If you want a large 3d printer that makes your first steps easy, the sovol sv08 max stands out as a smart choice. This large 3d printer brings advanced features like a smart feeder, fast bed leveling, and reliable performance. You get a 3d printer with a large build volume, rapid 3d printing speeds, and consistent results. The sovol sv08 max lets you create large 3d models without hassle. You will find this large 3d printer easy to use, powerful, and ready for big ideas.

Key Takeaways

- The Sovol SV08 Max offers a large 500×500×500 mm build volume, letting you print big models or many parts at once without hassle.

- Its CoreXY motion system and smart features like advanced bed leveling and a smart feeder ensure fast, precise, and reliable printing.

- You can print with many materials, including flexible and carbon-fiber filaments, making it versatile for different projects.

- The printer is beginner-friendly with an easy touchscreen, clear instructions, and automatic systems that reduce print failures.

- Planning your space, maintenance, and choosing the right features help you get the best results and enjoy large-format 3D printing.

Sovol SV08 Max Overview

Key Advantages

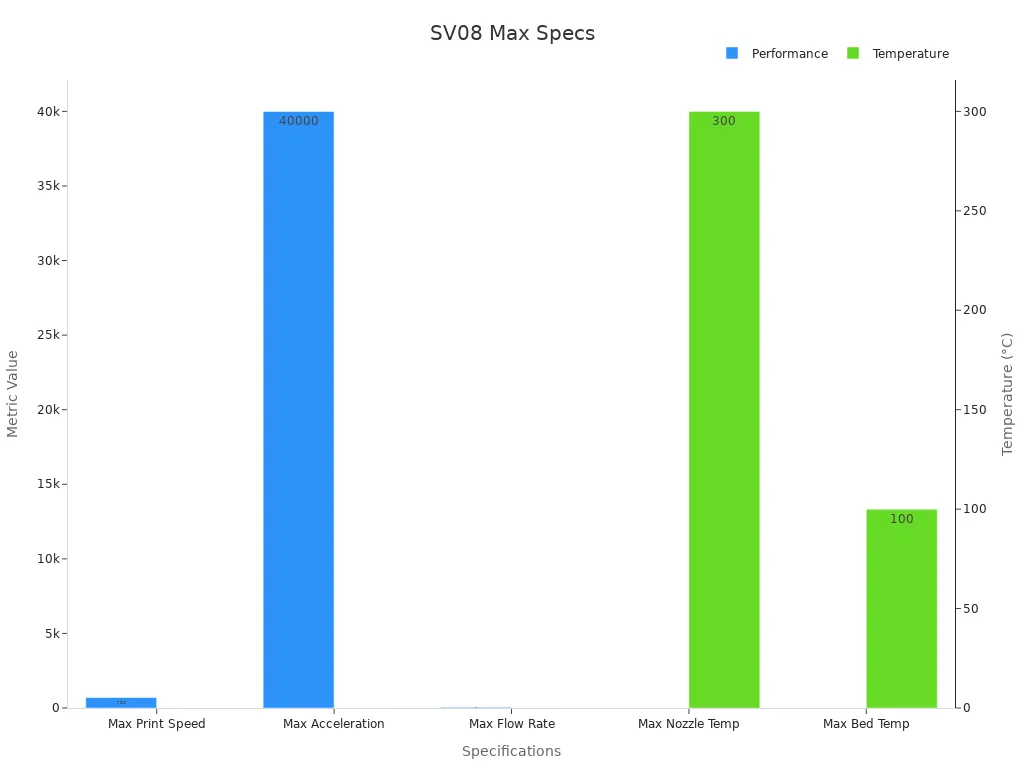

You get a large FDM 3D printer that stands out for its impressive build volume and advanced engineering. The Sovol SV08 Max offers a massive 500x500x500mm build volume, letting you print large models or multiple parts in one session. This 3D printer supports high-speed printing up to 700mm/s and delivers consistent results with a maximum acceleration of 40,000 mm/s². You can rely on its robust 1300W heated bed for even temperature distribution, which helps prevent warping and ensures strong adhesion for large prints.

