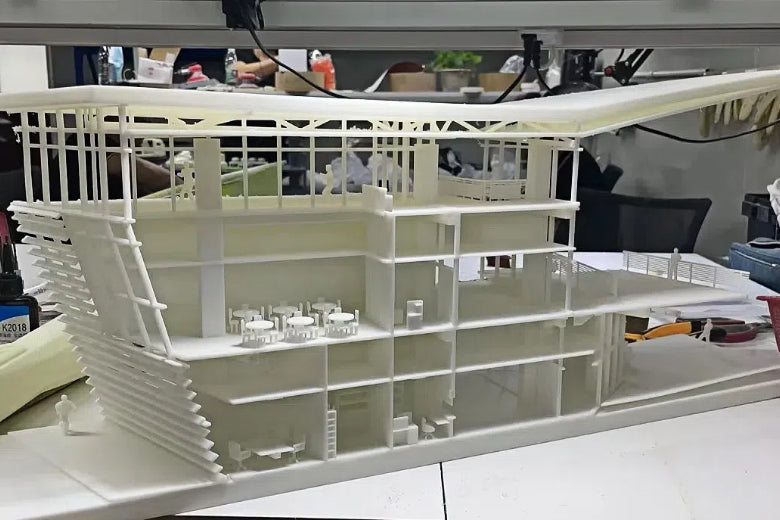

The Sovol SV08 Max changes what you can do with a 3D printer. It mixes fast printing with great accuracy. It can print up to 700 mm/s and has a large 500×500×500 mm build space. This makes it perfect for prototypes, working models, and creative projects. Its CoreXY system moves smoothly and precisely. Smart tools help keep prints high-quality, even at fast speeds.

To get accurate prints, you need to adjust settings carefully. This is important for assembly kits or machine parts. Good calibration and a stable environment make printing more reliable. Adjusting slicer settings like layer height and wall thickness improves details. By learning these steps, you can use the Sovol SV08 Max fully and get great results every time.

Key Takeaways

- The Sovol SV08 Max prints fast, up to 700 mm/s. It stays accurate, making it great for models and fun projects.

- Setting up the printer right, like layer height and speed, is key for good prints.

- A strong frame and good cooling stop shaking. This helps prints look better, even when printing fast.

- Fixing retraction and Z-hop settings stops problems like strings and blobs. This makes prints neater.

- Trying different materials and settings helps improve your prints. You can get both speed and detail in your work.

Why Speed and Precision Matter in 3D Printing

How speed and precision work together

In 3D printing, speed and precision can seem opposite. Printing faster saves time but might lower quality. Precision ensures your designs are accurate and detailed. The Sovol SV08 Max balances both with smart features. Its CoreXY system reduces vibrations for better prints at high speeds. This is important for projects like prototypes or working models where both speed and accuracy are needed.

Studies show that a stable printer frame helps with precision. A strong frame, like the SV08 Max has, cuts down vibrations. Adjusting settings like nozzle height and bed leveling also improves results.

Why precision affects accuracy

Precision impacts how close prints match the design. Without it, prints may not work as planned. Things like layer thickness and print direction affect accuracy. Research shows small features often have more errors, especially under 10 mm. Larger features, over 25 mm, usually stay within 1% error. This shows how important precision is for reliable results.

The SV08 Max keeps prints accurate with advanced cooling and fast motors. These features ensure smooth material flow, even at high speeds. This makes it great for projects needing exact measurements.

Handling trade-offs between speed and precision

Balancing speed and precision can be tricky. Faster printing may cause defects like shifted layers. Slower speeds improve quality but take longer. To fix this, adjust slicer settings like acceleration and jerk. Lowering acceleration reduces vibrations for smoother prints.

Experts suggest starting slow and increasing speed gradually. This keeps prints accurate while saving time. The SV08 Max’s strong frame and high-flow nozzle make this easier. It helps you get both speed and quality in your prints.

