Advanced modeling for large-scale 3D printing unlocks strong, precise, and efficient results. Large-scale 3d printing allows users to create massive parts in one build, but it demands careful planning. The Sovol SV08 Max stands out as a powerful tool for handling these projects. Designers use digital workflows to move from concept to finished product, often adopting sustainable technologies. Large-scale 3d printing continues to push boundaries as engineers refine techniques for accuracy and durability. Many experts see large-scale 3d printing as the future of custom manufacturing.

Key Takeaways

- Large-scale 3D printing enables creating big, strong parts in one piece, saving time and reducing waste compared to traditional methods.

- Design for Additive Manufacturing (DfAM) helps engineers optimize models for better print quality, strength, and material use by focusing on print orientation, wall thickness, and internal lattice structures.

- Splitting large models into smaller parts through model segmentation allows printing beyond size limits and improves surface finish and assembly quality.

- Combining 3D printing with traditional machining in hybrid manufacturing produces precise, strong parts faster and supports complex designs.

- Careful process planning, including printer calibration and slicing strategies, ensures consistent quality and reduces errors in large-scale prints.

- Choosing the right materials like PLA, ABS, or PETG affects part strength, flexibility, and heat resistance, so material selection must match the project needs.

- Real-time print monitoring with AI and sensors helps catch defects early, saving time and materials while improving reliability.

- Post-processing steps such as sanding, filling, and coating enhance the appearance and durability of printed parts, making them ready for real-world use.

Large-Scale 3D Printing

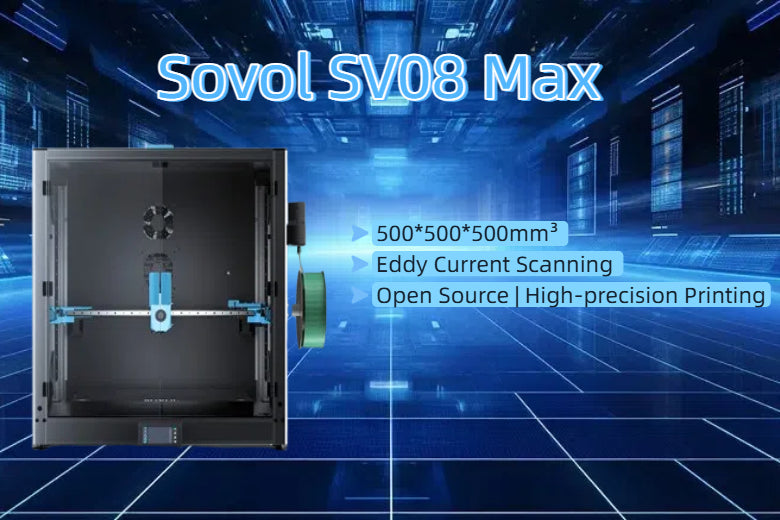

Large-scale 3d printing has transformed how designers and engineers approach manufacturing. Machines like the Sovol SV08 Max allow users to create large, complex parts in a single build. This technology reduces assembly steps and improves the strength of finished parts. The impact of large-scale 3d printing reaches many sectors, from aerospace to construction, by enabling new designs and faster production.

Opportunities

Large-scale 3d printing opens new possibilities for manufacturers and designers. The ability to print big parts in one piece means fewer joints and stronger structures. The Sovol SV08 Max, with its 500x500x500mm build volume, supports batch printing and high precision, which saves time and materials. Many industries now see the value of large-scale 3d printing in reducing costs and speeding up production.

Market Growth Highlights:

- The global 3D printing market reached $13.84 billion in 2021 and is expected to grow at a 20.8% CAGR through 2030.

- Industrial printers made up over 70% of market revenue in 2021, showing the importance of large-scale 3d printing.

- The automotive, aerospace, and medical sectors will account for 51% of the global 3D printing industry by 2025.

- Over 70% of businesses found new uses for 3D printing by 2019, and 79% plan to increase output in the next five years.

The Sovol SV08 Max also offers automation and user-friendly controls, which lower labor costs. In-house production with large-scale 3d printing leads to long-term savings and more control over the quality of parts.

Challenges

Despite its benefits, large-scale 3d printing presents several challenges. Maintaining quality and consistency across large parts requires strict quality control and regular equipment maintenance. Material limitations can affect part performance, especially when environmental factors come into play. Design optimization for large-scale 3d printing demands new skills and training.

|

Challenge Category |

Description |

Quantifiable Impact |

|---|---|---|

|

Quality and Consistency |

Need for quality control and documentation |

Affects defect rates and rework |

|

Material Limitations |

Environmental factors impact material performance |

Performance variability |

|

Scaling Production |

In-house vs. service bureau, automation, management software |

70% reduction in tooling costs, 85% decrease in lead time for tooling |

|

Sustainability |

Energy-intensive processes, limited recyclability, lifecycle assessment |

Sustainability remains a concern. Large-scale 3d printing uses significant energy, and recycling options for some materials are limited. Lifecycle assessments show trade-offs between energy use and part performance.

