Choosing the best materials for 3D printing car parts is crucial. The materials must effectively handle stress, heat, and wear. For instance, engine covers or brackets need to withstand high temperatures. When replacing old parts, it's essential to use materials that are both strong and flexible. If you're creating parts for moving systems, they must be durable enough to resist wearing out. A large 3D printer enables you to produce larger car parts with ease. Understanding these requirements is key to creating robust 3D printed car parts.

Key Takeaways

- Pick materials based on needs like heat and impact resistance. This helps parts last longer and stay strong.

- Lightweight materials make cars faster and save fuel. Try using carbon fiber or nylon mixes.

- Check product info sheets to learn about material features. This helps you choose the best material for your car part.

- Test materials in real situations to see if they work well. This avoids problems and makes parts more reliable.

- Change printer settings to match the material you use. Good settings make parts stronger and more precise.

Automotive Needs for 3D Printing Car Parts

Heat Resistance and Thermal Stability

Car parts must handle high heat without damage. Engine parts, for example, work in very hot conditions. Materials that stay strong in heat are important. They prevent parts from bending or weakening. In 3D printing, the filling ratio affects heat resistance. A higher ratio, like 70%, keeps thermal resistance above 0.5°C/W at 80 W. A lower ratio, like 60%, may fall below this level.

|

Filling Ratio |

Thermal Resistance (°C/W) at 80 W |

|---|---|

|

40% |

> 0.5 |

|

50% |

> 0.5 |

|

60% |

< 0.5 |

|

70% |

> 0.5 |

Picking heat-resistant materials helps car parts last longer and work well in hot places.

Impact Strength and Durability

Car parts often get hit or bumped during use. The materials need to absorb shocks without breaking. Strong impact resistance makes 3D printed parts safer and tougher. For example, bumpers must meet safety rules. Full-width bumpers handle hits at 2.5 mph (4.023 km/h). Corner bumpers manage impacts at 1 mph (1.609 km/h).

|

Standard Description |

Impact Speed (mph) |

Impact Speed (km/h) |

|---|---|---|

|

Full Width Bumper |

2.5 |

4.023 |

|

Corner Bumper |

1 |

1.609 |

|

No Damage Threshold |

8 (full impact) |

- |

Using materials with good impact strength ensures safety and long-lasting parts.

Wear Resistance for Moving Parts

Moving car parts rub against each other and wear out over time. Choosing materials with great wear resistance can make these parts last longer. Special 3D printing materials, like igus self-sliding polymers, resist wear much better than regular ones. These materials are tested in labs to ensure they work well under different speeds, loads, and movements.

|

Feature |

Description |

|---|---|

|

Wear Resistance |

igus self-sliding 3D printing materials have up to 50x greater wear resistance than standard materials. |

|

Service Life Calculation |

igus conducts extensive testing to calculate the service life of printed parts based on various parameters, including speed, load, and movement type. |

|

Testing Facilities |

igus operates a 3,800 m² lab and conducts over 15,000 tests each year to log different wear rates. |

By picking materials with strong wear resistance, moving car parts can last longer and work better.

Lightweight Materials for Efficiency

Using lightweight materials helps cars work better. Lighter parts make vehicles weigh less. This improves fuel use and driving performance. Electric cars can go farther with lighter parts because the battery lasts longer.

Some materials are great for 3D printing car parts. Carbon fiber composites are strong and light. They are good for brackets and panels. Nylon blends are durable and flexible. They are useful for parts that need strength but not extra weight.

Tip: Think about where the part will be used. Lightweight materials may need extra support in high-stress areas.

Another good choice is polycarbonate (PC). It is light and tough, perfect for headlights or inside parts. For chemical resistance, PETG is a smart option. It is strong and keeps the weight low.

Designing parts carefully can also save weight. Shapes like honeycombs use less material but stay strong. Many 3D printing programs let you test designs before making them.

Picking lightweight materials and smart designs makes car parts better and more efficient.

Best Materials for 3D Printing Automotive Parts

ABS for Affordable Durability

ABS is a common material for 3D printing car parts. It is cheap and strong, making it great for prototypes and replacement parts. ABS works well for parts needing medium strength and impact resistance. It handles stress, so it’s good for dashboards, trims, and covers.

ABS can handle heat, which is important for car parts. It’s not as strong as PLA, but it’s more flexible and absorbs impacts better. You can sand, paint, or glue ABS parts to customize them easily.