Here is a quick look at the technical specifications:

|

Specification |

Detail |

|---|---|

|

Build Volume |

500x500x500mm (500x500x450mm with enclosure) |

|

Maximum Print Speed |

Up to 700mm/s |

|

Maximum Acceleration |

40,000 mm/s² |

|

Maximum Flow Rate |

50mm³/s (high-flow nozzle) |

|

Maximum Nozzle Temperature |

300°C |

|

Maximum Bed Temperature |

100°C |

|

Bed Leveling System |

Advanced Eddy Current Scanning system |

|

Connectivity |

LAN, WiFi, USB |

|

Firmware |

Open Source Klipper |

|

Additional Features |

CoreXY kinematics, smart auxiliary feeder, 1300W heated bed, camera (1280x720p timelapse) |

|

Printer Dimensions |

700x710x750mm (excluding spool holder) |

You benefit from a user-friendly touchscreen interface, making adjustments and monitoring easy. The Sovol SV08 Max supports a wide range of filaments, including flexible and carbon-fiber reinforced materials. This versatility means you can tackle industrial parts, prototypes, or artistic projects with confidence. Independent reviews highlight the cost efficiency, noting that you can save money by producing large parts in-house and reducing reliance on external vendors. The sturdy frame and steel reinforcements keep vibration low, maintaining print quality even at high speeds.

Note: The Sovol SV08 Max has passed independent tests like the Box and Block Test and SHAP test, confirming its high precision and texture detail for demanding applications.

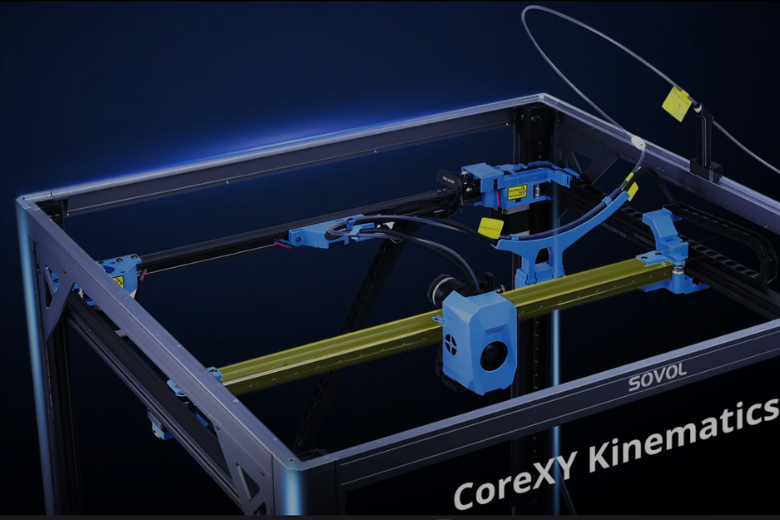

CoreXY Motion System

The Sovol SV08 Max uses a CoreXY motion system, which sets it apart from many other large FDM 3D printers. This design uses two stationary motors and crossed belts to move the print head. You get faster, smoother motion because the moving mass is minimized. The CoreXY system enables the printer to reach speeds up to 700mm/s and acceleration rates of 40,000 mm/s². You achieve high precision, with positional accuracy as fine as 0.02 mm and printing accuracy of ±0.1 mm.

|

Metric / Feature |

Value / Description |

|---|---|

|

Maximum Print Speed |

Up to 700 mm/s |

|

Maximum Acceleration |

40,000 mm/s² |

|

Positional Accuracy |

≤0.02 mm during fast moves and acceleration tests |

|

Ringing Artifacts Reduction |

92% reduction compared to disabled configurations |

|

Motion System |

CoreXY kinematics with belt-driven motion and stationary motors |

|

Stability Features |

Linear rails and sturdy frame reduce vibration and mechanical wear |

|

Firmware Integration |

Klipper firmware enables precise acceleration control and motion planning, improving print quality |

|

Extrusion Rate |

35 mm³/s |

|

Frame Strength |

180% stronger than comparable aluminum frames |

You will notice the difference in print quality. The CoreXY system, combined with linear rails and a reinforced frame, reduces vibration and mechanical wear. This stability keeps your prints sharp and clean, even at high speeds. The Klipper firmware lets you fine-tune acceleration and motion planning, so you get consistent results whether you print small detailed models or large functional parts.

