infill to help the top layer. Going from 30% to 50% infill gives better shells and smoother tops.

- Fix under-extrusion by checking if the filament moves well and the nozzle is clear.

- Change the cooling fan to stop dents and rough spots.

- Turn on ironing in your printer settings for a smoother top.

If your top layer is rough, check the heat and fan settings. Slowing down the print can also help make it smoother.

Optimizing 3D Printing Settings for Smooth Tops

You can get smoother tops by following these tips:

- Set ironing to only the very top layer.

- Adjust flow, speed, and line spacing for the best look.

- Use 4 to 6 shells for strong tops and tough parts.

- Make the extrusion width up to 140% for better sticking, but do not go higher or the top may get rough.

- Change infill density and pattern to support the top layer.

A table of common issues and fixes:

|

Issue |

Smoothing Solutions |

|---|---|

|

Gaps in top layer |

Add more shells, increase infill |

|

Weak top layer |

Raise top layer thickness, check extrusion |

|

Rough surface |

Lower speed, adjust cooling, use ironing |

You can also sand the top a little to make it even smoother.

You get smooth results by using 3 to 5 layers and adjusting slicer settings. Try smaller layers for better surface quality. Lower print speed and test partial prints before large projects.

|

Setting |

Recommendation |

|---|---|

|

Print Speed |

|

|

Layer Height |

0.1–0.2 mm |

- Sand, prime, or use a heat gun for smoother layers.

- Experiment with layers and infill for strong tops.

FAQ

How do top layers affect the strength of my 3D print?

You increase strength by adding more top layers. These layers cover the infill and help your print resist pressure. You get better strength and smoothing with proper settings.

What is the best way to improve smoothing on the top surface?

You achieve smoothing by using more top layers and a higher infill percentage. You also get better smoothing by lowering layer height and adjusting print speed for strength.

Can I use fewer top layers if I want faster prints?

You can use fewer top layers, but you lose strength and smoothing. Thin tops may show gaps. You should balance print speed with strength and smoothing for best results.