Consistent calibration and setup help you get the best prints with your Sovol SV08 Max. If you want great print quality, you should trust the 3d printing power and flexibility of this printer. The Sovol SV08 Max is great for making big and detailed prints. Every good 3d print starts with careful steps like bed leveling, checking the nozzle, and doing regular maintenance. Look at these numbers:

|

Calibration Step |

Statistic / Parameter |

Impact on Print Quality |

|---|---|---|

|

Bed Leveling |

Strong first layers, fewer failed prints |

|

|

Extruder Calibration |

100 mm filament, exact E-step |

No gaps or blobs in 3d prints |

|

PID Calibration |

Stable at ~234°C |

No warping or stringing |

You can use your Sovol SV08 Max in many ways by following easy tips. Good setup keeps the printer’s movement very accurate, under 0.02 mm. This gives you steady 3d printing every time. If you are new to 3d printing or already have experience, these tips will help you get better prints.

Key Takeaways

- Always level the bed before you print. This helps make strong first layers. It also helps stop failed prints. - Keep the nozzle clean. Calibrate the extruder often. This stops clogs and keeps the filament moving well. - Use the right print settings for each material. Set the correct temperature and fan speed. This helps you get the best results. - Store filaments in dry places. Moisture can cause bubbles and weak layers in your prints. - Watch your prints closely, especially the first layer. Change the settings during printing if you need to. This can help make your print better.

Key Takeaways

Best Prints Checklist

Want the best prints with your Sovol SV08 Max? Start with a solid checklist. This helps you catch problems before they start and keeps your 3d printing smooth. Here’s a quick table to guide you:

|

Parameter |

Recommended Range/Value |

Why It Matters |

|---|---|---|

|

Layer Height |

0.2 - 0.3 mm |

Balances speed and detail |

|

Print Speed |

40 - 60 mm/s |

Reduces vibration, boosts print quality |

|

Extrusion Multiplier |

1.0 |

Keeps filament flow steady |

|

Bed Adhesion |

Brim or Raft |

Helps first layer stick |

|

Nozzle Height |

0.1 - 0.2 mm |

Spreads filament evenly |

|

Bed Temp (PLA) |

50 - 70°C |

Stops warping, improves adhesion |

|

Bed Temp (ABS) |

110°C |

Prevents warping |

You should also:

- Place your Sovol SV08 Max on a stable surface.

- Clean the print bed after every print.

- Store filament in a dry place.

- Use real-time monitoring to spot issues early.

The Sovol SV08 Max uses eddy current scanning for bed leveling. This means you get fast, accurate setup with less maintenance. You can print large or detailed models with fewer flaws. The 1300W heated bed heats up quickly, so you spend less time waiting and more time 3d printing.

Common Mistakes

Even experienced users make mistakes. Here are some you should avoid if you want detailed results and the best results every time:

- Skipping bed leveling or using the wrong method. The Sovol SV08 Max’s automatic system is much faster and more accurate than manual setups.

- Ignoring regular maintenance. Dirty nozzles or beds can ruin print quality.

- Using the wrong print settings for your material. Always check your slicer before starting a new print.

- Printing too fast or with the wrong layer height. This can cause poor adhesion or rough prints.

- Not watching the first layer. Problems here can mess up the whole print.

Tip: Keep a log of your settings and results. This helps you track what works and what doesn’t for your Sovol SV08 Max. You’ll see your 3d prints improve with every project!

Sovol SV08 Max Setup

Setting up your Sovol SV08 Max the right way makes a huge difference in your print results. This printer gives you a large build volume and advanced features, but you need to start with a solid foundation. Let’s break down the most important steps for setup so you can get strong adhesion, high print accuracy, and reliable performance every time.

Bed Leveling

Bed leveling is the first thing you should check before every print. If your bed is not level, your first layer will not stick well, and your print might fail. The Sovol SV08 Max makes this process easier with flawless bed leveling features. You do not have to guess or use paper tricks. The printer scans the bed and adjusts itself.