You also benefit from advanced features like Pressure Advance and Input Shaping Technology. These tools help reduce print flaws such as ringing and uneven edges, giving your 3D prints a professional finish.

Smart Feeder and Bed Leveling

You can count on the Sovol SV08 Max’s Smart Auxiliary Feeder to keep your printing process smooth. This intelligent feeder monitors filament flow and detects tangles or clogs before they cause problems. You avoid interruptions and wasted material, which is especially important for large prints that take many hours to complete.

The advanced Eddy Current Scanning system makes bed leveling fast and accurate. You can level the entire 500x500mm bed in just 80 seconds. This contactless technology detects even the smallest surface deviations, ensuring perfect first-layer adhesion every time. You spend less time on setup and more time printing.

- The 8mm thick aluminum hotbed heats quickly and evenly, supporting a wide range of materials.

- The printer’s open-source Klipper firmware gives you flexibility and control, whether you are a beginner or an advanced user.

- You can assemble the Sovol SV08 Max with ease, thanks to its clear instructions and modular design.

You get a large FDM 3D printer that is reliable, precise, and ready for any challenge. The Sovol SV08 Max combines smart engineering with user-friendly features, making it a top choice for anyone looking to explore large-scale 3D printing.

What Is Large FDM 3D Printing

FDM Printing Technology

You use FDM printing technology to create objects layer by layer from thermoplastic materials. This method melts and extrudes plastic filament through a heated nozzle, building your 3d model on a flat surface. FDM stands for Fused Deposition Modeling, a process that has become the standard for both hobbyists and professionals. You can choose from a wide range of materials, such as PLA, ABS, and flexible TPU, to match your project’s needs.

FDM printing technology has evolved quickly. You now see improvements like high-flow nozzles, advanced feeder systems, and motion planners that boost productivity and print quality. For example, the UltiMaker S8 uses a Cheetah motion planner to increase productivity by four times and achieve a print quality of 0.15mm ± 0.15mm. You benefit from faster print speeds, larger build volumes, and more reliable results.

|

Aspect |

FDM Improvements and Features |

Comparative Statistics and Applications |

|---|---|---|

|

Latest Improvements |

UltiMaker S8 with UltiMaker Cheetah motion planner increases productivity 4x; print quality improved to 0.15mm ± 0.15%; new high flow cores and feeder system |

Layer heights: 50-400 microns (FDM) vs 25-100 microns (SLA); print speed faster for larger parts in FDM; build volume larger in FDM |

|

Material Properties |

Uses thermoplastics like ABS, PLA; stronger, more durable, better chemical and temperature resistance; flexible materials like TPU available |

SLA offers higher detail and smoother finish; FDM parts stronger and more durable; SLA parts more brittle but with isotropic strength |

|

Print Quality |

Visible layer lines, limited fine detail; requires post-processing for smooth finish |

SLA excels in detail resolution and surface finish; preferred for jewelry, dental models, intricate parts |

|

Speed and Efficiency |

Faster for larger, less detailed parts; simpler operation; variable infill saves material |

SLA slower overall but faster for small detailed parts; smaller build volume; post-processing differs between technologies |

|

Cost |

More affordable printers ($200-$300 entry level); filament costs $20-$50/kg |

SLA printers cost more ($1000-$3000 entry level); resin costs $50-$200/liter |

|

Creative Applications |

Functional prototypes, end-use parts, automotive parts |

SLA preferred for high-detail applications like dental and jewelry models |

You find FDM printing technology in many industries, from automotive to aerospace. You can create functional prototypes, end-use parts, and even large furniture pieces. The technology’s flexibility and affordability make it a top choice for anyone starting with a large FDM 3D printer.

