You can solve 3d printing stringing by adjusting retraction settings, lowering your print temperature, and drying your filament. Many people see stringing appear as thin, unwanted threads between parts of a print. This issue often frustrates beginners, but you can fix it with a few key changes.

3d printing stringing happens often, but you do not need to worry. Try these steps if you want to learn how to fix stringing and get cleaner prints.

- Adjust retraction settings

- Lower printing temperature

- Dry your filament

Key Takeaways

- Adjust your printer's retraction settings to pull filament back during travel moves and reduce stringing.

- Lower the print temperature within your filament's range to keep melted plastic from oozing out.

- Keep your filament dry by storing it properly and drying it before printing to prevent moisture-related stringing.

- Increase travel speed during non-print moves to limit the time melted filament can leak and form strings.

- Use slicer features like Z-Hop, wipe, and coasting to control nozzle movement and reduce stringing further.

3D Printing Stringing Causes

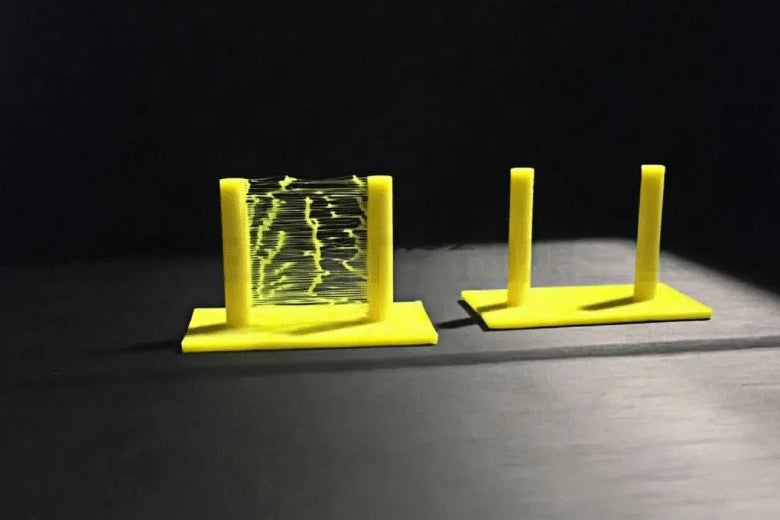

What Is Stringing or Oozing

You may notice thin, hair-like strands of plastic stretching between parts of your 3D print. This is called stringing or oozing. These unwanted threads form when your printer moves the nozzle across open spaces without printing. Stringing or oozing can leave your prints looking messy and reduce print quality. You might see surface defects, wasted material, or even small blobs on your finished object. While stringing or oozing usually does not destroy the mechanical strength of your print, it can introduce tiny flaws that affect the look and sometimes the performance of your part.

Tip: If you spot excessive stringing, check your print settings before starting another job. Quick adjustments can help you avoid stringing issues and improve your results.

Why 3D Printer Stringing Happens

Several factors can cause 3d printer stringing. You need to understand these causes to prevent stringing and get cleaner prints. The most common reasons include:

- Incorrect retraction settings: If your retraction distance or speed is too low, the nozzle does not pull the filament back enough during travel moves. This lets melted plastic ooze out and create strings.

- High nozzle temperature: When the nozzle gets too hot, the filament becomes very fluid. This makes it easier for the material to leak out and form stringing or oozing.

- Filament moisture: Filaments like PLA and PETG absorb moisture from the air. Wet filament can bubble and ooze, leading to excessive stringing.

- Travel speed: Slow travel speeds give the filament more time to ooze from the nozzle. Increasing travel speed can help prevent stringing.

- Nozzle and material type: Some materials, such as PETG, are more prone to stringing. Nozzle wear or clogs can also make stringing issues worse.

- Over-extrusion: If your printer pushes out too much filament, you will see more stringing and blobs.

You can avoid stringing issues by tuning your retraction settings, lowering your print temperature, and keeping your filament dry. Each material may need different adjustments. For example, PLA often needs lower temperatures, while PETG may require longer retraction. If you use Sovol printers or filaments, check their recommended settings for best results.

How to Fix Stringing: Common Solutions

If you want to fix 3d printer stringing, you need to focus on three main areas: retraction settings, print temperature, and travel speed. These common solutions help you reduce stringing and improve your print quality. Let’s look at each step in detail.

Retraction Settings

Retraction settings play a major role in controlling 3d printer stringing. When you enable retraction in your slicer, your printer pulls the filament back before moving the nozzle across open spaces. This action creates negative pressure inside the nozzle and helps prevent melted plastic from oozing out and forming strings.

