You might notice how some 3D prints shine with a smooth, glossy surface. That effect comes from silk pla, a type of filament known for its eye-catching finish. Many people choose it for projects where looks matter most. You can create models that stand out with a bright, reflective sheen.

Key Takeaways

Silk PLA has a shiny and glossy look. This makes 3D prints look better. It is great for art and decoration projects. - This filament works well with most 3D printers. It prints smoothly and is easy to use. It helps stop problems like clogs and stringing. - Silk PLA is good for the environment. It is made from things that can grow back. It is safe to use inside and does not smell strong.

Silk PLA Overview

What is Silk PLA

You may wonder what makes silk pla different from other filaments. Silk pla is a special type of pla that gives your 3D prints a shiny, smooth look. When you use silk pla, your models stand out with a glossy surface that catches the light. Many people choose silk pla for projects where appearance matters most. You can find silk pla in many bright colors, which makes it perfect for artistic and decorative prints. Silk pla works well in most 3D printers, so you do not need special equipment to use it. The main reason people like silk pla is the way it makes prints look more polished and professional.

Composition and Additives

Silk pla starts with the same base as regular pla, which comes from renewable resources like corn starch. What sets silk pla apart are the special additives mixed into the filament. These additives give silk pla its unique shine and smooth texture. Manufacturers use different materials to create the silk effect. Some use plant fibers, like bamboo or walnut shells, while others add small amounts of coffee grounds or carrot pomace. These ingredients can change the way silk pla behaves during printing. For example, adding up to 5% of certain materials can make silk pla stronger when you bend it, but too much can lower its breaking strength. You will notice that silk pla often prints with fewer clogs and smoother layers than regular pla. The additives also help silk pla flow better through the printer nozzle, which means you get cleaner prints with less stringing.

- Additives like carrot pomace and ground walnut shells can make silk pla stronger when you bend it.

- Adding 3% coffee grounds can increase the strength of silk pla, but adding 7% can make it weaker.

- Using up to 5% of these additives can help, but more than that can lower the breaking strength.

- Bamboo fibers can also help at first, but too much will make silk pla less strong.

- Pomace and nut shells in small amounts can boost bending strength but lower breaking stress.

You will find that silk pla costs a bit more than regular pla. Most silk pla spools cost between $28 and $36 for 1kg, while standard pla usually costs less. The demand for silk pla is growing, so you can find it more easily now, but it is still not as common as regular pla. Popular brands that make silk pla include Eryone, Fiberlogy, Hatchbox, eSun, Sunlu, MatterHackers, Polyalchemy, Hello3D, CC3D, and Geeetech.

Glossy Finish and Appearance

The main reason you might choose silk pla is its glossy finish. When you print with silk pla, your models look shiny and smooth, almost like they are made of real silk. This effect comes from the special additives in the filament. Regular pla has a matte finish, but silk pla reflects light and looks more polished. You can use silk pla to make eye-catching models, trophies, vases, and display pieces. The glossy surface hides layer lines, so your prints look even smoother. Silk pla also comes in many vibrant colors, which makes your projects stand out even more.

Here is a table that shows how silk pla compares to regular pla:

|

Feature |

PLA Filament |

Silk PLA Filament |

|---|---|---|

|

Finish |

Matte finish |

Glossy finish |

|

Print Temperature |

180°C to 220°C |

200°C to 230°C |

|

Layer Adhesion |

Good, can vary |

Generally better |

|

Strength |

Good strength |

Less tensile strength |

|

Applications |

Prototyping, functional parts |

Artistic, decorative, and display pieces |

Tip: If you want your prints to look shiny and smooth, try using silk pla. You will see a big difference in the final appearance.

Silk pla is a great choice if you want to make models that look beautiful and professional. You can use silk pla for gifts, decorations, or anything that needs a special touch. The glossy finish and bright colors make silk pla one of the most popular choices for creative 3D printing.

Silk PLA Benefits

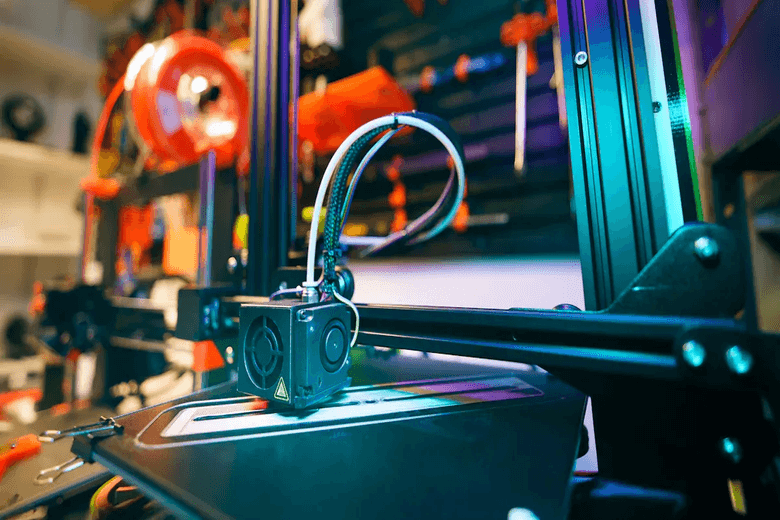

Printability and Ease of Use

Silk pla is very easy to use for 3D printing. Many people like it because it prints smoothly. You do not need special skills to use silk pla. The filament moves well through most printers. This helps you avoid problems like clogs or stringing. Silk pla is good for printing small details and tricky shapes.