Features of the Sovol SV08 Max That Enhance Speed and Precision

Fast motors and quick acceleration

The Sovol SV08 Max uses fast motors for high-speed printing. These motors let it print up to 700 mm/s. It’s great for quick prints without losing accuracy. With acceleration up to 400,000 mm/s², it reaches top speed fast. This saves time and keeps movements smooth.

Here’s a simple breakdown of its performance:

|

Feature |

Value |

|---|---|

|

Printing Speed |

Up to 700 mm/s |

|

Acceleration |

Up to 400,000 mm/s² |

|

Material Flow Rate |

50 mm³/s |

These numbers show how well it handles tough projects. Whether making prototypes or models, it prints with few errors.

Cooling systems for better accuracy

Good cooling is key for accurate 3D prints. The Sovol SV08 Max has advanced cooling to keep material flow steady. It cools filament quickly and evenly, stopping warping and improving layer bonding. This is especially helpful for fast printing, where cooling needs to be quick.

Cooling systems are important in many fields. For example:

- In chip-making, they keep conditions stable for quality parts.

- In medical tools, they ensure machines work precisely for correct results.

The Sovol SV08 Max uses these ideas to give you accurate prints, even at high speeds.

Strong frame for stable printing

A strong frame helps make accurate 3D prints. The Sovol SV08 Max has a sturdy frame that reduces vibrations. This keeps the printer steady during fast movements, improving print quality.

Studies show why strong frames matter for precision. Key ideas include:

|

Principle |

Explanation |

|---|---|

|

Frame Strength |

All parts should handle tension or compression. |

|

Full Stability |

Stability is needed in all directions: X, Y, and Z. |

|

Simple Structure |

Triangles are the strongest shape for rigid designs. |

|

Material Thickness |

Thicker materials make the frame stronger. |

|

Connection Strength |

How parts connect and their distance affects stability. |

The Sovol SV08 Max follows these rules for better results. It’s perfect for projects needing precise and reliable prints.

High-flow nozzle for faster extrusion

A high-flow nozzle helps print faster without losing quality. The Sovol SV08 Max has a nozzle that handles more material smoothly. This lets you print big models quickly while keeping layers strong and neat.

The nozzle is built to work well at high flow rates. Standard nozzles might struggle, but this one stays steady. Look at the table below for a comparison:

|

Nozzle Type |

Max Flow Rate (mm³/s) |

Under-Extrusion (%) |

|---|---|---|

|

Standard 0.6 mm V6 |

15 |

5 |

|

E3D Volcano |

30 |

5 |

|

Bondtech CHT |

40 |

5 |

For example, the Bondtech CHT nozzle can flow up to 40 mm³/s with just 5% under-extrusion. That’s 33% better than the E3D Volcano and nearly 200% better than the standard V6 nozzle. These improvements show how high-flow nozzles make printing faster and still accurate.

Here’s why this matters:

- It cuts down printing time, especially for large projects.

- It avoids under-extrusion, making prints stronger and more reliable.

- It keeps material flowing evenly, even at high speeds.

With the Sovol SV08 Max, you can print fast and still get great results. The high-flow nozzle ensures your prints are detailed and sturdy, even at top speed. This makes it a great tool for both experts and beginners looking to improve their 3D printing.

Optimizing Slicer Settings for the Sovol SV08 Max

Tweaking slicer settings is key for precise prints with the Sovol SV08 Max. Adjusting things like layer height, print speed, and acceleration improves results. These settings affect how well your prints turn out, even at fast speeds.

Changing layer height and print speed for better prints

Layer height and print speed are important for print quality. Thin layers make surfaces smoother and show more details. But they take longer to print. Thick layers print faster but may lose detail and accuracy.

|

Layer Height |

Effect on Speed |

Effect on Surface Quality |

|---|---|---|

|

Thick Layers |

Prints faster with fewer layers |

May lose detail |

|

Thin Layers |

Prints slower with more layers |

Improves detail |

For example, a 0.15mm layer height balances strength and detail. It reduces visible lines while keeping prints strong. For big models, use thicker layers like 0.3mm to save time. For detailed designs, thinner layers work best.