Applications

Large-scale 3d printing supports a wide range of applications in industry. Aerospace companies like Boeing and Airbus use it to produce lighter, stronger parts, cutting lead times from months to hours. Construction firms print entire buildings, reducing waste and labor. Automotive manufacturers create custom tools and fixtures, while healthcare providers print patient-specific models for surgery.

|

Industry |

Company/Project |

Application & Impact |

|---|---|---|

|

Aerospace |

Boeing |

Reduced lead times for rotor system parts; consolidated parts; weight reduction; less waste and fuel use. |

|

Construction |

ICON |

3D-printed homes with low-carbon materials; faster, eco-friendly construction. |

|

Automotive |

Ford, BMW, Audi |

Custom tools and fixtures; lightweight robot grippers; improved flexibility and speed. |

|

Healthcare |

Mayo Clinic, MIT |

Patient-specific anatomical models; faster design and production; better surgical outcomes. |

|

Fashion |

Adidas |

3D-printed midsoles for shoes; improved fit and cushioning. |

BigRep’s technology allows full-size furniture prototypes in days instead of months. The Sovol SV08 Max enables users to print large-format parts for retail displays, superyachts, and more. These examples show the broad value of large-scale 3d printing and its growing role in modern manufacturing.

Advanced Modeling for Large-Scale 3D Printing

DfAM Principles

Design for Additive Manufacturing (DfAM) forms the foundation of advanced modeling for large-scale 3d printing. DfAM guides engineers to create models that maximize the strengths of additive processes. These principles help designers achieve higher print accuracy, better surface quality, and efficient use of materials. When working with large 3d printed parts, DfAM ensures that models are not only printable but also optimized for function and aesthetics.

Key DfAM principles include:

- Print Orientation: The orientation of a model during printing has a major impact on accuracy and finish. The top side of a part often shows the best results because the printer deposits material directly, reducing contact with powder or supports.

- Wall Thickness and Placement Tolerances: Proper wall thickness prevents warping and ensures strength. Placement tolerances help parts fit together after printing.

- Lattice Structures: These internal patterns reduce weight while maintaining strength.

- 15° Orientation Rule: Surfaces printed at angles less than 15° show fewer stair-step effects, improving finish.

Print orientation and wall thickness play a critical role in achieving precise 3d printed parts. Surfaces in the X-Y plane are more accurate than those along the Z axis. Designers use the 15° rule to balance aesthetics and accuracy, especially for large models.

Recent studies confirm the need for advanced modeling for large-scale 3d printing:

- Dimensional accuracy issues in 3d printed parts can affect fit and function, so precise measurement and control are essential.

- Metrology methods like coordinate metrology and computed tomography help quantify deviations and surface quality.

- Statistical design of experiments (DOE) methods, such as the Taguchi L9 orthogonal array, identify key parameters like print speed that influence surface roughness.

- AI and machine learning now accelerate materials optimization, moving beyond trial-and-error.

- Finite Element Analysis (FEA) simulations predict material properties and failure modes, allowing for better design and process choices.

- Combining statistical methods, AI, and FEA creates a robust modeling framework, confirming the necessity of advanced modeling for large-scale 3d printing.

These DfAM techniques help engineers produce reliable, high-quality 3d printed molds and parts at scale.

Topology Optimization

Topology optimization stands out as a powerful tool in advanced modeling for large-scale 3d printing. This technique uses algorithms to remove unnecessary material from models while preserving strength and function. Engineers apply topology optimization to create lightweight, efficient parts that meet strict performance requirements.

The process begins with a digital model. Software analyzes the model under simulated loads and constraints. The algorithm then suggests ways to reduce material without sacrificing safety or durability. This approach leads to innovative shapes that traditional manufacturing cannot produce.

- Aerospace engineers have achieved up to 30% material reduction in turbine brackets, making parts lighter and improving fuel efficiency.

- Automotive designers report 30-40% less material in vehicle brackets and suspension components, while maintaining strength and safety.

- Medical teams use topology optimization for mandibular reconstruction plates, cutting volume by 44.9% but keeping mechanical properties intact.

