When you use extruder machines in fused deposition modeling, you rely on the extruder as the heart of your 3d printer. The extruder pulls in filament, melts the filament, and deposits filament layer by layer to form your object. Research shows that controlling extruder parameters—such as feed speed, flow rate, and temperature—directly impacts the dimensional accuracy and mechanical strength of your prints. In high-performance fdm printers like the Sovol SV08, you see how advanced extruder technology improves both speed and quality by ensuring the filament flows smoothly and consistently.

Key Takeaways

- Extruder machines are the heart of FDM 3D printers, melting and precisely depositing filament layer by layer to create strong, accurate prints.

- Choosing the right extruder type—direct drive, Bowden, or dual extruder—affects print quality, speed, and material options, with direct drive excelling in flexible filament control.

- Regular maintenance and troubleshooting keep extruders running smoothly, preventing clogs and ensuring consistent, high-quality 3D printing results.

Extruder Machines

What Is an Extruder?

You encounter the extruder as the central component in any FDM 3D printer. This device takes solid filament and transforms it into precise layers that form your 3D object. The extruder consists of two main sections: the cold end and the hot end. The cold end uses a motor and gears to grip and push the filament forward. The hot end heats the filament until it melts, then forces it through a nozzle onto the print bed.

- The extruder motor drives the filament through the system.

- The filament drive system, which includes gears and bearings, ensures steady movement.

- The hot end contains a heating block and nozzle, melting and depositing the filament.

- The cooling system, with fans and heat sinks, keeps temperatures stable and prevents jams.

- A thermistor measures and regulates the hot end temperature for consistent results.

You find different types of 3d printer extruder designs, such as direct drive and Bowden. Direct drive extruders attach the motor directly to the hot end, which shortens the filament path and improves control, especially for flexible materials. Bowden extruders separate the motor from the hot end, reducing moving mass and allowing faster print speeds. Some printers use dual extruders, letting you print with multiple materials or colors at once.

Tip: The extruder’s ability to handle various filament diameters and materials, including flexible and composite types, expands your creative possibilities in fused deposition modeling.

Why Are Extruder Machines Important?

Extruder machines serve as the heart of your FDM 3D printer. Without them, you cannot transform raw filament into a finished 3D object. The extruder feeds the filament into the hot end, melts it, and deposits it layer by layer. This process builds your model with precision and consistency.

- The extruder melts and extrudes filament in a controlled manner, forming each layer of your print.

- The nozzle deposits fine lines of molten material, which solidify and adhere to previous layers.

- The cooling system ensures each layer sets quickly, preventing deformation and improving accuracy.

You rely on extruder machines to work with a wide range of materials. Common options include PLA, PETG, ABS, TPU, Nylon, and advanced composites. PLA offers ease of use and versatility, while PETG provides durability and chemical resistance. ABS and ASA deliver strength and weather resistance. TPU gives you flexibility for shock-absorbing parts. Nylon stands out for strength and flexibility, and composite filaments add unique properties for specialized applications.

The extruder’s precise control over filament flow ensures that each layer bonds correctly, resulting in strong, accurate prints. If the extruder fails to feed or melt the filament properly, your print will suffer from gaps, weak spots, or total failure. You depend on the extruder for every successful 3D print, making it the most critical part of the entire process.

Note: In advanced 3d printer extruder systems like those found in the Sovol SV08, you benefit from features such as dual-gear drives and high-temperature hot ends. These innovations allow you to print faster, handle more materials, and achieve higher quality results.

3D Printer Extruder Components

Cold End

You interact with the cold end every time you load filament into your 3d printer extruder. The cold end grips and advances the filament before it reaches the hot end. This section of the extruder uses a motor, drive gear, and idler to push the filament with precision. The cold end keeps the filament cool and stiff, which helps maintain feeding accuracy. If the filament slips or the drive gear loses grip, you may notice underextrusion or inconsistent prints. Direct-drive systems place the cold end right on top of the hot end, giving you faster and more reliable filament feeding. Bowden systems keep the cold end stationary and feed filament through a tube, which can reduce feeding accuracy during rapid changes. The cold end’s design and placement directly affect how well your 3d printer extruder responds to commands and maintains print quality.

The cold end also helps with bed leveling by pre-tightening the filament, ensuring consistent contact and sensor readings.

Hot End

The hot end is where your 3d printer extruder transforms solid filament into molten plastic. This part heats the filament to the right temperature, melts it, and pushes it through the nozzle. The hot end includes several key components:

|

Component |

Function |

|---|---|

|

Hotend |

Heats and melts the filament, maintaining consistent temperature and thermal dissipation for extrusion. |

|

Nozzle |

Extrudes molten filament through a small opening onto the print bed or previous layers. |

|

Heater Cartridge |

Raises the hotend’s temperature to melt the filament. |

|

Thermistor |

Monitors and controls the hotend’s temperature for precise melting. |

|

Heat Break |

Acts as a barrier to prevent heat from traveling up and melting filament too early. |

|

Heat Sink |

Cools the heat break, keeping the cold end and hot end separate. |

|

Cooling System |

Uses fans to solidify printed parts and prevent heat creep or nozzle clogs. |

You rely on the hot end to maintain a stable temperature, usually between 190°C and 300°C, depending on the filament. The hotend’s ability to control heat flow and prevent heat creep ensures that only the right section of filament melts. The nozzle at the hot end determines the width and detail of each printed line. If the hotend overheats or cools too much, your 3d prints may suffer from poor adhesion or surface defects. A well-designed hot end gives you consistent extrusion, strong layer bonding, and smooth finishes.

