You can use an open source MMU 3d printing system to print with more than one type or color of filament in a single project. This device lets your 3D printer switch between materials during a print. Unlike memory management units in computers, this MMU focuses on controlling filaments. Open source designs give you the power to customize, join a helpful community, and enjoy broad compatibility with many printers.

Key Takeaways

- Open source MMU systems let you print with multiple colors or materials in one project, making your prints more detailed and professional.

- You can customize and upgrade your 3D printer easily with open source MMUs, thanks to modular designs and a large supportive community.

- Using open source MMUs saves money by allowing you to use affordable parts and fix issues yourself without relying on expensive brand-name options.

- Good hardware and firmware setup, along with regular maintenance, help keep your MMU system reliable and improve print quality.

- Joining online communities gives you access to helpful guides, troubleshooting tips, and shared experiences to make your MMU journey smoother.

What Is an Open Source MMU 3D Printing?

Multi-Material Printing

You can use an open source MMU 3D printing system to create objects with different colors or materials in one print. This technology lets your printer switch between filaments during a single job. You might want to print a toy with bright colors or a part that needs both flexible and strong sections. The MMU makes this possible by moving filaments in and out of the hotend as needed.

When you use multi-material printing, you can:

- Combine colors for detailed models.

- Mix materials for special features, like soft grips or clear windows.

- Reduce the need for painting or gluing parts after printing.

Tip: Multi-material printing can save you time and make your projects look more professional.

Open Source Benefits

Open source MMU 3D printing gives you more control over your printer. You can choose from many designs, such as ERCF, Angry Beaver, Box Turtle, and others. These designs work with different firmware, like Happy Hare, which supports modular setups and user-friendly interfaces.

Here is a table showing some key features you can find in open source MMU systems:

|

Specification/Feature Category |

Details and Benchmarks |

|---|---|

|

Supported MMU Designs |

ERCF, Angry Beaver, Box Turtle, Night Owl, 3MS, Tradrack, QuattroBox, PicoMMU, 3D Chameleon, MMX, Custom designs |

|

Firmware Support |

Happy Hare v2.0.1 to v3.2.0, modular design, multi-MMU support, sensor configurations, UI integrations |

|

Multi-MMU Operation |

Combine multiple MMUs, support for separate steppers, easy disable/enable |

|

Sensor and Hardware Features |

Gate sensors, extruder sensors, encoder support, filament cutting, buffer options |

|

Calibration and Tuning |

Auto calibration, extruder homing, temperature per gate, speed tuning |

|

Performance Benchmarks |

Fewer errors, detailed statistics, swap times, pause durations |

|

UI and Visualization |

Filament position rendering, animations, status LEDs, error dialogs |

|

Purge Volume Management |

Calculated purge volumes, command support, purge maps |

|

Advanced Features |

Eject commands, pre-load during pause, state persistence, third-party addons |

You can join a large community that helps you solve problems and improve your setup. Open source MMU 3D printing also lets you upgrade or change parts as you learn more. You do not have to rely on one company for updates or repairs. This freedom makes your 3D printing experience more flexible and rewarding.

How Open Source MMU 3D Printing Works

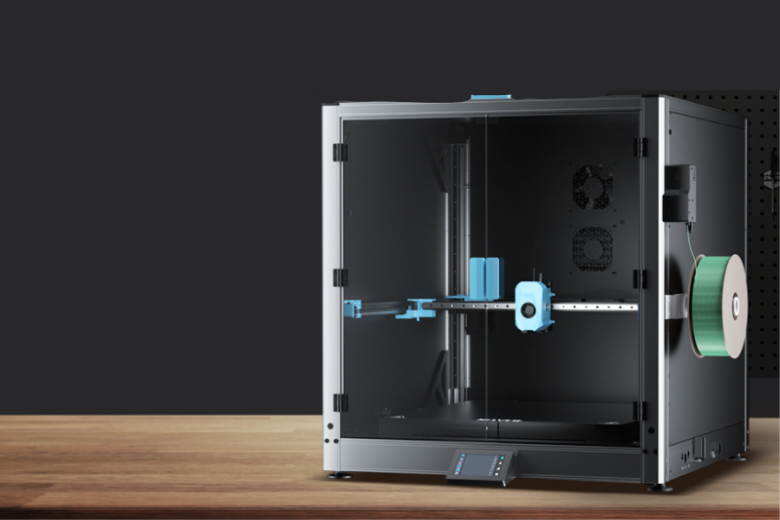

Hardware Basics

When you use an open source MMU 3D printing system, you rely on several key hardware parts. These include stepper motors, a control board, and a filament buffer. Stepper motors move the filaments in and out of the extruder with high precision. The control board acts as the brain, sending signals to the motors and sensors. A filament buffer stores and organizes the filaments, making sure they do not tangle or jam.

