If you hear 3d printer clicking during a print, you probably notice rough layers or gaps in your models. Clicking often means your extruder can’t push filament smoothly. The most common causes of extruder clicking include a clogged nozzle, low temperature, or filament feed trouble. Sometimes, mechanical issues like loose gears or worn parts also lead to clicking. The extruder pulls and pushes filament, so any resistance or blockage makes it click or skip. These causes of extruder clicking can ruin prints fast. For quick troubleshooting, always check the filament path and listen for unusual clicking sounds.

Key Takeaways

- Clicking noises usually mean the extruder struggles to push filament smoothly, often due to low nozzle temperature, clogs, or filament feed problems.

- Check and adjust extruder tension carefully to avoid slipping or crushing the filament, which causes clicking and print issues.

- Keep the nozzle and Bowden tube clean and free of blockages by regular maintenance and cleaning to ensure smooth filament flow.

- Lower print speed and properly level the bed to help the extruder feed filament without skipping steps or clicking.

- Use dry, high-quality filament and store it well to prevent moisture and damage that lead to extrusion problems.

- 3D Printer Clicking

When you hear a clicking noise from your 3D printer, it usually means something is stopping the filament from moving smoothly. This clicking can show up as under-extrusion, rough layers, or even failed prints. Let’s break down the most common causes of extruder clicking and what you can do to fix them.

3D Printer Extruder Clicking

You might notice 3d printer extruder clicking when the extruder motor struggles to push filament through the hotend. This happens for several reasons:

- The nozzle temperature is too low, so the filament doesn’t melt enough. When the filament stays too solid, the extruder has to work harder, and you hear that clicking noise.

- The filament path has resistance. This could be from a partial clog in the nozzle, debris in the extruder gears, or even a kink in the Bowden tube.

- The extruder tension is off. If the spring is too tight or too loose, the extruder gear can’t grip the filament properly, causing it to slip and click.

- Filament diameter inconsistencies. If your filament is thicker than 1.75mm or varies in size, the extruder may struggle to feed it, leading to clicking and filament extrusion inconsistencies.

Tip: If you hear 3d printer clicking, stop the print and check the extruder right away. Ignoring it can lead to bigger problems like clogs or even damage to the extruder motor.

Here’s what you can do:

- Increase the temperature of your nozzle to make sure the filament melts fully. For PLA, try between 200°C and 230°C.

- Clean the nozzle and extruder gears. Use a brush or compressed air to remove dust and debris.

- Adjust the extruder tension. Make small changes and test until the filament feeds smoothly.

- Measure your filament diameter with calipers. If it’s inconsistent, try a different spool or adjust your slicer settings.

Filament Feed Issues

Filament feed issues are a top reason for 3d printer clicking. If the filament can’t move freely, the extruder will click or skip steps. Here are some common problems:

- The filament has been chewed by the extruder gear, creating flat spots that make feeding harder.

- Dust or debris inside the extruder or nozzle increases resistance.

- The filament is damp or brittle, which can cause jams or breakage.

- Loose screws on the extruder lever arm reduce pressure, so the gear slips instead of pushing the filament.

To fix these issues:

- Disassemble and clean the extruder gears and bearings. Use a small brush or compressed air.

- Perform a cold pull to clear out any clogs in the nozzle.

- Tighten the screws that control the extruder’s pressure on the filament.

- Store filament in a dry box or sealed bag with desiccant to prevent moisture problems.

Note: If you notice under-extrusion or hear a clicking noise during extrusion or retraction, check for filament jams or broken pieces inside the extruder.

Print Speed and Bed Leveling

Print speed and bed leveling also play a big role in 3d printer clicking and skipping steps. If you print too fast, the extruder may not keep up with the required filament flow, especially if the nozzle temperature is too low. This can cause under-extrusion and clicking.

Improper bed leveling can make things worse. If the nozzle is too close to the bed, the filament can’t come out easily, and the extruder will skip steps or click. This is especially common during the first layer.

