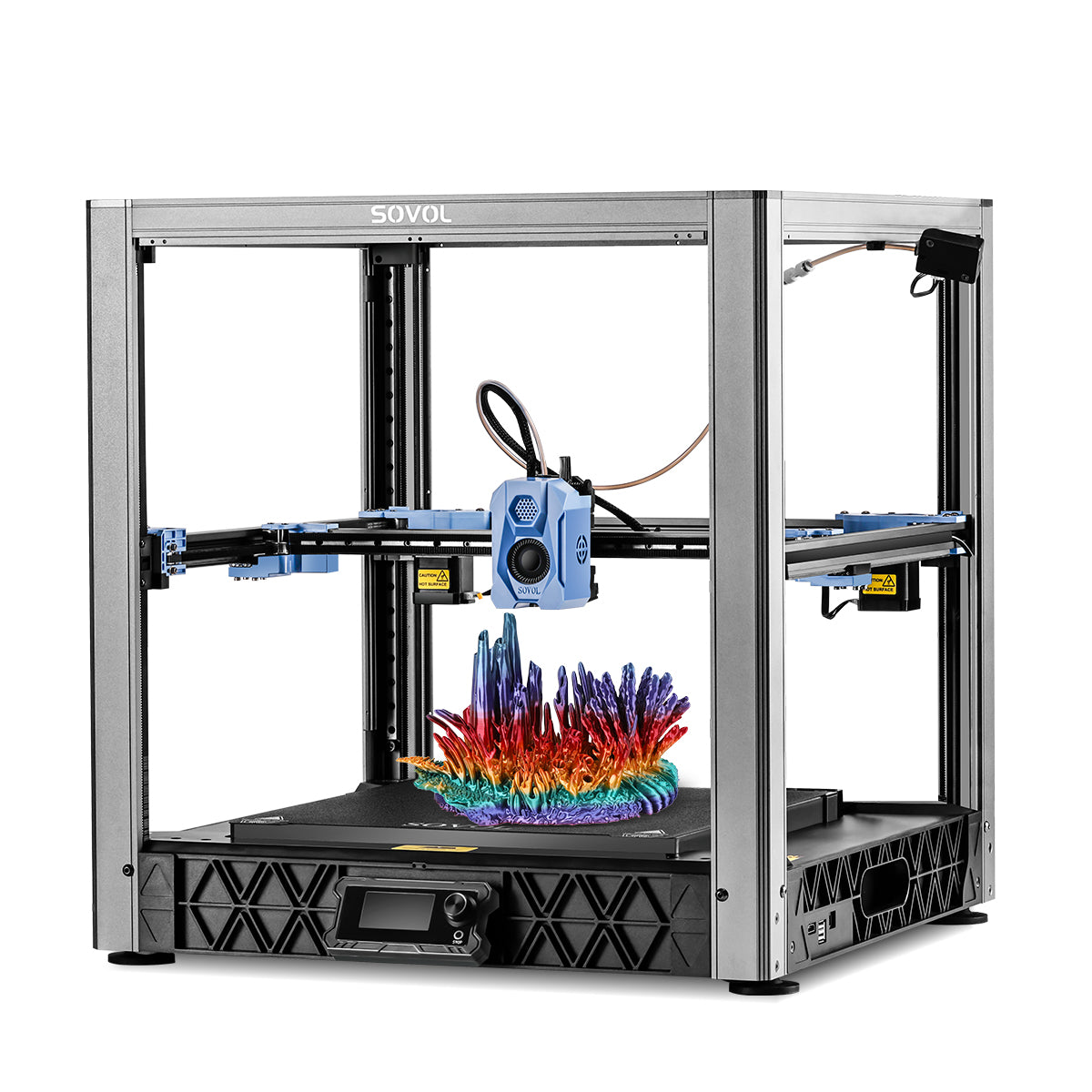

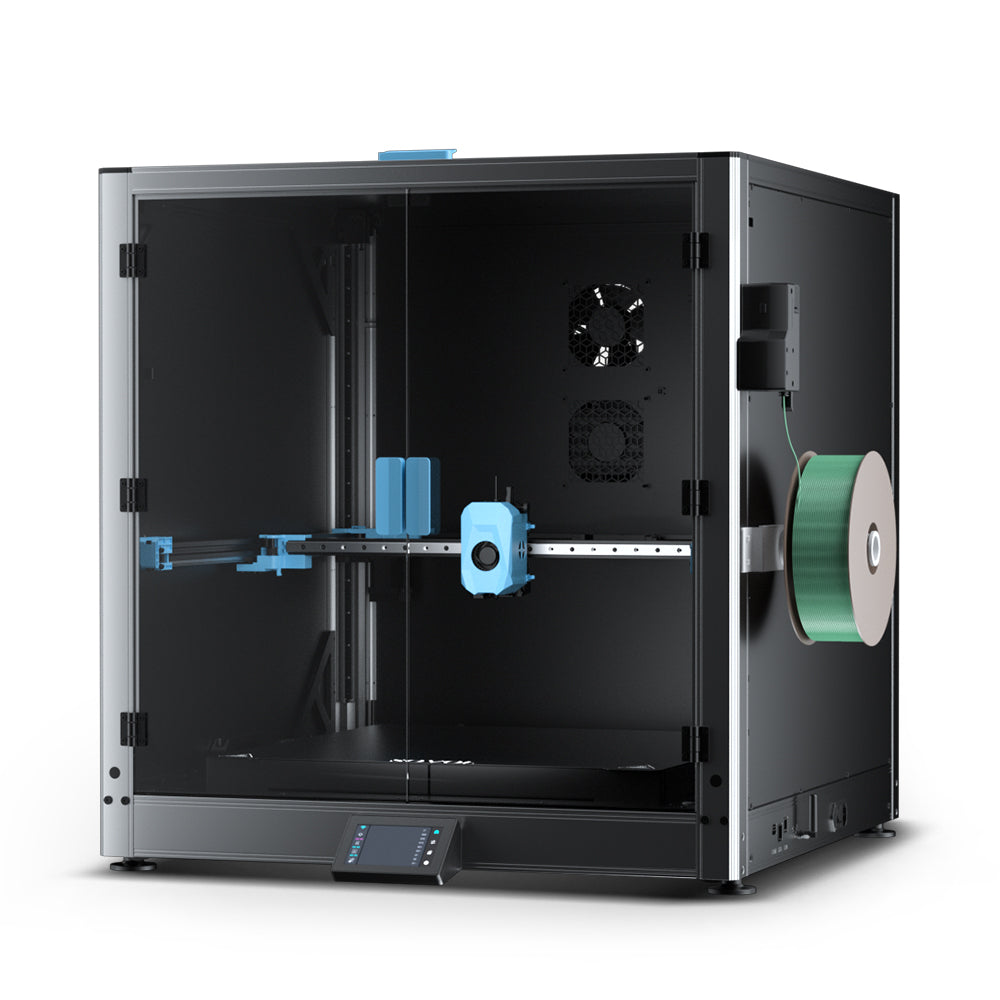

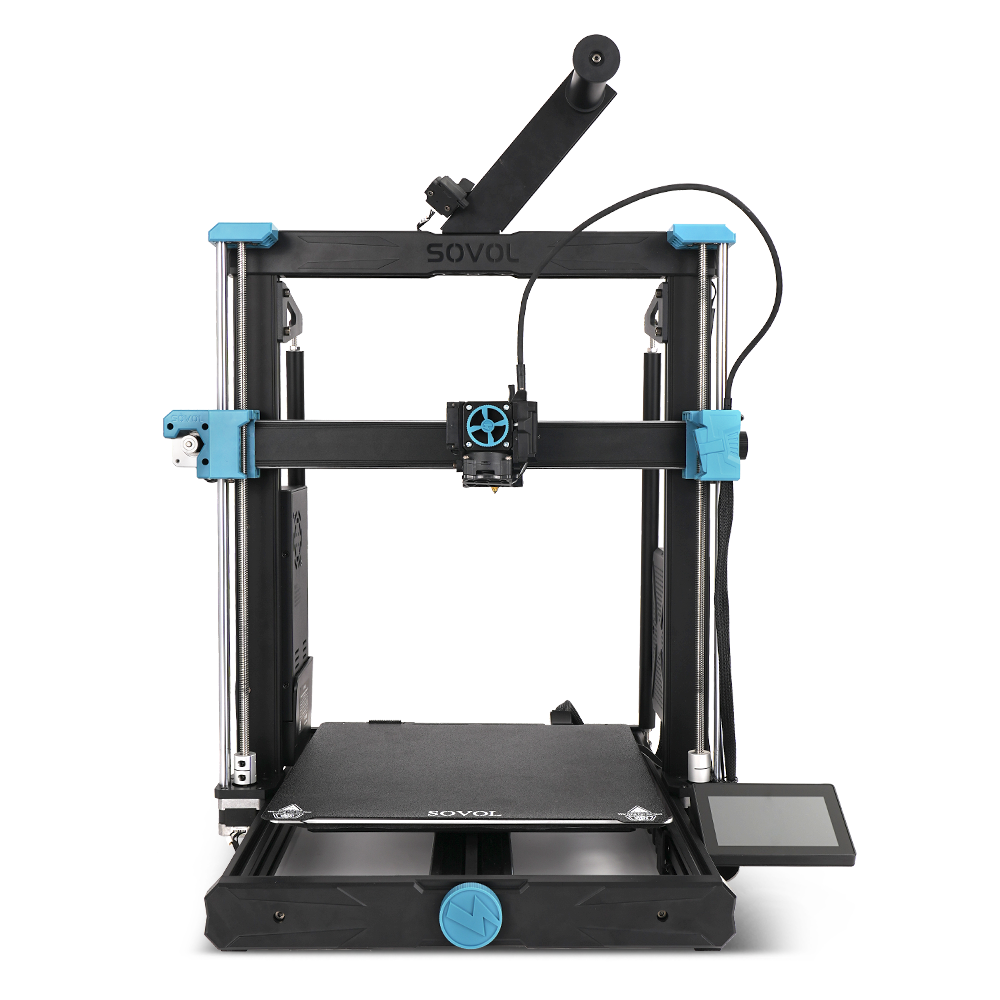

Can any other 3d printer match the comgrow t500 in sheer scale and precision? The comgrow t500 delivers a massive 500 × 500 × 500 mm build volume, advanced print quality, and robust construction. These features allow professionals to tackle high-volume 3d projects with confidence. The sovol comgrow t500 supports a wide range of 3d materials and offers exceptional quality, making it a standout choice for demanding 3d applications.