You can see how important these parts are by looking at their performance statistics:

|

Parameter |

Value |

|---|---|

|

Nozzle diameter |

0.84 mm |

|

Prime |

0.72 mm |

|

Coasting |

0 mm |

|

Toolpath speed |

400–600 mm/min |

|

Volumetric flow rate |

200 steps/min |

|

E-Steps |

3500–5000 steps/mm |

These numbers help you achieve smooth and accurate prints. The progressive cavity pump extrusion system, often used in advanced setups, gives you reliable and consistent extrusion. It starts and stops cleanly, which is important for handling tricky materials like silicone or UV curing polymers. You can print with many types of materials, from thin liquids to thick pastes, and still get high-quality results.

To keep your hardware running well, you should follow some simple maintenance steps:

- Clean dispensers and adapters before each use.

- Make sure all parts are dry before putting them back together.

- Replace O-rings and stepper motor adapters if they show wear.

- Use vacuum grease if you notice air leaks.

- Follow the maintenance guides for your printer and MMU.

These steps help you avoid clogs and leaks, keeping your system reliable for every print.

Software and Firmware

The software and firmware in open source MMU 3D printing systems give you a lot of flexibility. You can use popular open-source firmware like Marlin or TH3D Unified Firmware 2. These programs work on many control boards, such as the MKS Gen L, and support both 8-bit and 32-bit systems. You can set up your printer for multi-material printing by adjusting settings like stepper motor steps, nozzle offsets, and temperature controls.

You can also add features like bed leveling with mechanical or capacitive probes. Firmware updates let you use new sensors and hardware as they become available. Many users have converted standard printers, like the Ender 3 Pro, into multi-material machines by updating the firmware and adding MMU hardware. These changes let you print with different materials, including special bioinks, while keeping good temperature control and print quality.

Tip: Always check for the latest firmware updates and community guides. These resources help you get the most out of your open source MMU 3D printing setup.

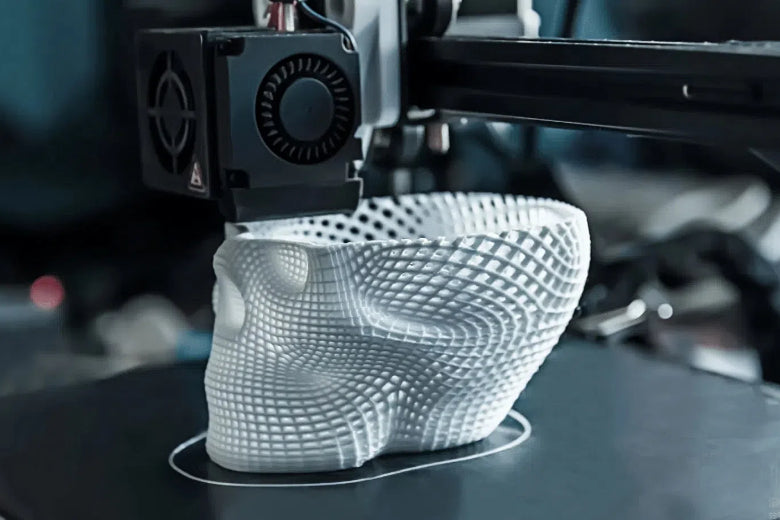

Filament Switching

Filament switching is the heart of any open source MMU 3D printing system. Your printer must unload one filament and load another quickly and smoothly. Modern systems, like the Prusa MMU3, can switch filaments in about 35 to 45 seconds. This speed helps you finish prints faster and with fewer errors.

Designers have improved the filament switching process by adding better sensors and smarter firmware. For example, sensors can detect if the filament is present and stop the print if something goes wrong. Some systems use powerful motors and short inlet tubes to make loading easier. Heated and sealed chambers keep filaments in good condition, which is important for reliable switching.

You will find different MMU designs, each with its own strengths:

- Type-A designs are affordable and easy to expand but need careful tuning.

- Type-B designs use more motors for faster switching but cost more.

- Type-C designs promise even better performance but are more complex.

Sensors play a big role in making sure the filament switches correctly. They check the filament’s position before and after it moves. If a problem happens, the printer can pause and alert you. This reduces the risk of mixing colors or clogging the nozzle.

Note: Regularly check and tune your sensors and motors. This keeps your filament switching process smooth and reliable.

Features and Advantages

Modularity

You can build your open source MMU 3D printing system in a modular way. This means you can add or remove parts as you need. If you want to print with more filaments, you can add more slots. If you want to try a new sensor or motor, you can swap it in. Modularity lets you upgrade your setup without starting over. You can also fix problems by changing only the broken part.

Tip: Modularity helps you keep your printer up to date. You do not need to buy a whole new system when you want to improve your prints.

Community Support

You do not have to work alone when you use open source MMU 3D printing. Many people share their ideas, guides, and fixes online. You can join forums, Discord groups, or social media pages. If you have a problem, you can ask for help and get answers from others who use the same system. The community often creates new features and updates, so you can learn from others and share your own tips.

- Find troubleshooting guides for common issues.

- Download printable upgrades and add-ons.

- Share your results and get feedback.、

The community makes it easier to solve problems and try new things.