- Simulations of L-shaped beams show reduced stress concentrations and high stiffness after optimization.

|

Application Area |

Description |

Material Reduction |

Strength/Performance Outcome |

|---|---|---|---|

|

Mandibular Reconstruction |

Seebach et al. achieved volume reduction in plates while ensuring stability, stiffness, durability |

44.9% |

Maintained sufficient stability, stiffness, and durability |

|

Aerospace Turbine Brackets |

Topology optimization reduced material usage in turbine brackets |

~30% |

Maintained or improved strength and fuel efficiency |

|

Automotive Suspension Parts |

Use of topology optimization in vehicle brackets |

30-40% |

Components remain tough and improve fuel efficiency |

|

L-shaped Beam Simulation |

Stress-constrained topology optimization refined design to reduce stress concentrations |

Not specified |

Final design shows sufficient strength and high stiffness |

Engineers use topology optimization to create 3d printed molds and parts that are both strong and resource-efficient. This method supports sustainability by reducing waste and energy use in large-scale projects.

Lattice Structures

Lattice structures represent a key innovation in advanced modeling for large-scale 3d printing. These repeating internal patterns replace solid infill, making parts lighter without losing strength. Designers use lattice structures to improve the performance of 3d printed parts in demanding applications.

Lattice structures offer several advantages:

- High strength-to-weight and stiffness-to-weight ratios due to efficient axial load transfer.

- Improved energy absorption and fatigue strength, which are critical for aerospace and automotive parts.

- Customizable mechanical properties by adjusting unit cell size, shape, and density.

- Recent engineering tests show that lattice structures deliver reliable results:

- Mechanical properties such as energy absorption, yield point, and critical force have been measured for different lattice types.

- Tensile lattice structures provide higher strength and stiffness, while bending types absorb more energy.

- Additive manufacturing methods like stereolithography (SLA) enable precise fabrication of complex lattice geometries with controlled unit cell structures.

- Experimental studies confirm that printed lattice structures show minimal dimensional deviations (less than 0.5%) and uniform unit cell printing, which boosts print accuracy and reliability.

- The relative density of the lattice and the material’s properties influence how the part behaves under load.

Lattice structures allow engineers to replace solid parts with lighter, optimized models. This approach reduces material use and improves performance, making it ideal for industries that demand both strength and efficiency.

Lattice structures have become essential in advanced modeling for large-scale 3d printing. They help engineers create parts that meet strict requirements for weight, strength, and durability. These techniques support the production of high-performance 3d printed parts and models for aerospace, automotive, and medical applications.

Model Segmentation

Model segmentation plays a critical role in advanced modeling for large-scale 3d printing. Designers often face size limitations with printers, so they must split large models into smaller, manageable parts. This approach allows for the fabrication of complex 3d printed parts that would otherwise exceed the build volume of most machines.

A modern segmentation workflow uses deep learning to analyze 3D mesh models. The process extracts features like surface quality, support structure needs, and normal curvature. By pre-segmenting large or intricate models into sub-graphs, engineers reduce clustering complexity and improve feature extraction. A Stacked Auto-encoder (SAE) then learns hidden features that represent important printing characteristics. Affinity Propagation clustering determines the best number of clusters, dividing the model into parts that can be printed with optimal orientations.

Segmentation not only makes large-scale printing possible but also improves the quality of 3d printed parts. By fitting planar interfaces between adjacent parts, designers create smooth surfaces that fit together well during assembly.

Case studies on models such as airplanes, chairs, and fish show that this method enhances surface quality and reduces the need for support material. Experimental results confirm that segmentation enables the printing of large-scale parts in smaller pieces, resulting in better surface finish and easier assembly. This technique directly improves the assembly quality of 3d printed molds and finished products.

Key steps in model segmentation for large-scale 3d printing:

- Analyze the 3D mesh to extract features relevant to printing.

- Pre-segment the model into sub-graphs to simplify clustering.

- Train a deep learning model (SAE) to identify hidden features.

- Use clustering to divide the model into printable parts.

- Optimize interfaces for smooth assembly and minimal support.

Model segmentation stands as a cornerstone of advanced modeling for large-scale 3d printing. It enables the production of large, complex 3d printed parts and 3d printed molds with high assembly quality and surface finish.

Hybrid Manufacturing

Hybrid manufacturing combines additive and subtractive techniques to unlock new possibilities in advanced modeling for large-scale 3d printing. This approach merges the strengths of 3D printing with traditional CNC machining, allowing manufacturers to produce parts that meet strict requirements for strength, precision, and complexity.

Companies like Curtiss Motorcycle Company have demonstrated the power of hybrid manufacturing. They use multi-axis CNC machining for large, structural parts and additive manufacturing for smaller, intricate components. This integration leads to stronger parts, higher operational efficiency, and faster product delivery—sometimes in as little as 12 days. Additive manufacturing enables cost-effective fabrication of complex geometries, while subtractive methods ensure consistent strength and tight tolerances, especially for metal parts.

