You might see vfas (vertical fine artifacts) if you look closely at your 3D prints. These vfas can look like small lines or patterns on the surface. Vertical fine artifacts can change how your models look and feel. If you want better prints, you should notice vfas (vertical fine artifacts) and learn why they show up. Watching these details helps you get smoother and nicer results.

Key Takeaways

- Vertical Fine Artifacts (VFAs) look like small lines or bumps on 3D prints. You can often see them in bright light or with a magnifying glass.

- VFAs usually happen because the printer shakes or has loose parts. Problems with the motor or firmware can also cause uneven movement while printing.

- These artifacts can make prints look rough and weak. This is worse on shiny materials or thin parts.

- Check your prints for VFAs by using test shapes. Feel the surface to find problems early.

- You can stop VFAs by tightening printer parts. Try changing print speed and layer height. Update the firmware and do regular maintenance.

VFA Appearance

Visual Signs

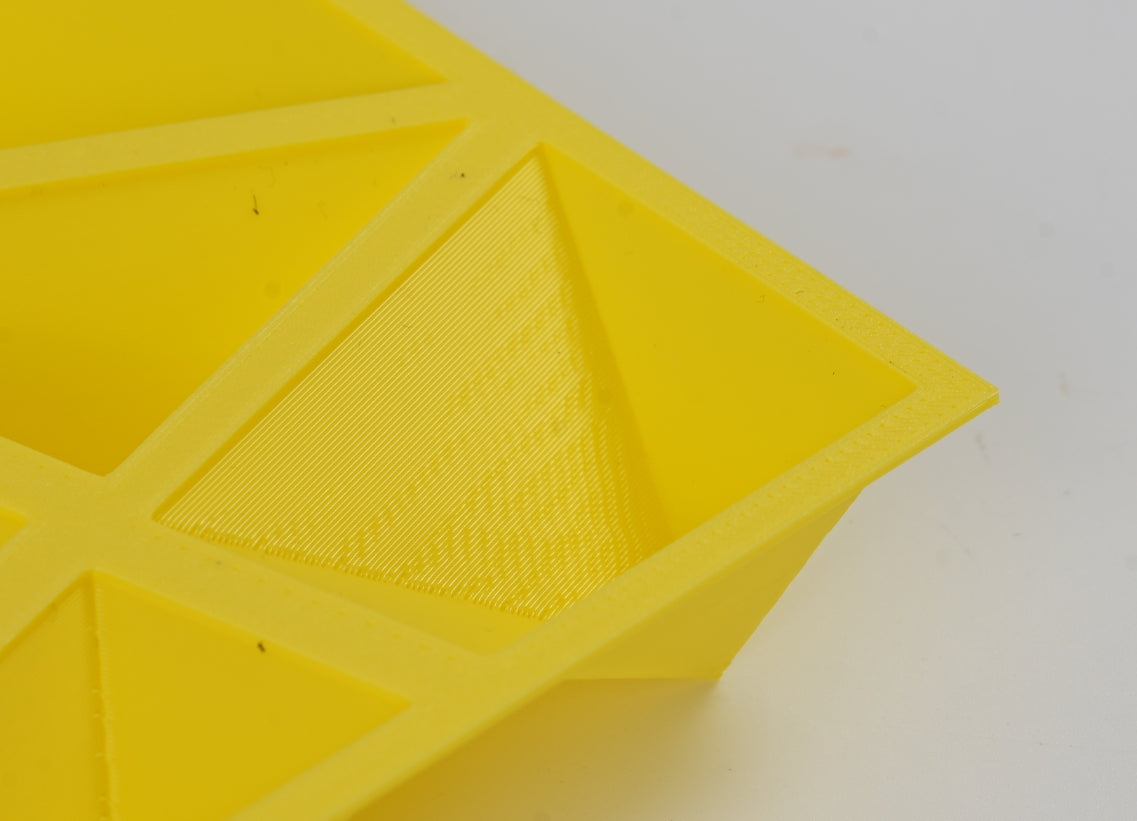

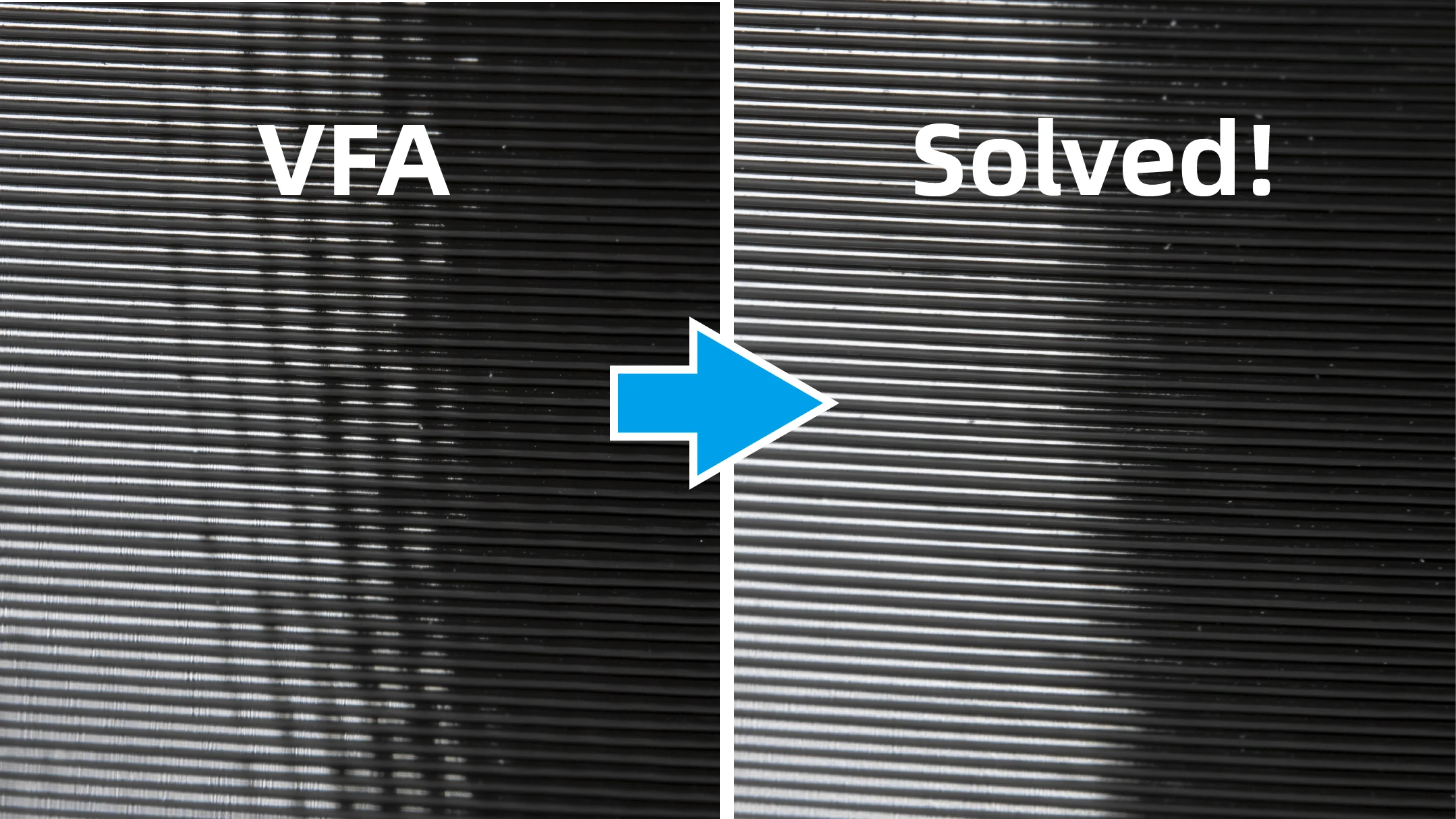

When you check your 3D prints, you might see tiny lines or bumps. These go up and down the sides. These lines are called vfas (vertical fine artifacts). You can spot them as straight or slanted lines, small bumps, or even little ridges. Sometimes, you need to look very closely or use a bright light to see them. This is especially true if your print is shiny. Most of these artifacts are between 10 and 40 micrometers wide. They are hard to notice from far away. But if you look closely, you can see them better.

Tip: Hold your print near a window or lamp. Move it around and look for lines or patterns that repeat along the Z-axis. These are signs of vfas.

You might also see vfas with about 2mm between each one. This means the lines or bumps show up every 2 millimeters on the print. If you see these repeating marks, you are looking at a common vfa.

Surface Patterns

Artifacts do not show up in random spots. You will usually find them in a repeating pattern. These patterns match the Z-axis of your printer. The space between each artifact stays the same all over the print. For example, you might see vfas with about 2mm between them from top to bottom. This even spacing helps you know they are vfas and not another problem.

