With Klipper resonance compensation and testing, you can use Klipper firmware to identify and correct resonance issues in your 3D printer using real sensor data. By attaching a supported accelerometer, your printer can detect mechanical vibrations that often lead to ringing and other print defects. Klipper’s Input Shaping feature, combined with klipper resonance compensation / testing, helps reduce these problems, resulting in smoother-looking prints. You may also experience improved reliability when using stealthChop mode in Trinamic stepper drivers. Overall, klipper resonance compensation / testing enables you to achieve higher quality prints and faster print speeds.

Key Takeaways

- Use an accelerometer to check for shaking in your 3D printer. This helps you find problems that can make prints look bad.

- After you measure resonance, use Klipper's Input Shaping feature. This helps stop ringing and makes your prints look better.

- Check and adjust your printer settings often. This keeps your print quality good and lets you print faster.

- Read the newest Klipper guides for setup and fixing problems. Keeping up with updates helps you avoid errors and use new features well.

- Test for resonance after you change something big on your printer. This helps keep your settings working their best.

Understanding Resonance in 3D Printing

What Is Resonance?

Resonance happens when your 3D printer shakes more at certain speeds. The moving parts in the printer have their own natural speeds. If the printer’s motors move at these same speeds, the shaking gets much stronger. This is like what happens in engineering when something moves back and forth a lot at a special speed.

- Resonance means energy moves into the printer’s frame or moving parts, making them shake more.

- This happens when the force matches the part’s natural speed.

Here is a table showing different types of mechanical vibration:

|

Type of Mechanical Vibration |

Description |

|---|---|

|

Damped (Td < 1) |

Energy goes away, so the shaking gets smaller over time. |

|

Undamped (Td = 1) |

The system keeps shaking at the same size. |

|

Resonance (Td > 1) |

The shaking gets bigger when the system moves at its special speed. |

Impact on Print Quality

Resonance can make your prints look bad. You might see lines, shadows, or bumpy spots on your prints. These problems show up as repeating marks or waves on the outside of your printed parts. Printing faster makes resonance more likely. The printer’s frame and moving parts can shake more, so the problems get worse.

Tip: If you notice wavy lines or repeating marks on your prints, resonance is probably the reason.

Ringing does not just change how your prints look. It also makes the size less exact. Bumpy spots can make parts not work right, especially if you need them to fit together well. Printing fast makes these problems easier to see, so stopping resonance is important for good prints.

Why Measure Resonance?

You should measure resonance before you try to fix it. This helps you find the exact speeds where your printer shakes the most. Klipper firmware uses accelerometer data to check and record these shakes. When you know the problem speeds, you can use input shaping and compensation to help stop them.

Here is a table that explains why measuring resonance matters:

|

Aspect |

Description |

|---|---|

|

Measurement |

You check how much the printer shakes at different speeds. |

|

Fine-tuning |

You change print settings based on what you find to stop shaking. |

|

Print Accuracy |

Stopping shakes makes your prints more exact and correct. |

|

Operational Speed |

With less shaking, you can print faster without problems. |

|

Overall Efficiency |

Changing settings also helps other things, making prints better. |

By measuring resonance, you make sure your fixes go to the real problem. This step gives you better prints, faster speeds, and more reliable results.

Klipper Resonance Compensation Setup

Required Hardware and Compatibility

You need special hardware to use klipper resonance compensation / testing. The main thing you need is the accelerometer. This sensor checks how much your printer shakes. Klipper works with a few different accelerometer models. Each model connects in its own way and has special features. Here is a table to help you pick:

|

Accelerometer Model |

Connection Method |

Key Specifications |

|---|---|---|

|

ADXL345 |

SPI |

Fast connection to Raspberry Pi or MCU |

|

MPU-9250 |

I2C |

Needs 400kbit/s fast mode |

|

LIS2DW |

SPI/I2C |

Has flexible connection options |

|

LIS3DH |

SPI/I2C |

Has flexible connection options |

You can put the accelerometer on the toolhead or bed. Use short and tight wires for the best signal. Most people see that klipper resonance compensation / testing works well with these sensors. You do not have to do more tuning after the main steps.

Note: Klipper’s resonance tools are better now. Always look at the newest Klipper guide before you begin. This helps you not make mistakes and use new features.