Key Takeaways

- The Comgrow T500 offers a huge 500 × 500 × 500 mm build volume, letting users print large models or many parts at once, saving time and improving accuracy.

- It supports many materials like PLA, PETG, TPU, and carbon fiber, thanks to its all-metal hotend and hardened steel nozzle, giving users flexibility for different projects.

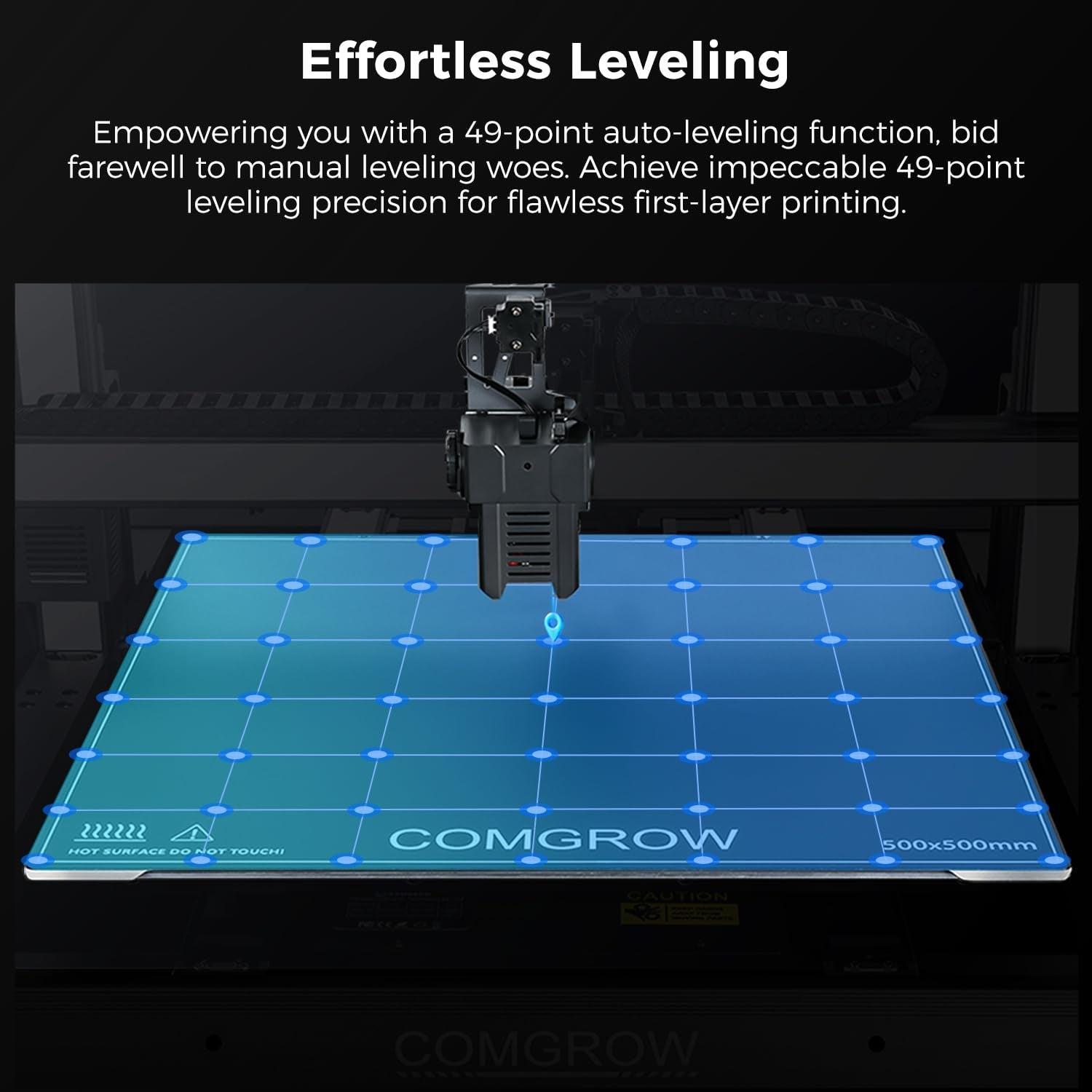

- Advanced features like 49-point automatic bed leveling and Klipper firmware ensure precise, high-quality prints with less effort and fewer errors.

- The printer’s strong frame, dual motors, and cooling system provide stability and reliability, even during long or complex prints.

- User-friendly options such as a 7-inch touchscreen and multiple connectivity choices make the T500 easy to control and fit into various workflows.