Extrusion Process

How the Extruder Works

You control the extrusion process by managing how the extruder feeds and melts the filament. The cold end grips the filament and pushes it toward the hot end. The hot end heats the filament to a precise temperature, turning it into a semi-liquid state. The extruder then forces the hot filament through a nozzle, depositing it onto the print bed. You must monitor several variables to keep the process efficient:

- Melt pressure and melt temperature in the hot end

- Motor load and screw speed in the extruder

- Barrel and die temperatures

- Feedstock moisture and pellet size

- Ambient conditions like room temperature and humidity

Skilled operation and regular maintenance of the extruder ensure consistent filament flow and prevent downtime. You should calibrate the machine and check the hot end for clogs or wear. Data acquisition systems help you track process variables in real time, reducing scrap rates and improving print quality. Consistent feeding methods and proper environmental control also stabilize the extrusion process.

Tip: Balancing quality and speed in the 3d printing process helps you avoid trade-offs that can affect efficiency.

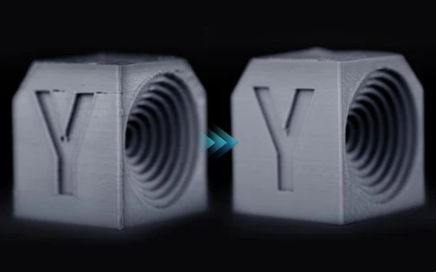

Layer-by-Layer Printing

The extruder enables the 3d printing process by depositing hot filament in thin layers. The hot end moves along the X, Y, and Z axes, placing each layer with precision. As the hot filament cools, it bonds to the previous layer, building your 3d object from the bottom up. This controlled process allows you to create complex shapes and detailed models.

You may encounter challenges during the layer-by-layer process. Filament quality, nozzle clogs, and uneven cooling can cause defects like warping, stringing, or layer misalignment. Incorrect hot end temperature or print speed can lead to under-extrusion or overheating. Environmental factors such as humidity and air currents also impact the process. To achieve the best results, you should maintain the extruder, optimize print settings, and manage filament storage.

|

Challenge |

Description |

|---|---|

|

Layer Misalignment |

Layers shift, causing structural and visual defects. |

|

Nozzle Clogging |

Hot end becomes blocked, stopping extrusion. |

|

Warping |

Corners lift due to uneven cooling or poor bed adhesion. |

|

Stringing |

Thin strands form between parts during movement. |

|

Overheating |

Small features deform from excess heat in the hot end. |

3D Printer Extruder Types

When you explore FDM 3D printing, you encounter several types of extruders. Each design impacts how the filament travels from the spool to the hot end, influencing print quality, speed, and material compatibility. Understanding these differences helps you select the right extruder for your projects.

