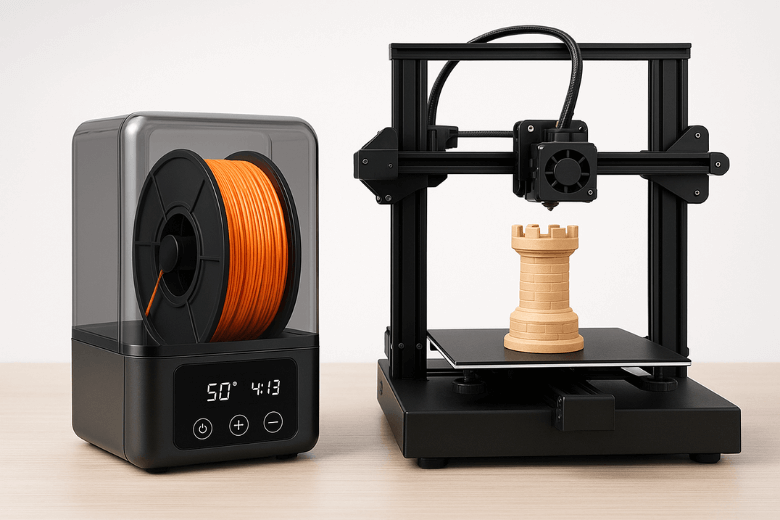

You might wonder if filament dryers are worth the investment. If you care about 3d printing, you know that moisture can ruin your day fast. When moisture sneaks into your filament, you get stringy prints, weak layers, and wasted material. Here’s what happens when you use a Filament Dryer:

-

Your print quality gets a big boost. Dry filament means smooth surfaces and strong layers.

-

You waste less plastic since fewer prints fail from moisture problems.

-

Your filament lasts longer, especially if you store moisture-sensitive spools for weeks or months.

If you live in a humid place or print with delicate materials, filament dryers can save you a lot of frustration. Take a look at your space and your projects—do you battle moisture often? If so, this tool could make your prints shine.

Key Takeaways

Filament dryers help prints look better by taking out moisture. This makes surfaces smoother and layers stronger. Using a filament dryer means less waste. It stops failed prints that happen because of moisture. Some materials like nylon and PETG need a filament dryer. It helps keep prints good and stops problems. You can dry filament yourself, but it may not work as well. Filament dryers do a better job. Buying a filament dryer can save money over time. It lowers wasted filament and helps prints work more often.

Filament dryers and how they work

What are filament dryers

Filament dryers are machines that keep your 3d printing filament dry. You put your spool inside and set the heat. The dryer warms the air around the filament. This makes water leave the filament and go into the air. The filament gets dry and works better for printing.

Tip: Using a filament dryer before you print can help you avoid bad prints and wasting filament.

Why moisture matters

Moisture is a big problem for people who 3d print. If your filament gets wet, your prints can have bubbles or weak spots. Some filaments, like nylon, soak up water fast. This happens more if you live where it is humid. Even ABS and PLA can get wet, but not as fast. When water gets inside, it changes how strong and bendy your prints are.

|

Environmental Factor |

Effect on Filament |

Observations |

|---|---|---|

|

More water in filament |

Prints are weaker, stringy, and not as strong |

Types of filament dryers

There are different kinds of filament dryers. Some look like little ovens with buttons. Others are simple boxes with heaters. You can even make one from a food dehydrator. Some dryers work better for certain filaments. A simple box might be fine for PLA. But you may need a better dryer for nylon or PETG. If you print a lot or use filaments that get wet easily, a good dryer can really help.

Print quality improvements

Common moisture issues

You might not notice it at first, but moisture can sneak into your filament and cause all sorts of problems. When you start 3d printing with wet filament, you may hear popping sounds or see bubbles in your prints. These are signs that water inside the filament is turning to steam as it heats up. This steam creates tiny holes and weak spots in your finished parts.

Here are some common issues you might see when moisture gets into your filament:

-

Bubbles form inside your prints, making them look rough or even causing them to fail.

-

You notice more stringing, especially with nylon and PETG. Thin threads of plastic stretch between parts of your print.