Comgrow T500 Features

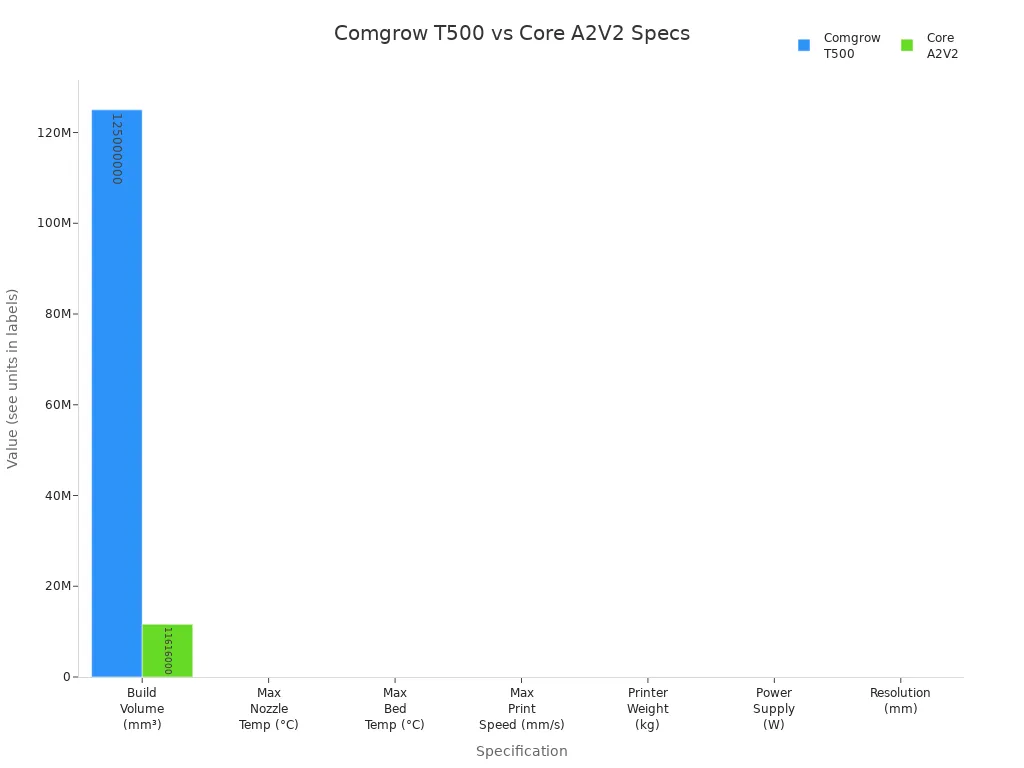

Build Volume

The Comgrow T500 stands out with its large build volume of 500 × 500 × 500 mm. This size allows users to print big models or multiple parts in one run. Many standard 3D printers offer much smaller print areas, which means users often need to split large projects into several pieces. The T500’s large print volume saves time and improves accuracy by reducing the need for assembly.

|

Feature |

Comgrow T500 |

Ultimaker S7 |

|---|---|---|

|

Build Volume (mm) |

500 x 500 x 500 |

240 x 330 x 300 |

|

Printing Speed (mm/s) |

Up to 180 |

|

|

Filament Compatibility |

PLA, PETG, TPU, Nylon* |

PLA, ABS, PETG, Nylon |

|

Bed Leveling |

49-point automatic |

Advanced automatic |

|

Assembly |

95% pre-assembled |

Fully assembled |

The large build volume of the Comgrow T500 opens up new possibilities for 3D printing. Users can create prototypes, functional parts, or artistic pieces in one piece, making the printer ideal for businesses and advanced hobbyists.

The T500’s 49-point automatic bed leveling system ensures a flat print surface, which helps with first-layer adhesion and print reliability. The printer comes 95% pre-assembled, so the setup process is convenient and quick.

Material Compatibility

The Comgrow T500 supports a wide range of 3D printing materials. Its all-metal hotend can reach up to 300°C, and the hardened steel nozzle handles abrasive filaments like carbon fiber. The direct drive extruder with a 6.5:1 gear ratio ensures smooth extrusion, even with flexible or composite filaments. Users can print with PLA, PETG, TPU, and carbon fiber composites, which makes the printer suitable for many applications.

The T500’s material compatibility gives users the flexibility to choose the best filament for each project. This feature is especially important for professionals who need to produce strong, functional parts or experiment with new materials.