To start, always enable retraction in your slicer. Most slicers have this option under the material or print settings tab. If you skip this step, stringing will almost always appear. Adjusting retraction is the first thing you should try.

Now, focus on retraction distance. For most printers using 1.75mm filament, a good starting point is 3 mm. Some brands suggest starting with 5 mm and a speed of 25 mm/s or lower, but you should tune these values based on your print results. Increase or decrease the retraction distance in 0.5 to 1 mm steps. Avoid going above 5 mm or below 0.5 mm, as this can cause other issues like clogs or under-extrusion. For Bowden tube printers, you may need a longer retraction distance because the tube stretches more than in direct-drive systems.

Retraction speed also matters. Start with a moderate speed, such as 25 mm/s. If you use 1.75mm filament, some experts recommend reducing the default retraction speed to about 3 mm/s to avoid filament buckling. However, many users find that speeds between 20–100 mm/s work well, so you should test what works best for your setup. Remember, increasing retraction speed too much can grind the filament, while going too slow can allow oozing.

Tip: Print a simple test model with several towers or cones to fine-tune your retraction distance and speed. This method helps you see the effect of each change and find the best settings for your printer and filament.

Important retraction settings also include features like "wipe" and "Z-hop." Enabling wipe tells the nozzle to move back over the last printed area before traveling, which can further reduce stringing. Z-hop lifts the nozzle slightly during travel moves, helping to avoid dragging strings across your print.

If you use flexible filaments like TPU, be careful with retraction. Too much retraction can cause jams or extrusion problems. For PLA, PETG, and ABS, retraction is usually safe and effective.

Temperature Adjustments

Print temperature has a big impact on 3d printer stringing. If your extruder temperature is too high, the filament becomes very liquid and leaks out of the nozzle during travel moves. Lowering the print temperature helps the filament stay more solid, which reduces stringing.

You should set the right temperature for your filament. For PLA, the optimal range is 190–220°C, with the best results often near 200°C. PETG prints well between 220–250°C, but starting around 235°C is common. TPU works best from 210–230°C. Lowering the temperature within these ranges can help reduce stringing, but dropping it too low may cause under-extrusion or poor layer adhesion.

|

Filament |

Optimal Nozzle Temperature Range (°C) |

Notes on Stringing Reduction |

|---|---|---|

|

PLA |

190 - 220 |

Lower temps reduce stringing |

|

PETG |

220 - 250 |

Lower temp within range helps |

|

TPU |

210 - 230 |

Higher temps prevent clogs |

To find the best print temperature, lower it in 5°C increments and watch for changes in stringing. If you see less stringing but the filament stops extruding smoothly, you may have gone too low. Use a temperature tower test print to compare results at different temperatures.

Note: Lowering the print temperature slows filament flow, so you may need to reduce print speed to avoid gaps or holes in your print.

If you still see stringing after adjusting retraction settings, lowering the extruder temperature is often the next best step. Many users find that temperature adjustment and filament drying have a bigger effect on stringing than changing retraction speed alone.

Travel Speed

Travel speed controls how fast the nozzle moves when it is not printing. If you check the travel speed and increase it, you can reduce the time the nozzle spends moving over open spaces. This action limits the time melted filament can ooze out and form strings.

Most slicers let you set travel speed under the "Travel Speed" or "Movement" section. A typical range for reducing stringing is 190–200 mm/s. Some users find that even 150 mm/s works well, especially if your printer cannot handle higher speeds without mechanical issues. Increasing travel speed helps reduce stringing, but going too fast can cause problems like layer shifts or missed steps. Always test your printer’s limits.

- Increasing travel speed during non-print moves reduces the time filament can ooze.

- Adjust travel speed in your slicer to optimize print quality.

- Excessively high travel speeds may cause mechanical issues, so balance speed with your printer’s capabilities.

Calibrating your printer’s e-steps and flow rate also helps control 3d printer stringing. E-steps calibration ensures your extruder pushes the correct amount of filament. If your printer extrudes too much, you will see more stringing. Flow rate acts as a fine-tuning tool for different filament brands or types. Over-extrusion from incorrect e-steps or flow rate settings directly causes stringing. Make sure you calibrate both for the best results.

Block Quote:

"New filament does not always mean dry filament. Many users forget to dry even newly opened spools, which leads to stringing. Always dry your filament before printing, especially if you notice stringing."