Start with medium print speeds and slowly increase them. The Sovol SV08 Max handles high speeds well without losing quality. Faster speeds might need extra cooling to keep prints accurate.

Tip: Test different layer heights and speeds to find the best settings for your project.

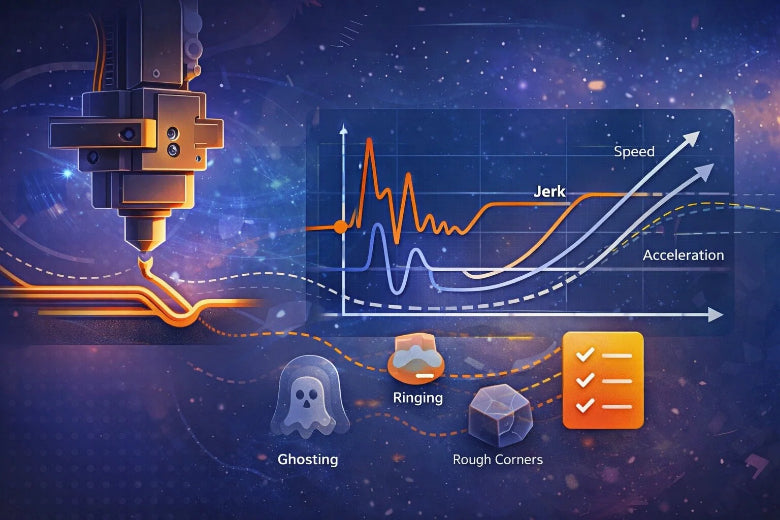

Adjusting acceleration and jerk for smoother prints

Acceleration and jerk settings affect how stable your prints are. Acceleration controls how quickly the printer speeds up. Jerk decides how suddenly it starts or stops. Wrong settings can cause shaky prints or ripples.

- High acceleration can make movements rough, causing marks. Lower it to around 500 mm/s² for smoother prints.

- Jerk settings affect how steady the printer moves. High jerk can cause shaking, while lower values (5-10 mm/s) make movements smoother.

Test different settings to find what works best. Start low and increase slowly. The Sovol SV08 Max’s strong frame helps reduce vibrations, so you can adjust these settings without losing accuracy.

Note: Better settings improve print quality and reduce wear on your printer.

Picking infill patterns for stronger prints

Infill patterns affect strength and accuracy. The right pattern spreads material evenly, stopping warping or bending. Common patterns include grid, honeycomb, and gyroid.

- Grid: Balances strength and speed. Good for parts needing medium strength.

- Honeycomb: Adds strength and stiffness. Great for heavy-duty parts.

- Gyroid: Gives equal strength in all directions. Best for complex designs.

For large prints, use low infill density (10-20%) to save time. Increase density for stronger or more precise parts. Test different patterns to find the best one for your project.

Pro Tip: Combine infill patterns with good layer heights and speeds for accurate prints that don’t waste time.

By learning these slicer settings, you can use the Sovol SV08 Max fully. Whether making prototypes, working models, or art, these changes ensure every print is high-quality and precise.

Retraction and Z-hop settings to reduce defects

Retraction and Z-hop settings help avoid problems like stringing, blobs, and nozzle crashes during fast 3D printing. Adjusting these settings makes prints cleaner and keeps designs accurate.

What Retraction Does and Why It Matters

Retraction pulls filament back into the nozzle during non-printing moves. This stops extra material from leaking out, which can cause stringing or blobs. The Sovol SV08 Max needs careful retraction settings to keep prints neat at high speeds.

Here’s how to set retraction:

- Retraction Distance: Start with 1-2 mm for direct drive extruders like the Sovol SV08 Max. Increase if stringing happens.