Note: ABS gives off fumes while printing. Use good ventilation when working with it.

Nylon for Strength and Flexibility

Nylon is one of the strongest materials for 3D printing. It’s tough and bendable, perfect for parts that face heavy loads or repeated use. Nylon is great for moving parts like gears, hinges, and bushings because it resists wear.

Nylon absorbs shocks, making car parts work better. It stays strong under pressure and bending, even in tough conditions. Nylon mixed with carbon fiber is even stronger and still lightweight.

Keep nylon dry because it absorbs water. Store it properly to keep it working well.

PETG for Chemical Resistance

PETG is strong and resists chemicals, oils, and grease. It’s good for car parts inside or outside the vehicle. PETG doesn’t absorb water and stands up to sunlight, making it durable.

PETG is great for prototypes and replacement parts needing strength and flexibility. It can handle small impacts without breaking. It’s also easy to print, so beginners can use it without trouble.

Tip: PETG is clear, so you can make cool designs like light covers or panels.

Choosing the right material improves your car parts’ performance and lifespan. ABS, nylon, and PETG are excellent options for 3D printing automotive parts.

Carbon Fiber Composites for Lightweight Strength

Carbon fiber composites are great for making car parts light and strong. These materials mix carbon fibers with a plastic base, creating stiff and tough components. They help reduce the weight of car parts while keeping them strong. This makes them perfect for things like brackets, panels, and frames.

|

Feature |

Description |

|---|---|

|

Material Type |

|

|

Key Advantages |

Lightweight parts with high stiffness and strength |

|

Application Areas |

Cars, planes, medical tools, and more |

|

Impact on Manufacturing |

Improves printed parts' strength and allows complex designs |

These composites are very useful in cars. They make vehicles lighter, which saves fuel. Electric cars also benefit because lighter parts make batteries last longer. Carbon fiber composites can create detailed designs that regular methods cannot. This makes them a top pick for replacement parts that need to be light and tough.

Tip: Check if your 3D printer works with rough materials. Carbon fiber composites can wear out normal nozzles. Use a steel nozzle for better results.

Metal Filaments for High-Performance Applications

Metal filaments bring metal strength to 3D printing. They mix metal powders with plastic, making them easier to print than solid metals. These filaments are great for car parts that need to handle tough conditions.

Popular metal filaments include stainless steel, bronze, and copper. Stainless steel works well for parts under heat or stress, like engine pieces. Bronze and copper are good for decorative or electrical parts. Metal filaments are also great for strong and precise replacement parts.

Note: Metal filaments often need extra steps after printing. Polishing or heating can make the parts stronger and look better.

Metal filaments are strong and flexible, making them great for car parts. They combine the benefits of metalworking with the ease of 3D printing.

ASA for UV Resistance and Mechanical Properties

ASA is made for outdoor car parts. It resists sunlight, so it doesn’t fade or weaken from UV rays. This makes it ideal for mirrors, trims, and other outside parts.

ASA is also tough and weatherproof. It handles impacts and stays strong over time. You can use it for durable replacement parts. ASA prints easily and doesn’t warp much during printing.

Tip: Use a heated bed and enclosed printer for ASA. This prevents warping and gives a smooth finish.

ASA is strong, UV-resistant, and easy to use. It’s a great choice for car parts that need to last and work well outdoors.