If you follow these common solutions—adjusting retraction settings, lowering print temperature, and increasing travel speed—you will see a big improvement in your prints. Remember to test one change at a time and keep notes on what works best for your printer and filament.

Filament and Maintenance Tips

Filament Type and Drying

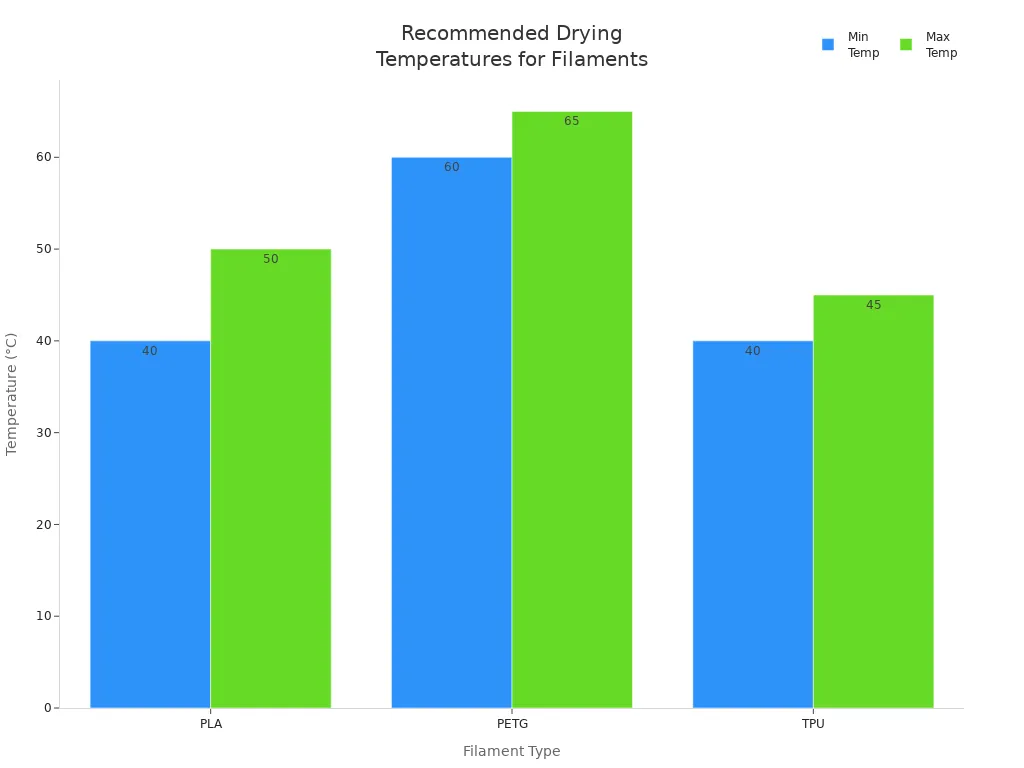

You can prevent stringing by making sure your filament stays dry. Moist filament causes many problems during printing. When moisture gets into PLA, PETG, or TPU, it turns into steam inside the hot nozzle. This creates bubbles, rough surfaces, and weak layer adhesion. You might hear popping or sizzling sounds, which means your filament needs drying.

To reduce stringing, use proper filament drying methods for each material. The table below shows the best drying temperatures and times:

|

Filament Type |

Recommended Drying Temperature (°C) |

Recommended Drying Time |

Notes |

|---|---|---|---|

|

PLA |

40-50 |

4-6 hours |

Use low heat; avoid over 60°C. |

|

PETG |

60-65 |

4-6 hours |

Moderate heat; avoid over 70°C. |

|

TPU |

40-45 |

4-6 hours |

Keep below 50°C. |

For Sovol printers, users report less stringing when they dry filament before printing and set temperatures 5-10°C lower than usual. Always check your Sovol Cura settings, as they often work well out of the box.

Storage and Handling

Proper storage helps prevent stringing by blocking moisture from reaching your filament. Store your spools in airtight containers or vacuum bags with desiccant packs. This keeps the filament dry and ready for use.

- Moisture absorption leads to bubbles, uneven layers, and stringing.

- Desiccant packs absorb humidity and keep filament in good condition.

- Keep filament away from sunlight, dust, and temperature changes.

|

Filament Type |

Storage Condition |

|---|---|

|

PLA |

Keep dry, sealed container |

|

PETG |

Keep dry, sealed container |

|

TPU |

Airtight container with desiccant |

Replace desiccant packs regularly. For sensitive filaments like TPU, use a dry cabinet or filament dryer for best results.