Firmware and Software Preparation

Before you start klipper resonance compensation / testing, you must set up your firmware and software. Your Raspberry Pi or computer needs the right programs. Follow these steps:

-

Update your system:

-

sudo apt update -

sudo apt install python3-numpy python3-matplotlib libatlas-base-dev libopenblas-dev

-

- Install NumPy in the Klipper environment:

-

~/klippy-env/bin/pip install -v "numpy<1.26"

-

- Check that NumPy works:

-

-

~/klippy-env/bin/python -c 'import numpy;'

-

You need these programs for klipper resonance compensation / testing to use the accelerometer data. The newest Klipper firmware supports these steps. If you follow the new process, you will get good resonance compensation results.

Tip: Klipper’s new resonance measurement gives you better data. Always use the latest steps for klipper resonance compensation / testing.

Resonance Measurement Steps

Installing the Accelerometer

You must put the accelerometer on your 3D printer before measuring resonance. Here are the steps to set up the hardware safely and correctly:

- Wiring: Connect the accelerometer, like the ADXL345, to your Raspberry Pi with the SPI interface. Make sure you use the right pins. Check the wires again so you do not break the sensor.

- Mounting: Attach the accelerometer to the toolhead. Keep it lined up with the printer’s axes. Use a mount that holds it tight but keeps it away from the printer frame’s electricity. This stops wrong readings.

- Electrical Safety: Do not let the accelerometer touch metal parts. Use tape or a 3D-printed holder to keep it safe.

- Cable Management: Use short and tight wires for the connection. Long or loose wires can pick up noise and mess up your results.

- Check Placement: Make sure the accelerometer does not block the print head. Move the axes by hand to check if there is enough space.

⚠️ Tip: If you put the accelerometer in the wrong spot, it can get damaged. This can happen if the print head moves in a way you did not expect. Always check the Z-axis height and keep the sensor away from things during calibration.

Configuring Klipper for Testing

After you install the accelerometer, you need to set up Klipper for resonance testing. This means you must update your configuration file and make sure all the software is ready.

- Software Installation: Install the needed programs on your Raspberry Pi. Use these commands:

sudo apt update sudo apt install python3-numpy python3-matplotlib libatlas-base-dev libopenblas-dev ~/klippy-env/bin/pip install -v "numpy<1.26" ~/klippy-env/bin/python -c 'import numpy;'-

SPI Setup: Turn on SPI on your Raspberry Pi. You can do this with

raspi-configor by changing the/boot/config.txtfile. -

Configuration File: Open your

printer.cfgfile and add the accelerometer section. Here are some important settings:

|

Parameter |

Description |

|---|---|

|

probe_points |

List of X, Y, Z spots for resonance testing; you need at least one. |

|

accel_chip |

Name of the accelerometer chip for measurements; you must set this. |

|

max_smoothing |

Most input shaper smoothing allowed during auto-calibration; check the guide for more. |

|

min_freq |

Lowest frequency for resonance testing; default is 5 Hz. |

|

max_freq |

Highest frequency for resonance testing; default is 133.33 Hz. |

|

accel_per_hz |

Sets acceleration for each frequency; default is 75 mm/sec. |

|

hz_per_sec |

Speed of the test; default is 1.0 Hz/sec. |

- Testing Setup: Save your changes and restart Klipper. Use Octoprint or your web interface to check if the accelerometer is connected. You can send a test command to see if Klipper finds the sensor.

Note: If you see errors or the accelerometer is missing, check your wires and settings. Wi-Fi problems or loose cables can cause connection issues.

Running Measurement Commands

When you finish setting up the accelerometer and Klipper, you can start measuring resonance. Klipper gives you some commands for this job.

|

Command |

Description |

|---|---|

|

|

Starts resonance measurement for one axis and gives raw data. |

|

|

Runs resonance measurement in the other direction for the same axis. |

|

|

Starts and ends measurements during normal printing, making output files. |

To run a test, open your printer’s terminal in Octoprint or Mainsail. Type the command for the axis you want to check. The printer will move and the accelerometer will record vibration data. Always watch the printer while testing to stop accidents.

Tip: If you hear weird sounds or the accelerometer moves, stop the test and check your setup. Some people have seen problems with other electronics, like Wi-Fi, especially when tuning the Y-axis.