- Retraction Speed: Use 30-50 mm/s. Too fast can grind filament, while too slow may not pull enough back.

- Testing: Print a model with towers to check for stringing. Adjust until strings are gone.

Tip: Use good-quality filament with a steady diameter for better retraction results.

How Z-hop Prevents Printing Problems

Z-hop lifts the nozzle slightly during travel moves. This stops it from scratching or hitting the print surface. It’s especially helpful for fast printing to avoid defects.

The Sovol SV08 Max lets you adjust Z-hop in slicer software. Here’s how to set it:

- Z-hop Height: Use 0.2-0.4 mm. This clears obstacles without slowing down the printer.

- When to Use Z-hop: Turn it on only during retraction to save time and keep prints stable.

The table below shows why Z-hop is useful:

|

Feature Tested |

Outcome |

|---|---|

|

Stops nozzle crashes and keeps prints smooth |

|

|

Testing with different movement styles |

Reduces stringing and improves quality |

|

Real-world print tests, including tough models |

No defects found, works well to avoid issues |

Using Retraction and Z-hop Together

To get the best results, balance retraction and Z-hop settings. Too much retraction can cause under-extrusion, and too much Z-hop can slow printing. The Sovol SV08 Max’s strong frame and fast acceleration make fine-tuning easier.

Follow these steps:

- Start with Default Settings: Use the slicer’s default retraction and Z-hop values first.

- Test and Adjust: Print a small, detailed model. Change settings based on the results.

- Check Print Quality: Watch for stringing, blobs, or scratches. Adjust retraction distance and speed as needed.

- Use Z-hop Wisely: Enable it only for tall or tricky prints.

Pro Tip: Pair good retraction and Z-hop settings with proper cooling and acceleration for even better prints.

By learning these settings, you can make the most of the Sovol SV08 Max. Whether creating prototypes or art, these tweaks will give you cleaner and more accurate prints.

Calibration Tips for Precision Results

Getting precise prints with high-speed 3D printing needs good calibration. The Sovol SV08 Max has smart features that make calibration easier. By following these tips, you can get great results every time.

Using the Eddy Current Scanning system for bed leveling

Bed leveling is very important for accurate printing. The Sovol SV08 Max uses an Eddy Current Scanning system to make this step simple. It levels the bed in just 80 seconds, saving time and effort.

Here’s how this system helps:

- It reduces the need for manual adjustments, making setup quicker.

- It ensures the first layer is even, which improves print quality.

- It prevents adhesion problems, so prints stick well to the bed.

To use it:

- Start bed leveling from the printer’s menu.

- Let the Eddy Current Scanning system adjust the bed automatically.

- Print a small test model to check the first layer.

Tip: Clean the print bed before leveling for better accuracy.

Extruder calibration for consistent material flow

Calibrating the extruder keeps material flow steady during printing. Different filament types or sizes can cause uneven prints. Proper calibration avoids issues like too much or too little material.

Steps for extruder calibration:

- Set Correct Values: Adjust slicer settings for filament size and flow rate.

- Print a Test Model: Watch for problems like blobs or uneven layers.

- Check the Print: Look for defects like stringing or rough surfaces.

- Make Changes: Adjust flow rate or extrusion settings and reprint to compare.

Calibration is key when changing filament brands or types. Each filament behaves differently, so regular checks ensure smooth printing.

Note: Use good-quality filament to reduce calibration problems.

PID tuning for temperature stability

Keeping temperatures steady is crucial for precise printing. The Sovol SV08 Max uses PID control to manage hotend and bed temperatures. Tuning PID settings stops temperature swings that can ruin prints.

Why PID tuning matters:

- It heats efficiently, avoiding temperature-related print issues.

- It keeps hotend and bed temperatures stable for better adhesion.

- It improves print quality by maintaining consistent heat levels.

How to tune PID settings:

- Open the PID tuning option in the printer or slicer software.