- Automatic bed leveling scans many points on the bed. It measures the distance between the nozzle and the bed at each spot.

- Mesh bed leveling creates a map of the bed surface. This map helps the printer adjust for any bumps or dips.

- Z offset lets you fine-tune the nozzle height. You can get the perfect first layer for strong adhesion.

Tip: Always run bed leveling after moving your printer or changing the build plate. This keeps your first layer smooth and even.

When you use flawless bed leveling, you get even first layers across the whole large build volume. This means fewer failed prints and better results, even with big or complex models.

Auto-Leveling

The Sovol SV08 Max uses advanced auto-leveling technology. It has an eddy current scanning system that checks the entire 500×500 mm build surface in just 80 seconds. This system does not touch the bed, so it avoids wear and tear. You get flawless bed leveling every time.

- The auto-leveling system collects thousands of data points. It finds even tiny bumps or dips on the bed.

- The printer adjusts the z-axis automatically. This keeps the nozzle at the perfect height for every part of your print.

- You save time because you do not have to level the bed by hand.

With this feature, you get strong adhesion and uniform first layers. Your prints look better, and you waste less filament. The Sovol SV08 Max’s auto-leveling also works great for large build volume prints. You can trust it to handle big projects with enhanced precision.

Frame Alignment

Frame alignment is just as important as bed leveling. If your printer’s frame is not square, you will see problems like twisted prints or ringing artifacts. The Sovol SV08 Max has a sturdy aluminum and steel frame. You should check that all parts are tight and square before you start printing.

|

Metric |

Value |

|---|---|

|

Positional Deviation |

|

|

Printing Accuracy |

±0.1 mm |

|

Reduction in Ringing Artifacts |

92% reduction compared to disabled configurations |

- Tighten all bolts and check the linear rails.

- Make sure the gantry is not twisted.

- Align the frame so the printer moves smoothly.

When you set up the frame correctly, you get better print accuracy and fewer print defects. Your Sovol SV08 Max will deliver enhanced precision, even at high speeds. This is key for large build volume projects and detailed parts.

Nozzle Checks

Nozzle checks are a simple step that can save you a lot of trouble. Before every print, look at your nozzle. Make sure it is clean and free of old filament. A clogged or dirty nozzle can cause gaps, blobs, or weak prints.

- Wipe the nozzle to remove leftover filament.

- Heat the nozzle and clean out any buildup.

- Run extruder calibration to make sure filament flows correctly.

Regular nozzle checks help you avoid common print problems. They also extend the life of your nozzle and other parts. If you use a ruby nozzle, you can print over 100 models before needing a replacement. Standard nozzles last for about five prints before they need attention. Good nozzle care means fewer failed prints and better compatibility with different materials.

Note: Operator training and routine maintenance, including nozzle checks, keep your Sovol SV08 Max running smoothly. You get consistent results and strong adhesion for every print.

Why Proper Setup Matters

You might wonder why all these steps matter. Here’s what happens when you follow a good setup routine:

- Cleaning dust and debris, tightening bolts, and lubricating moving parts prevent jams and print defects.

- Calibration steps like axis homing, bed leveling, and extruder calibration give you strong adhesion and accurate prints.

- Real-time monitoring and first layer checks help you catch problems early, saving time and filament.

- Regular calibration after moving the printer or changing parts keeps your Sovol SV08 Max reliable.

- Studies show that users who skip setup have a 20% higher failure rate.

When you take the time to set up your Sovol SV08 Max, you unlock its full compatibility and large build volume. You get flawless bed leveling, strong adhesion, and prints that look great every time.

Preparation

Filament Storage

To get the best 3d prints, keep your filaments dry. Some materials, like PLA, PETG, and nylon, can soak up water from the air. Wet filament can make bubbles, strings, or weak layers in your prints. Always put your filaments in airtight boxes with silica gel packs. Some people use food dehydrators to dry their filament before printing. If you hear popping or see steam while printing, your filament is too wet. Good filament gives you better prints and fewer problems.