Evaluating 3D Printing Material Properties

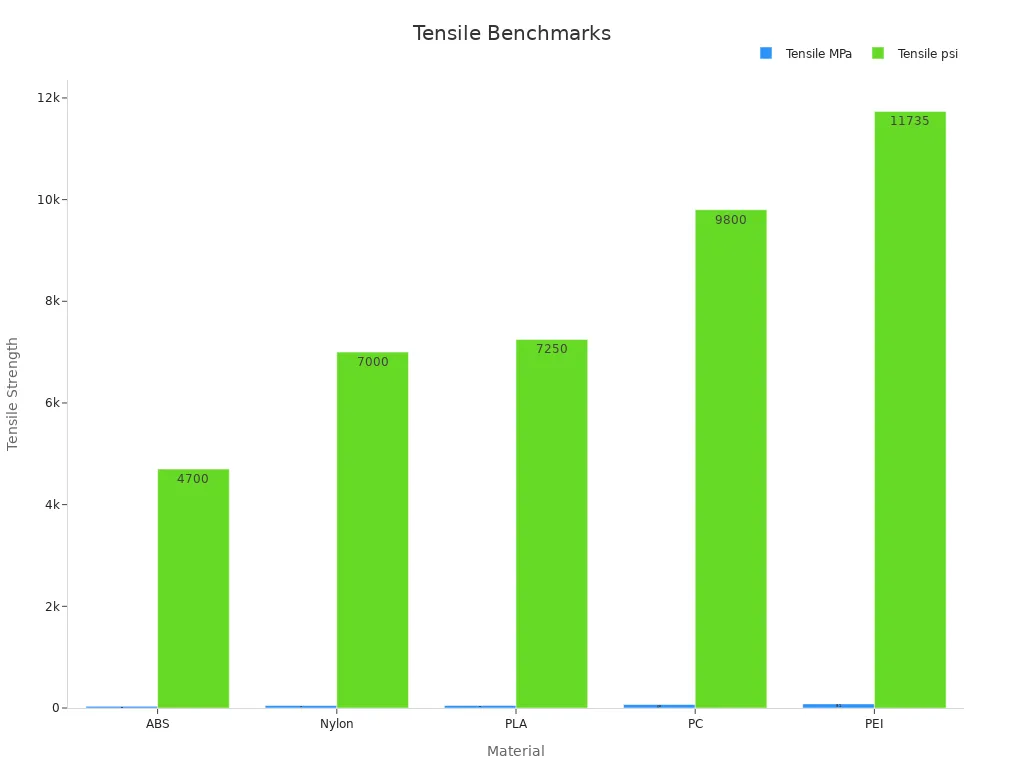

Tensile Strength and Load-Bearing Capacity

When picking a material for car parts, tensile strength is key. This shows how much force a material can take before breaking. For parts that carry weight, strong materials are needed for safety and durability.

Different materials have different tensile strengths. For example, polycarbonate (PC) is very strong at 68 MPa. It works well for tough parts like brackets. ABS, with 33 MPa, is better for lighter parts like trims. Below is a table showing tensile strength for common materials:

|

Material |

Tensile Strength (MPa) |

Tensile Strength (psi) |

|---|---|---|

|

ABS |

33 |

4,700 |

|

Nylon |

48 |

7,000 |

|

PLA |

50 |

7,250 |

|

PC |

68 |

9,800 |

|

PEI |

81 |

11,735 |

Other factors also affect tensile strength. For example, parts printed in the ZX direction are weaker than those printed in XY or XZ. Moisture can also lower strength, as shown below:

|

Factor |

Impact on Tensile Strength |

|---|---|

|

Print Orientation |

ZX parts < 50% strength of XY/XZ |

|

Moisture |

Dry: ~55 MPa, Soaked: ~27 MPa |

|

Environmental Conditions |

Retained moisture affects properties |

To get the best results, match the material's strength to your part's needs.

Flexibility and Elasticity

Flexibility is important for parts that bend or absorb shocks. It shows how well a material can stretch and return to its shape. Materials like nylon and TPU are great for flexible parts like hinges and seals.

Nylon is strong and flexible, so it handles repeated stress well. TPU is stretchy like rubber, making it good for reducing vibrations. When choosing a material, balance flexibility and strength for the best performance.

Tip: Test your part in real conditions to check its flexibility and fit. This ensures it works as planned.

Flexible materials can shrink or warp during printing. This may affect the part's size and shape. To fix this, use accurate printer settings. Post-processing, like heating, can also help stabilize the material.

Thermal Resistance and Operating Temperatures

Thermal resistance is vital for car parts exposed to heat. Materials that resist heat keep their properties and stay safe. For example, polycarbonate (PC) and PEEK handle high temperatures well.

Here’s a table of materials with good thermal resistance:

|

Material |

Thermal Resistance Characteristics |

Applications |

|---|---|---|

|

Polycarbonate (PC) |

Handles heat, great for tough conditions. |

Headlights, engine covers |

|

PEEK |

Stays stable in high heat, resists damage. |

Turbocharger parts |

|

Aluminium AlSi10Mg |

Lightweight, conducts heat well. |

Car parts |

|

Stainless Steel 316L |

Resists rust, stays strong in harsh places. |

Marine and medical uses |

|

Inconel 718 |

Works in extreme heat up to 700°C (1290°F). |

Jet engines |

|

Carbon Fiber |

Handles heat, lightweight, and strong. |

Car and airplane parts |

For cars, PC is good for headlights, while PEEK works for high-performance parts. Carbon fiber is also a great choice for strong, lightweight parts.