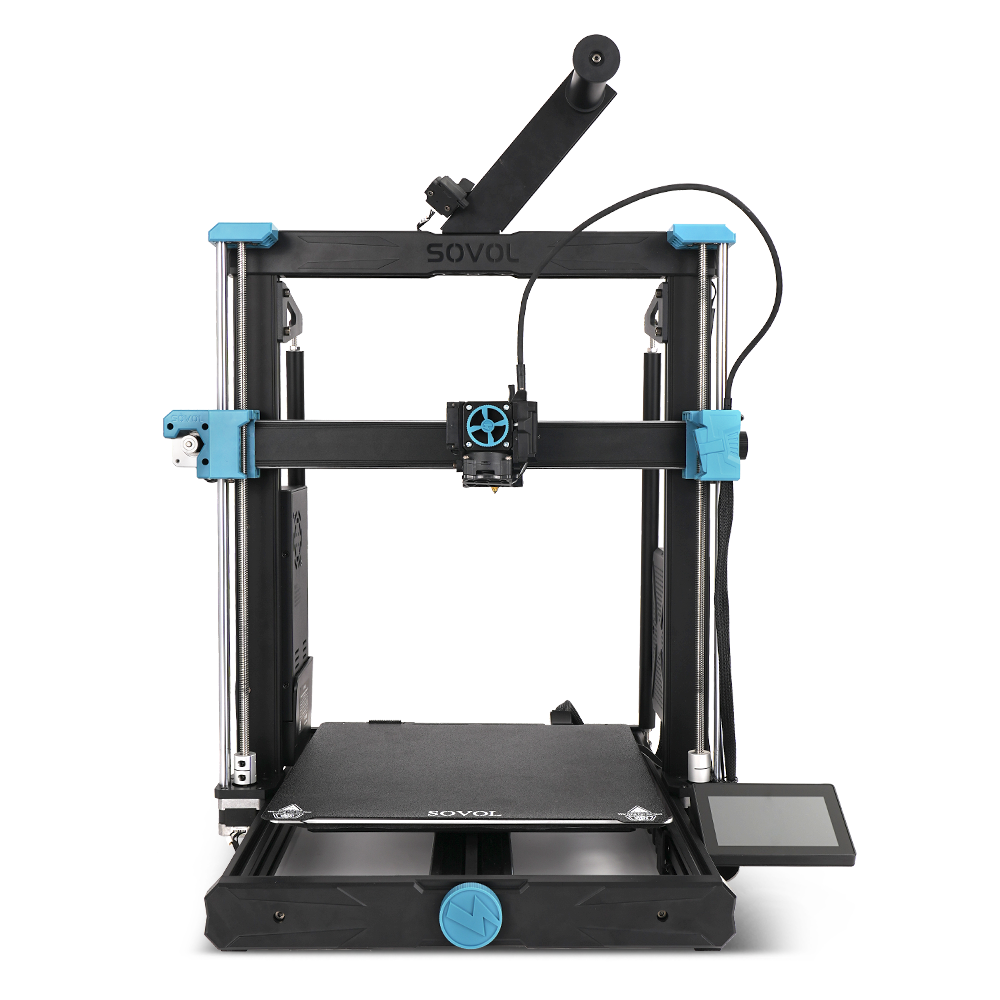

Direct Drive

A direct drive extruder places the extruder motor and drive mechanism directly above the hot end. This configuration shortens the filament path, giving you precise control over extrusion. You benefit from improved responsiveness, especially when printing with flexible filaments like TPU or TPE. The short distance between the extruder and hot end reduces the risk of filament buckling, which often causes jams or inconsistent flow.