Tip: Write the date you open each filament spool. This helps you know how long it has been out in the air.

Slicer Settings

The right print settings are very important. Every material needs different slicer settings for the best results. Here is a simple guide:

- Calibrate your extruder when you change filament or brands. This keeps the flow steady and stops blobs or gaps.

- Run PID tuning to keep your hotend and bed at the right temperature. Stable heat helps your prints stick and look smooth.

- Change your bed temperature, fan speed, and layer height for each material. PLA likes a cooler bed and more fan. ABS needs a hotter bed and less fan.

- Use input shaping if you want to print faster. This setting lowers vibrations and keeps your layers even.

You can find these settings in your slicer software. Test and calibrate often to match your settings to each filament. This helps your prints look better and work with more materials.

Test Prints

Do some test prints before starting a big project. Small test prints help you check your settings and see how your material works. Print a simple cube to check the layers. Print a snap-together part to test the fit. Here is a table that shows what each test print can tell you:

|

Purpose |

Outcome |

|

|---|---|---|

|

Component Printing Test |

Check layer line quality |

Smoother surface, fewer defects |

|

Partial Printing Test |

Test part fit and connectivity |

Better fit, easier assembly |

|

Full Model Assembly Test |

Validate assembly sequence |

Stronger structure, improved teamwork |

Test prints help you find problems early. You can change your settings, try new filaments, and see how each one works. This step saves time and filament. You also learn how well your Sovol SV08 Max works with different materials and filaments.

Print Settings

Getting the right print settings on your Sovol SV08 Max makes all the difference between a failed print and a masterpiece. This printer gives you the versatility to work with many 3d print materials, but you need to know how to set it up for each one. Let’s break down the best ways to get high-quality prints, no matter what filament you use.

PLA, PETG, ABS

You can print with a wide range of filaments on the Sovol SV08 Max. The printer’s advanced hardware, like the high-temperature hotend and thick aluminum heated bed, gives you strong adhesion and great compatibility with different materials. Here’s a quick guide to the most common 3d print materials:

|

Material |

Nozzle Temp |

Bed Temp |

Print Speed |

Fan |

Notes |

|---|---|---|---|---|---|

|

PLA |

200-220°C |

50-70°C |

40-60 mm/s |

100% |

Easy to print, needs cooling |

|

PETG |

230-250°C |

70-90°C |

40-60 mm/s |

40-60% |

Needs less cooling, sticks well |

|

ABS |

240-260°C |

100-110°C |

40-50 mm/s |

0-20% |

Needs high temp, keep drafts away |

- PLA is the easiest to use. You get smooth prints and bright colors. Use high fan speed for the best results.

- PETG gives you strong, flexible prints. Lower the fan to avoid stringing. The Sovol SV08 Max’s heated bed helps PETG stick well.

- ABS is tough and heat-resistant. You need a hot bed and low fan. The thick aluminum bed on this printer heats up fast and keeps the build surface even, so your prints don’t warp.

Tip: Always clean your nozzle and bed after every print. This simple step prevents clogs and helps your next print stick better.

The Sovol SV08 Max’s smart feeder system also helps you switch filaments without tangles or jams. You can try new materials with confidence and get consistent results.

Speed and Layer Height

You want your prints to look good and finish fast. The Sovol SV08 Max’s CoreXY motion system and strong frame let you print at high speeds without losing print quality. But you need to balance speed and detail.

- For most prints, use a layer height of 0.2 mm. This gives you a good mix of speed and detail.

- If you want more detail, try 0.1 mm. For faster prints, go up to 0.3 mm, but you might lose some sharpness.

- Start with a print speed of 40-60 mm/s. You can go faster, but check your print quality as you increase speed.

- The Sovol SV08 Max can reach speeds up to 700 mm/s, but for best results, increase speed slowly and watch for any loss in detail.