Here’s how you can solve these issues:

- Decrease the print speed if you notice clicking or under-extrusion. Slower speeds give the filament more time to melt and flow.

- Level the printing bed carefully. Make sure the nozzle is at the right height, not too close or too far from the bed.

- Run a temperature tower test to find the best nozzle temperature for your filament. This helps prevent both under-extrusion and stringing.

If you keep hearing a clicking noise or see under-extrusion on the first layer, double-check your bed leveling and nozzle height.

By understanding the causes of extruder clicking and taking these troubleshooting steps, you can keep your 3D printer running smoothly and avoid most common print failures.

Nozzle Blockage

Identifying Nozzle Clogs

Nozzle blockage is one of the most common reasons your 3D printer starts clicking or skipping steps. When the extruder tries to push filament through a clogged nozzle, you might notice some clear warning signs:

- Erratic extrusion during printing

- Abrupt halts in material flow

- Diminished print quality

- Filament comes out thinner than normal

- Weak lines with poor layer adhesion

- Slower extrusion when loading filament

- Complete stoppage of filament extrusion

You might see a semi-clog, where the filament still comes out but looks weak and thin. A full clog means nothing comes out at all. If you hear the extruder clicking or skipping, always check for nozzle jams first. Sometimes, you can spot a blockage by watching the filament feed. If the extruder motor works hard but nothing moves, you probably have a clogged nozzle.

Some printers use sensors or even AI to detect nozzle jams early. These systems watch for changes in filament movement, spikes in motor current, or even strange sounds. If you notice any of these signs, pause your print and inspect the nozzle right away.

Tip: If you see under-extrusion or hear clicking, check the nozzle before changing other settings.

Cleaning and Prevention

You can fix most nozzle blockages with a few simple steps. Always wear gloves and safety glasses before you start. Here’s how you can clean or replace the nozzle:

- Remove the nozzle and soak it in warm water for about 15 minutes.

- Use a soft brush and a bit of detergent to scrub away any residue.

- Soak the nozzle again in the cleaning solution for another 5–10 minutes.

- Rinse with water and let it dry before reinstalling.

For stubborn clogs, try a nozzle cleaning drill or the cold pull method. Push cleaning filament through the heated nozzle, then let it cool and pull it out to remove debris.

To prevent future nozzle jams, follow these tips:

- Inspect and trim the PTFE tube regularly so it fits flush with the nozzle.

- Use high-quality filament and store it dry.

- Clean the nozzle exterior with a brass brush while the printer is hot.

- Avoid sudden temperature changes during printing.

- Set a routine maintenance schedule for your printer.

Regular cleaning and inspection help you avoid most blockage problems and keep your prints looking great.

Solving Extruder Clicking Problems

When you want to stop extruder clicking for good, you need to look beyond just the nozzle and filament. Many times, the real trouble hides in the mechanical parts of your printer. Let’s walk through the most common mechanical causes and how you can fix them for smoother prints and fewer headaches.

Extruder Tension Adjustment

Getting the right extruder tension is one of the most important steps in solving extruder clicking problems. If the tension is off, your printer can’t grip the filament correctly. Too much tension crushes the filament, causing extra resistance and making the stepper motor skip steps. Too little tension means the gear can’t grab the filament, so it slips and you hear clicking or see under-extrusion.

Here’s a simple way to adjust extruder tension:

- First, check for any obvious extrusion issues. Look for blockages, dirty gears, or a worn Bowden tube.

- Extrude some filament and inspect it. If you see deep grooves or crushed spots, the tension is too high. If you barely see gear marks, the tension is too low.

- Adjust the tension screw in small steps. For most printers, the screw should stick out less than 1mm.

- Test with different filaments. Flexible filaments like TPU need less tension to avoid buckling.

- Run a few extrusion tests. You want the gear to grip the filament just enough to avoid stripped filament but not so much that it deforms.

- If you still hear clicking or see under-extrusion, check the drive gear alignment and make sure nothing blocks the filament path.