Why Size Matters

When you choose a large FDM 3D printer, you unlock new possibilities for your projects. Large build volumes let you print bigger parts or multiple items at once. You save time and reduce the need for assembling smaller pieces. Industry standards define large FDM printing by the size of the build envelope, with models like the Stratasys F900 and F770 leading the way for industrial-scale parts.

|

Aspect |

Details |

|---|---|

|

Printers with large build envelopes such as Stratasys F900 and F770 models, designed for industrial-scale parts. |

|

|

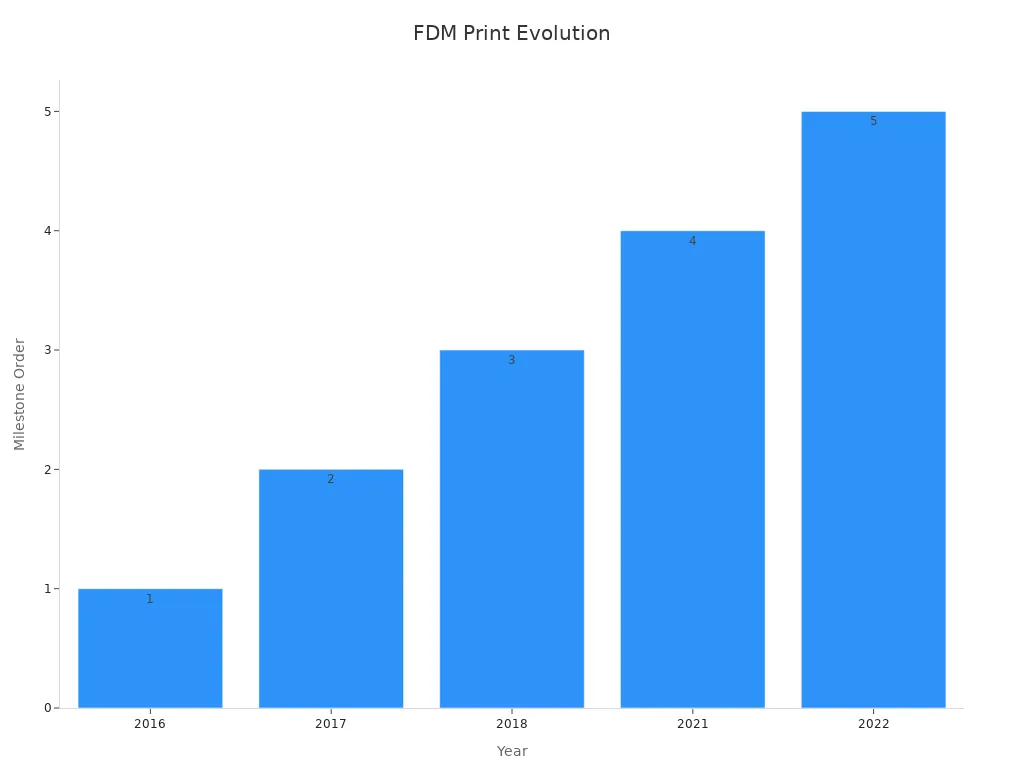

Historical Milestones |

- 2016: Acquisition of GrabCAD Print software for improved pre-processing. |

|

Material Advancements |

Use of ULTEM, Antero, Nylon 12 CF enabling parts with injection molding-like properties. |

|

Industry Adoption |

Automotive (e.g., Dash CAE producing large motorsport parts), Aerospace (e.g., BAE Systems' Factory of the Future), Railway (e.g., Rustin sealing systems). |

|

Industry Standards |

Use of FDM for reliable, durable parts requiring large build volumes and repeatability, accepted across multiple sectors. |

You see the impact of large-format printing in industries that demand strength, durability, and repeatability. The expiration of the core FDM patent in 2009 made large FDM 3D printers more affordable and accessible. Since then, you have seen rapid advancements in machine size, material options, and workflow simplicity.

Large FDM 3D Printer Benefits

Versatility

You gain unmatched versatility when you use a large FDM 3D printer. This technology lets you work with a wide range of materials, including advanced composites like carbon fiber, glass fiber, and even metal-filled filaments. These materials boost the mechanical strength, thermal stability, and electrical conductivity of your 3D prints. You can combine flexible and rigid materials in a single print, which means you create complex, multi-component objects without extra assembly.

Large FDM 3D printing has proven its value in many industries.

- In aerospace, you can produce lightweight structures and engine parts.