Downloading and Managing Data

After you run the resonance tests, you need to get and manage the data files. Klipper saves the accelerometer data as files, usually in the /tmp folder or a similar place on your Raspberry Pi.

-

Find the Data: Use the web interface or SSH to your Raspberry Pi to find the files. The files usually have names like

resonances_x_axis.csvorresonances_y_axis.csv. - Download the Files: Move the files to your computer to look at them. You can use SCP, SFTP, or the file browser in your web interface.

- Analyze the Data: Open the files with a spreadsheet program or use Klipper’s plotting tools. Look for high spots in the data, which show where resonance happens.

- Keep Records: Save your original data files. You might want to compare them after you change your printer or run new tests.

Note: Always back up your data before you change your printer or settings. This helps you see what got better and fix problems later.

If you follow these steps, you can use the accelerometer to measure resonance well. Careful setup and testing will help you get the best results from Klipper’s resonance compensation.

Analyzing Resonance Compensation Results

Reading Resonance Graphs

After you finish a resonance test, Klipper shows you graphs. These graphs tell you how much your printer shakes at different speeds. Look for tall spikes in the graphs. Spikes mean your printer shakes a lot at those speeds. These are the places where you need to fix things the most.

Here is a table to help you know what the graphs mean:

|

Characteristic |

Implication |

|---|---|

|

Low power spectral density (< 1e3) |

The axis might be stuck and not move well. |

|

Very broad spectrum |

The axis could be rough and needs cleaning. |

|

High proportions of auxiliary directions |

There might be other mechanical problems. |

If you see low power spectral density, check the rods and bearings. Clean them and make sure the bed moves without problems. If the graph is very wide, look for loose or wobbly parts. Doing these things helps you get better tuning.

Setting Compensation Values

Once you find the problem speeds, you need to set compensation values. Klipper can do this by itself, but you can also set them by hand if you want more control. The best value is usually between 20% and 25%. Many people think 24.445% works well for tuning.

To get the best results:

- Use the same accelerometer for every test.

- Make sure your controls are the same as your test setup.

- Your test print should be as clear or clearer than normal prints.

- Try not to let other signals mess up your tuning.

Most people should use automatic tuning. It is faster and gives good results. Manual tuning is good if you want to make special changes.

Troubleshooting and Best Practices

Sometimes tuning does not work right. You might see extra spikes or weird results. Here is a table with common problems and ways to fix them:

|

Troubleshooting Issues |

Solutions |

|---|---|

|

Structural resonances increase emissions |

Use isolation, damping, and better ground connections. |

|

Sensitivity to external interference |

Use isolation, damping, and better ground connections. |

For the best tuning, follow these steps:

- Keep your printer clean and check moving parts often.

- Use short and tight wires for your accelerometer.

- Tune again after you change your printer a lot.

- Keep your workspace steady and neat.

Tuning is not something you do just once. You need to check and tune again to keep your prints looking good. Careful tuning helps you print faster and makes your prints look better.

Real-World Results and Print Quality

Before-and-After Comparison

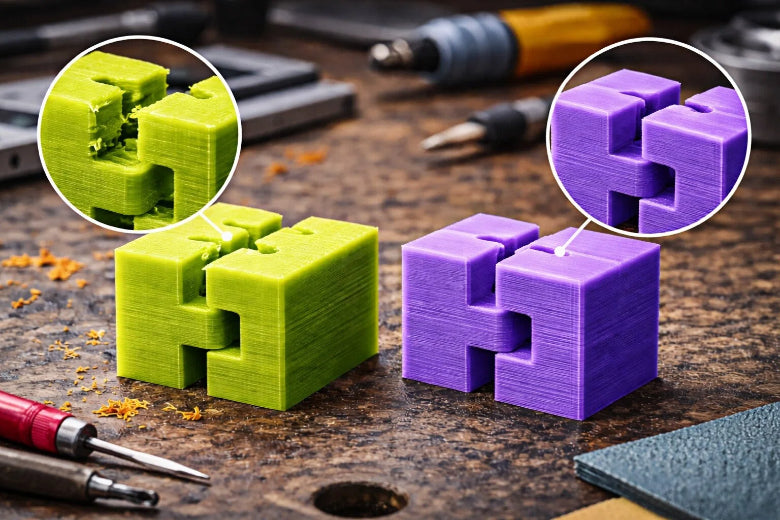

When you use an accelerometer with Klipper, your prints look better. The input shaper helps stop ringing and surface problems. After you measure resonance and set up input shaper, your prints have smoother sides and sharper corners. You see less ghosting and fewer wavy lines on flat spots.