Tip: Proper tension helps prevent both under-extrusion and clicking. Always check tension after changing filament types or cleaning the extruder.

Here’s a quick table to help you spot tension problems:

|

Tension Setting |

What You See on Filament |

What Happens During Print |

|---|---|---|

|

Too Low |

Barely visible marks |

Filament slips, under-extrusion, clicking |

|

Too High |

Deep grooves, crushed |

Stripped filament, clicking, jams |

|

Just Right |

Faint gear marks |

Smooth filament flow, no clicking |

Gear and Motor Checks

Sometimes, the extruder clicking comes from gear slippage or motor problems. If the drive gear or idler wheel is loose, the extruder can’t push the filament properly. You might hear a “clunk” or “dnk dnk dnk” sound, or see the motor shaft move backward during extrusion. These are signs that the gear is slipping or the motor is skipping steps.

Here’s what you should check:

- Make sure all set screws on the drive gear and motor shaft are tight.

- Inspect the gear teeth for wear or debris. Clean them with a small brush.

- Listen for unusual noises from the stepper motor. Overheating or inconsistent movement can mean the motor needs attention.

- Check the wiring and connectors for any loose or damaged parts.

- If you have a control board with a display, watch for alarms or error codes.

- Test the motor by rotating it by hand (with the printer off). It should move smoothly without binding.

Regular maintenance keeps your extruder running strong. Here’s a simple maintenance schedule:

|

Frequency |

What to Check or Do |

|---|---|

|

Daily |

Listen for odd noises, check motor temperature, clean fans |

|

Weekly |

Inspect gears for wear, tighten bolts, check oil if needed |

|

Monthly |

Clean motor housing, check for dust, record temperatures |

|

Quarterly |

Inspect for vibration, check alignment, clean inside covers |

Note: Always power off your printer before working on the extruder or motor. Safety first!

Bowden Tube Maintenance

A blocked or damaged Bowden tube can cause all sorts of extrusion issues, including clicking, skipping steps, and under-extrusion. The Bowden tube guides the filament from the feeder to the hotend. If it gets dirty, kinked, or pulled out of place, the filament flow slows down or stops. You might notice flakes near the extruder gear or have trouble pushing filament through by hand.

To keep your Bowden tube in top shape:

- Regularly inspect the tube for kinks, bends, or signs of wear.

- Remove the tube and clean it every couple of months. Push a small piece of sponge or cloth through the tube using a spare filament strand to clean the inside.

- Make sure the tube fits snugly into the couplers. Gaps can trap dirt or let the tube melt, causing blockages.

- Replace the PTFE couplers if they look worn or loose.

- Store your filament properly to avoid moisture, which can lead to clogs inside the tube.

- Keep the cooling fan working well to prevent heat from creeping up the tube and melting the filament too soon.

If you notice under-extrusion, clicking, or low feeder settings, always check and clean the Bowden tube first. This simple step can save you from bigger problems later.

Quick Troubleshooting Checklist

- Do you hear clicking or see under-extrusion? Check extruder tension and gear alignment.

- Is the filament hard to push or does it look stripped? Clean the Bowden tube and inspect for blockages.

- Does the motor feel hot or make strange noises? Check wiring, tighten screws, and inspect for wear.

Regular maintenance and careful troubleshooting help you avoid most extruder clicking issues. When you take care of your printer’s mechanical parts, you get smoother filament flow, fewer print failures, and better results every time.

You can solve most 3D printer clicking and skipping issues by checking a few key areas. Start with these main causes:

- Print speed too high or nozzle temperature too low.

- Blocked or loose Bowden tube and filament path.

- Clogged hot end or nozzle.

- Faulty extruder tension or dirty gears.

- Nozzle too close to the bed.