- Run the process to adjust temperature controls.

- Print a small model to check if temperatures stay stable.

Pro Tip: Tune PID settings after replacing the hotend or bed for best results.

By following these calibration tips, you’ll get accurate prints with the Sovol SV08 Max. Whether making prototypes or art, proper calibration ensures reliable and high-quality results.

Input shaping to reduce vibrations

Vibrations can mess up your prints, especially at high speeds. Input shaping is a helpful feature that lowers these vibrations. It adjusts the printer’s movements to cancel out shaking caused by quick starts and stops. With the Sovol SV08 Max, input shaping helps you get smoother and more accurate prints.

How Input Shaping Works

Input shaping changes how the printer moves. It predicts vibrations during fast motions and adjusts the timing of commands. This keeps the printer steady and the nozzle on track. By reducing vibrations, input shaping improves layer alignment and prevents flaws like ghosting.

Think of it like carrying a cup of water while walking. If you move too fast, the water spills. Input shaping is like walking carefully to keep the water steady. In 3D printing, it keeps the nozzle steady for clean and precise prints.

Benefits of Input Shaping

Using input shaping has many perks:

- Better Print Quality: It removes ghosting and ripples, making prints look nicer.

- Faster Printing: You can print quicker without losing accuracy.

- Longer Printer Life: It reduces stress on the printer’s parts, helping them last longer.

The Sovol SV08 Max has a strong frame and advanced motion system. These features make it perfect for input shaping, giving you fast prints with fewer vibrations.

Setting Up Input Shaping on the Sovol SV08 Max

To use input shaping, you need to calibrate your printer. Calibration matches the settings to your printer’s vibration patterns. Follow these steps to set it up:

- Find Vibrations: Print a test model to see which frequencies cause problems.

- Turn On Input Shaping: Use the printer’s firmware or slicer software to enable it.

- Adjust Settings: Fine-tune the input shaping based on your test results.

- Test Prints: Print another model to check for improvements.

Tip: Recalibrate often, especially if you change speeds or materials.

Real-World Uses

Input shaping is great for many projects, such as:

- Prototypes: It keeps prints accurate even when speed is important.

- Mechanical Parts: It improves the fit and finish of working components.

- Art Models: It removes flaws, making detailed designs look perfect.

By learning input shaping, you can make the most of the Sovol SV08 Max. Whether printing big models or tiny details, this feature ensures your prints are fast and flawless.

Material Selection for High-Speed Printing

Best filaments for the Sovol SV08 Max

Choosing the right material is key for great results with the Sovol SV08 Max. This printer works with many filaments, making it useful for different projects. For fast printing, pick materials that flow smoothly and don’t warp much. Here are some good options:

- PLA (Polylactic Acid): Perfect for beginners and everyday prints. It’s accurate and easy to use at high speeds.

- PETG (Polyethylene Terephthalate Glycol): Good for strong, flexible parts. It combines durability with good print quality.

- ABS (Acrylonitrile Butadiene Styrene): Best for engineering models. It’s tough and heat-resistant but needs careful handling to avoid warping.

These materials work well, even when printing quickly.

How material properties affect speed and quality

The properties of a material can change how well it prints at high speeds. Things like thickness, toughness, and flow stability affect the final print. The table below shows how certain factors impact print quality:

|

Factor |

Effect on Surface Smoothness (Ra) |

Notes |

|---|---|---|

|

Printing Speed |

At 90 mm/s, rougher surfaces were seen due to uneven flow. |

|

|

Layer Thickness |

Thinner layers make smoother prints |

Found to be the most important factor for surface quality. |

|

Raster Angle |

Affects part quality |

Plays a big role in how good the printed part looks. |

Materials with lower viscosity flow better at high speeds, reducing errors. Toughness and wear resistance are also important for parts that need to handle stress.