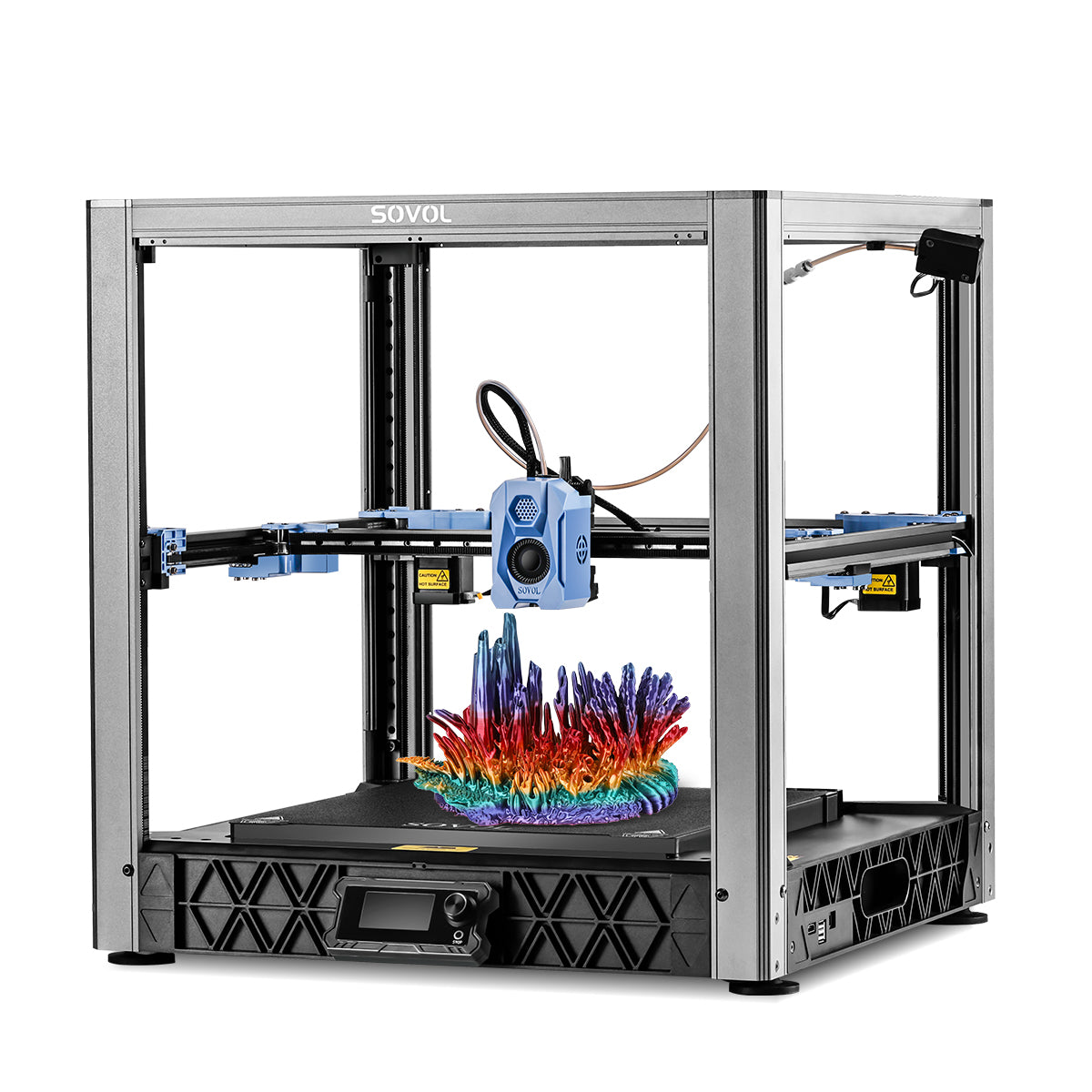

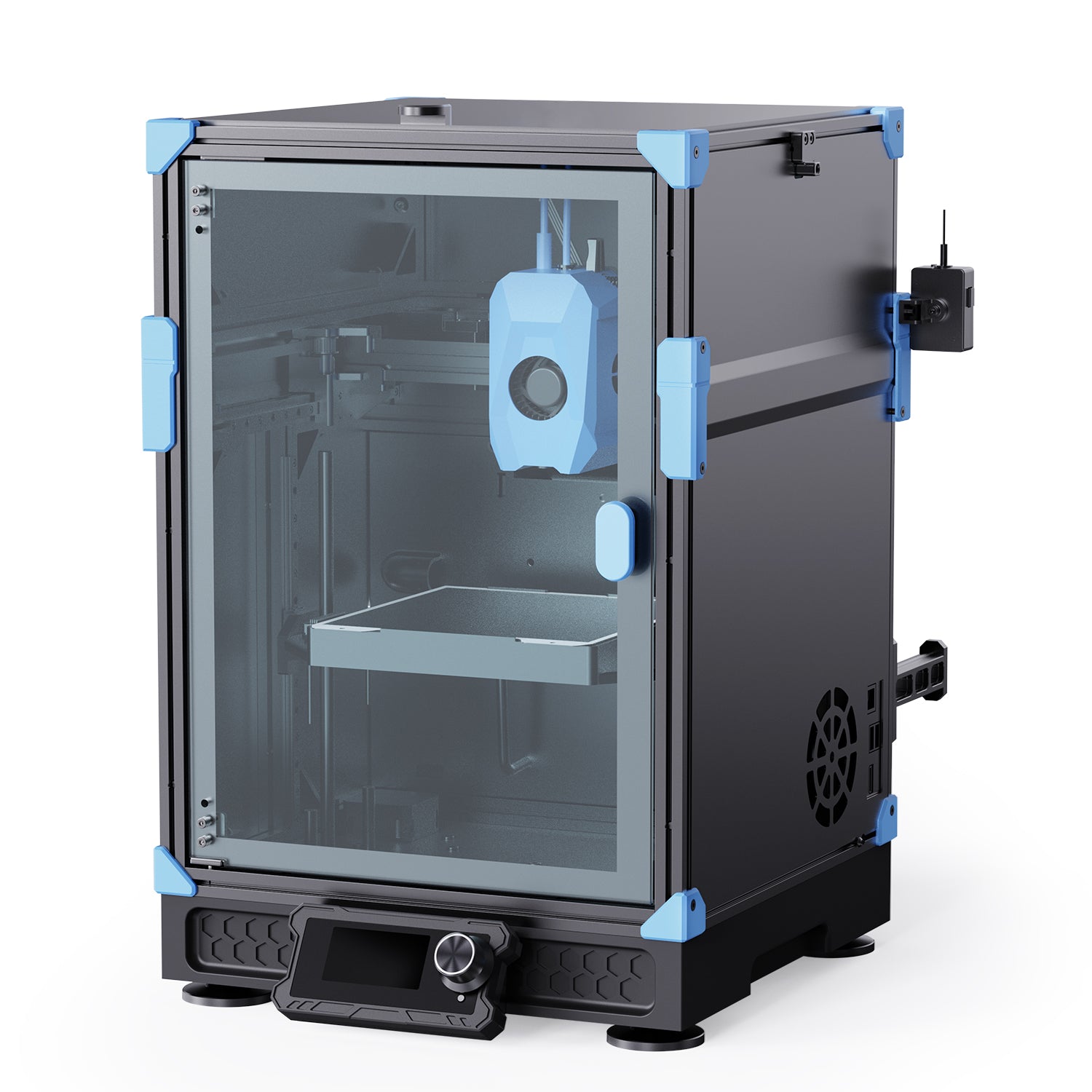

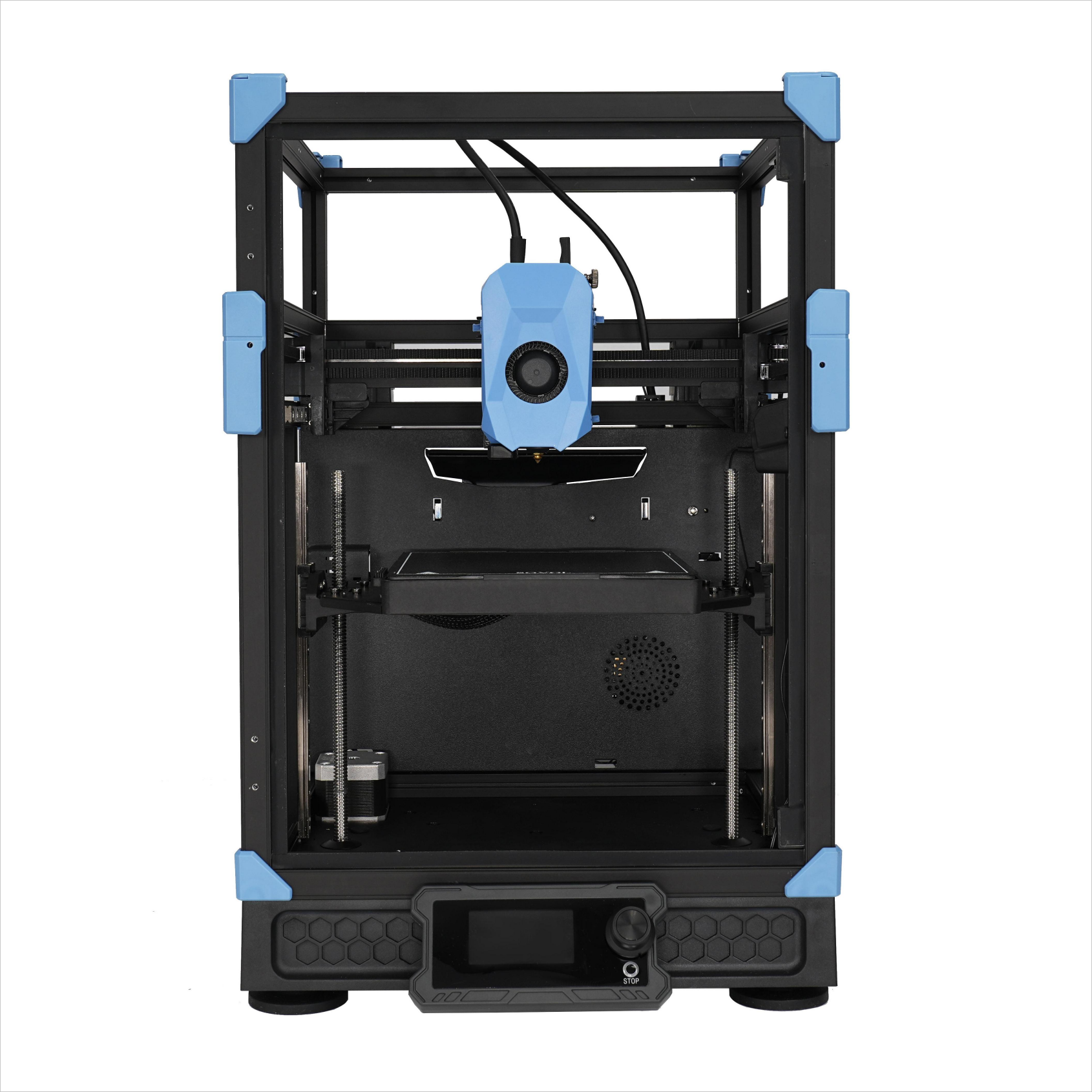

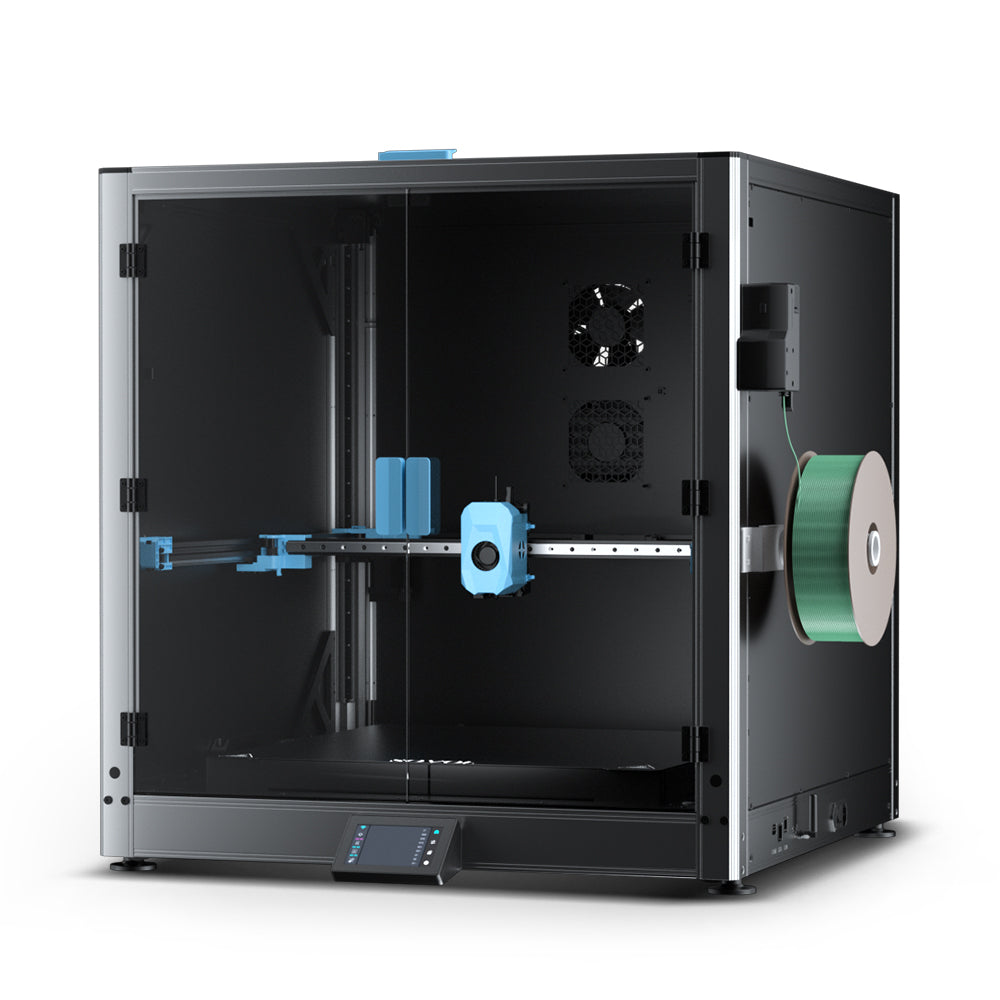

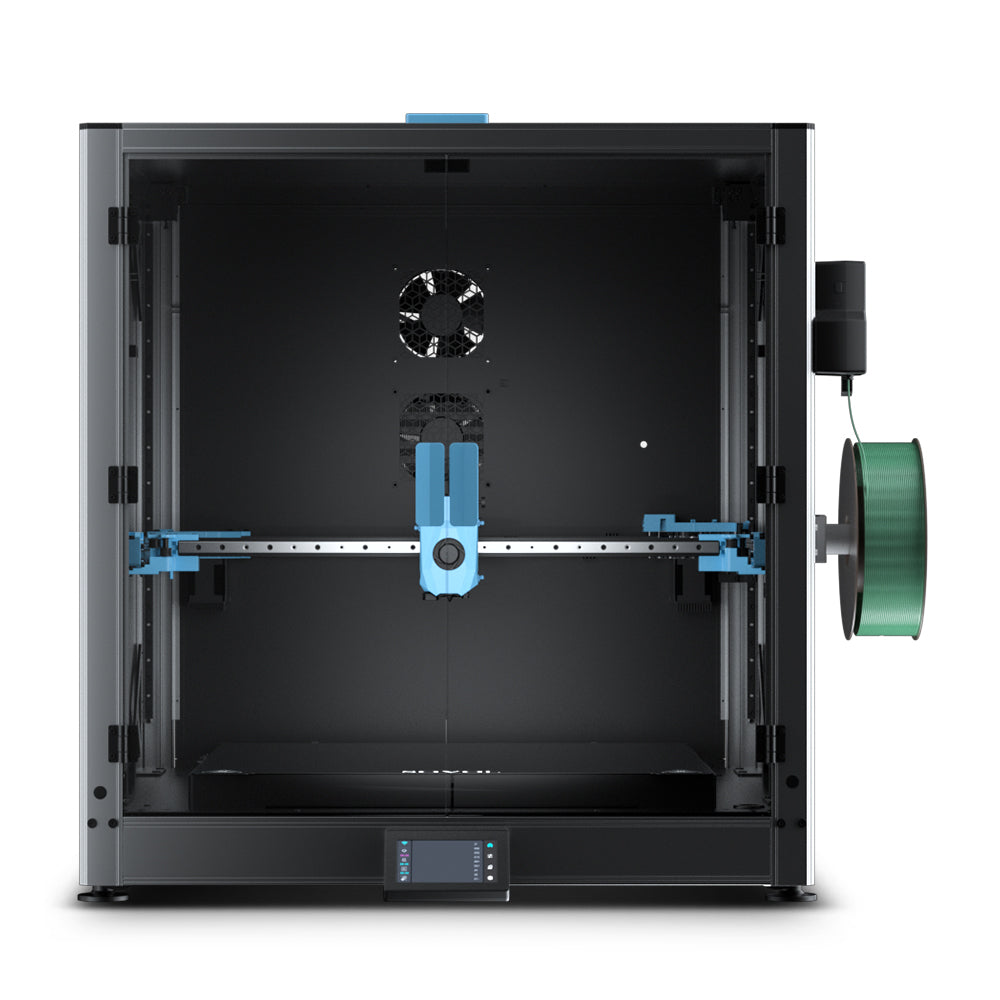

The Sovol SV08 stands out as a prime example of a dual-gear direct drive extruder. Its dual-gear system grips the filament securely, minimizing slippage and under-extrusion. You achieve consistent results, even with challenging materials. The SV08’s extruder works seamlessly with its high-flow hot end, enabling high-speed printing without sacrificing quality. This setup excels in both industrial prototypes and artistic models, giving you versatility and reliability.

Tip: Direct extruder systems allow you to fine-tune retraction settings, reducing stringing and oozing. You gain more accurate extrusion control, which is essential for detailed prints.

|

Feature |

Bowden Extruder |

Direct Drive Extruder |

|---|---|---|

|

Performance with Flexibles |

Struggles due to long filament path |

Excels with short filament path, reducing buckling and flexing |

|

Retraction Settings |

Requires longer retraction, prone to stringing |

Allows shorter, more precise retraction, reducing oozing and stringing |

|