Note: Adjust your acceleration and jerk settings in the slicer. Start slow, then speed up as you get more comfortable with your printer’s capabilities.

The printer’s dual linear actuators keep your build steady, even at high speeds. You get great print accuracy and fewer print defects, even on large build volume projects.

Cooling and Fan Use

Cooling is key for strong adhesion and smooth layers. The Sovol SV08 Max has a multi-fan cooling system that gives you more control over your prints.

- For PLA, set your fan to 100%. This cools the filament fast and gives you crisp details.

- For PETG, use 40-60% fan. Too much cooling can make PETG brittle or cause poor layer bonding.

- For ABS, keep the fan low (0-20%). ABS needs to cool slowly to avoid warping and cracks.

Studies show that the Sovol SV08 Max’s advanced cooling system helps you print faster without losing quality. The fans cool the filament evenly, which stops warping and keeps your layers tight. If you notice ghosting or wavy lines, try lowering the fan speed a bit. This reduces vibrations and makes your prints smoother.

Tip: In your slicer, adjust the nozzle path to avoid sharp turns. This helps your printer move smoothly and keeps your prints looking clean.

You can print big models or small parts with the same strong adhesion and smooth finish. The Sovol SV08 Max’s cooling system gives you the versatility to handle any project.

Flow and Temperature

Getting the right flow and temperature settings is one of the most important steps for high-quality prints. You want your printer to push out just the right amount of filament at the perfect temperature.

- Calibrate your extruder to make sure you get the right flow. Print a test cube and measure it. Adjust your extrusion multiplier in the slicer if needed.

- Use PID tuning to keep your nozzle and bed temperatures steady. This stops warping, stringing, and other common problems.

- For each material, start with the recommended temperatures, then adjust up or down by 5°C if you see issues like blobs or gaps.

- Store your filaments in a dry place. Wet filament can cause bubbles and weak layers.

When you fine-tune your flow and temperature, you get fewer print failures and better results. The Sovol SV08 Max’s mesh bed leveling and real-time monitoring help you catch problems early. You can pause your print, fix the issue, and keep going.

The printer’s thick aluminum bed heats up fast and stays even, which is perfect for ABS and PETG. You get strong adhesion and fewer warping issues. Regular maintenance, like lubricating moving parts and cleaning the nozzle, also keeps your printer running smoothly and your prints looking great.

Note: Keep a log of your print settings for each filament. This helps you remember what works best and makes it easy to get the same great results every time.

With the Sovol SV08 Max, you have the capabilities and compatibility to print almost anything. Take the time to dial in your settings, and you’ll see your 3d prints reach a new level of quality.

Print Tips

First Layer

Getting the first layer right sets you up for a successful print. The Sovol SV08 Max uses advanced bed leveling and eddy current scanning to make sure your first layer sticks every time. These features help you avoid problems and get detailed results from the start.

|

Evidence Aspect |

Explanation |

|---|---|

|

Advanced Bed Leveling Technology |

Gives you a flat, even surface for every print. |

|

Eddy Current Scanning |

Finds tiny bumps without touching the bed, so it lasts longer. |

|

Consistent First Layers |

Adjusts for any dips or high spots, so your print always starts strong. |

|

High-Speed Scanning |

Gets your bed ready fast, so you can start printing sooner. |

|

Sensitivity to Surface Defects |

Spots defects as small as 0.5 mm, which helps you get flawless first layers. |

If you see any issues with the first layer, pause the print and fix them right away. This step saves you time and filament.

Pre-Print Checklist

Before you start any 3d print, run through this checklist. It helps you catch problems early and boosts your print quality.

- Level the bed for strong first layer adhesion.

- Calibrate the extruder for steady filament flow.

- Run PID calibration to keep temperatures stable.

- Adjust the first layer Z height for perfect nozzle distance.

- Clean the bed and nozzle to remove dust.

- Watch the first layer and pause if you see problems.

- Use auto and mesh bed leveling for uneven beds.