- In automotive, you print both prototypes and final products.

- In healthcare, you create prosthetics, implants, and surgical guides.

- Electronics and architecture also benefit from large 3D printing, from functional components to full-scale models.

You can quickly change designs and print unique shapes that traditional manufacturing cannot handle. The adaptability and economic benefits of FDM 3D printing help you move from prototyping to real industrial production. You see fewer defects and better part performance because you can optimize printing parameters for each project.

Speed and Precision

Large FDM 3D printers deliver impressive speed and precision. You can print big models faster, thanks to high-flow nozzles and advanced motion systems. The Sovol SV08 Max, for example, uses a CoreXY system that allows rapid movement and keeps vibration low. This means you get high print quality even at fast speeds.

You notice the difference in print quality right away. Each layer lines up with great accuracy, and you see fewer flaws or rough edges. The advanced bed leveling and smart feeder systems keep your prints consistent from start to finish. You achieve print accuracy that meets industrial standards, making your 3D models reliable for both prototypes and end-use parts.

Tip: When you use a large FDM 3D printer, you save time and get professional results. You can trust the quality and precision of your prints, no matter how complex or large your project is.

Key Features to Consider

Build Volume

When you choose a large FDM printer, build volume becomes a top priority. A generous build volume, such as 500×500×500mm, lets you print oversized models in one piece. This reduces assembly errors and saves you valuable time. You can see how different printers compare in the table below:

|

Printer Model / Category |

Build Volume (mm) |

Typical Use Cases / Project Types |

|---|---|---|

|

Sovol SV08 Max |

500 × 500 × 500 |

Large prototypes, furniture, architectural parts |

|

Creality K1 Max |

300 × 300 × 300 |

Medium-sized models |

|

Standard 3D Printer |

200 × 200 × 200 |

Small models, toys |

|

Large Format 3D Printer |

500 × 500 × 500 |

Furniture, prototypes, tools |

|

Extra Large Industrial Printer |

1500 × 1500 × 2000 |

Industrial parts, automotive, molds |

You gain the flexibility to tackle ambitious projects and reduce the need for splitting designs.

Material Compatibility

A large FDM printer should support a wide range of materials. You want to print with PLA, PETG, ABS, TPU, and even carbon-fiber composites. The Sovol SV08 Max features a high-temperature hotend and a thick, heated bed. This combination allows you to work with advanced engineering filaments and ensures strong adhesion. The smart feeder system monitors filament flow, preventing clogs and tangles. You achieve consistent print quality, whether you create flexible wearables or durable industrial parts.

- Print with multiple materials for diverse applications.

- Maintain high quality with advanced extrusion and bed heating.

- Avoid interruptions with smart filament monitoring.

Software and Firmware

Software and firmware play a crucial role in large FDM printing. The Sovol SV08 Max uses open-source Klipper firmware, which enables advanced features like input shaping and pressure advance. You benefit from faster processing, smoother motion, and higher print quality. Compatibility with popular slicers such as Cura and PrusaSlicer gives you flexibility in preparing your models. The CoreXY motion system, optimized by firmware, delivers high speed and accuracy, setting your printer apart from basic models.

|

Feature |

CoreXY |

Cartesian |

|---|---|---|

|

Print Speed |

Fast and smooth |

Slower for bigger items |

|

Accuracy |

Very precise movements |

Good accuracy but slower |

Reliability

Reliability defines your experience with a large FDM printer. Industrial-grade models undergo rigorous testing to ensure durability and consistent print quality. Robust components, such as a reinforced frame and thick aluminum bed, support heavy-duty use. Smart monitoring systems and regular firmware updates minimize downtime. You enjoy fewer repairs, better uptime, and consistent results over time. This reliability reduces your total cost of ownership and keeps your projects on track.

Tip: Choose a large FDM printer with proven reliability and advanced monitoring to ensure high-quality results every time.

Buying Guide for FDM Printers

Assessing Needs

Before you invest in a large FDM 3d printer, you should evaluate your workspace, project goals, and experience level. Start by measuring the available space for your printer. Large 3d printers like the sovol sv08 max require a dedicated area with stable surfaces and good ventilation. Think about the types of projects you want to create. If you plan to print industrial parts, prototypes, or oversized models, you need a printer with a large build volume and strong mechanical properties. Consider your experience with 3d printing. Beginners benefit from user-friendly features, while advanced users may want more control and customization.

