Choosing the strongest 3D printer filament ensures your projects meet durability, functionality, and performance demands. Filament strength directly impacts how well your printed objects handle stress and environmental conditions. For example, tensile strength values as high as 60.006 MPa allow for sturdy builds, while a three-point bending strength of 125.423 MPa ensures resistance to deformation. Additionally, an impact strength of 16.961 kJ/m² highlights the filament’s ability to withstand sudden forces. Opting for the best 3D printing filament enhances the quality and longevity of your designs, making it a critical decision for any 3D printing enthusiast or professional.

Key Takeaways

- Pick filaments based on how strong they are, like how much they can stretch, bend, or handle hits, to make your projects last longer.

- Think about what your project needs, like handling pressure or tough weather, to choose the right filament.

- Make sure your 3D printer works with the filament. Check the nozzle type and heat settings for the best results.

- Keep filaments in sealed containers to stop moisture, which can make them weaker and mess up your prints.

- Start with easy filaments like PETG or ABS before trying harder ones like PEEK or carbon fiber blends.

Understanding Filament Strength

What Does Strength Mean in 3D Printing

Strength in 3D printing refers to the ability of a filament to withstand forces without breaking, deforming, or losing functionality. It encompasses several mechanical properties, including tensile strength, flexural strength, and compressive strength. These properties determine how well your printed object performs under stress, whether it’s resisting bending, stretching, or compressive forces. For example, a filament with high tensile strength can endure pulling forces, making it ideal for load-bearing applications.

In practical terms, strength is crucial for projects requiring durability and reliability. If you’re designing parts for engineering or industrial use, you need filaments that can handle mechanical stress and environmental challenges. Materials like polycarbonate and carbon fiber composites are popular choices due to their exceptional mechanical strength and resistance to wear and tear.

Key Properties of Strong 3D Printer Filaments

When selecting strong 3D printer filaments, you should focus on key properties that contribute to their performance. These properties include:

- Tensile Strength: Measures the filament’s ability to resist pulling forces. Filaments like carbon fiber composites and polycarbonate exhibit high tensile strength, making them suitable for structural components.

- Flexural Strength: Indicates resistance to bending forces. Materials with high flexural strength, such as polycarbonate, are ideal for applications requiring rigidity.

- Compressive Strength: Reflects the filament’s ability to withstand compressive forces without collapsing. Nylon and polycarbonate are known for their high compressive strength, making them perfect for functional parts.

- Impact Resistance: Determines how well the filament absorbs energy from sudden forces. ABS and polycarbonate excel in impact resistance, ensuring durability in dynamic environments.

- Temperature Resistance: Shows the filament’s ability to maintain its properties at high temperatures. Engineering-grade materials like PEEK and polycarbonate are excellent for heat-intensive applications.

- Chemical Resistance: Indicates the filament’s ability to resist degradation from chemical exposure. Industrial-grade filaments often feature superior chemical resistance.

Here’s a table summarizing these properties and their measurement methods:

|

Property |

Description |

Measurement Method |

Example Materials |

|---|---|---|---|

|

Tear Strength |

Ability to resist tearing under concentrated force. |

Force applied to initiate and propagate a tear. |

TPU, flexible filaments |

|

Fatigue Strength |

Resistance to weakening under repeated stress cycles. |

Subjected to repeated cycles of stress. |

Nylon, carbon fiber-reinforced filaments |

|

UV Resistance |

Resistance to degradation from UV light exposure. |

Exposure to UV light over time. |

UV-stabilized filaments |

|

Temperature Resistance |

Ability to withstand high temperatures without losing properties. |

Measured by glass transition temperature (Tg) and melting point. |

Polycarbonate, carbon fiber-reinforced |

|

Impact Strength |

Ability to resist breaking under sudden forces. |

Energy absorbed before failure (Charpy or Izod tests). |

ABS, polycarbonate |

How to Measure the Strength of 3D Printing Filaments

To determine the strength of 3D printing filaments, manufacturers and researchers use various testing methods. These techniques provide quantitative assessments of mechanical properties, helping you choose the best filament for your needs. Common measurement methods include:

- High-Temperature Tensile Testing: This test evaluates the filament’s tensile strength at elevated temperatures. It’s essential for applications like engine components where heat resistance is critical.