- Keep a log of your calibration settings.

- Store filament in a dry place for consistent prints.

Following these steps leads to fewer failed prints and more high-quality prints.

Monitoring Prints

Keep an eye on your 3d prints, especially during the first few layers. The Sovol SV08 Max lets you watch prints in real time. If you spot any issues, you can pause and fix them. This habit helps you catch problems before they ruin your print. You get better print quality and save time.

Tip: Use the printer’s live feedback to spot stringing, blobs, or poor adhesion early.

Mid-Print Adjustments

Sometimes, you need to tweak settings while your print runs. You can adjust speed, temperature, or fan settings to fix issues as they appear. Try changing acceleration or jerk to reduce vibrations. Adjust retraction to stop stringing. Use Z-hop to avoid nozzle crashes. The Sovol SV08 Max’s smart sensors help you pause and fix problems, so you get optimal print quality every time. These mid-print tips help you get more detailed results and fewer failed prints.

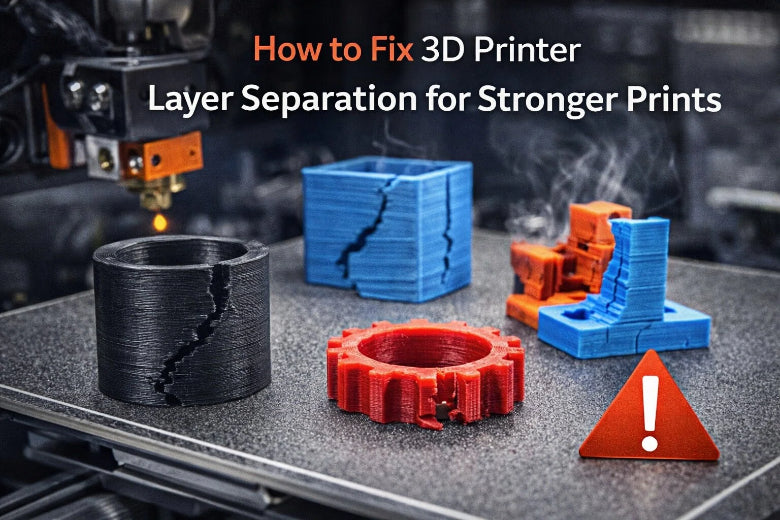

Troubleshooting Prints

When you print with the Sovol SV08 Max, you want every print to look great. Sometimes, you run into problems. Let’s look at the most common issues and how you can fix them.

Warping and Adhesion

Warping can ruin your prints, especially on big build plates. You might see corners lifting or prints popping off the bed. Here’s what you can do:

- Clean the print bed before every print. Dust and oils stop prints from sticking.

- Level the bed carefully. A flat bed keeps the nozzle at the right height for strong adhesion.

- Set the bed temperature to 60-70°C for PLA and 100-120°C for ABS. Start with a slightly higher temperature for the first layer.

- Use a PEI sheet for PLA or heated glass for ABS. These surfaces help prints stick.

- Try glue sticks or hairspray for extra grip.

- Add a brim or raft in your slicer to give prints more contact with the bed.

- Slow down the first layers and turn off the fan at the start.

- Use a heated enclosure to keep the build area warm and block drafts.

The Sovol SV08 Max’s thick aluminum hotbed heats up fast and evenly. Real-time monitoring helps you catch problems early.

Clogs and Extrusion

Clogs stop your print in its tracks. You might see gaps or missing parts in your prints. To avoid this:

- Clean the nozzle often. Old filament can block the flow.

- Check the filament path for jams.

- Store filament in dry boxes. Wet filament causes clogs and weak prints.

- Use the right temperature for your material.

- Lubricate moving parts to keep extrusion smooth.

- The Sovol SV08 Max’s high-flow nozzle and dual-gear extruder help you print flexible and tough materials without jams.

Layer Lines

Layer lines make prints look rough. You want smooth sides on your parts. Try these tips:

- Calibrate your layer height and print speed.