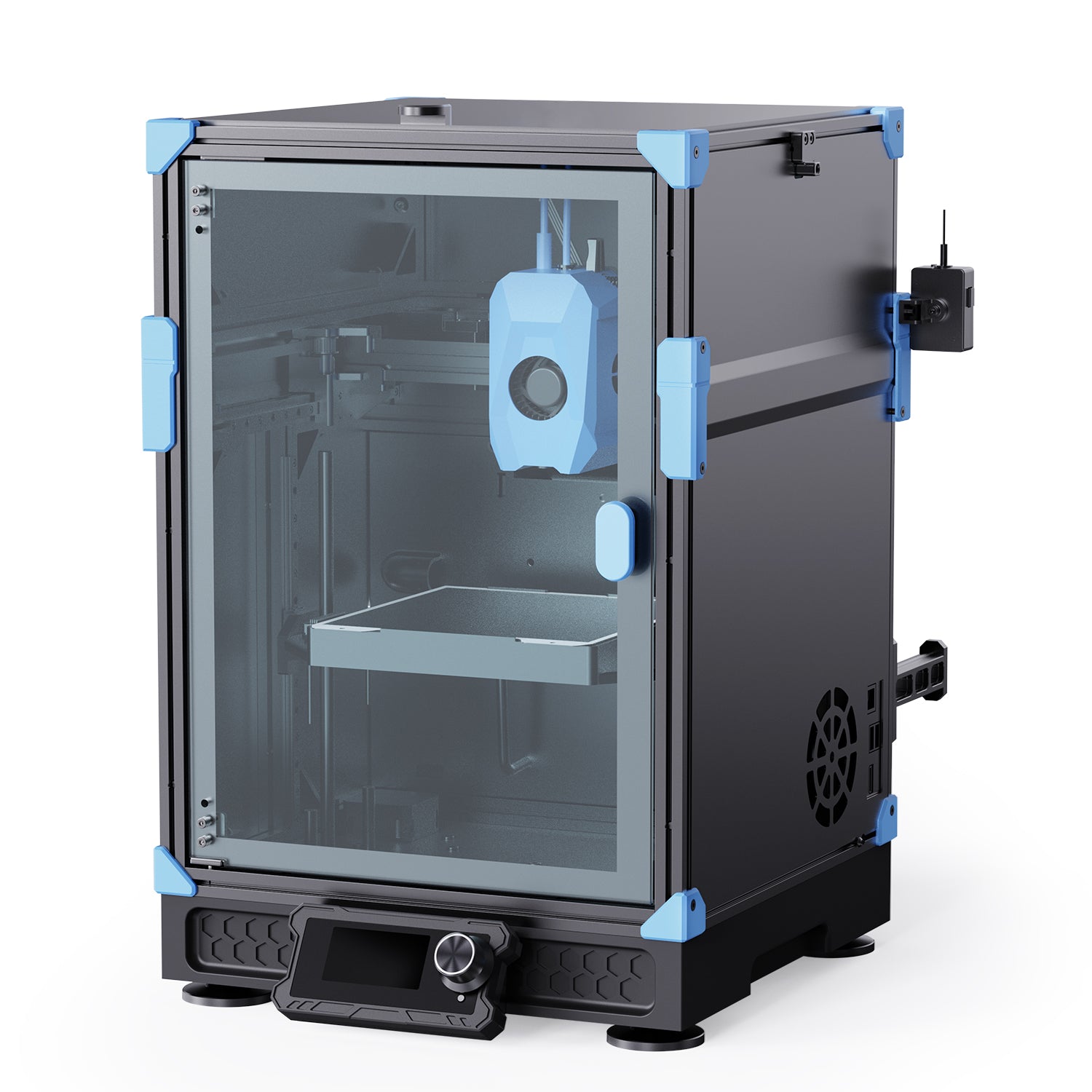

Connectivity Options

The Comgrow T500 offers several connectivity options to fit different workflows. Users can connect through Wi-Fi, USB 2.0 and 3.0, Type-C, and LAN. These features make it easy to send files to the printer from computers or networks. Wireless connectivity allows teams to manage multiple printers from one location, improving efficiency in busy workspaces.

The 7-inch IPS touchscreen with Klipper firmware provides a user-friendly interface. The touchscreen makes it simple to control the printer, adjust settings, and monitor progress. These user-friendly features help both new and experienced users operate the printer with confidence.

|

Feature |

Specification |

|---|---|

|

Build Volume (mm) |

500 x 500 x 500 |

|

Max Nozzle Temperature (°C) |

300 |

|

Max Bed Temperature (°C) |

80 |

|

Max Print Speed (mm/s) |

500 |

|

Extruder Type |

Direct Drive, 6.5:1 gear ratio |

|

Bed Leveling |

49-point automatic leveling |

|

Display |

7" IPS touchscreen with Klipper |

|

Connectivity |

WiFi, SD, USB, Type-C, LAN |

|

Filament Compatibility |

PLA, PETG, TPU, Carbon Fiber, Wood |

|

Power Supply (W) |

500 |

|

Weight (kg) |

Approx. 39 |

|

Assembly |

95% pre-assembled, ~15 minutes |

The combination of advanced connectivity and a responsive touchscreen makes the Comgrow T500 a powerful tool for efficient printing and workflow integration.