In medical manufacturing, hybrid workflows allow the creation of complex 3d printed parts with a balance of speed, accuracy, and cost-effectiveness. Advanced planning and scheduling systems help coordinate both additive and subtractive processes, boosting efficiency and quality. This integration supports the production of high-performance 3d printed molds and end-use parts that meet demanding industry standards.

Hybrid manufacturing future-proofs production by combining the flexibility of 3D printing with the reliability of CNC machining. Manufacturers gain the ability to fabricate innovative parts that would be impossible with either method alone.

Hybrid manufacturing stands as a vital technique in advanced modeling for large-scale 3d printing. It enables the creation of parts with complex shapes, superior strength, and precise dimensions, supporting industries from aerospace to healthcare.

3D Printing Techniques

Slicing Tactics

Slicing tactics form the backbone of successful large-scale 3D printing. Slicing software converts digital models into layers and generates the toolpaths that guide the printer. For large-format projects, engineers must optimize slicing parameters to balance speed, resolution, and material use.

Several quantitative studies highlight how slicing tactics influence print resolution and quality:

- Extrusion-based 3D printing achieves about 100 microns resolution, with needle diameter, print head velocity, and extrusion pressure as key factors.

- Selective laser sintering (SLS) reaches 20–100 microns resolution but prints more slowly.

- Stereolithography (SLA) offers sub-100 micron resolution in all dimensions by exposing entire layers at once.

- Inkjet printing delivers high resolution for small features but lacks strength for large structures.

- Researchers emphasize optimizing slicing and printing parameters to improve fidelity and reproducibility, using factorial design experiments to characterize materials and conditions.

- Multi-material printing and printability characterization remain challenging, directly tied to slicing tactics and layer deposition strategies.

Recent advances in continuous liquid interface production (CLIP) show that dynamic slicing optimization and photopolymer formulation can achieve single-digit micrometer resolution. For example, a 30 µm pixel size CLIP printer improved print resolution by refining slicing strategies and printing parameters, reducing feature size and surface roughness.

Engineers use adaptive slicing, which varies layer height based on model geometry. Thicker layers speed up printing in less detailed areas, while thinner layers capture fine features. This approach reduces print time without sacrificing quality. Factorial design experiments help teams identify the best combination of speed, temperature, and extrusion settings for each material and geometry.

Tip: Adaptive slicing and parameter optimization are essential techniques for achieving high-quality, large-scale prints. Engineers should test different settings on small sections before committing to a full build.

Support Strategies

Support strategies play a crucial role in large-scale 3D printing. Large models often require extensive support structures to prevent sagging, warping, or collapse during printing. However, excessive supports increase material use and post-processing time.

Engineers select support types based on model geometry and overhang angles. Tree-like supports minimize contact with the part, making removal easier and reducing surface blemishes. Grid or linear supports provide more stability for heavy or complex sections. The choice of support density and pattern affects both print success and ease of cleanup.

Best practices for support strategies include:

- Orienting the model to minimize overhangs and unsupported spans.

- Using custom support blockers or modifiers in slicing software to target only critical areas.

- Adjusting support interface layers to balance adhesion and removability.

- Testing support removal on prototypes to refine settings before large-scale production.

Support placement also impacts surface finish. Placing supports on less visible surfaces or internal cavities helps preserve the appearance of critical areas. Engineers often combine manual and automatic support generation to achieve the best results.

Note: Efficient support strategies reduce material waste and post-processing time, improving the overall efficiency of large-scale 3D printing techniques.

Build Orientation

Build orientation directly affects print quality, structural integrity, and material use. Engineers must carefully choose the orientation that balances support requirements, surface finish, and mechanical strength.

Statistical data shows that different build angles (0°, 45°, 90°) significantly impact support density, dimensional accuracy, and distortion. The 45° orientation often provides the best trueness and fit. At 0°, models require more supports due to large horizontal layers, leading to greater distortion and poor adaptation in critical areas. The 90° orientation increases the number of layers, which correlates with higher dimensional errors.

The staircase effect, which causes visible layer lines, depends on both build orientation and layer thickness. Optimizing the build angle, especially at 45°, reduces this effect and improves surface accuracy. Support structure placement on the cameo surface enhances trueness, but removing supports can cause distortion at attachment points.

|

Orientation |

Support Density |

Dimensional Accuracy |

Distortion |

Surface Finish |

|---|---|---|---|---|

|

0° |

High |

Low |

High |

Poor |

|

45° |

Moderate |

High |

Low |

Good |

|

90° |

Low |

Moderate |

Moderate |

Fair |

Comparisons between SLA and DLP technologies reveal that at 45°, SLA achieves better accuracy. Printing starting points and separation forces also vary with build angle, influencing warping and dimensional accuracy.