Note: Always check the heat range of your material. This avoids problems from heat damage.

By knowing how materials handle heat, you can pick the best one for your car parts.

Oil and Grease Resistance

Car parts often touch oil and grease, especially in engines. These substances can harm some materials over time. This may cause parts to fail or work poorly. To avoid this, pick materials that resist oil and grease well. This keeps the parts strong and working in tough conditions.

Materials like PETG and Nylon are great options. PETG does not soak up oil, so it’s good for fluid containers or covers. Nylon is strong and resists grease, making it perfect for gears and bushings in oily systems.

Tip: Think about where the part will be used. Engine parts facing heat and oil need materials that handle both.

Testing materials in real-life conditions is very important. During prototyping, expose the material to oil and grease. This helps check if it works as expected. Testing prevents failures and makes sure your 3D printed parts last longer.

Using Product Data Sheets for Material Selection

Product data sheets help you pick the right material for your car parts. These sheets show details about material properties. They help you match the material to your needs. By using them, you can improve the strength and durability of your parts.

Look for key details like tensile strength, heat resistance, and chemical safety. For example, ABS is stable in heat and flexible, good for prototypes. TPU is stretchy and stiff, great for seals and hoses. PA12 is strong and impact-resistant, ideal for tough car parts. The table below shows these features:

|

Material |

Key Properties |

Applications |

|---|---|---|

|

ABS |

Cheap, heat-stable, flexible |

Prototypes, small production runs |

|

TPU |

Stretchy, stiff, Shore A Hardness 88 |

Seals, hoses, and tubes |

|

PA12 |

Strong (48 MPa), impact-resistant |

Durable car parts, small production |

Note: Check the data sheet with your printer’s specs. Some materials need special settings like heated beds or strong nozzles.

Using product data sheets makes choosing materials easier. It ensures your parts meet the demands of their job. This saves time and improves the quality of your 3D printed car parts.

Printer Compatibility with 3D Printing Materials

Matching Materials to Printer Capabilities

Not all printers can use every 3D printing material. You must check if your printer fits the material's needs. Here are some key factors to consider:

- Diameter of Raw Materials: Materials come in sizes like 1.75 mm or 2.85 mm. Smaller sizes allow better precision and improve print quality.

- Melting Points: Each material melts at a specific temperature. For example, ABS melts at 230 °C, while PLA melts at 180 °C. Your printer must reach the right heat for smooth melting and bonding.

- Viscosity: This shows how easily a material flows. Thicker materials need more heat and pressure. If your printer isn’t built for this, it may struggle.

Always check your printer's specs before starting. This ensures it can handle the material you want to use.

Challenges with Advanced Materials

Using advanced materials like carbon fiber composites or metal filaments can be hard. These materials often need special printers or settings. For example, carbon fiber can damage regular nozzles. A hardened steel nozzle is better. Metal filaments may need extra steps, like polishing, to make them stronger.

Another issue is the lack of experts in some areas. This makes fixing problems or improving prints harder. Also, advanced materials can be costly or hard to find.

To solve these problems, learn more about advanced materials. Training and research can help you use them correctly.

Adjusting Printer Settings for Optimal Results

Changing printer settings is important for good prints. First, set the nozzle temperature to match the material. For example, use 230 °C for ABS or 250 °C for PETG.

Next, adjust the print speed. Slower speeds work better for thicker materials, as they flow more smoothly. Also, set the bed temperature to avoid warping. For instance, ABS needs a heated bed at 100 °C, while PLA works at 60 °C.

Tip: Check your printer manual or online guides for the best settings. Printing small test pieces can help you find the right setup.

By adjusting your printer settings to fit the material, you can make stronger, more accurate, and longer-lasting parts.