- Fracture Toughness Testing: This method measures the filament’s ability to resist crack propagation under stress. It’s particularly useful for parts exposed to impact loading.

- Fatigue Testing: This test analyzes how the filament performs under repeated cyclic stresses. It’s ideal for components subjected to continuous vibrations or mechanical wear.

The table below highlights these techniques:

|

Measurement Technique |

Description |

|---|---|

|

High-Temperature Tensile Testing |

Evaluates the material's strength at elevated temperatures, crucial for applications like engine components. |

|

Fracture Toughness Testing |

Measures the material's resistance to crack propagation, important for parts under impact loading. |

|

Fatigue Testing |

Analyzes the material's behavior under repeated cyclic stresses, relevant for components experiencing continuous vibrations. |

By understanding these testing methods, you can better assess the mechanical strength of different filaments and select the strongest 3D printer filament for your project.

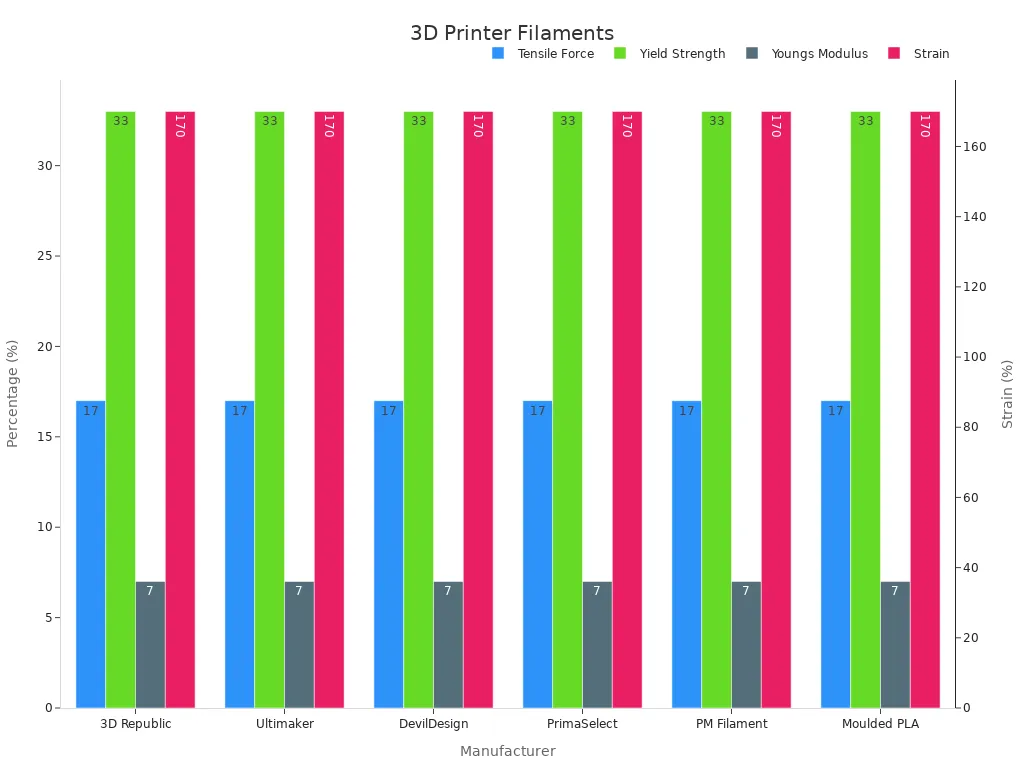

Comparing the Strongest 3D Printer Filaments

Polycarbonate: Features, Strengths, and Applications

Polycarbonate stands out as one of the strongest 3D printer filaments for ultimate strength. Its high impact resistance and durability make it a top choice for demanding applications. This filament is also heat-resistant, withstanding temperatures up to 110°C, making it suitable for engineering-grade materials like metal-forming dies. When printed correctly, polycarbonate offers optical clarity, which is ideal for projects requiring transparency.