-

Your prints feel weaker and break more easily.

|

Defect Type |

Description |

|---|---|

|

Bubbles |

Formed due to inadequate drying, leading to voids and failed prints. |

|

Increased Stringing |

Particularly observed with nylon and PETG, resulting in excess filament being drawn out during printing. |

If you see these problems, your filament probably has too much moisture.

Benefits of using filament dryers

Filament dryers can make a big difference in your print quality. When you dry your filament before printing, you get smoother surfaces and stronger layers. You also see fewer printing mistakes, like bubbles or stringing. Many users say their prints improved a lot after they started using a dryer. Some even say they could not get good results until they used one.

Here are some ways filament dryers help:

-

You get better surface finishes and fewer printing artifacts.

-

Your prints have more accurate shapes and sizes, especially for small or thin parts.

-

You avoid problems like holes or weak spots caused by trapped moisture.

-

Drying your filament fixes issues with surface finish, dimensional accuracy, and how well the layers stick together.

Tip: If you want your prints to look their best, try drying your filament at the right temperature for a few hours before you start.

Filament types affected

Not all filaments react the same way to moisture. Some types soak up water much faster than others. Nylon is one of the worst for this. It can start to print badly almost right away if it gets wet. PETG also has trouble with stringing and bubbles when it absorbs water. ABS can warp and lose strength if it is not dry. TPU can lose its stickiness between layers and become inconsistent.

Here are some filaments that benefit most from using filament dryers:

-

PETG: Shows stringing and bubbles if not dry.

-

ABS: Can warp and become weak from moisture.

-

TPU: Loses layer adhesion and print consistency when wet.

If you use any of these materials, keeping them dry will help you get the best results.

Alternatives to filament dryers

DIY drying methods

You can dry filament without buying a special machine. Many people use a food dehydrator. It can dry several spools at once. This works well for hobbyists and pros. You will not get features like humidity sensors. But you still get better layer sticking and stronger prints. Some people use their kitchen oven. You must watch the temperature closely. If it gets too hot, your filament can melt. Another way is a passive dryer with silica beads. These beads soak up moisture from the air. This method is simple and cheap. It does not work as fast or as well as a real dryer. It is not great for tricky materials like nylon or TPU.

Tip: DIY methods save money, but they may not remove as much moisture as a dedicated filament dryer.

Storage solutions

Good storage helps keep filament dry. You can use airtight containers with desiccants. This protects your spools from humidity and dust. Some people vacuum-seal their filament for long-term storage. Others use a dry box with a heater. This keeps the air inside dry. Here are some best ways to store filament:

-

Use airtight containers and add desiccants.

-

Store filament in a dry room. Keep humidity below 50%.

-

Vacuum-seal spools if you will not use them soon.

-

Put spools on shelves to stop tangling.

-

Use a dry box for daily printing.

-

Label your spools and use older ones first.

-

Check humidity with a hygrometer.

|

Solution |

Cost Range |

RH Control |

Best Use Case |

Maintenance Needed |

|---|---|---|---|---|

|

Vacuum Sealing |

$10–$50 |

Passive |

Long-term (>1 month) |

Reseal after use |

|

Climate-Controlled Box |

$30–$150 |

Active |

Frequent printing |

Recharge desiccant monthly |

|

Active Dry Box |

$80–$200 |

Active |

Daily printing |

Clean fans annually |

Cost and effectiveness

You might wonder how these choices compare. Filament dryers remove moisture quickly and completely. DIY methods like food dehydrators help. But they do not give the same control or results. Storage solutions stop new moisture from getting in. They cannot fix filament that is already wet. Many users say filament dryers save their prints. This is true when they need to fix water-logged spools. If you print a lot or use sensitive materials, a dryer helps you worry less. For casual users, good storage and a passive dryer with silica beads may be enough to keep your 3d printing projects working well.

Cost and necessity

Who needs a filament dryer

You may ask if you need a filament dryer. It depends on where you print and what you use. Humid places make filament sticky or brittle quickly. Basements and garages have lots of moisture. This can ruin your spools fast. PETG and nylon are very sensitive to water. People who want good prints use filament dryers often. If you print a lot or store filament for months, you will see benefits.

-

Professionals and hobbyists get better prints with a dryer.

