The need for big 3D printers is growing fast in industries. They help businesses make detailed designs quickly and accurately. In 2023, the global 3D printing market was worth $20.37 billion. Experts say it will grow 18% to 27% each year. Many companies using 3D printers are seeing big improvements. About 70% made more parts in 2023 than in 2022. These facts show that cheaper prices and new ideas make large 3D printers important for all businesses.

Key Takeaways

- Big 3D printers cut costs by skipping pricey molds and workers.

- They make large items in one step, saving time and adding strength.

- Large 3D printers are good for the planet. They use less material and waste.

- New technology makes these printers cheaper, helping small businesses grow.

- Fields like medicine and space use these printers for faster, better products.

Advantages of Large 3D Printers

Saving Money and Less Manual Work

Big 3D printers help save money by making production easier. They create complex parts straight from digital designs. This means no need for costly molds or tools. Fewer skilled workers are needed, which lowers labor costs.

- A study showed 3D-printed models used in surgeries saved time and money.

- Research proves 3D printing cuts material costs and reduces maintenance expenses compared to old methods.

|

Feature |

3D Printing |

Traditional Methods |

|---|---|---|

|

Material Costs |

Lower with on-demand printing |

Higher with bulk buying |

|

Maintenance Costs |

Usually lower |

Higher due to complex machines |

|

Labor |

Needs fewer skilled workers |

Needs more skilled workers |

Using large 3D printers can save money while keeping quality high.

Making Big Objects in One Go

Large 3D printers can make big items in one print. This removes the need to join smaller parts, saving time and keeping items strong.

Making prototypes is faster with 3D printing. Old methods take longer and cost more. With 3D printers, you can make prototypes from digital designs, cutting time by half.

- This method speeds up delivery and allows flexible production.

- In sand casting, 3D printing can save up to 75% of costs and skips assembly steps.

Large 3D printers help finish projects faster and cheaper by reducing work steps.

Being Eco-Friendly and Wasting Less

Large 3D printers are better for the environment. They use additive manufacturing, building layer by layer, which wastes less material. Unlike older methods, they only use what’s needed.

|

Feature |

Details |

|---|---|

|

Material Use |

|

|

Full Impact View |

Promotes studying all environmental effects of 3D construction printing (3DCP). |

|

Green Framework |

Focuses on materials, design, and structure performance. |

By using eco-friendly materials and wasting less, you can meet green goals. This helps the planet and boosts your brand as a responsible company.

Affordability of Large 3D Printers

Technology Making 3D Printers Cheaper

New technology has made big 3D printers less expensive. Faster and more accurate machines now use a variety of materials. This lowers costs and helps businesses make complex designs easily.

- The market for large 3D printers may reach $61.3 billion by 2028.

- Aerospace companies use these printers to make lightweight parts quickly.

As technology improves, you can save money and get better results. Large 3D printers are now a smart choice for many industries.

Easier for Small Businesses to Use

Lower prices and simple designs let small businesses use big 3D printers. These machines were once only for large companies. Now, smaller businesses can use them to grow and compete.

The 3D printing market is growing because of better affordability. Small businesses use these printers for testing ideas and making products. In 2023, the Desktop 3D Printing Market was worth $3 billion, showing high demand.

Using large 3D printers helps small businesses save time and money. They can improve their work without spending too much.

Saving Money Over Time

Buying a large 3D printer can save money later. These machines cut costs for testing, designing, and making parts. They also remove the need for expensive tools and molds.

- 51% of manufacturers now use 3D printing for making parts.

- 60% say it lowers testing costs.

- 52% enjoy more flexible designs.

By using large 3D printers, you can save on materials and labor. Over time, these savings make the machines a good investment for your business.

Power and Capabilities of Large 3D Printers

Scaling Up for Big Projects

Large 3D printers can handle big jobs easily. They make large parts or many pieces in one go. This reduces the need to put parts together. Businesses can meet higher demands faster with these printers.

- The industrial 3D printing market may grow from $2.92 billion in 2024 to $6.27 billion by 2029, growing 16.5% yearly.

- This growth shows how 3D printing solves problems and creates new chances.

- It can make complex shapes that old methods cannot, improving production.

Using large 3D printers helps businesses grow and work more efficiently.