Tips for using PLA, PETG, and ABS successfully

To get the best out of the Sovol SV08 Max, adjust your settings for each material:

- PLA: Use a bed temperature of 50-60°C and ensure good cooling. Thin layers (0.15-0.2 mm) improve surface detail.

- PETG: Set the bed to 70-80°C and lower retraction to avoid stringing. Slower fan speeds help layers stick better.

- ABS: Keep the bed at 90-110°C and use an enclosure to stop warping. Add a thin adhesive layer to help prints stick.

Try these tips to get the best results for your projects.

Avoiding warping and adhesion issues

Warping and bad adhesion can ruin your 3D prints. These problems might bend your designs or make them fall off the bed. Follow these steps to keep your prints steady and accurate.

First, level the print bed carefully. A flat bed helps the nozzle stay at the right height. This is important for making the filament stick well. Clean the bed before printing to remove dust or leftover material.

Set the right temperatures for your printer. Heat the bed and nozzle to the highest safe temperature for your filament. Raise the temperature slightly for the first layer to improve sticking. Turn off the cooling fan for the first few layers to keep them warm and avoid bending.

Use a heated enclosure if possible. It keeps the area around the printer warm and stops sudden temperature changes. If you don’t have an enclosure, add rafts or brims to your design. These features help the print stick better by increasing the contact area with the bed.

Change slicer settings to improve your prints. Slow down the speed for the first layers to stop curling. Lower infill density to reduce shrinking, especially for materials that warp easily. You can also use glue sticks or sprays to help the filament stick better.

By using these tips, you can fix warping and adhesion problems. Whether you’re printing with PLA, PETG, or ABS, knowing your material and adjusting your setup will give you better results.

Tip: Test your settings with a small print first. This saves time and helps you make better adjustments.

Troubleshooting Common Issues

Fixing layer shifting at fast speeds

Layer shifting can mess up your prints. It happens more often at fast speeds. To fix it, check your printer’s parts carefully. Start by lowering the speed and acceleration of the A and B motors. Test speeds up to 300 mm/s and accelerations of 5,000 mm/s². Turn off Stealthchop mode because it can cause problems during quick movements.

Look at the belts to make sure they’re aligned. They shouldn’t touch the plastic parts near the A or B motors. Adjust the belt tension to about 110 Hz on a 150 mm length. Loose belts can slip, and tight belts can strain the motors. Tighten the screws on the motor shafts to stop them from slipping.

Cooling is also important. Check if the stepper drivers have heatsinks and if the fans are working. Warping on the back panel can affect the belts, so look for bends or damage. Turn on Z-hop to lift the nozzle over curled edges. Listen for clicking sounds during fast movements, as they may signal a problem.

Solving under-extrusion and over-extrusion

Extrusion problems can ruin your print quality. Under-extrusion happens when not enough material comes out. Over-extrusion happens when too much material is used. Both need careful adjustments.

|

Problem with Under-Extrusion |

How to Fix It |

|---|---|

|

Clean with a wire brush or replace the nozzle. |

|

|

Damaged PTFE Coupler |

Replace it if it’s bent or melted. |

|

Dirty Bowden Tube |

Push a cloth through the tube to clean it. |

|

Worn Drive Gear |

Check and replace gears if needed. |

|

Broken Cooling Fan |

Remove dirt and make sure it’s installed correctly. |

|

Wet Filament |

Store filament in a dry box or use a dryer. |

|

Wrong Print Settings |

Adjust flow rate, nozzle temperature, and first-layer settings. |

For over-extrusion, lower the flow rate in your slicer software. Check the filament size and match it to the slicer settings. Regularly calibrate the extruder to keep material flow steady.

Preventing warping and adhesion problems

Warping and bad adhesion can ruin your prints. Warping bends your design, and poor adhesion makes it fall off the bed. To fix these, start by cleaning the print bed. Dust and leftover material can stop prints from sticking. Use the right surface for your filament. For example, PLA works well on a PEI sheet, and ABS sticks better to heated glass.