Print Quality

Precision and Speed

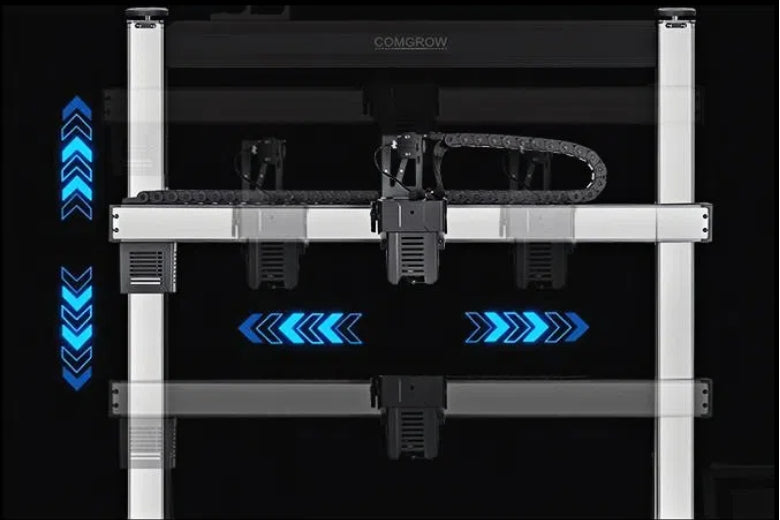

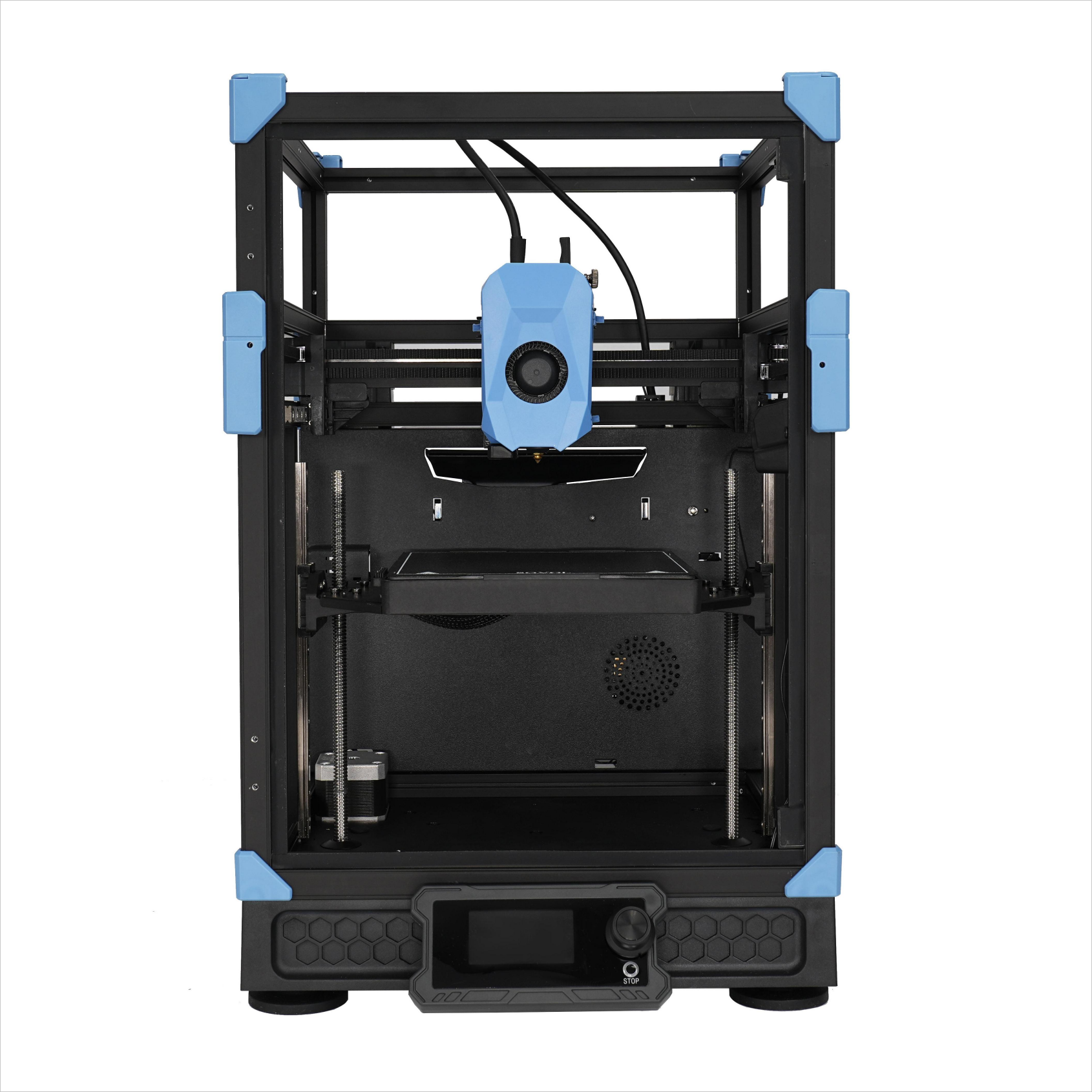

The Comgrow T500 sets a high standard for precision and speed in large-format 3D printing. Linear rails on all three axes reduce friction and play, which leads to smoother print head movements. This design improves layer alignment and reduces the risk of layer shifting. Dual motors on the Z and Y axes add stability, ensuring the printer maintains accuracy even during high-speed operations. The printer achieves ±0.1mm accuracy, which is essential for professional applications that demand consistent results.

The T500 supports a max speed up to 500mm/s, with acceleration reaching 8000mm/s². This capability allows users to complete large projects faster without sacrificing quality. The direct drive extruder, featuring a 6.5:1 gear ratio, delivers consistent extrusion and supports high flow rates. The printer’s print performance stands out, as it balances speed and quality for both detailed and functional prints.

When comparing industry standards, the T500 achieves a maximum print speed of 220 mm/s and a minimum layer height of 50 microns. While some printers reach higher speeds, the T500 matches the industry’s best in terms of detail and surface finish. Its minimum layer height ensures smooth, professional results, making it a strong choice for those who value superior print quality.

The combination of industrial-grade hardware and advanced motion systems enables the T500 to deliver superior print quality, even at high speeds.