Tip: Surveys show that risks such as manufacturing defects, poor design, and insufficient financing can impact your project. Careful planning and clear goals help you avoid these issues.

Comparing Options

When you compare large FDM 3d printers, focus on the features that matter most for your needs. Look at build volume, motion system, material compatibility, and ease of use. The sovol sv08 max stands out with its 500×500×500 mm build volume, CoreXY kinematics, and support for advanced materials. Use expert guides and reviews to check print quality, reliability, and customer support. User feedback often highlights the importance of consistent performance and easy maintenance.

|

Feature |

Sovol SV08 Max |

Other Large FDM Printers |

|---|---|---|

|

Build Volume |

500×500×500 mm |

Varies (often smaller) |

|

Motion System |

CoreXY |

Cartesian/CoreXY |

|

Material Compatibility |

PLA, PETG, ABS, TPU, carbon-fiber |

Limited in some models |

|

Advanced Features |

Smart Feeder, Eddy Current Leveling |

Basic leveling, standard feeder |

Note: Comprehensive guides recommend evaluating print speed, accuracy, and support structure to ensure you choose the right 3d printer.

Budget Considerations

Budget plays a key role in your decision. The total cost of owning a large FDM 3d printer includes more than just the purchase price. You should factor in material costs, maintenance, software, and labor. FDM printers offer the best value for most users, with lower material and operational costs compared to other technologies. The sovol sv08 max delivers professional features at a competitive price, making it a smart investment for both beginners and experienced users.

|

Cost Factor |

FDM (e.g., Sovol SV08 Max) |

SLS/SLA Printers |

|---|---|---|

|

$100+ per liter/kg |

||

|

Machine Costs |

$200 - $5,000 |

$3,000+ |

|

Maintenance |

Low |

Moderate to high |

Remember: A thorough cost analysis helps you maximize your return on investment and avoid unexpected expenses.

Challenges and Solutions

Space and Setup

You need to plan your workspace carefully before installing a large FDM 3D printer. Large-format machines like the Sovol SV08 Max require more than just a sturdy table. You must consider the printer’s footprint, room for material storage, and space for post-processing. Studies show that advanced hardware, such as robotic arms and flexible motion systems, can increase spatial demands. You should also account for the movement of the print head and the need for collision-free paths.

|

Typical Build Volume Range (mm) |

Large-Format Examples |

Relevant Use Cases |

|

|---|---|---|---|

|

FDM (Fused Deposition Modeling) |

200 × 200 × 200 up to 500 × 500 × 500 |

BigRep PRO, Modix (up to 1000 × 1000 × 1000) |

Prototypes, tooling, furniture |

You may face challenges like warping and shrinkage, especially with larger parts. Print times can stretch into dozens of hours. You should plan for extra space to handle post-processing, cleaning, and assembly. Many users segment large models into smaller sections for easier handling and improved print quality.

Tip: A dedicated, well-ventilated area helps you maintain a safe and efficient printing environment.

Maintenance

Routine maintenance keeps your large FDM printer running smoothly and ensures high print quality. You should focus on nozzle cleaning, lubrication of moving parts, and regular bed leveling. Research shows that nozzle clogs, filament jams, and temperature fluctuations are common issues. About 30% of 3D printing errors come from poor calibration and maintenance.

You can reduce downtime by following a preventive maintenance schedule. This includes checking filament quality, updating firmware, and replacing worn parts. Condition-based strategies, such as monitoring for signs of wear or uneven prints, help you address problems before they affect print quality. Large-format printers often have lower maintenance costs than traditional manufacturing, but you must stay proactive to avoid failures.

- Clean the nozzle and bed after each print.

- Lubricate rails and moving parts regularly.

- Monitor filament feed and replace build plates as needed.