You can use silk pla at many different temperatures. It works at settings close to regular pla. Silk pla can also print a little faster than regular pla. The smooth flow helps you finish your prints quickly. Silk pla does not make strong smells when printing. This is nice if you print inside your house.

Layer adhesion matters for every 3D print. Silk pla usually sticks well between layers. But silk pla can be more brittle than regular pla. Even if you change settings, silk pla is not as strong as other filaments. Your prints will look great, but they might not be as tough. Silk pla is best for decorations. If you need strong parts, try another type of pla.

Tip: Try silk pla if you want easy printing and shiny results. You will like how simple it is and how good your prints look.

Decorative Applications

Silk pla is great for making pretty 3D prints. You can use it to make models that look like shiny metal or silk. The glossy finish makes details stand out and shine. Artists and designers use silk pla when looks are important.

Here are some popular ways to use silk pla for decorations:

- Artistic models and sculptures: Make art, figurines, and statues with shiny details.

- Home decor and display items: Print vases, wall art, and stylish things for your room.

- Cosplay and costume accessories: Create props, jewelry, and costume parts that look like metal or silk.

- Prototyping for presentations: Make smooth prototypes that look ready to show.

- Personalized gifts and custom products: Design keychains, ornaments, and special gifts for friends.

People also use silk pla for trophies, awards, and display miniatures. Many choose it for holiday decorations and fancy gifts. Silk pla is light, so it works well for jewelry and ornaments. Cosplay fans like how silk pla looks on stage or in photos.

Note: Use silk pla if you want your prints to look special at events or at home. It gives a shiny and fancy finish.

Strength and Durability

Silk pla prints look amazing, but you should know about their strength. Silk pla has a special mix that makes it shiny. This can change how strong your prints are. Scientists test silk pla in different ways:

|

Test Type |

Description |

|---|---|

|

Pulling tests to measure how strong silk pla is. |

|

|

Rheological Studies |

Tests to see how silk pla flows and moves. |

|

Thermal Analysis |

Tests to check how heat changes silk pla with silk fiber. |

|

Degradation Tests |

Soaking samples in a warm solution to see how they break down over time. |

Silk pla prints can break more easily than regular pla. Many people say silk pla snaps faster, even with good settings. The layers do not stick as strong as with regular pla. If you need a model that bends or takes stress, silk pla may not work well. But for decorations, silk pla is strong enough.

Silk pla is still okay for light use and display. You can use it for gifts, decorations, and things you do not use a lot. The shiny look of silk pla makes up for its lower strength. If you want something that looks great and is a little durable, silk pla is a good pick.

Remember: Silk pla gives a beautiful finish, but use it for projects where looks are more important than strength.

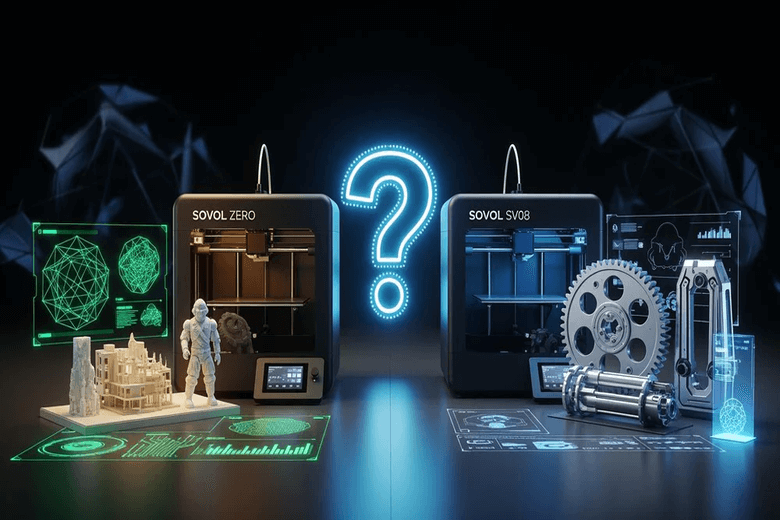

Silk PLA vs Other Filaments

Silk PLA vs PLA

When you compare silk pla to regular pla, you notice big differences in how your prints look and feel. Silk pla gives your models a glossy, reflective finish. This shine makes your prints stand out, especially for artistic or decorative items. Regular pla does not have this shine. It has a matte look, which works better for functional prototypes or everyday prints where appearance is not as important.