Pro Tip: The 45-degree rule stands as a proven guideline for large-scale 3D printing. This orientation balances support needs, minimizes the staircase effect, and improves both print quality and structural strength.

Engineers should document orientation choices and outcomes for each project. This practice builds a knowledge base that supports continuous improvement in 3d printing techniques.

Process Planning

Process planning stands as the backbone of successful large-scale 3D printing. Engineers must map out every step, from digital model preparation to final print execution. This careful planning ensures that each print meets quality standards, uses resources efficiently, and avoids costly errors.

A robust process plan starts with a clear understanding of the model’s geometry, material requirements, and printer capabilities. Engineers analyze the digital file, identify potential problem areas, and select the best slicing and support strategies. They also determine the optimal build orientation, which directly affects print time, surface finish, and structural strength.

Machine calibration plays a critical role in process planning. Accurate calibration ensures that the printer produces consistent results across large builds. Recent studies highlight several advanced calibration methods that improve reliability and predictability:

- Engineers use Latin Hypercube sampling with dozens of design points and multiple replicates to create robust calibration models.

- Gaussian process emulators help build predictive models, allowing teams to analyze uncertainty and sensitivity in the printing process.

- The inclusion of a ‘nugget’ variance term accounts for minor errors in computer code, making the calibration process more robust.

- Bayesian methods, such as Automatic Relevance Determination (ARD) and Sparse Bayesian Learning (SBL), help reduce the number of parameters, streamlining the calibration process.

- Statistical frameworks provide quantified uncertainty and sensitivity metrics, guiding parameter selection and improving prediction accuracy.

|

Aspect |

Quantified Outcome / Detail |

Relevance to Process Planning for Large-Scale Prints |

|---|---|---|

|

Printer Cost |

Demonstrates cost-effective calibration model scalable to large printers |

|

|

Calibration Method |

Statistical analysis used to optimize printing parameters |

Ensures consistent quality and supports parameter selection strategies |

|

Printing Parameters Optimization |

Quantified improvements in print quality and consistency |

Provides data-driven basis for process planning and parameter tuning |

|

Comparative Analysis |

Benchmarked against large-scale 3D printers |

Validates small-scale calibration as a proxy for large-scale process planning |

|

Application |

Cement-based materials with thermal property testing |

Supports material-specific process planning in construction 3D printing |

Engineers often use process planning checklists to ensure nothing gets overlooked. A typical checklist includes:

- Model analysis and repair

- Material selection and compatibility check

- Printer calibration and test prints

- Slicing parameter optimization

- Support and orientation strategy review

- Environmental controls (temperature, humidity)

- Print monitoring setup

Tip: Documenting each step in the process plan helps teams identify sources of error and improve future projects. Consistent record-keeping leads to better outcomes and faster troubleshooting.

Process planning also involves risk assessment. Engineers evaluate potential failure points, such as warping, layer separation, or material shortages. They develop contingency plans, like pausing the print for inspection or switching materials if needed.

In large-scale 3D printing, process planning must adapt to the unique challenges of size and complexity. Teams use statistical models and calibration data to predict outcomes and adjust parameters in real time. This data-driven approach reduces waste, improves print quality, and shortens production cycles.

By integrating advanced process planning with modern 3d printing techniques, engineers achieve reliable, high-quality results on even the most ambitious projects.

Design to Production

Material Selection

Material selection shapes the success of large-scale 3D printing projects. Engineers and designers must match material properties to the demands of each application. PLA, ABS, and PETG remain the most common choices for large-format fabrication. Each material offers unique strengths and limitations.

|

Property |

PLA |

ABS |

PETG |

|---|---|---|---|

|

Tensile Strength |

High (~7,250 psi) |

Moderate (~4,600 psi) |

High (~7,250 psi) |

|

Elongation at Break |

Low (6%) |

Moderate (20%) |

High (20-30%) |

|

Glass Transition Temp. |

Low (60-65°C) |

High (~105°C) |

Medium (85°C) |

|

Printing Temperature |

Low (200-220°C) |

High (220-250°C) |

Medium-High (220-260°C) |

PLA prints easily and delivers high accuracy, but it is brittle and not ideal for parts under stress. ABS provides better impact resistance and heat tolerance, though it requires higher temperatures and careful handling to prevent warping. PETG combines the strength of PLA with the flexibility of ABS, making it a versatile option for functional parts. Specialty materials, such as carbon fiber-reinforced filaments, expand possibilities for demanding industrial applications. Designers also consider environmental impact. PLA is biodegradable, while ABS and PETG are petroleum-based.