Extrusion Control |

Less responsive, can cause print quality issues |

More accurate and responsive, improving print quality especially for flexible filaments |

You notice that direct extruder systems handle a wide range of filaments, including abrasive and composite types. The Sovol SV08’s dual-gear design further enhances grip, making it ideal for flexible and engineering-grade materials. You can print intricate designs with confidence, knowing the extruder delivers consistent flow to the hot end.

Bowden

A bowden extruder separates the extruder motor from the hot end. The filament travels through a PTFE tube before reaching the hotend. This design reduces the moving mass on the print head, allowing for faster print speeds and smoother motion. You experience less vibration and cleaner movements, which benefits large or fast prints.

However, bowden extruder systems present challenges with flexible filaments. The longer filament path increases friction and elasticity, making it harder to control extrusion. You may need to adjust retraction settings significantly to prevent stringing or oozing. Maintenance becomes more frequent, as the PTFE tube can wear down over time, especially with abrasive filaments.

|

Reduces moving mass on the print head, allowing faster print speeds and higher accelerations. |

Struggles with flexible filaments due to increased friction and elasticity in the filament path. |

|

Improves thermal isolation by distancing hot print materials from the print head, reducing heat creep. |

Delayed extrusion response caused by elasticity in the filament feed, leading to less precise control. |

|

Allows for lower print head height, enabling taller prints on some machines. |

Retraction control is more complex and less reliable because of friction and elasticity. |

|

Enables smoother printhead movements, minimizing issues like ringing and ghosting. |

Loading and unloading filament can be more cumbersome compared to direct drive systems. |

|

Offloads extruder weight to the printer frame, reducing inertia on moving parts. |

Bowden tubes experience increased wear and friction, especially with abrasive or composite filaments, requiring more maintenance. |

You find bowden extruder setups well-suited for standard filaments like PLA and PETG. If you prioritize speed and efficiency, especially for large prints, this system offers clear advantages. For flexible or specialty filaments, you may encounter more tuning and maintenance.