Klipper Firmware

Klipper firmware plays a key role in achieving superior print quality on the Comgrow T500. This fast Klipper firmware enables advanced features like Input Shaping and Smooth Pressure Advance, which reduce vibrations and prevent oozing. These improvements result in cleaner, more precise prints. The firmware supports high stepping rates, allowing the printer to operate smoothly and efficiently.

Users benefit from the klipper firmware touch screen, which provides an intuitive interface for controlling the printer. Real-time monitoring and remote adjustment features increase productivity and convenience. The modular design of Klipper allows for easy customization and synchronization, making it suitable for both beginners and experienced users. The firmware’s advanced kinematic calculations further enhance accuracy and print performance, ensuring the T500 consistently delivers superior print quality.

The fast klipper firmware optimizes the printer’s capabilities, allowing it to reach its full potential. With easy configuration and powerful features, Klipper helps users achieve the best possible results in every print.

Auto Bed Leveling

The T500’s 49-point auto-leveling system ensures a perfectly flat print surface across the entire build plate. This auto-leveling feature maintains an even nozzle-to-bed distance, which is critical for first-layer adhesion. By automating the leveling process, the printer eliminates the need for manual adjustments, saving time and reducing errors.

The auto-leveling system directly improves print reliability. It minimizes common issues such as warping and layer shifting, which can affect the final quality of a print. With a properly calibrated bed, users experience fewer failed prints and more consistent results. The T500’s auto-leveling system stands out as a key factor in achieving superior print quality, especially for large and complex 3D projects.

The advanced auto-leveling system gives users confidence that every print will start on a solid foundation, leading to better outcomes and higher productivity.

The Comgrow T500 combines precision hardware, advanced firmware, and a robust auto-leveling system to deliver print quality that meets the demands of professionals and businesses. By focusing on achieving superior print quality, the T500 ensures every project benefits from reliable performance, high accuracy, and exceptional results.

Printer Reliability

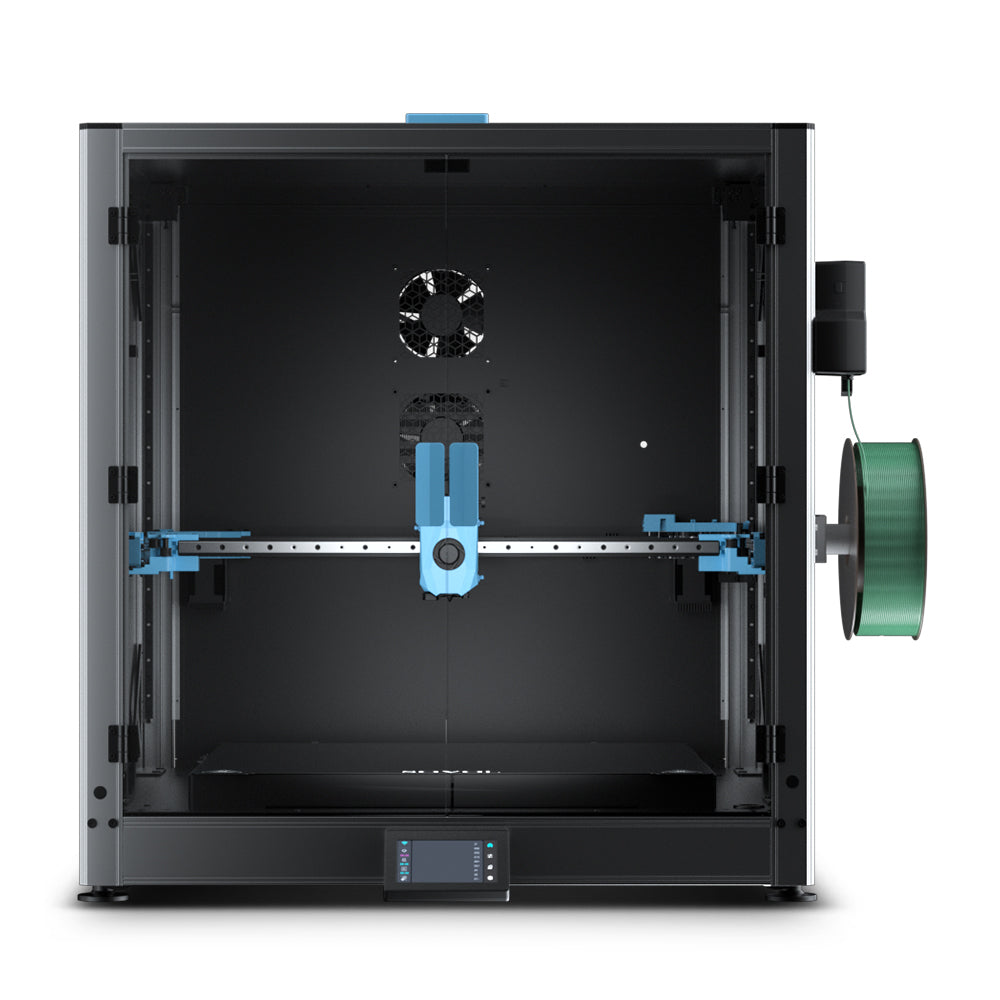

Construction

The Comgrow T500 uses a strong frame and a Z-axis support bracket to keep the printer stable during operation. Dual motors on both the Z and Y axes help the printer move smoothly and stay aligned. Internal linear rails on the X, Y, and Z axes reduce friction, which leads to better layer alignment and fewer print failures. The 49-point automatic bed leveling system keeps the nozzle at the right height, so each print starts with a solid foundation. The all-metal hotend can reach high temperatures, making it possible to use a wide range of materials. The hardened steel nozzle resists wear, even when printing with abrasive filaments.