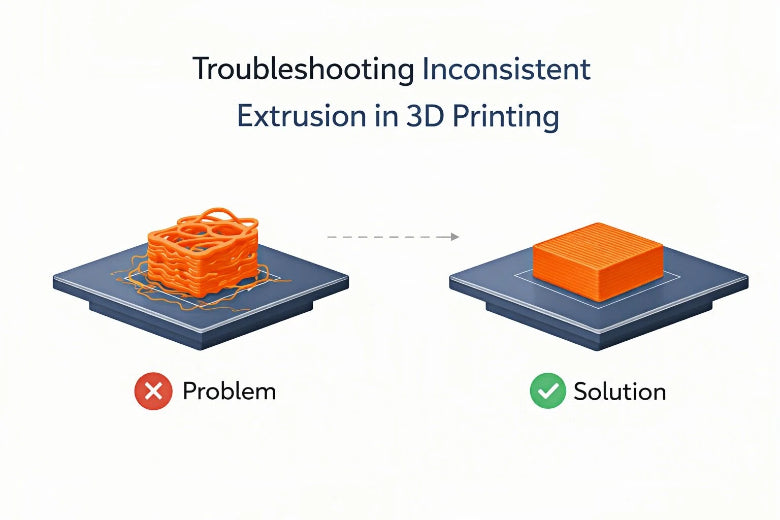

Accurate and Detailed Designs

Large 3D printers are very precise. They can make detailed designs and prototypes. Advanced tools ensure each layer is perfect, giving high-quality results.

Industries like aerospace and healthcare use this precision for special parts. These include lightweight airplane parts and custom medical tools. Printing directly from digital files avoids mistakes and saves materials. Large printers handle tricky projects well, giving great results every time.

Fast and Strong Production

Large 3D printers work quickly and make durable items. Methods like Directed Energy Deposition (DED) help build and fix big metal parts fast. This is useful for industries like aerospace, defense, and energy.

- In 2022, 76% of users printed over 10 parts, and this trend grew in 2023.

- Users printing over 1,000 parts rose from 4.7% to 6.2% between 2022 and 2023.

- Printing for final-use parts increased to 21% in 2023.

These numbers show large 3D printers are fast and strong. They are great for tough and demanding jobs.

Applications of Large Scale 3D Printing Across Industries

Large scale 3D printing is changing many industries. It solves tough problems with new ideas. This technology makes big objects quickly and accurately. It helps in areas like manufacturing, healthcare, and construction.

Manufacturing: Making Prototypes and Final Parts

Large 3D printers are useful for making prototypes and parts. They help test designs without needing expensive tools or molds. This saves time and money during development.

- Companies use 3D printers to make lightweight parts for cars and planes.

- The technology allows creating custom parts for special needs.

- By skipping assembly steps, businesses save money and keep quality high.

For example, manufacturers use 3D printers to make molds for sand casting. This cuts costs by up to 75%. Large 3D printers are now key tools for modern factories.

Healthcare: Custom Medical Tools and Prosthetics

Healthcare uses large 3D printers to make custom medical items. These include prosthetics and devices designed for each patient. This improves comfort and usability.

- 3D printing skips the need for many tools and molds.

- It speeds up making and delivering prosthetics, saving time.

- Designs can be tested and improved quickly, lowering costs.

- Large printers can make one item or many at once.

- Affordable prosthetics help more patients and improve their lives.

A hospital used 3D printers to make custom prosthetics and implants. Doctors also practiced surgeries using printed models of patients' bodies. This improved surgery results.

Large 3D printers make healthcare more personal, affordable, and effective.

Construction: Printing Big Structures and Parts

Construction uses large 3D printers to build faster and smarter. They print big structures and parts with great accuracy and speed.

|

Project Name |

Description |

|---|---|

|

Galleria Gwanggyo |

Unique building parts made with 3D printing. |

|

Siedle House |

Showed new ways to use 3D printing in architecture. |

|

Pillar project Doka |

Printed molds for concrete parts in an office building. |

|

Column cladding SL Rasch GmbH |

Used 3D printing for architectural designs. |

|

Mersitem Wall |

Created sustainable building designs with 3D printing. |

|

AIRLAB |

Made eco-friendly table legs using 3D printing. |

|

Intelligent 3D printed formwork |

Printed molds for smart concrete ceilings. |

|

Doka's complex formworks |

Used 3D printing for advanced concrete molds. |

|

Restoration projects |

Restored old items using 3D printing at a museum. |

In the Netherlands, a house was printed in 120 hours, showing how fast this technology works. Another project in Nantes built a five-room house in 54 hours, cutting time by 70%. Dubai also made the world’s largest 3D-printed building, reducing labor costs by 50% and waste by 60%.

These examples show how large 3D printers make construction faster, cheaper, and greener.