Key features of polycarbonate include:

- High impact strength and durability, ensuring long-lasting performance.

- Dimensional stability, which helps retain the shape of printed parts under stress.

- Cost-effectiveness compared to other high-performance materials.

However, printing with polycarbonate requires high temperatures (260-310°C) and a heated bed (90-110°C). This makes it more suitable for advanced users with compatible printers. Its versatility makes it ideal for applications such as protective gear, automotive parts, and even molds for industrial use.

Tip: To achieve the best results with polycarbonate, ensure your printer has an enclosed build chamber to maintain consistent temperatures and prevent warping.

Nylon: Durability and Flexibility for Tough Projects

Nylon is a go-to filament for projects requiring a balance of durability and flexibility. Its high tensile strength and excellent wear resistance make it perfect for functional parts like gears, bearings, and hinges. Nylon also offers significant flexibility, allowing parts to bend without breaking, which is crucial for dynamic applications.

Here’s a breakdown of nylon’s key properties:

|

Property |

Description |

|---|---|

|

Durability and Strength |

High tensile strength and excellent wear resistance for functional parts. |

|

Flexibility |

Significant flexibility allowing parts to bend without breaking. |

|

Thermal Resistance |

Can withstand higher temperatures for heat-exposed applications. |

|

Chemical Resistance |

Resistant to oils, fuels, and solvents for industrial utility. |

|

Low Friction Coefficient |

Smooth surface minimizes friction, beneficial for gears and bearings. |

|

Reduced Moisture Absorption |

Certain types like PA12 are less susceptible, improving dimensional stability. |

Nylon’s chemical resistance makes it a favorite for industrial applications where exposure to oils, fuels, or solvents is common. However, it is hygroscopic, meaning it absorbs moisture from the air. You’ll need to store it in a dry environment to maintain its performance.

Note: For best results, dry your nylon filament before printing. Moisture can cause bubbling and weaken the final print.

PEEK: High-Performance Filament for Industrial Use

PEEK (Polyether Ether Ketone) is a high-performance filament designed for industrial applications. It exhibits mechanical properties comparable to metals like aluminum, making it one of the strongest 3D printer filaments available. PEEK can withstand extreme temperatures, operating between -196°C (-321°F) and 260°C (500°F), and has a high melting point of 343°C (649°F). This makes it ideal for applications in aerospace, automotive, and medical industries.

Key advantages of PEEK include:

- Exceptional tensile strength and heat resistance, suitable for demanding environments.

- The ability to withstand pressures up to 200 MPa (~29,000 PSI), making it perfect for engine components and sealing parts.

- Compatibility with complex geometries, reducing material usage while maintaining strength.

PEEK’s versatility allows it to replace traditional manufacturing methods like injection molding. For example, FFF 3D printed PEEK parts often achieve superior strength compared to injection-molded counterparts. However, printing with PEEK requires specialized equipment capable of maintaining high temperatures.

Tip: If you’re considering PEEK, ensure your printer supports high-temperature printing and has a heated chamber to prevent warping.

Carbon Fiber Composites: Lightweight and Strong

Carbon fiber composites are among the strongest 3D printer filaments available, offering a unique combination of lightweight properties and exceptional strength. These filaments consist of carbon fibers embedded in a polymer matrix, which enhances their mechanical performance. You’ll find them ideal for applications requiring high strength-to-weight ratios, such as aerospace components, automotive parts, and sporting equipment.

Carbon fibers exhibit remarkable tensile strength and stiffness, making them suitable for reinforcement in composite materials. Their negative coefficient of thermal expansion ensures dimensional stability under temperature fluctuations. Additionally, carbon fibers resist fatigue and chemical degradation, which contributes to their durability in demanding environments.

|

Fiber Type |

Tensile Strength (GPa) |

Young’s Modulus (GPa) |

Maximum Elongation (%) |

|---|---|---|---|

|

High Tension |

3–5 |

200–250 |

1–2 |

|

Intermediate Modulus |

4–7 |

250–350 |

1–2 |

|

High Modulus |

2–4.5 |

350–450 |

<1 |

|

Ultra High Modulus |

~3 |

>700 |

<0.5 |

Carbon fiber reinforced filaments are lightweight yet strong due to these properties. For example, intermediate modulus fibers offer a balance of tensile strength and stiffness, making them versatile for structural applications. High modulus fibers provide superior stiffness, which is essential for precision parts.