Cost Savings

You can save money with open source MMU 3D printing. Many designs use parts you can print yourself or buy at low cost. You do not have to pay for expensive brand-name upgrades. You can choose only the features you need, which helps you avoid waste. If something breaks, you can fix it yourself instead of sending it away for repairs.

|

Cost Factor |

Open Source MMU |

Proprietary MMU |

|---|---|---|

|

Initial Price |

Low |

High |

|

Upgrade Flexibility |

High |

Low |

|

Repair Costs |

Low |

High |

Saving money lets you spend more on new materials or other projects.

Open Source vs Proprietary MMUs

Flexibility

You get more flexibility with open source MMU 3d printing. You can change the hardware or software to fit your needs. If you want to add more filament slots or try a new sensor, you can do it. You can even use different firmware or mix parts from other projects. Proprietary MMUs, like those from Bambu Lab, often limit your choices. You must use their parts and follow their rules. This makes it hard to customize your printer.

- Open source MMUs let you:

-

- Change designs and settings.

- Use parts from different brands.

- Try new features as soon as they come out.

You control your upgrades and repairs with open source systems.

Support

Support works differently for open source and proprietary MMUs. With open source mmu 3d printing, you join a large community. People share guides, answer questions, and post updates. If you have a problem, you can ask for help online. Many users say Prusa’s MMU systems feel complex and hard to use. They report slow updates and long testing periods. This can make support feel slow.

Proprietary MMUs, like those from Bambu Lab, focus on easy use and fast help. The company uses its experience from other consumer products to give you quick updates and clear instructions. You get official support, but you may not find as many user-made guides or fixes.

|

Support Type |

Open Source MMU |

Proprietary MMU |

|---|---|---|

|

Community Forums |

Yes |

Sometimes |

|

Official Help |

Limited |

Strong |

|

User Guides |

Many |

Fewer |

|

Update Speed |

Varies |

Fast |

Upgrades

You can upgrade open source MMUs at your own pace. If you want a new feature, you can add it when you like. You do not need to wait for a company to release an update. Many users enjoy testing new ideas and sharing them with others. Proprietary MMUs, such as those from Bambu Lab, offer fast updates and new features, but you must wait for the company to release them. You cannot always add your own changes.

- Open source upgrades:

- Add new sensors or motors.

- Change software for better performance.

- Share your upgrades with others.

- Proprietary upgrades:

-

- Get updates from the company.

- Use only approved parts and features.

Open source MMU 3d printing gives you the freedom to grow and learn with your printer.

Getting Started

Finding Projects

You can find many open source MMU projects online. Start by visiting popular sites like GitHub, Printables, and Thingiverse. These platforms offer free files, build guides, and community feedback. Many users share their designs and updates, so you can see which projects are active and well-supported. Forums such as Reddit’s r/3Dprinting and the Prusa forums also provide advice and troubleshooting tips. When you join these communities, you get access to real stories and solutions from people who have built their own MMU systems.

Building and Setup

Building your own MMU system can feel challenging, but you can follow clear steps to make the process easier. Here are some lessons from a documented case study:

- Enable the filament sensor to help your printer detect jams or missing filament.

- Synchronize the extruder and MMU gears for smoother filament loading.

- Add a preheat option before unloading filament to prevent clogs.

- Adjust the idler screw force to match your filament type.

- Check gear alignment and assembly to avoid jams.

- Test different print temperatures for better results.

You should follow the instructions for your chosen project closely. Many guides include photos and troubleshooting sections. Take your time with each step, and double-check your work before moving on.

Tips for Beginners

Starting with an MMU system can be rewarding, but you may face some challenges. Reports from user forums show that about half of beginners succeed on their first try with systems like the Prusa MMU2. Prusa’s official data shows a 93% print success rate, but this is lower than their single-material printers. Most success stories come from users who take time to learn and adjust their setup.

Tip: Start with simple prints and only add more filaments when you feel comfortable. Keep your workspace organized and label your filaments. If you run into problems, ask for help in online communities. Many users have faced the same issues and can offer advice.

You can improve your chances by reading guides, watching videos, and practicing with small projects. Patience and careful setup will help you get the best results.

You can unlock new possibilities with an open source MMU. This technology lets you print in many colors and materials. You gain the power to customize your printer and join a helpful community. Upgrading your setup becomes easy. Many users share ideas and support each other. If you want to improve your 3D prints, try exploring open source MMU options for your next project.

FAQ

What does an MMU do in 3D printing?

An MMU lets your printer use more than one filament in a single print. You can print objects with different colors or materials without stopping the printer.

Can you add an open source MMU to any 3D printer?

You can add an open source MMU to many popular printers. Check your printer’s compatibility before starting. Some printers may need extra parts or firmware updates.

How hard is it to build an open source MMU?

You can build an open source MMU if you follow guides and take your time. Many users succeed by reading instructions, watching videos, and asking for help in online groups.

What problems might you face with an MMU?

You might see filament jams, loading errors, or sensor issues. Regular cleaning and careful setup help prevent most problems. The community often shares solutions for common issues.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.