Cost and Availability of 3D Printing Materials

Balancing Quality and Budget

Picking materials for 3D printing needs careful planning. High-quality materials cost more but last longer. Nylon costs $50 per kilogram. It is strong and flexible, great for tough jobs. ABS costs $30 per kilogram. It is strong and affordable, good for car parts. Polyetherimide (PEI) costs over $100 per kilogram. It resists heat and flames, perfect for special uses.

|

Material |

Cost per kg |

Properties |

|---|---|---|

|

Nylon |

$50 |

Strong, flexible, and durable for heavy-duty tasks. |

|

ABS |

$30 |

Affordable, strong, and impact-resistant for car parts. |

|

Polyetherimide |

$100+ |

Heat-resistant, flameproof, and lightweight for special applications. |

Think about the part’s job and stress levels. This helps you pick the best material for your budget.

Sourcing Reliable Suppliers

Good suppliers give you quality materials every time. Look for suppliers with good reviews and experience in car parts. Online stores like Amazon show user ratings to help you choose. Local suppliers can save shipping time and costs. For special materials like metal filaments, use experts who know your needs.

Tip: Test sample materials before buying a lot. This checks if they work well with your printer.

Evaluating Long-Term Cost Efficiency

Think about long-term savings, not just upfront costs. Durable materials like nylon or metal filaments cost more but last longer. For example, a strong gear avoids frequent replacements, saving money over time.

Some materials need extra steps, like polishing or heating. These add to the total cost. Plan for these expenses to avoid surprises.

Using high-quality materials makes parts last longer and work better. This saves money and reduces waste over time.

Post-Processing and Testing for 3D Printing Car Parts

Post-Processing Techniques for Strength and Finish

Post-processing makes 3D printed car parts stronger and smoother. Sanding removes rough spots and fixes flaws. Polishing adds shine and makes parts look better. Heating, called annealing, makes parts tougher and last longer.

Painting protects parts and gives them a custom look. Coatings can make parts resist chemicals or sunlight. For example, clear coats on ASA parts help them last outside.

Tip: Clean parts before post-processing. Dirt can ruin the results.

Testing for Durability and Performance

Testing checks if car parts are strong and work well. Strength tests show how much force parts can handle. Moving parts need wear tests to see if they last.

Heat tests check if parts stay strong in hot places. Materials like polycarbonate or PEEK should work well under heat. Oil tests show if engine parts resist grease and stay durable.

Note: Testing finds weak spots before using parts in real life.

Iterative Improvements Based on Testing Results

Testing helps improve designs and materials. If a part fails, use stronger materials like nylon or carbon fiber composites. For heat problems, change printer settings or use heat-safe materials.

Small changes and retesting make parts better. If a part breaks, make it thicker or change its shape. This ensures parts meet strength and performance needs.

Tip: Write down test results. It helps track progress and avoid mistakes.

Picking the right materials for 3D printing car parts is important. It helps parts last longer and work better. First, figure out what the part needs, like handling heat or impacts. Look at different materials that might work and test them. Testing prototypes helps you find the best material for the job.

|

Step |

Description |

|---|---|

|

Find out what the part must handle, like heat or stress. |

|

|

Check Materials |

Look at materials that fit the needs and work with 3D printers. |

|

Test Materials |

Try out materials to see if they meet the part’s needs. |

|

Make Prototypes |

Print test parts and check how well they perform. |

|

Follow Rules |

Make sure materials meet industry rules and get certifications. |

By testing and improving, you can make strong, cost-effective car parts. This ensures they last longer and work well in real conditions.

FAQ

What is the best material for 3D printing car parts?

The best material depends on what the part will do. For strong parts, use nylon or carbon fiber. For heat resistance, pick polycarbonate or PEEK. If the part needs UV protection, ASA is a good choice. Always choose materials based on the part's needs.

Can all 3D printers use advanced materials like carbon fiber?

No, not every printer can use advanced materials. Carbon fiber needs a printer with a strong steel nozzle. Check your printer's details to see if it works with these materials.

How do you check if 3D printed car parts are durable?

You can test durability by copying real-life conditions. Do strength, heat, and wear tests. For moving parts, check how they hold up over time. Testing makes sure the part works as expected.

Are 3D printed car parts as strong as regular ones?

Yes, they can be just as strong or stronger. Use the right materials like carbon fiber or nylon. Good printer settings and post-processing also make parts tougher.

How can you save money when 3D printing car parts?

Use cheaper materials like ABS or PETG for simple parts. Design parts to use less material, like honeycomb shapes. Test small prototypes first to avoid wasting materials. Buying from trusted suppliers can also lower costs.