- Dual Z-axis and Y-axis motors for precise alignment

- Internal linear rails for smooth movement

- 49-point automatic bed leveling for consistent first layers

- All-metal hotend and hardened steel nozzle for durability

These features work together to deliver reliable printing and high-quality results, even on large or complex projects.

Cooling and Stability

The triple 3010 fans in the T500 keep the extruded material at the right temperature. This cooling system prevents overheating and helps maintain print quality during long jobs. Stable temperatures reduce the risk of warping or detachment, which is important for large-format printing. The fans also allow the printer to handle high-temperature materials without losing stability. This setup supports consistent performance and helps users complete prints successfully.

The cooling system and sturdy frame make the T500 a dependable choice for demanding 3d printing tasks.

User Feedback

Many users praise the T500 for its print quality and large build volume. They find the setup process straightforward, thanks to user-friendly features like the touchscreen and automatic bed leveling. Some users report that the printer completes multiple prints without failure when used as designed. The stable frame and dual-motor design stand out as key reasons for fewer print failures compared to other large-format printers. These strengths make the T500 a solid option for those who want reliable, high-quality printing.

Sovol Comgrow T500 Applications

Prototyping

The sovol comgrow t500 helps engineers and designers create prototypes quickly. Its large build volume allows teams to print full-size models or several parts at once. This saves time and boosts efficiency in the design process. The automatic bed leveling and high-performance motors ensure each prototype has smooth surfaces and accurate details. Many professionals use the sovol comgrow t500 to test new ideas, check fit and function, and make changes before final production. The ability to use different materials, including carbon fiber composites, lets users create strong and realistic prototypes.

The sovol comgrow t500 supports batch production, making it easy to test multiple designs in a single print job.

Large Models

The sovol comgrow t500 stands out for large-scale 3d printing. Its 500mm x 500mm x 500mm build area supports projects that smaller printers cannot handle. This capability benefits industries such as engineering, education, and art. For example, engineers print functional parts and prototypes, while artists and hobbyists create sculptures or cosplay props. Educational groups use the printer for group projects and teaching aids.

|

Industries / User Groups |

|

|---|---|

|

Large-scale prototypes |

Engineers, product designers |

|

Functional parts |

Engineers, product designers |

|

Artistic creations |

Makers, hobbyists, small businesses |

|

Batch production items |

Small businesses, studios |

|

Custom products |

Small businesses, studios |

|

Decorative items, cosplay props |

Makers, hobbyists |

|

Educational models, group projects |

Educational institutions |

The large build volume and stable design ensure high-quality results, even for complex or tall models.

Custom Parts

Businesses and advanced hobbyists use the sovol comgrow t500 to produce custom parts with precision. The printer’s all-metal hotend reaches 300°C, supporting a wide range of materials. Users can choose different nozzle sizes for fine detail or faster production. The dual Z and Y axes, along with industrial-grade linear rails, keep prints stable and accurate. The 49-point automatic bed leveling system reduces print failures and makes setup simple. WiFi connectivity and a 7-inch touchscreen help users manage files and monitor progress, improving workflow efficiency.

- Print large or multiple custom parts in one job

- Use advanced materials for durable, functional parts

- Achieve consistent quality with stable motion and precise alignment

These features make the sovol comgrow t500 a reliable tool for creating unique solutions in business and creative projects.

The Comgrow T500 stands out with its large 500 × 500 × 500 mm build volume, advanced hardware, and high-speed printing. Many professionals and businesses choose the T500 for its ability to handle demanding projects, support for a wide range of materials, and user-friendly touchscreen. The printer offers a strong price-to-performance ratio, making it a smart investment for those who need both quality and value. Users benefit from helpful resources, including setup guides, community support, and a public GitHub for firmware updates.

For teams seeking reliable, large-format 3D printing, the T500 delivers performance, flexibility, and support—making it an excellent choice for your next project.

FAQ

What materials can the Comgrow T500 print?

The Comgrow T500 supports PLA, PETG, TPU, and carbon fiber composites. The all-metal hotend reaches 300°C, so users can print with many advanced filaments. The hardened steel nozzle allows for abrasive materials.

How does the 49-point automatic bed leveling work?

The printer uses sensors to measure 49 points on the bed. It adjusts the nozzle height automatically. This process ensures a flat surface for every print and helps prevent first-layer issues.

Can users control the T500 remotely?

Yes. The T500 offers Wi-Fi, LAN, and USB connectivity. Users can send files, monitor prints, and adjust settings from a computer or mobile device. The 7-inch touchscreen also provides easy local control.

What is the maximum print speed of the T500?

The T500 can print up to 500 mm/s. The direct drive extruder and dual motors help maintain quality at high speeds. This speed allows for faster project completion.

Is the Comgrow T500 suitable for beginners?

The T500 works best for users with some 3D printing experience. Features like auto bed leveling and a touchscreen make setup easier. However, the large build volume and advanced options suit professionals and advanced hobbyists.