Dual Extruder

Dual extruders introduce a new level of capability to your 3D printer. With two independent extruders and hot ends, you can print with multiple filaments at once. This setup enables multi-material and multi-color prints, expanding your creative and functional options. You can combine rigid and flexible materials in a single model or use soluble supports for complex geometries.

Dual extruder systems, especially those with direct drive extruders, provide precise filament control. You achieve cleaner transitions between materials and reduce print time by printing supports and main structures simultaneously. The Sovol SV08’s dual-gear direct drive extruder enhances this process, delivering reliable extrusion for both standard and flexible filaments.

Note: Dual extruders require careful calibration and regular maintenance. You need to align both hot ends and manage filament switching to avoid cross-contamination or print defects.

- Advantages of Dual Extruder Systems:

- Print with two different filaments or colors in one job.

- Use soluble supports for intricate designs, improving surface finish.

- Combine materials with different properties for functional prototypes.

- Reduce print time by printing supports and main parts together.

- Considerations:

- Increased hardware complexity and maintenance.

- Higher cost and larger printer footprint.

- Requires advanced slicer settings and calibration.

Comparing Types of Extruders

You should evaluate the types of extruders based on your printing needs:

|

Extruder Type |

Filament Path |

Advantages |

Disadvantages |

|---|---|---|---|

|

Direct Extruder |

Filament runs directly from extruder to hot end |

Best for flexible filaments, precise extrusion, easy retraction tuning |

Adds weight to print head, may limit speed |

|

Bowden Extruder |

Filament travels through PTFE tube to hot end |

Faster print speeds, reduced moving mass, smoother motion |

Less effective with flexible filaments, more complex retraction settings |

|

Dual Extruders |

Two extruders and hot ends, independent or shared |

Multi-material and multi-color printing, soluble supports, design flexibility |

More complex setup, higher maintenance, increased cost and size |

You gain the most from a direct extruder if you work with flexible filaments or require high precision. Bowden extruder systems suit high-speed, large-format printing with standard filaments. Dual extruders unlock advanced applications, letting you combine materials and colors for professional results.

🛠️ Pro Tip: The Sovol SV08’s dual-gear direct drive extruder combines the best of both worlds—precision, versatility, and speed—making it a top choice for demanding 3D printing projects.

Troubleshooting & Maintenance

Common Issues

You may encounter several common issues with extruder machines in FDM 3D printing. Recognizing these problems early helps you maintain consistent print quality and avoid downtime. The table below summarizes frequent issues, their causes, and practical solutions:

|

Issue Type |

Description |

Causes |

Solutions |

|---|---|---|---|

|

Extruder Clog |

Filament gets stuck inside the extruder, causing extrusion to end unexpectedly. |

High chamber temperature, worn gears, soft filament, or inconsistent filament diameter. |

Lower bed temperature, improve heat dissipation, clean or replace gears, use proper filament. |

|

Nozzle Clog |

Molten filament cannot exit the nozzle, leading to a sudden end of extrusion. |

Low nozzle temperature, high print speed, or a narrowed nozzle channel. |

Set correct temperature, slow print speed, clean or replace nozzle. |

|

Insufficient Extrusion |

Sparse lines or lack of extruded material between layers, resulting in underextrusion. |

Tangled filament, blocked PTFE tube, low flow rate, or incorrect pressure advance. |

Rearrange filament, clean PTFE tube, adjust flow rate, recalibrate settings. |

|

Mechanical Issues |

Drive gear fails to grip filament, causing extrusion to end or become inconsistent. |

Loose drive gear pressure or worn components. |

Adjust gear pressure, inspect and replace worn parts. |

Tip: If you notice inconsistent extrusion or a lack of extruded material, check for debris inside the nozzle and verify smooth filament flow with manual extrusion. Clean the nozzle and inspect the drive gear for proper engagement.

Maintenance Tips

You can extend the lifespan of your extruder machine and ensure reliable operation by following a few essential maintenance practices:

- Lubricate moving parts regularly to prevent wear and keep the end of the extruder running smoothly.

- Schedule preventive maintenance using detailed checklists. This reduces emergency repairs and helps you catch issues before they cause a complete end to printing.

- Calibrate sensors and controls, such as temperature and speed sensors, to maintain precise operation from start to end.

- Inspect barrels, screws, and drive gears for wear. Replace or rebuild these parts as needed to avoid sudden end of extrusion.

- Keep a well-organized inventory of spare parts, focusing on original components for the best fit and reliability.

- Train operators to recognize early signs of underextrusion or mechanical failure, so you can address problems before they reach a critical end.

- Maintain comprehensive maintenance logs. These records help you track repairs and schedule future maintenance, ensuring your extruder performs well from start to end.

Regular maintenance and early detection of issues help you avoid costly downtime and ensure every print reaches a successful end.