- Make sure the frame and rails are tight and square.

- Use input shaping to reduce vibrations.

- Upgrade to a carbon fiber build plate to cut down on Z-banding and get cleaner prints.

Artifacts

Artifacts are strange marks or patterns on your prints. They can come from loose parts or wrong settings.

- Tighten all bolts and check the build for wobbles.

- Adjust slicer settings like acceleration and jerk.

- Keep the Sovol SV08 Max’s firmware updated for the best performance.

- Test with small prints before starting big builds.

Tip: Keep a log of your settings and results. This helps you spot patterns and improve your prints over time.

Maintenance Tips

Keeping your Sovol SV08 Max in top shape is the secret to unlocking its full capabilities and versatility. If you want your printer to deliver perfect prints every time, you need to follow some simple maintenance tips. Let’s break it down so you can keep your printer running smoothly and enjoy all the versatility it offers.

Cleaning

You should clean your printer often. Dust and debris can cause jams and ruin print quality. Here are some easy tips:

- Wipe the nozzle after every print to stop clogs.

- Clean the build plate so your prints stick better.

- Check the filament path for any leftover bits.

- Store your filament in a dry box to avoid moisture.

A clean printer means fewer problems and better results. Skilled users who clean their printer regularly see fewer build-up issues and save money on repairs.

Lubrication

Moving parts need a little help to stay smooth. Lubricate the rails and lead screws every few weeks. This reduces friction and keeps your printer quiet. Tighten bolts and check belts for wear. If you keep everything moving well, your printer will last longer and keep its high print quality.

Upgrades

Want even more versatility? Try some upgrades. A ruby nozzle can print over 100 models before you need to replace it. Upgrading to a carbon fiber build plate can cut down on Z-banding and improve adhesion. Updating your firmware gives your printer new features and better performance. These upgrades boost your printer’s capabilities and make it even more fun to use.

Maintenance Schedule

Set up a simple schedule to keep your printer in top shape. Here’s a quick table to help you remember:

|

Task |

How Often |

|---|---|

|

Clean nozzle/bed |

After every print |

|

Lubricate rails |

Every 2 weeks |

|

Tighten bolts/belts |

Monthly |

|

Replace worn parts |

As needed |

|

Update firmware |

When available |

Follow these tips and your Sovol SV08 Max will keep showing off its versatility and capabilities for years. A little care goes a long way!

You can get amazing prints with your Sovol SV08 Max by following a few simple steps. Always set up your printer, calibrate it, and keep it clean. The Sovol SV08 Max’s auto-bed leveling takes just 80 seconds, so you start every print with a flat bed. Clean your nozzle often and you’ll get over 100 prints before changing it. Try new slicer settings and watch your prints improve. The printer’s CoreXY system lets you print fast and still get sharp details. Many users save time and money by tuning their Sovol SV08 Max.

Keep experimenting and tweaking your settings. Every print helps you learn more about your printer. Soon, you’ll master the Sovol SV08 Max and create prints you’re proud of!

FAQ

How often should I level the bed on my Sovol SV08 Max?

You should level the bed before every big print or after moving the printer. If you notice poor first layers, run the auto-leveling feature. This keeps your prints sticking well and looking sharp.

What is the best way to store filament?

Keep your filament in a dry box with silica gel packs. Moisture can ruin prints. If you hear popping sounds or see steam, dry your filament before printing. Good storage means fewer print problems.

Why does my print not stick to the bed?

Check if the bed is clean and level. Use the right bed temperature for your filament. Try a brim or glue stick for extra grip. Watch the first layer closely and pause if you see lifting.

Can I print flexible filaments with the Sovol SV08 Max?

Yes, you can print flexible filaments like TPU. Slow down your print speed to 20-30 mm/s. Make sure the filament path is clear. The Sovol SV08 Max’s direct drive extruder helps with flexible materials.

Got more questions? Share your tips or ask for help in the comments! Your feedback helps everyone get better prints.