When printing with carbon fiber composites, you’ll need a printer equipped with a hardened nozzle to prevent wear caused by the abrasive nature of the fibers. Additionally, optimizing your printer settings, such as increasing nozzle temperature and slowing print speed, ensures better adhesion and reduces warping.

Tip: Use a heated bed and an enclosure to maintain consistent temperatures during printing. This minimizes warping and improves the overall quality of your prints.

Other Strong 3D Printer Filaments to Consider (ABS, PETG, TPU)

While carbon fiber composites are among the strongest, other strong 3D printer filaments like ABS, PETG, and TPU offer unique advantages for various applications.

- ABS: Known for its robustness and impact resistance, ABS is widely used in automotive components, toys, and electronic casings. Its durability makes it ideal for parts exposed to mechanical stress. ABS also performs well under moderate heat, though it requires a heated bed to prevent warping during printing.

- PETG: PETG combines the best properties of PLA and ABS, offering good strength and UV resistance. It’s easy to print and suitable for food-safe applications and outdoor use. PETG’s flexibility and chemical resistance make it a versatile choice for functional parts.

- TPU: TPU stands out for its flexibility and elasticity, making it perfect for applications requiring impact resistance and stretchability. You’ll find TPU useful for phone cases, toys, and shoe soles. Its oil and grease resistance further enhance its utility in industrial settings.

|

Material |

Properties |

Applications |

|---|---|---|

|

ABS |

Robust, pliable, impact-resistant |

Automotive components, toys, electronic casings |

|

PETG |

Good strength, easy to print, UV resistant |

Food-safe applications, outdoor use |

|

TPU |

Flexible, elastic, oil and grease resistant |

Phone cases, toys, shoe soles |

To maximize the performance of these filaments, consider the following:

- Increase infill density in ABS prints to enhance tensile strength by reducing voids.

- Use honeycomb or grid patterns for PETG to achieve lightweight yet strong parts.

- Experiment with PLA-TPU composites for applications requiring a balance of rigidity and flexibility.

Note: Each filament has specific printing requirements. ABS needs a heated bed, PETG benefits from slower print speeds, and TPU requires precise extrusion settings to avoid stringing.

By understanding the strengths and applications of these materials, you can select the strongest 3D printer filament for your project needs.

Factors to Consider When Choosing a Strong 3D Printer Filament

Application Requirements (Mechanical Stress, Environmental Conditions)

When selecting a filament, you must consider the specific demands of your project. Mechanical stress and environmental conditions play a significant role in determining the performance of strong 3D printer filaments. For instance, if your project involves functional parts exposed to high humidity, you should know that moisture can weaken the filament. Studies show that increased humidity leads to higher ductility, reducing stiffness and printability. On the other hand, low humidity enhances stiffness, improving the mechanical properties of the printed object.

Environmental factors like temperature and chemical exposure also affect filament performance. Engineering-grade materials such as polycarbonate and PEEK excel in heat resistance, making them ideal for high-temperature applications. For outdoor projects, UV-resistant filaments like PETG ensure durability under sunlight. Always match the filament’s properties to the environmental conditions your project will face.

Tip: Store your filaments in a dry, sealed container to prevent moisture absorption and maintain their tensile strength.

Printer Compatibility (Nozzle Type, Temperature Range)

Your printer’s compatibility with the filament is another critical factor. Different filaments require specific nozzle types and temperature ranges for optimal performance. For example, carbon fiber composites are abrasive and need a hardened nozzle to prevent wear. Similarly, high-performance filaments like PEEK demand printers capable of reaching temperatures above 300°C.