Nozzle Cleaning

A clean nozzle helps you prevent stringing and keeps your prints looking sharp. Check your nozzle before each print and clean it monthly if you print often.

- Heat the nozzle to printing temperature.

- Wipe the outside with a brass brush.

- Use a 0.4mm cleaning needle to clear clogs.

- Try a cold pull to remove burnt filament.

If you print with Sovol or other brands, clean the nozzle when you switch filament types. Replace worn nozzles if stringing continues.

Tip: Regular maintenance, like cleaning the extruder gears and checking belts, also helps prevent stringing and keeps your 3D printer running smoothly.

Slicer Features and Advanced Fixes

Slicer Settings for Stringing

You can use slicer settings to control stringing and improve your 3D prints. Most slicers offer advanced features that help you manage filament flow and nozzle movement. Here are some important slicer settings you should try:

- Z-Hop: This setting lifts the nozzle during travel moves. Z-Hop helps you prevent the nozzle from dragging filament across gaps, which reduces stringing and protects delicate parts. You should use Z-Hop with retraction for the best results. However, avoid using Z-Hop with flexible filaments like TPU, as it may cause extrusion issues.

- Coasting: Coasting stops extrusion just before the end of a print move. The leftover pressure in the nozzle finishes the line, which helps you avoid extra oozing.

- Wipe: When you enable wipe, the nozzle moves over the last printed area before traveling. This action cleans off excess filament and keeps your print surface neat.

- Retraction: Retraction pulls filament back during travel moves. You already learned that tuning retraction is the most effective way to reduce stringing.

- Combing: Combing tells the nozzle to travel only within printed areas. This helps you avoid crossing outline for travel movement, which can leave strings on the outer surface.

You should adjust slicer settings for each filament type. PLA, PETG, and TPU all respond differently, so test and fine-tune these options for your material. Many slicers, like Orca Slicer, include calibration tools to help you find the best combination of Z-Hop and retraction.

Tip: Always dry your filament before adjusting slicer settings. Moisture can make stringing worse, even if your settings are correct.

Post-Processing Methods

Sometimes, you need to remove leftover strings after printing. You can use manual stringing removal methods for the best results. Try these techniques:

- Use a hobby knife with a chisel blade to cut off strings. This gives you precise control and protects your print surface.

- Pull off loose strings by hand. Afterward, pass a lighter flame quickly over the area to melt any fine hairs.

- For ABS prints, use acetone vapor smoothing. Place your print in a sealed container with acetone vapor. This melts the surface slightly and gives a glossy finish. Do not use acetone on PLA, as it does not react.

- A heat gun can soften the outer surface of PLA or ABS. Hold the heat gun a few inches away and sweep it quickly over the print. Start with a low temperature to avoid warping or color changes. This method works best for larger parts without fine details.

Note: Sanding can dull the surface gloss, so only use it if you plan to paint or prime your print.

You can combine slicer settings and post-processing to achieve clean, professional-looking prints with minimal stringing.

You can achieve cleaner prints by focusing on retraction, temperature, filament care, and slicer adjustments. Test one change at a time to see what works best for your setup. Regular maintenance and proper filament storage prevent moisture, brittleness, and tangling, which protects your materials and reduces print failures. 🛠️ For persistent issues, try community-recommended tools like heat guns or precision knives. Share your tips or questions in the comments to help others improve their results.

FAQ

What causes stringing in 3D printing?

Stringing happens when melted filament leaks from the nozzle during travel moves. You often see this with incorrect retraction settings, high print temperatures, or wet filament. Sovol printers and quality filament help reduce these issues.

How do you fix stringing with PLA, PETG, or TPU?

You should adjust retraction and temperature for each material. PLA needs lower temperatures and short retraction. PETG benefits from longer retraction and slightly higher heat. TPU requires slow speeds and minimal retraction. Always dry your filament before printing.

Does drying filament really help reduce stringing?

Yes! Moist filament causes bubbles and oozing. You can dry PLA at 45°C, PETG at 60°C, and TPU at 45°C for 4–6 hours. Use a Sovol filament dryer or a home oven for best results.

What Sovol products help prevent stringing?

You can use Sovol PLA filament, Sovol filament dryers, and Sovol nozzles. These products keep your filament dry and your nozzle clean. Many users report fewer stringing issues with Sovol accessories.

Can slicer settings alone fix all stringing problems?

Slicer settings help a lot, but you also need dry filament and a clean nozzle. Try changing one setting at a time. If stringing continues, check your filament and printer hardware.