Aerospace and Automotive: Fast Prototypes and Lightweight Parts

Large 3D printing is changing aerospace and car-making industries. It helps make prototypes quickly and easily. You can design, test, and improve ideas faster. This saves time and gets products ready for sale sooner.

In aerospace, large 3D printing speeds up making new products. It skips old steps like tooling, cutting time by 64%. This makes it easier to finish tricky projects faster. It also uses less material, saving money and helping the environment.

Car makers love 3D printing for making light, strong parts. Old methods can’t make such detailed designs. With 3D printing, you can create car parts that are light but tough. These parts help cars use less fuel and work better.

Why Large 3D Printing is Great for Aerospace and Cars:

- Makes prototypes faster, saving time on designs.

- Creates light, detailed parts for better performance.

- Skips expensive tools, lowering costs.

- Wastes less material, helping the planet.

For example, airplane makers use 3D printing for custom parts. These parts are lighter and stronger, making planes safer. Car companies use it to make exact parts without needing assembly. This saves time and keeps parts strong.

🚀 Fun Fact! Large 3D printers can make whole car frames or airplane parts in one go. This saves time and ensures every detail is perfect.

Using large 3D printing helps you stay ahead in aerospace and car-making. It lets you create better products, save money, and meet modern needs.

Why Sovol SV08 is Great for Industrial 3D Printing

Big Printing Space for Many Uses

The Sovol SV08 is a large 3D printer with lots of space. Its printing area is 350 x 350 x 345 mm (13.77 x 13.77 x 13.58 inches). This size lets you make big projects easily. You can print prototypes, working parts, or creative designs. It works well for many different needs.

|

Feature |

Details |

|---|---|

|

Printing Space |

350 x 350 x 345 mm |

|

Size in Inches |

13.77 x 13.77 x 13.58 inches |

This big space means you don’t have to split designs into smaller pieces. It saves time and keeps items strong. It’s great for industries like building, healthcare, and manufacturing. Printing large items in one go is very helpful.