The table below highlights key compatibility parameters:

|

Parameter |

Details |

|---|---|

|

Nozzle Diameter |

Ranges from 0.1 to 1 mm, affecting flow and precision. |

|

Operating Temperature |

Typically between 150 to 300 °C, depending on the filament type. |

|

Material Characteristics |

Thermoplastics like ABS and PETG are easier to process, while PEEK requires advanced equipment. |

Using the correct settings ensures proper melting, flow, and layer bonding, which directly impacts the strength of your printed parts.

Note: Check your printer’s specifications before choosing a filament to avoid compatibility issues.

Cost vs. Performance Trade-offs

Balancing cost and performance is essential when choosing the strongest 3D printer filament. High-performance materials like PEEK and carbon fiber composites offer exceptional strength but come at a premium price. To evaluate cost-effectiveness, consider the cost per unit mass normalized by the filament’s strength. For example, PLA with glass powder provides a cost-effective option for projects requiring moderate strength.

Printing costs also depend on factors like nozzle size and infill density. Larger nozzles and lower infill densities reduce production time but may compromise the part’s strength. Additionally, environmental benefits, such as reduced waste and emissions, can offset higher material costs in the long run.

Tip: For budget-friendly options, ABS and PETG offer a good balance of strength and affordability, making them suitable for a wide range of applications.

Ease of Use and Post-Processing Needs

When choosing a strong 3D printer filament, ease of use plays a significant role. Some filaments are beginner-friendly, while others require advanced skills and specialized equipment. Understanding the challenges of working with different materials helps you achieve better results.

Ease of Use

- Beginner-Friendly Filaments: Materials like PETG and ABS are relatively easy to print. PETG offers good adhesion and minimal warping, making it ideal for users with basic 3D printing experience. ABS, while slightly more challenging, becomes manageable with a heated bed and proper ventilation.

- Advanced Filaments: High-performance options like PEEK and carbon fiber composites demand precise settings and high-temperature printers. For example, PEEK requires a heated chamber to prevent warping, while carbon fiber filaments need a hardened nozzle to handle their abrasive nature.

Tip: Start with easier filaments like PETG if you’re new to 3D printing. Gradually move to advanced materials as you gain experience.

Post-Processing Needs

Post-processing enhances the strength, appearance, and functionality of your prints. Different filaments require varying levels of effort:

- Sanding and Smoothing: ABS and PETG can be sanded to remove imperfections. ABS also allows acetone vapor smoothing for a polished finish.

- Annealing: Materials like nylon and polycarbonate benefit from annealing. Heating the printed part in an oven improves its strength and heat resistance.

- Painting and Coating: ABS and PLA accept paint well, while PETG may need a primer for better adhesion.

|

Filament Type |

Post-Processing Options |

Difficulty Level |

|---|---|---|

|

ABS |

Sanding, acetone smoothing, painting |

Moderate |

|

PETG |

Sanding, painting with primer |

Easy |

|

Carbon Fiber Composites |

Minimal (usually no sanding needed) |

Advanced |

Note: Always follow safety guidelines when sanding or using chemicals for post-processing.

By considering ease of use and post-processing needs, you can select a filament that matches your skill level and project requirements.

Tips for Printing with Strong 3D Printer Filaments

Optimizing Printer Settings (Temperature, Speed, Bed Adhesion)

Getting the right printer settings is essential for achieving strong and reliable prints. You can optimize your settings by focusing on temperature, speed, and bed adhesion. Start by adjusting the nozzle temperature based on the filament type. For example, set it between 190-220°C for PLA and 220-250°C for ABS. Similarly, increase the bed temperature to approximately 60°C for PLA and around 100°C for ABS.

To improve bed adhesion, apply adhesive materials like glue sticks or specialized sheets such as PEI. Reduce the print speed for the first layer to 20-30% of the standard speed. This ensures better contact with the print bed. Regularly upgrade your slicing software to access optimized settings for your printer and filament. Proper bed leveling and calibration also prevent adhesion issues.

Tip: Increase extrusion width and layer height for better bonding between layers. This enhances the overall strength of your printed parts.