- Surface roughness gets better after tuning with input shaper and accelerometer data.

- Parts are more accurate in size, especially gears and mechanical pieces.

- Smoother prints make sanding and grinding easier.

- Metallography and hardness tests give more steady results after input shaper fixes.

You can check before-and-after prints by looking at the surface and measuring the size. Input shaper and accelerometer tuning help your prints look pro and fit together well.

Bed Slinger vs CoreXY Examples

You might use a bed slinger or a CoreXY printer. Both types get better with accelerometer-based resonance checks and input shaper fixes. Bed slinger printers often have more ringing on the Y-axis because the bed moves. CoreXY printers have lighter moving parts, so they can print faster with less shaking.

|

Printer Type |

Common Resonance Issues |

Input Shaper Impact |

|---|---|---|

|

Bed Slinger |

Y-axis ringing, bed vibration |

Smoother walls, better accuracy |

|

CoreXY |

High-speed vibration, X/Y mix |

Cleaner corners, faster print speeds |

Put the accelerometer on the toolhead for both printers. Input shaper settings may change, but the steps are the same. Run resonance tests, look at the graphs, and set input shaper values for each axis.

High-Speed Printing Tips

If you want to print fast, use the accelerometer and input shaper together. First, measure resonance at the speed you want to use. Use short wires for the accelerometer to keep out noise. Set input shaper values from your test results. Always check your printer after you make changes.

Tip: Print a small test after each input shaper change. Look for smooth sides and sharp edges.

You can print faster when you use input shaper and accelerometer data. Clean your printer, tighten all bolts, and keep the accelerometer mount tight. Input shaper lets you print quicker without losing quality.

You can get smoother and more exact prints by using Klipper resonance compensation with accelerometer data. First, you should measure the ringing frequencies on your printer. Next, change your input shaper and acceleration settings. Always look at the newest Klipper instructions for any changes. Using real data to tune your printer makes your prints look better and work more reliably.

Quick Tuning Checklist:

- Use a test print to find ringing frequencies.

- Change input shaper and set

max_accelin your printer’s settings. - Change

shaper_freq_xandshaper_freq_yif you need to. - If you use Pressure Advance, tune it again.

- Check your calibration steps to get the best prints.

|

Calibration Technique |

Print Quality Impact |

|---|---|

|

Bed Leveling |

Helps the first layer stick and line up better |

|

Extruder Calibration |

Makes sure filament comes out right and is the right size |

|

Temperature Tuning |

Gets the best results for each kind of filament |

Keep checking Klipper’s official guides and keep making your setup better. This helps you print faster and get great-looking prints.

FAQ

What is ringing in 3D printing, and how does input shaping help?

Ringing shows up as wavy lines or echoes on your prints. You see it most after sharp corners or fast moves. Input shaping changes how your printer moves. This reduces the shaking that causes ringing. You get smoother prints and better details.

How do I measure ringing frequency with Klipper?

You use an accelerometer to measure how much your printer shakes. Klipper records the ringing frequency for each axis. You run a test, then look at the graph. The highest spike shows the main ringing frequency. Input shaping uses this data to set the best compensation.

Can I use auto-tune input shapers for input shaper auto-calibration?

Yes, you can use auto-tune input shapers in Klipper. Input shaper auto-calibration finds the best settings for your printer. You start the process, and Klipper tests different input shaping types. It picks the one that reduces ringing the most.

Why does ringing get worse at higher speeds?

When you print faster, your printer moves quickly and changes direction more often. This makes the frame and moving parts shake more. The shaking matches the ringing frequency, so ringing gets worse. Input shaping helps control this, even at high speeds.

How often should I run input shaper auto-calibration?

You should run input shaper auto-calibration after you change belts, pulleys, or frame parts. If you see new ringing or change print speeds, run it again. This keeps your input shaping tuned to your printer’s current ringing frequency.