You may need to adjust your printer settings when you use silk pla. A layer height between 0.1mm and 0.2mm works best for silk pla. You should also use a higher printing temperature, usually between 190°C and 230°C. Print speed for silk pla should stay between 40mm/s and 60mm/s. Retraction settings for silk pla start at a distance of 4mm to 6mm and a speed of 25mm/s to 40mm/s. Regular pla is easier for beginners because it needs less fine-tuning.

Silk pla can be more brittle than regular pla. The additives that create the silk effect can make silk pla less strong. If you want a print that needs to handle stress, regular pla is a better choice. For beautiful, shiny models, silk pla is the best option.

- Silk pla: Glossy, reflective, great for art and display.

- Regular pla: Matte, strong, good for everyday use.

Silk PLA vs ABS and PETG

You might wonder how silk pla compares to other popular filaments like ABS and PETG. Silk pla prints at lower temperatures than ABS and PETG. You do not need a heated bed for silk pla, but ABS and PETG often require one. Silk pla does not give off strong smells when printing, so you can use it indoors without worry.

ABS is strong and heat-resistant, but it can warp and needs careful handling. PETG is tough and flexible, but it does not have the shine of silk pla. Silk pla is easier to print than ABS and PETG. You get smooth, shiny results with silk pla, but it is not as strong as ABS or PETG. If you want a print that looks like silk and is easy to make, silk pla is a smart pick.

|

Filament |

Finish |

Printability |

Strength |

Use Case |

|---|---|---|---|---|

|

Silk PLA |

Glossy, shiny |

Easy |

Brittle |

Art, display, decor |

|

PLA |

Matte |

Very easy |

Strong |

Prototypes, daily use |

|

ABS |

Matte |

Hard |

Very strong |

Functional, industrial |

|

PETG |

Slightly shiny |

Medium |

Tough |

Mechanical, outdoor |

Environmental Impact

Silk pla and regular pla both come from renewable resources like corn starch. This makes them better for the environment than ABS or PETG, which use petroleum. Silk pla is biodegradable under the right conditions. You can print with silk pla without worrying about strong odors or harmful fumes. This makes silk pla a safe choice for home and school projects.

Tip: Choose silk pla if you want a filament that looks great, prints easily, and is better for the environment.

Printing Silk PLA

Printer Settings

You can get the best results from silk pla by adjusting your printer settings. Start by setting your nozzle temperature between 215 °C and 220 °C if you print at a slow speed (40–60 mm/s). For faster printing, raise the temperature to 230 °C or even 235 °C. Many users find that 235 °C gives the smoothest finish. Here is a quick guide:

|

Printing Speed |

Temperature Range |

|---|---|

|

40–60 mm/s |

215 °C to 220 °C |

|

Over 100 mm/s |

230 °C to 235 °C |

If you notice problems during printing, try these steps:

- Dry your filament if you see bubbles or rough surfaces.

- Calibrate the flow rate to fix small bumps or "zits."

- Adjust the temperature up or down to see what works best.

- Clean the print bed with alcohol and a fresh paper towel.

- Change the extruder tension if you hear grinding.

- Lower retraction distance and speed to reduce stringing.

- Print one object at a time to avoid too many retractions.

Tip: Always check your printer before starting a new silk pla project. Clean equipment helps you avoid common printing issues.

Post-Processing Tips

You can make your silk pla prints even shinier with a few simple steps. Start with coarse sandpaper (120 grit) to remove big layer lines. Move to 220 grit for a smoother surface. Use wet sanding with 400 grit or higher for a polished look. Check your work under good light and repeat with finer grits if needed.

- Apply a plastic or automotive polish to boost the shine.

- Buff the surface in small circles until it gleams.

- Add a clear coat or wax to protect your print and keep it glossy.

Some people use epoxy resin for a high-gloss finish and extra strength. A heat gun can also smooth the surface, but use it carefully to avoid melting your print. Sanding and clear coating improve appearance without hurting durability. Epoxy resin adds both shine and strength.

Note: Take your time with post-processing. Careful work makes your silk pla prints look professional and last longer.

Silk PLA gives you a shiny, eye-catching finish that stands out in every project. You get easy printing, eco-friendly material, and enough strength for most decorative uses.

- Shiny, satin-like finish for impressive models

- Simple to print with most 3D printers

- Great for cosplay, gifts, and home decor

Try silk PLA for your next print. You will see how it makes your designs look special with little effort.

FAQ

What makes silk PLA different from other 3d printing materials?

You get a glossy, smooth finish with silk PLA. Other 3d printing materials often look matte or dull. Silk PLA stands out for decorative projects.

Is silk PLA safe to use at home or in schools?

Yes, you can use silk PLA safely. It does not release strong odors. This filament comes from polylactic acid, which is plant-based and non-toxic.

Can you recycle silk PLA prints?

You cannot recycle silk PLA in most curbside bins. Some special recycling centers accept it. Always check local rules before you throw away prints.