Here is an easy way to spot these surface patterns:

- Look for straight lines or ridges going up and down.

- See if the space between each artifact is always the same.

- Notice if the artifacts repeat in a way you can guess.

|

Artifact Feature |

What to Look For |

|---|---|

|

Direction |

Vertical or diagonal lines |

|

Size |

10-40 micrometers |

|

Spacing |

Regular, often ~2mm |

|

Surface |

Glossy or smooth materials |

If you see these patterns, you probably have vfas (vertical fine artifacts). Knowing about these artifacts helps you get better prints and fix common problems.

VFA Causes

When you see vfas on your 3D prints, you might wonder why they appear. These artifacts often come from how your printer moves and how its parts work together. If you want to fix or prevent these marks, you need to know what causes them.

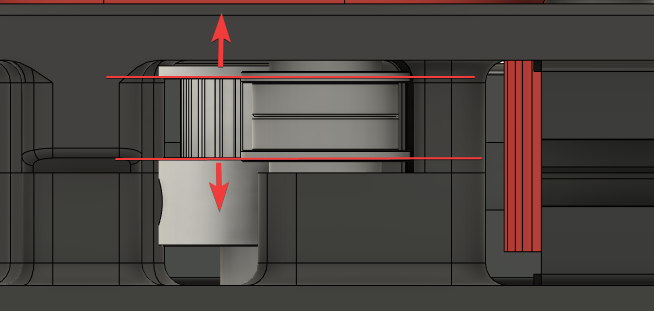

Mechanical Resonance

Mechanical resonance happens when your printer's moving parts vibrate at certain speeds. These vibrations can leave marks on your prints. You may notice vertical lines or repeating patterns. This effect is called motor resonance rippling (MRR). When the stepper motors move, they can shake the printer frame. The shaking creates tiny, regular lines on the print surface. If you see vfas with non-2mm spacing, this often points to resonance problems. You might also spot vfas with non-2mm spacing if your printer runs at different speeds or uses different layer heights.

Note: If you hear a humming or buzzing sound while printing, your printer might have resonance issues. These sounds often match the spots where you see artifacts.

Loose Components

Loose parts in your printer can also cause artifacts. If a belt, pulley, or idler is not tight, it can slip or wobble. This movement shows up as lines or bumps on your print. You may see these marks repeat at regular intervals. Sometimes, the spacing is not exactly 2mm, which means you have vfas with non-2mm spacing. Loose extruder gears can also create uneven layers. Even small vibrations from the printer frame or table can make the problem worse.

Here are some common sources of artifacts from loose components:

- Belts that are not tight enough

- Pulleys or idlers that move side to side

- Gears that skip or slip

- Printer frames that shake during printing

You should check these parts often. Tighten them if you find any movement.

Motor and Firmware

Stepper motors control how your printer moves. If the motors do not run smoothly, you will see artifacts on your prints. Sometimes, the motors create small jumps or skips. These show up as vertical fine artifacts (vfas) on the surface. The printer's firmware also plays a big role. Good firmware can help reduce or remove these marks. Some firmware updates add features that fight resonance and smooth out motor movement.

Tip: Update your printer's firmware if you see new artifacts after changing settings. Many printers have options to adjust motor speed and vibration control.

You can also try changing the motor current or using special firmware features like input shaping. These steps help you get cleaner prints and fewer artifacts.

VFA Impact

Print Quality

You want your 3D prints to look smooth and professional. Vertical fine artifacts can make this hard. These small lines or bumps can lower the overall quality of your prints. When you see these marks, you might notice that the surface feels rough or uneven. This can make your models look less polished.

If you print objects for display, these artifacts can stand out under bright light. Shiny materials show these lines even more. You may feel disappointed if your hard work does not give you the finish you expect. Many users find that fixing these issues leads to a big jump in print quality.

Tip: Use a magnifying glass to check your prints. You can spot tiny lines that affect the final look.

A table can help you see how artifacts change the quality of your prints:

|

Print Feature |

With VFAs |

Without VFAs |

|---|---|---|

|

Surface Smoothness |

Rough, lined |

Smooth, clean |

|

Shine |

Dull, streaked |

Glossy, even |

|

Detail |

Blurred |

Sharp |

Strength and Function

Artifacts do not just change how your prints look. They can also affect how your models work. When you see vertical fine artifacts, you might find weak spots along the lines. These weak spots can make your prints break more easily, especially if you use them for moving parts or tools.