Choosing an Extruder

Key Factors

When choosing the right extruder for your FDM 3D printer, you need to evaluate several important factors. The type of extruder—direct drive or Bowden—affects how well you can print flexible filaments and maintain consistent flow. Direct drive extruders, like the dual-gear system in the Sovol SV08, offer a fully constrained filament path from the idler to the hot end. This design gives you better control over flexible materials and reduces the risk of jams. You should also consider the rigidity of your printer. Cartesian printers often benefit from direct extruders, while Delta printers may perform better with lighter Bowden setups. Material compatibility matters as well. If you plan to use a wide range of filaments, including flexible or composite types, a direct drive with a robust hot end will serve you best.

|

Key Factor |

Explanation |

|---|---|

|

Extruder Type |

Direct-drive offers better filament control, especially for flexible filaments. |

|

Filament Path Constraint |

A fully constrained path ensures reliable flexible filament printing. |

|

Geared Extruders |

Dual-gear systems provide strong grip and precise feeding. |

|

Printer Type Considerations |

Direct extruders suit rigid frames; Bowden setups reduce moving mass for speed. |

|

Printing Speed & Rigidity |

Bowden extruders allow faster moves; direct extruders improve accuracy. |

|

Material Compatibility |

Direct drive and high-temp hot ends support a wider range of filaments. |

Tip: Always match your extruder’s capabilities to your printing goals and the materials you want to use.

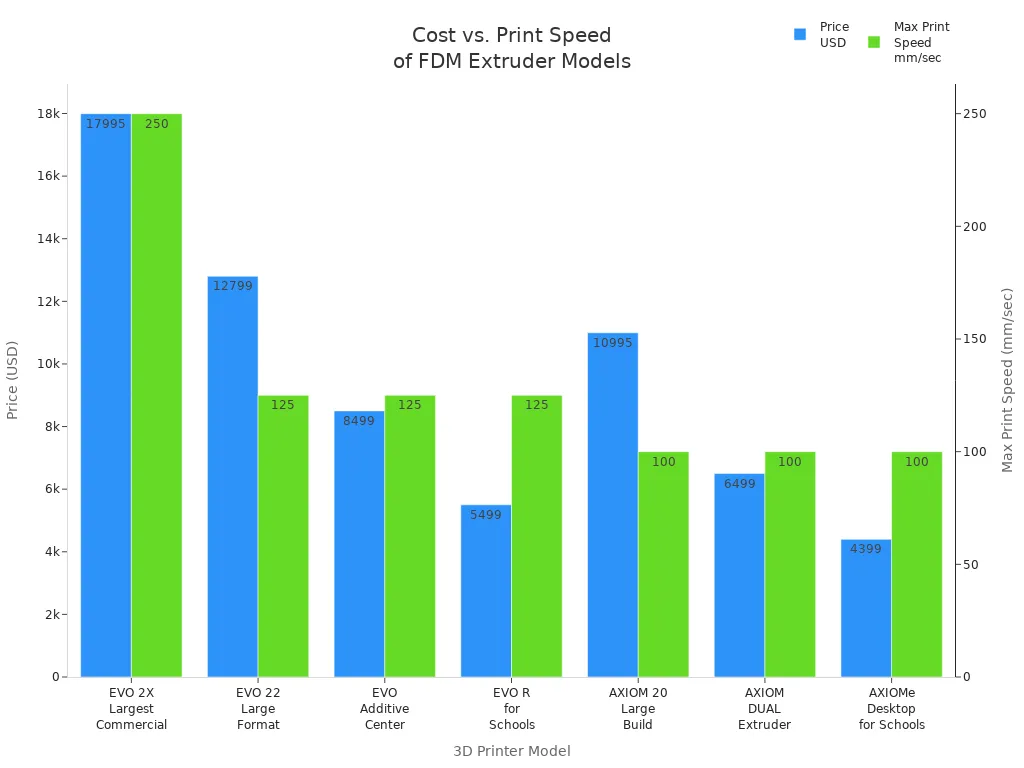

Cost & Performance

You must balance cost and performance when selecting an extruder. High-end models, such as those found in commercial printers, can reach prices above $15,000 and offer advanced features like heated chambers and auto-leveling. However, you can achieve excellent print quality and speed with more affordable options. The Sovol SV08, for example, provides a high-temp hot end, dual-gear drive, and open-source design at a competitive price. This combination supports fast printing, a broad range of filaments, and easy upgrades. When you compare models, look at maximum print speed, supported materials, and build volume. Ease of maintenance and calibration also play a role in long-term performance.

Choosing the right extruder means considering not just the initial investment but also the ongoing value. Features like a high-temperature hot end and a reliable dual-gear system, as seen in the Sovol SV08, can make a significant difference for both hobbyists and professionals.

You rely on extruder machines for precise, reliable FDM 3D printing. Understanding extruder types, the extrusion process, and regular maintenance ensures consistent results. Advanced options like the Sovol SV08 offer high-flow extrusion, rapid bed leveling, and a robust frame, delivering stable, high-speed performance and supporting a wide range of materials for your projects.

FAQ

What is the main difference between direct drive and Bowden extruders?

You get better control with direct drive extruders, especially for flexible filaments. Bowden extruders reduce moving mass, which helps you achieve faster print speeds.

How often should you clean your 3D printer extruder?

You should clean your extruder after every 10–20 prints. Regular cleaning prevents clogs and ensures consistent filament flow.

Can you use flexible filaments with any extruder?

You achieve the best results with direct drive extruders. Bowden setups often struggle with flexible filaments due to the longer filament path.