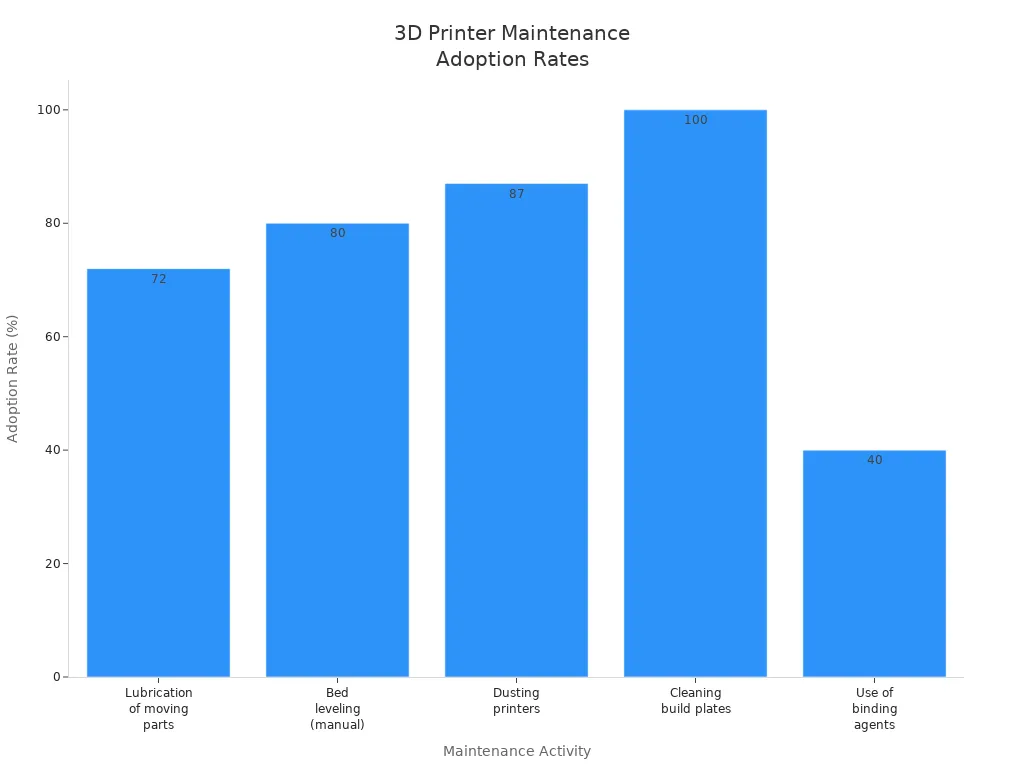

Keep your extruder clean and adjust tension as needed. Always use dry, high-quality filament. Regular maintenance makes a big difference. Check out how common routines help:

|

Maintenance Activity |

Adoption Rate |

Impact on Print Quality |

|---|---|---|

|

Cleaning build plates |

Better first layer adhesion |

|

|

Dusting printers |

87% |

Fewer particles in prints |

|

Bed leveling (manual) |

80% |

Smoother first layers |

|

Lubrication of moving parts |

72% |

Prevents mechanical failures |

Stay on top of your extruder, nozzle, and filament checks. You’ll get smoother prints and avoid most clicking problems.

FAQ

Why does my 3D printer make a clicking noise during printing?

You usually hear clicking when the extruder struggles to push filament. This can happen if the nozzle is clogged, the temperature is too low, or the filament path has resistance. Check these areas first to fix the problem.

How do I know if my nozzle is clogged?

You might see weak or thin extrusion, or nothing comes out at all. The extruder may click or skip. Try a cold pull or remove the nozzle to check for blockages.

What should I do if my extruder keeps skipping steps?

First, lower your print speed and increase the nozzle temperature. Check the extruder tension and clean the gears. Make sure the filament moves smoothly through the Bowden tube.

Tip: Always listen for new noises. They often warn you about mechanical issues before a print fails.

How can I prevent clicking and skipping in the future?

Keep your printer clean and well-maintained. Use dry, high-quality filament. Regularly check the extruder, nozzle, and Bowden tube for wear or debris. Adjust tension when you change filament types.