Software Tools

Digital tools drive the design to production workflow in additive manufacturing. Advanced software enables engineers to model, simulate, and optimize every stage of the process. NASA’s AM-PM software, for example, allows teams to model builds efficiently and detect potential issues before printing begins. This reduces risk and shortens time to market.

|

Metric Description |

Value/Statistic |

Impact on Adoption and Workflow |

|---|---|---|

|

Users employing six or more software tools |

Indicates a fragmented software landscape requiring multiple tools to manage AM processes. |

|

|

Adoption rate of integrated workflow management software |

29% |

Shows low usage of cohesive software solutions, highlighting a gap in streamlined AM workflow management. |

|

Agreement that better software would accelerate AM use |

88% |

Reflects strong user consensus on the need for improved software to boost AM adoption and efficiency. |

|

Most frequently used tools |

Shared data repositories, Excel, machine scheduling tools |

Demonstrates reliance on general-purpose tools rather than AM-specific integrated software. |

|

Desired software features |

Real-time tracking, industry-specific information |

Emphasizes the need for specialized software to improve process visibility and industry alignment. |

Most users rely on several different programs, from CAD and mesh repair tools to scheduling and data management platforms. Many seek better integration and real-time tracking to streamline production. Improved software can help teams reduce errors, manage supply chains, and deliver parts faster.

Calibration

Calibration ensures consistent quality in every print. Proper calibration aligns printer hardware and software, guaranteeing that each part matches design specifications. Teams use digital workflows to automate and speed up calibration tasks. Ricoh’s Auto Color Adjuster, for example, reduces profiling time from hours to minutes, allowing for frequent and precise adjustments.

|

Calibration Performance Statistic |

Description and Impact on Print Quality |

|---|---|

|

Precision in Color Matching |

Ensures brand consistency and accurate reproduction of intended colors, critical for aesthetic appeal and brand integrity. |

|

Consistency in Output Quality |

Guarantees uniform color and print quality across different print runs, reducing variability and errors. |

|

Real-Time Color Adjustments |

Enables immediate correction of color discrepancies during printing, maintaining color accuracy and reducing waste. |

|

Print Durability |

Accurate color matching contributes to longer-lasting prints that resist fading and wear. |

|

Workflow Optimization |

Streamlines production processes, ensuring consistent adherence to color standards and improving efficiency. |

Teams that integrate calibration into their digital workflow see improved print quality, reduced waste, and faster project turnaround. Calibration stands as a key step in moving from design to production in large-scale 3D printing.

Sustainability

Sustainability shapes every stage of large-scale 3D printing, from initial design to final production. Manufacturers and designers now face growing pressure to reduce energy use, cut waste, and lower emissions. The design phase holds the greatest influence over a product’s environmental footprint. Studies show that design decisions affect up to 80% of a product’s total cost and sustainability characteristics. By integrating sustainable practices early, teams can minimize downstream impacts and improve overall efficiency.

Many organizations use lifecycle assessment (LCA) to measure and manage environmental effects. LCA methods, such as those outlined in ISO 14000 standards, help teams estimate impacts across a product’s entire life—from raw material extraction to end-of-life disposal. Databases like the European reference Lifecycle Database and the US Lifecycle Inventory Database provide valuable data for these assessments. These tools allow engineers to compare materials, processes, and design choices based on real-world environmental performance.

ASTM standards (E2986-15, E3012-16, E3096-17) and ISO 20140 offer clear guidelines for sustainable manufacturing. These standards support quantitative comparisons and help teams classify and improve their processes.

Manufacturing remains a major contributor to energy consumption and greenhouse gas emissions. In the United States, manufacturing accounts for more than half of the total environmental impact of the economy. Companies that adopt sustainable practices see measurable benefits:

- General Motors reduced energy use by 40% and cut CO2 emissions by 41% over 20 years, while increasing productivity. These changes saved the company over $435 million.

- Environmental key performance indicators (KPIs) and scheduling techniques now link design decisions directly to manufacturing performance. This connection enables teams to track progress and make data-driven improvements.

|

Sustainable Practice |

Impact on Production |

Example/Standard |

|---|---|---|

|

Early Design Integration |

Reduces downstream waste and cost |

70-80% of cost set at design |

|

Lifecycle Assessment (LCA) |

Quantifies total environmental load |

ISO 14000, LCA databases |

|

Standards Adoption |

Ensures process transparency |

ASTM E2986-15, ISO 20140 |

|

KPI Tracking |

Links design to sustainability |

Energy, emissions, waste metrics |

Teams that prioritize sustainability in large-scale 3D printing gain a competitive edge. They reduce costs, meet regulatory requirements, and appeal to environmentally conscious customers. By following established standards and using LCA tools, engineers can design products that perform well and protect the planet.