-

If you use ABS, PETG, TPU, or carbon fiber, keep them dry.

-

Even a few days in a humid room can make filament print badly.

A smart dryer like the SH04 keeps heat steady. This helps you get good prints every time, even with tricky filament.

Is the investment worth it

Let’s talk about cost. Filament dryers cost $50 to $150. Some hold one spool. Others can dry several at once. Here are some popular choices:

|

Product Name |

Price |

Capacity |

Temperature Range |

Key Features |

|---|---|---|---|---|

|

SUNLU Official Filament Dryer Box S4 |

$150 |

Four 1 kg spools |

35°C–70°C |

Fast heating, humidity sensor, desiccant pockets |

|

CREALITY Space Pi Filament Dryer Plus |

$90 |

Two spools |

40°C–65°C |

160W heating, filament feed port, simple display |

|

Comgrow 3D Printer Filament Dryer Box |

$50 |

One spool |

35°C–65°C |

Digital timer, adjustable temps, clear door |

|

Polymaker 3D Printing Filament Dryer |

$80 |

One spool |

40°C–60°C |

Dryer and storage combo, desiccant trays, airtight seal |

Dryers cost more at first than silica gel or food dehydrators. But dryers work faster and give you more control. You do not spend much to keep them running. You only clean them and sometimes change the desiccant. Silica gel is cheap but needs drying or replacing often. Some people use molecular sieves, but these need baking to work again.

|

Aspect |

Details |

|---|---|

|

Initial Costs |

$50 to $150 or more |

|

Ongoing Expenses |

Generally low |

|

Potential Savings |

Reduced print failures and waste |

|

Impact of Moisture |

Causes failed prints and wasted material |

|

Improvement from Drying |

Better print quality and reduced frequency of failures |

Big print shops found most failed parts came from moisture. After using dryers, their failures dropped by almost 30%. If you print a lot, a dryer can save you money. You waste less filament and have fewer failed prints.

User and expert opinions

Many people have trouble with wet filament. They hear popping or crackling sounds when printing. Some see bubbles, rough spots, or weak layers. These problems happen more with sensitive filaments. Experts say high humidity makes things worse. You might see bubbles, cracks, or poor layer sticking with wet filament. Some users say dryers can overheat or make filament brittle. Most find that careful use fixes these problems.

Here’s what users and experts notice most:

-

Weak layers break and ruin your print.

-

Print quality drops fast in humid rooms.

-

Some dryers may overheat or dry unevenly, so check your settings.

Note: For the best 3d prints, keep filament dry. A dryer is smart if you print often, use sensitive materials, or live in a humid place.