Control the bed temperature based on the filament type. Set it to 60-70°C for PLA and 100-120°C for ABS. Use an enclosure to keep the area warm and stop drafts. Glue sticks or hairspray can help prints stick better.

Change slicer settings to improve stability. Add brims or rafts to increase the area touching the bed. Slow down the first few layers to make them stick better. If warping continues, try using a heat chamber or switch to a filament that doesn’t warp easily.

By fixing these common problems, your Sovol SV08 Max will work better. Regular checks and good filament care will make your prints more accurate and reliable.

Reducing ghosting and vibrations in prints

Ghosting looks like faint ripples or shadows on prints. It happens because of vibrations during fast movements. The Sovol SV08 Max helps reduce this, but adjusting settings improves results.

Adjusting Print Speed and Acceleration

Fast printing can cause more vibrations and ghosting. Lower the speed to 60-80 mm/s for detailed prints. Reduce acceleration to 500-1,000 mm/s² to slow sudden movements. This keeps the printer steady.

Tip: Print a small test cube to find the best speed and acceleration for your project.

Tightening Belts and Checking Frame Stability

Loose belts make the printer wobble, causing ghosting. Check the X and Y belts to ensure they are firm but not too tight. Use a belt tension tool if you have one. Look for loose screws or parts on the frame. A strong frame helps the printer move smoothly.

Using Input Shaping

Input shaping adjusts the printer’s movements to reduce vibrations. Turn it on in the firmware or slicer software. Print a test model to calibrate it. Combine input shaping with good speed and acceleration settings for better results.

Optimizing Cooling and Nozzle Path

Cooling fans can vibrate if they run too fast. Lower the fan speed slightly to stop this. Change the nozzle path in the slicer to avoid sharp turns that cause jerks.

Follow these tips to reduce ghosting and vibrations. Your prints will look smoother, more detailed, and professional.

The Sovol SV08 Max is a fast 3D printer that stays accurate. Its smart design, strong frame, and dual linear actuators keep it steady. Even at high speeds, it prints with great precision. Check out its main features below:

|

Feature |

Details |

|---|---|

|

Smart Design |

|

|

Speed and Stability |

Prints faster while staying steady and reducing shaking. |

|

Material Options |

Works with many materials, including advanced and mixed filaments. |

|

Easy Maintenance |

Keep belts tight and parts oiled for lasting accuracy. |

|

Firmware Setup |

Needs special firmware and slicer settings for top performance. |

For the best prints, adjust slicer settings like layer height and retraction. Calibrate the extruder and level the bed carefully. Pick the right material for your project. Tools like the load cell sensor and input shaping help make prints smooth and reliable.

Try different settings and materials to see what works best. With practice, you’ll learn how to print quickly and accurately, making perfect models every time.

FAQ

How fast can the Sovol SV08 Max print without losing detail?

The Sovol SV08 Max can reach speeds of 700 mm/s. For detailed prints, start slower at 300-400 mm/s. Gradually increase speed to keep prints precise and smooth.

How can I stop stringing when printing quickly?

To avoid stringing, change retraction settings in your slicer. Begin with a retraction distance of 1-2 mm and a speed of 30-50 mm/s. Use dry filament and test small models to adjust settings.

Can flexible filaments work with the Sovol SV08 Max?

Yes, flexible filaments like TPU work with the Sovol SV08 Max. Print slowly at 20-40 mm/s and check extruder tension. A direct-drive extruder setup helps handle flexible materials better.

How often should I calibrate the printer for good results?

Calibrate the printer after changing filament types or every 10-15 prints. Regularly check bed leveling, extruder flow, and PID tuning to keep prints consistent.

What can I do if my prints warp?

Use a heated bed and set the right temperature for your filament. For ABS, use an enclosure to keep the environment stable. Adding a brim or raft improves adhesion and reduces warping.

Tip: Always clean the print bed before starting a new print for better results.