Advanced 3D Printing: Execution and Finishing

Print Monitoring

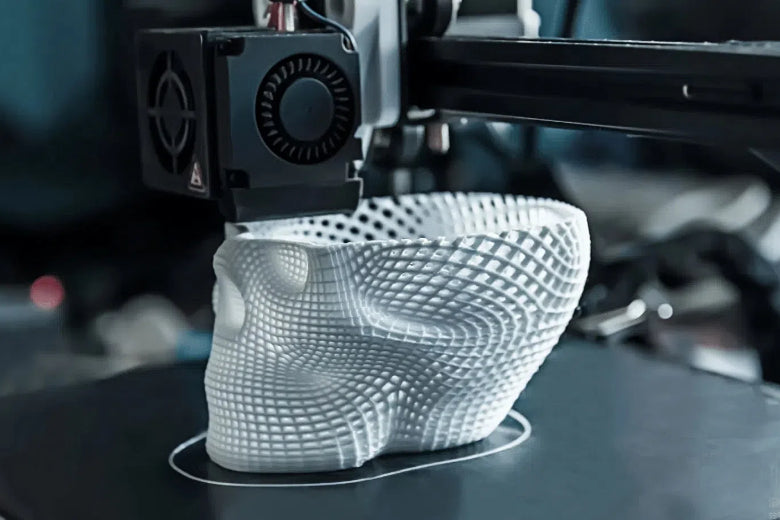

Print monitoring stands as a critical step in advanced 3d printing. Engineers use real-time monitoring systems to track the progress of large builds and detect issues before they cause failures. Modern systems often rely on cameras and sensors that watch for defects such as stringing, layer shifts, or nozzle clogs. Artificial intelligence now plays a major role. For example, a deep learning model trained on thousands of images can spot stringing defects with 99.31% accuracy. This high level of precision allows teams to stop the printer immediately if a problem appears, saving both time and material. Remote monitoring tools, powered by Raspberry Pi and Python, let operators control printers from anywhere. These systems provide instant feedback and help maintain quality throughout the process. By using these tools, teams improve reliability and reduce waste in 3d printed parts.

Tip: Real-time monitoring not only catches defects early but also supports continuous improvement by collecting valuable data on every print.

Assembly Methods

Large-scale projects often require assembling multiple 3d printed parts into a final structure. Engineers test different assembly methods to ensure strong connections and smooth finishes. They use scaled fabrication models (SFMs) to evaluate how parts fit together. In one approach, teams print components with parallel slicing to improve the quality of layer lines on angled surfaces. Partial printing tests help assess the contact surfaces and the way parts connect. These tests reveal issues like messy layers or poor fit, which can be fixed before full production. After passing these checks, teams print and assemble the full model. This process mimics real construction and helps refine the assembly sequence. It also improves communication among team members and clients.

|

Test Type |

Purpose |

Outcome |

|---|---|---|

|

Component Printing Test |

Check layer line quality and slicing effects |

Improved surface quality, fewer defects |

|

Partial Printing Test |

Assess fit and connectivity |

Optimized part interfaces and assembly logic |

|

Full Model Assembly Test |

Validate assembly sequence |

Better structural performance and teamwork |

Quality control metrics support these methods. Machine vision models use scores like the Brier score and AUROC to classify good and defective 3d printed parts. Balanced datasets and intentional defect introduction help validate these models, ensuring reliable assembly outcomes.

Post-Processing

Post-processing transforms raw 3d printed parts into finished products. Engineers use several techniques to enhance strength, appearance, and function. Common steps include removing supports, sanding, and filling gaps between parts. For advanced 3d printing, teams may also use electroplating to add a metal layer, texturing to improve grip, or reinforcement to boost durability. Cross-sectional analysis helps identify defects such as cracks or over-curing, guiding further refinement.

A comparison of 3d printed ceramic parts and cast ceramics shows that printed parts can achieve similar or even higher compressive strength. However, printed parts may have higher porosity and water absorption, which post-processing can address. By analyzing these properties, engineers adjust their finishing techniques to improve performance.

- Removing supports and smoothing surfaces improves the look and feel of 3d printed parts.

- Filling and bonding ensure strong connections between assembled parts.

- Advanced finishes like electroplating or reinforcement increase durability for demanding applications.