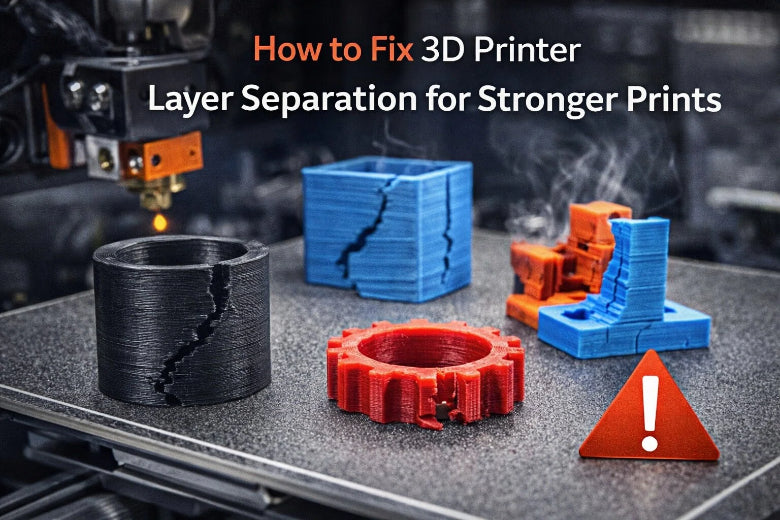

Print Quality

Achieving consistent print quality is essential for successful large-format printing. You must pay attention to calibration, material selection, and environmental factors. Common issues include warping, layer separation, and poor bed adhesion. These problems often result from inadequate calibration or unstable temperatures.

|

Description |

Impact on Print Quality |

|

|---|---|---|

|

Dimensional Accuracy |

Precision of printed part sizes |

Ensures parts conform to design specifications |

|

Print Speed |

Rate of layer or part printing |

Balances efficiency with quality |

|

Material Efficiency |

Ratio of material used vs waste |

Reduces cost and improves sustainability |

|

Automation & Sensors |

Use of smart cameras and sensors |

Enables real-time error detection and correction |

|

User Interface |

Ease of setup and control |

Reduces user errors and improves print outcomes |

You should use printers with advanced features like smart sensors and live feedback systems. These tools help you detect and correct errors in real time, improving print quality. Optimizing parameters such as nozzle temperature and bed leveling also boosts print quality. The Sovol SV08 Max uses CoreXY kinematics and Eddy Current Scanning to maintain high print quality, even at fast speeds. Customer feedback highlights the importance of reliability and consistent print quality, especially for long, complex prints.

You want a large-format 3D printer that delivers speed, precision, and reliability. The sovol sv08 max stands out for first-time buyers because it combines advanced features with user-friendly design. You benefit from:

- A 500×500×500 mm build volume for ambitious projects

- CoreXY kinematics and high-speed printing up to 700 mm/s

- Smart bed leveling and feeder systems that boost print success

- Support for advanced materials and open-source firmware

- Proven accuracy and strong customer support

Choose the sovol sv08 max to start your large FDM 3D printing journey with confidence. Explore online tutorials, join user communities, and experiment with different materials to unlock your creative potential.

FAQ

What makes the Sovol SV08 Max suitable for beginners?

You benefit from an intuitive touchscreen, clear assembly instructions, and automatic bed leveling. The smart feeder system prevents filament issues. You can start printing large models quickly, even if you have no prior experience.

Can I print with advanced materials on the Sovol SV08 Max?

You can print with PLA, PETG, ABS, TPU, and carbon-fiber composites. The high-temperature hotend and robust heated bed support a wide range of engineering filaments for both functional and artistic projects.

How does the smart feeder system help during long prints?

The smart feeder monitors filament flow and detects tangles or clogs. You avoid print failures and wasted material. This feature ensures your large, multi-hour prints finish successfully.

Is the Sovol SV08 Max compatible with open-source software?

You can use open-source Klipper firmware and popular slicers like Cura or PrusaSlicer. This compatibility gives you flexibility and control over your print settings.

What maintenance does the Sovol SV08 Max require?

You should clean the nozzle and bed after each print. Lubricate moving parts regularly. Monitor filament quality and update firmware as needed. Routine care keeps your printer running smoothly and ensures consistent results.

Tip: Regular maintenance extends your printer’s lifespan and improves print quality.