Handling and Storage of 3D Printing Filaments

Proper handling and storage maintain the quality of your filament and ensure consistent printing results. Store your filament in a cool, dry place with stable temperatures. High temperatures can soften or melt the filament, while low temperatures can make flexible filaments brittle. Use vacuum-sealed bags or airtight containers with desiccants to minimize moisture absorption.

Keep filaments away from direct sunlight and heat sources to prevent degradation. For high-humidity areas, consider using filament dryer devices to remove moisture safely. Following the manufacturer’s recommendations for storage temperature ranges also helps preserve filament strength.

- Use zip-lock bags with silica gel packs for simple storage.

- Invest in dry-storage boxes for better moisture control.

- Maintain a clean and dust-free storage environment to protect the filament.

Note: Moisture can weaken your filament and cause bubbling during printing. Always store it in a dry environment.

Common Challenges and How to Overcome Them

Printing with strong filaments often presents challenges, but you can overcome them with the right strategies. Poor adhesion is a common issue. To fix this, ensure proper bed leveling and use adhesives like glue sticks or PEI sheets. Warping can occur with high-performance filaments like PEEK. Using a heated chamber and maintaining consistent temperatures reduces this problem.

Another challenge is nozzle wear caused by abrasive filaments like carbon fiber composites. Switch to a hardened nozzle to prevent damage. FDM printers also face limitations in controlling material composition. While multimaterial filaments offer slight improvements, they still struggle with uneven material distribution.

Tip: Reduce print speed and increase extrusion width to improve bonding and minimize warping. These adjustments enhance the strength of your printed parts.

Selecting the strongest 3D printer filament ensures your projects meet durability and performance goals. Matching the filament’s properties to your project’s needs improves reliability and functionality. For beginners, PLA offers versatility and ease of use. Professionals benefit from PETG’s strength and chemical resistance. Industrial users rely on high-performance materials like PEEK for demanding applications.

|

Applications |

Advantages |

Limitations |

|

|---|---|---|---|

|

PLA |

Prototyping, Toys, Decorative Items, Education |

Easy to post-process, cost-effective |

Brittle, prone to cracking |

|

PETG |

Packaging, Medical Devices, Automotive Parts |

Strong, durable, resistant to chemicals |

More challenging to post-process |

Experimenting with different filaments helps you discover the best fit for your projects. Testing allows you to refine your techniques and achieve optimal results.

Tip: Start with simpler filaments and gradually explore advanced options as your skills improve.

FAQ

What is the strongest filament for industrial applications?

PEEK is the strongest filament for industrial use. It withstands extreme temperatures and pressures, making it ideal for aerospace, automotive, and medical projects. Its mechanical properties rival metals like aluminum. However, you need a high-temperature printer to work with PEEK effectively.

Tip: Use a heated chamber to prevent warping when printing with PEEK.

Can beginners use strong filaments like polycarbonate?

Polycarbonate is challenging for beginners due to its high printing temperature requirements. Start with easier filaments like PETG or ABS. These materials offer good strength and are more forgiving during the printing process.

Note: Upgrade your printer as you gain experience to handle advanced filaments like polycarbonate.

How do I store filaments to maintain their strength?

Store filaments in airtight containers with desiccants to prevent moisture absorption. Keep them away from sunlight and heat sources. For hygroscopic materials like nylon, use filament dryers to remove moisture before printing.

Tip: Vacuum-sealed bags are a cost-effective storage solution for most filaments.

What printer upgrades are needed for carbon fiber filaments?

Carbon fiber filaments require a hardened nozzle to resist wear. You may also need a heated bed and an enclosure to maintain consistent temperatures. These upgrades ensure better adhesion and reduce warping during printing.

Are strong filaments suitable for outdoor projects?

Yes, UV-resistant filaments like PETG work well for outdoor projects. They resist sunlight and environmental degradation. Other strong filaments, such as ABS, can also perform outdoors but may require additional coatings for protection.

Tip: Apply a UV-resistant spray to extend the lifespan of outdoor prints.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.