Note: Careful post-processing and quality checks ensure that large 3d printed parts meet industry standards for strength and reliability.

Surface Finishing

Surface finishing gives large-scale 3D printed parts their final look and feel. Engineers use this step to improve both appearance and function. A smooth surface can make a part easier to clean, more durable, and better for painting or coating. In advanced 3d printing, surface finishing also helps meet strict industry standards for quality.

Many surface finishing methods exist. Sanding is the most common. Engineers start with coarse sandpaper and move to finer grits. This process removes layer lines and small bumps. For plastic parts, vapor smoothing uses chemicals like acetone to melt the outer layer slightly. This creates a glossy, sealed finish. Media blasting uses tiny beads or sand to smooth the surface quickly. For metal prints, polishing and tumbling give a shiny, even result. Some teams use coatings or paints to add color and protect the part from wear.

Quality control in surface finishing relies on measuring surface roughness. Surface roughness, often called Ra, tells how smooth or bumpy a part feels. Different 3D printing methods produce different roughness levels. The table below shows typical ranges for several popular processes:

|

Additive Manufacturing Process |

Surface Roughness Range (Ra, µm) |

|---|---|

|

Stereolithography (SLA) |

2 – 10 |

|

Selective Laser Sintering (SLS) |

5 – 25 |

|

Fused Deposition Modeling (FDM) |

0.5 – 20 |

|

Laminated Object Manufacturing (LOM) |

0.8 – 2.5 |

|

Electron Beam Melting (EBM) |

1 – 20 |

These numbers show that even with the best printers, surface quality can vary. Engineers must choose the right finishing method based on the starting roughness. For example, FDM parts with high Ra values may need more sanding or coating. SLA and LOM often need less work to reach a smooth finish.

Tip: Teams should always test finishing methods on sample parts before working on the final product. This practice helps avoid mistakes and ensures the best results.

Surface finishing also affects how well large parts fit together. A smooth edge makes assembly easier and improves the strength of joints. Careful finishing can hide seams and make the final product look like a single piece. In industries like aerospace or healthcare, a high-quality finish can mean the difference between success and failure.

Large-scale 3d printing delivers faster production, less waste, and greater design freedom than traditional methods. The table below highlights these advantages and offers strategic steps for future projects:

|

Aspect |

Traditional Manufacturing |

Advanced 3D Printing |

|---|---|---|

|

Material Waste (%) |

25-70% |

5-10% |

|

Production Time |

Long |

Short |

|

Design Flexibility |

Limited |

High |

|

Recommendations |

N/A |

Audit tech, train staff |

To succeed with large-scale 3d printing, teams should:

- Invest in training and digital tools.

- Pilot new modeling strategies.

- Use data analytics for process improvement.

Market forecasts show rapid growth for large-scale 3d printing, driven by new materials and digital solutions. Teams that experiment and adapt will lead the next wave of innovation.

FAQ

What is the main benefit of advanced modeling for large-scale 3D printing?

Advanced modeling helps engineers create strong, lightweight parts with less material. It improves print quality and reduces waste. Teams can design complex shapes that traditional methods cannot produce.

How does model segmentation improve large-format 3D printing?

Model segmentation splits big designs into smaller, printable sections. This method allows users to print parts that exceed the printer’s build volume. Segmentation also makes assembly easier and improves surface finish.

Which software tools work best for advanced modeling?

Many engineers use Fusion 360, Rhino, or Blender for modeling. Meshmixer and Netfabb help repair and optimize files. These tools support complex geometry and ensure models are ready for large-scale printing.

Why is print orientation important in large-scale projects?

Print orientation affects strength, surface finish, and support needs. A 45-degree angle often gives the best results. Good orientation reduces print time and improves the final part’s quality.

What materials are most suitable for large-scale 3D printing?

PLA, ABS, and PETG are common choices. PLA is easy to print but brittle. ABS offers better heat resistance. PETG combines strength and flexibility. For demanding jobs, carbon fiber-reinforced filaments provide extra durability.

How do teams ensure quality during long prints?

Teams use real-time monitoring with cameras and sensors. AI systems detect problems like layer shifts or clogs. Early detection helps prevent waste and ensures each part meets quality standards.

What finishing steps improve the look and strength of large prints?

Engineers sand, fill, and coat parts to smooth surfaces. Vapor smoothing or media blasting can remove layer lines. Electroplating and reinforcement add strength for demanding applications.

Can large-scale 3D printing support sustainable manufacturing?

Yes. Teams use lifecycle assessment tools to measure environmental impact. Choosing efficient designs, recyclable materials, and energy-saving workflows helps reduce waste and emissions.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.