If you use your prints for testing or real-world jobs, you want strong and reliable results. Artifacts can lower the strength of thin walls or small features. You may notice that parts snap or bend where the lines appear. For best results, you should aim for high quality in both looks and function.

Note: Always check for artifacts before using your prints in important projects. Good quality means better performance and longer life.

Identifying Vertical Fine Artifacts

Inspection Tips

You can spot vertical fine artifacts by looking closely at your 3D prints. Start by holding your print under a bright light. Move the object slowly and watch for lines that run up and down the sides. These lines often appear as tiny ridges or bumps. You may notice that the lines have even spacing between them. This spacing helps you tell if you are seeing vertical fine artifacts or another issue.

Try using your fingers to feel the surface. Sometimes, you can feel the lines even if you cannot see them well. A magnifying glass can help you check for very small marks. If you want to be sure, take a photo of your print and zoom in on the image. This method makes it easier to see the fine details.

Tip: Compare different sides of your print. Artifacts may show up more on one side, especially if your printer has uneven movement.

Test Prints

You can use special test prints to check for vertical fine artifacts. Print a simple cylinder or a tall, smooth tower. These shapes make it easier to see any lines or patterns. When you finish printing, look for repeating marks that follow the Z-axis. Check if the spacing between the lines stays the same from top to bottom.

A table can help you track your results:

|

Test Print Shape |

Signs of Artifacts |

Spacing Consistent? |

|---|---|---|

|

Cylinder |

Yes/No |

Yes/No |

|

Tower |

Yes/No |

Yes/No |

If you see regular lines with even spacing, you have found vertical fine artifacts. You can try changing your printer settings or checking for loose parts to reduce these marks. Careful inspection and test printing help you get smoother results every time.

Preventing and Fixing VFAs

Printer Settings

You can make vertical fine artifacts show up less by changing printer settings. Try slowing down the print speed. Moving slower helps the printer make smoother layers. You can also use a smaller layer height. This can hide some of the small lines. Change the motor current if you see more artifacts. If the current is too high or too low, lines may appear. Some printers have input shaping or vibration compensation. Turn these features on if your printer has them.

Tip: Print a small test object after each change. This lets you see which setting works best for your printer.

Maintenance

Doing regular maintenance helps your printer work better. Check if the belts and pulleys are tight. Loose parts can move and cause lines to show up. Clean the rails and lead screws to remove dust and dirt. Dirty parts can make the printer shake or skip. Put some lubricant on moving parts to keep them smooth. Look at the frame and check for loose screws. Tighten any screws that are not tight.

A simple maintenance checklist:

- Check belt tension

- Clean rails and lead screws

- Lubricate moving parts

- Tighten frame screws

Do these steps often to stop problems before they start.

Upgrades

Upgrading your printer can help get rid of vertical fine artifacts. You can add stronger frame supports to stop vibrations. Change old stepper motors for new, quieter ones. Some people use better motor drivers for smoother movement. If you can, update your printer’s firmware to the newest version. New firmware can help fight resonance and make prints look better.

|

Upgrade Option |

Benefit |

|---|---|

|

Stiffer frame |

Less vibration |

|

New stepper motors |

Smoother movement |

|

Better motor drivers |

Fewer artifacts |

|

Firmware update |

Improved compensation |

Note: Always check if upgrades fit your printer before you buy new parts.

You can achieve smoother and stronger 3D prints when you spot and fix VFAs early. Regular checks and small changes to your printer settings help you avoid these unwanted lines.

- Keep your printer clean and tight.

- Try new test prints to see what works best.

Keep learning about your printer. Testing and practice help you get better results every time.

FAQ

What materials show VFAs the most?

You will notice VFAs more on glossy or smooth materials. Shiny filaments like silk PLA or PETG make lines stand out. Matte filaments can hide these marks better.

Can VFAs affect moving parts?

Yes, VFAs can weaken thin or moving parts. You may see cracks or breaks along the lines. Always check for artifacts if you need strong or flexible prints.

How often should you check for VFAs?

Check your prints for VFAs after every major change. This includes new filament, upgrades, or firmware updates. Regular checks help you catch problems early.

Do slicer settings help reduce VFAs?

Try lowering print speed and layer height in your slicer. These changes can make lines less visible. Some slicers offer vibration compensation features. Turn these on if available.

Will upgrading your printer always remove VFAs?

Upgrades can help, but you may still see some VFAs. You should combine upgrades with good maintenance and careful settings for the best results.