Choosing your solution

Factors to consider

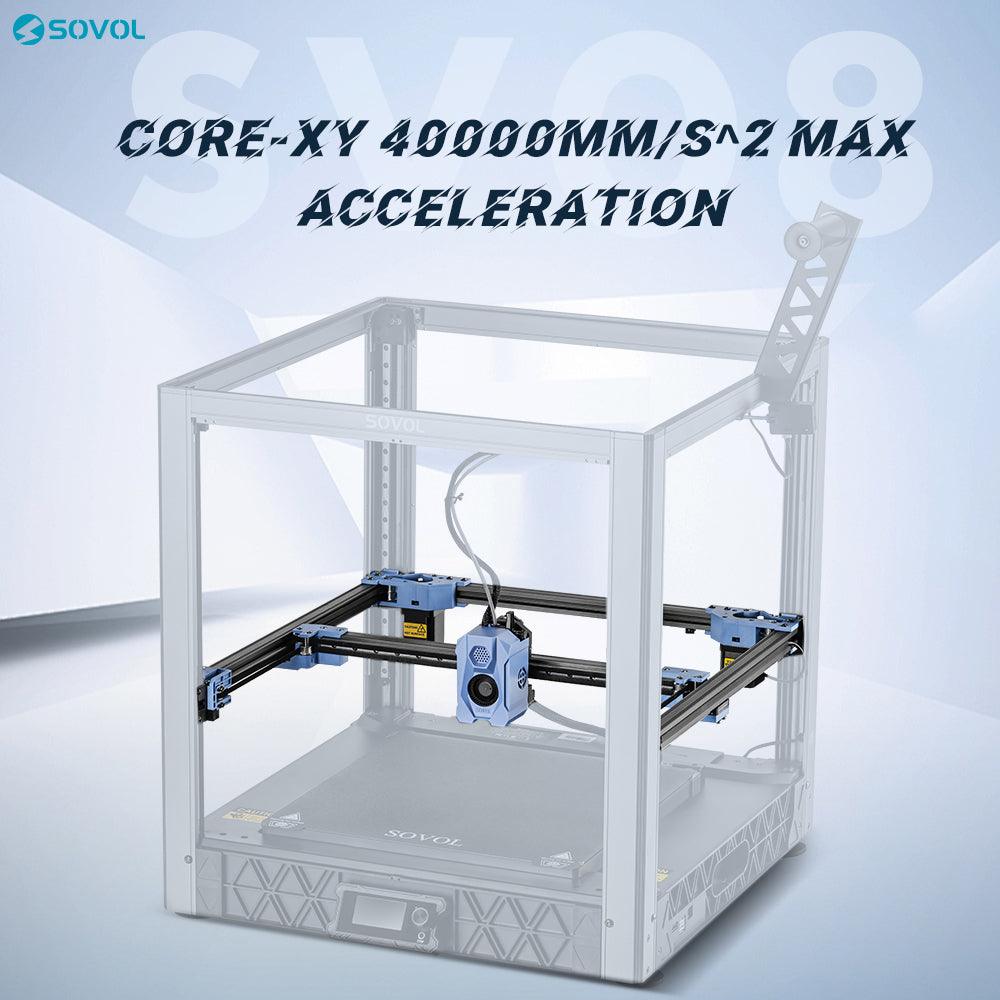

Picking the right way to keep your filament dry can feel tricky. You want your prints to look great and last long. Here are some things you should think about before you decide:

-

Check your material needs. Do you use standard filaments like PLA or PETG, or do you print with advanced materials like nylon or TPU?

-

Think about spool capacity. Do you need to dry one spool at a time, or do you want to dry several spools together?

-

Choose the right type of dryer. Some dryers work with any brand, while others only fit certain spools.

-

Decide on drying style. Do you want to dry your filament before printing (offline), or do you want to dry it while it feeds into your printer (inline)?

-

Look at the drying method. Some dryers use hot air to remove moisture. Others use desiccant packs.

-

Consider extra features. Features like sensors, alarms, or automatic controls can make drying easier and more reliable.

Tip: If you print with many types of filament, a universal dryer with adjustable settings can save you time and trouble.

You should also compare how different dryers perform. Here’s a quick look at two popular models:

|

Model |

Performance |

Price |

User Satisfaction |

|---|---|---|---|

|

Sunlu S2 |

Low |

Cheaper |

Low |

|

Creality Space PI |

High |

Higher |

High |

You want your prints to look great. Keeping filament dry helps a lot. Filament dryers work well and give you more control. They cost more than homemade options. Here is a simple guide:

|

Method |

Benefits |

Limitations |

|---|---|---|

|

Filament Dryers |

Precise, reliable drying |

Higher price |

|

Food Dehydrators |

Cheap, easy to use |

Less control |

|

DIY Dry Boxes |

Budget-friendly |

Not as effective |

If you print a lot, a dryer is smart. It helps if you live where it is humid. Sensitive filaments need extra care. Think about what you want and how much you can spend. Decide what works best for your printing needs.

FAQ

How do I know if my filament has absorbed moisture?

You might hear popping or crackling during printing. Prints can look rough or have bubbles. If you see stringing or weak layers, your filament probably has moisture.

Can I use my kitchen oven to dry filament?

You can, but you must watch the temperature closely. Most ovens do not control heat well at low settings. If it gets too hot, your filament can melt.

How long should I dry my filament?

Most filaments need 4–6 hours in a dryer at the right temperature. Check your filament’s label for the best settings. Some materials, like nylon, may need longer.

Do all filaments need drying?

No, not all filaments need drying. PLA and PETG can work fine if you store them well. Nylon, TPU, and ABS need more care. If you live in a humid place, drying helps most filaments.