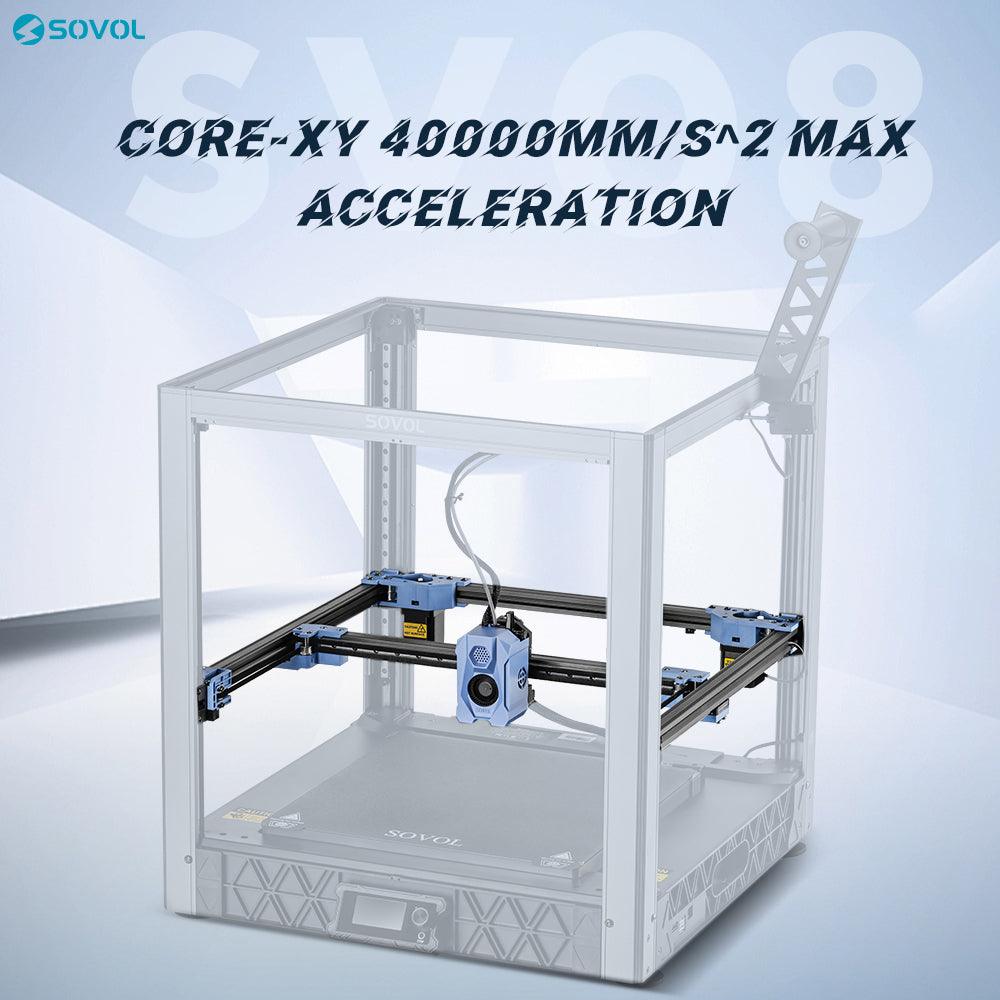

Fast Printing That Stays Stable

The Sovol SV08 prints quickly without losing quality. Its CoreXY design helps it move smoothly and precisely. This setup reduces shaking, keeping prints steady even at high speeds.

Speed and stability are important for industrial printing. The Sovol SV08 does both well. It helps you finish projects on time while keeping prints high-quality. Whether you’re making test models or final parts, this printer gives reliable results every time.

Affordable, Strong, and Reliable

The Sovol SV08 is affordable and works well for a long time. Its CoreXY design is tough and needs fewer repairs. This saves money over time. The belt system lowers failed prints, reducing wasted materials and costs.

- CoreXY printers like Sovol SV08 last longer with fewer problems.

- Fewer moving parts mean less wear and tear, making it durable.

- Strong belts and pulleys keep movements smooth and accurate.

- It works with cheaper filaments, saving money on materials.

This mix of features makes the Sovol SV08 a smart choice for businesses. It’s a big 3D printer that offers great performance without costing too much.

A smart pick for all types of businesses

The Sovol SV08 is a large 3D printer that works well for small and big businesses. It helps improve work and makes tasks easier.

Why the Sovol SV08 Fits Everyone

- Affordable Option: You don’t need a huge budget to use this 3D printer. The Sovol SV08 gives great results at a price small businesses can afford.

- Many Uses: Its big size lets you make prototypes, finished parts, or creative designs. This makes it useful for industries like healthcare, construction, and manufacturing.

- Easy to Use: The Sovol SV08 is simple to operate, even for beginners.

💡 Tip: Want a printer that’s both affordable and advanced? The Sovol SV08 is a great choice.

Comparing Sovol SV08 to Other Large 3D Printers

|

Feature |

Sovol SV08 |

Other Large 3D Printers |

|---|---|---|

|

Price |

Budget-friendly |

Often costly |

|

Build Volume |

350 x 350 x 345 mm |

Sometimes smaller |

|

Stability |

CoreXY design for accuracy |

May lack steady printing |

|

Material Compatibility |

Uses cheaper filaments |

Limited choices |

The Sovol SV08 combines good price, strong performance, and reliability better than many others.

Built for Business Growth

As your business expands, the Sovol SV08 can handle bigger jobs. It’s durable and works well for tough projects, making it a long-term solution.

🚀 Fun Fact: Companies using large 3D printers like the Sovol SV08 often finish projects faster and spend less money.

The Sovol SV08 isn’t just a machine; it’s a helper for innovation. It lets you design, test, and deliver products quickly, helping your business succeed.

Big 3D printers are changing industries with their low cost and power. They make things faster, waste less material, and help the environment. Many industries, like building, healthcare, and car-making, use 3D printing for smart ideas. For example, Ford and Boeing use 3D printers to make light, strong parts. This saves money and works better. The Sovol SV08 is a great pick for businesses. It has a big printing space, stays steady, and costs less. This makes it perfect for growing and creating new ideas. With 3D printing, you can find new ways to succeed and lead in your field.

FAQ

What industries use large 3D printers the most?

Large 3D printers are helpful in many industries. These include manufacturing, healthcare, construction, aerospace, and automotive. They make prototypes, custom parts, and big structures quickly.

Are large 3D printers costly to maintain?

No, modern large 3D printers like the Sovol SV08 are built to last. They need little maintenance because their features prevent damage. This saves money on repairs.

Can small businesses buy large 3D printers?

Yes, new technology has made large 3D printers cheaper. Models like the Sovol SV08 are high-quality and affordable. Small businesses can now use them easily.

What materials can large 3D printers work with?

Large 3D printers can use many materials, like plastics and metals. Some even use eco-friendly materials. This makes them flexible for different projects.

How do large 3D printers cut down on waste?

Large 3D printers build items layer by layer. This method uses only the needed material. It wastes less compared to older methods, making it better for the planet.