Large format 3D printed tables change how modern rooms look and work. The worldwide 3D printing market was $13.84 billion in 2021. It keeps getting bigger. This shows that 3D printed furniture is becoming real, not just an idea. Many designers use large format 3D printing to make furniture. They can create special shapes and use strong materials. These tables let people customize and make things fast. They are a good pick for homes, offices, and creative places.

Aspect

Statistic / Detail

Market Size & Growth

$13.84B in 2021, 20.8% CAGR expected through 2030

Material Strength

PLA/PETG tensile strength up to ~7,250 psi

Efficiency

70% tooling cost reduction, 85% lead time decrease

Key Takeaways

- Large format 3D printing helps designers make strong tables fast. These tables can have special shapes that old ways cannot do.

- The tables work well in homes, offices, and public places. They arrive quickly, have parts you can change, and smart things like charging spots.

- Using earth-friendly materials and careful printing makes less trash and saves energy. This makes 3D printed furniture better for the planet.

- After printing, steps like sanding and coating make tables stronger and look nicer. These steps help the tables last long and feel smooth.

- New printers like the Sovol SV08 Max make big, exact prints with fewer pieces. This lowers costs and makes putting tables together faster.

Large Format 3D Printing Overview

Technology Basics

Large-scale 3d printing has changed a lot over time. Some important moments are:

- Dr. Hideo Kodama made the first additive manufacturing system in the early 1980s.

- In 1984, Chuck Hull got a patent for Stereolithography (SLA), which was the first 3D printing technology sold to people.

- Scott Crump came up with Fused Filament Fabrication (FFF) in the late 1980s.

- Dr. Carl Deckard and Dr. Joe Beaman made Selective Laser Sintering (SLS) in 1986.

- The 1990s brought better SLA, FFF, and SLS, and Multi-Jet Modeling started.

- In 1999, doctors put the first 3D-printed human organ scaffold into a person.

- The 2000s had multi-material printing and new SLA improvements.

- The 2010s saw Selective Laser Melting (SLM) and new bioprinting ideas.

- In the 2020s, large format 3d printing became popular for buildings and furniture.

Large-format additive manufacturing builds things layer by layer. This method makes 3D printing bigger by using robotic arms or gantry systems. These machines push out thermoplastics and composites. Special software helps make sure each part is made the same way every time. Milling and other finishing steps make the surface smoother. Big industries like aerospace, automotive, and construction use large-scale 3d printing to make strong and light parts.

Materials Used

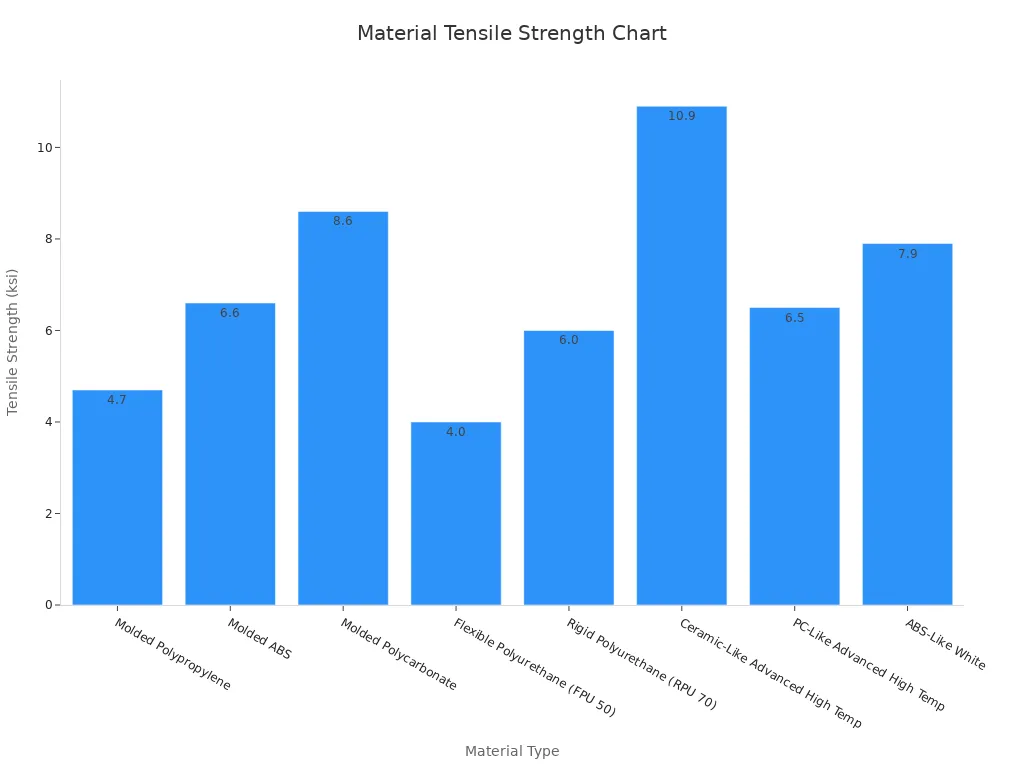

The material you pick affects how well large format 3d printing works. People often use plastics, composites, powders, and metals. The table below lists some important facts:

|

Material Type |

Tensile Strength (ksi) |

Elongation (%) |

Heat Deflection (°F) |

|---|---|---|---|

|

Molded Polypropylene |

4.7 |

100 |

164 |

|

Molded ABS |

6.6 |

30 |

200 |

|

Molded Polycarbonate |

8.6 |

75 |

265 |

|

Flexible Polyurethane (FPU 50) |

4.0 |

200 |

155 |

|

Ceramic-Like Advanced High Temp |

10.9 |

1 |

514 |

Large-scale 3d printing often uses carbon fiber composites. These help stop warping and make things stronger. Advanced thermoplastics like ULTEM and PEEK work well for high-heat and strong parts.

Design Possibilities

Large format 3d printing gives designers more ways to create. They can make tables in one piece with special inside shapes. Old methods cannot do this. Large-scale 3d printing can make things up to 100 feet long. It also prints 200-500 times faster than regular printers. Adaptive slicing and better supports help save material and finish jobs faster.

- Large-format additive manufacturing lets people print with more than one material and make detailed shapes.

- Industrial printers have heated chambers and smart sensors for tough projects.

- Some examples are museum sculptures and full-size furniture made in one piece.

Large-scale 3d printing means fewer assembly steps and stronger tables. It also lets people change designs quickly. These benefits make it a great choice for modern table design.

Large Format 3D Printed Table Applications

Home Spaces

A large format 3d printed table gives new options for homes. Many people now pick these tables for living rooms, kitchens, and home offices. Custom shapes help families match furniture to their style. Some use large-scale 3d printing to make dining tables with legs that look like tree roots. Others design workbenches with cable channels and storage. These features help keep life simple and neat. Families like how fast large format 3d printing is. Tables that took weeks before now come in just days. Fewer assembly steps mean the furniture is strong and ready to use. Many people pick eco-friendly materials to cut down on waste. The smooth finish and strong build come from sanding and extra support. Homeowners like how these tables mix art and function.

Tip: Homeowners can make their tables special with colors, textures, or LED lights for a modern look.

Office and Co-Working

Modern offices and co-working spaces use large format 3d printed tables. Companies want furniture that can change for different team sizes and work needs. Large-scale 3d printing lets designers make tables that fit together in many ways. Teams can move tables around fast to help them work together. Some offices use large format 3d printed tables with power outlets and wireless charging. These features help workers stay connected and get more done. The technology also helps companies test new table ideas before making lots of them. BigRep, a leader in large-scale 3d printing, has made custom conference tables for tech startups and creative groups. These tables often have shapes that old methods cannot make.

- Offices save money and set up faster with large format 3d printed furniture.

- Tests check that each table fits well, looks good, and is strong.

- AI tools find problems early, with over 99% accuracy.

A large format 3d printed table in an office is useful and looks cool. It shows the company cares about new ideas and the planet.

Public and Urban Areas

Public spaces and cities use large format 3d printed tables in creative ways. City planners and designers use this technology to make outdoor furniture that lasts in all weather. The Ontigo T10 translucent design table, shown by Benkert Bänke at Formnext 2024, is a great example. Made with CEAD’s large-format 3d printing and Polymaker’s materials, this table glows and has shapes that old ways cannot make. Large-scale 3d printing helps cities save money and cut down on waste. For example, 3d printed houses can be built in just 54 hours, and labor costs are half as much. These same good things help with public furniture too. The Dubai Future Foundation’s 3d printed office and bridges in the Netherlands and China show how strong and creative this method is.

- Cities have up to 60% less waste with large-scale 3d printing.

- Tests make sure tables are smooth and safe for everyone.

- Extra steps like electroplating and support make tables last longer and look better.

A large format 3d printed table in a park or plaza is more than a place to sit. It is a piece of art and shows off modern design. These tables invite people to gather, relax, and enjoy being outside.

|

Application Area |

Key Benefits |

Example Project/Feature |

|---|---|---|

|

Home Spaces |

Custom shapes, fast delivery, eco-friendly |

Organic dining tables, cable-managed desks |

|

Office/Co-Working |

Modular design, tech integration, rapid prototyping |

BigRep conference tables, wireless charging |

|

Public/Urban Areas |

Durability, unique design, sustainability |

Ontigo T10 table, 3D printed bridges/buildings |

Design Types and Innovations

Modular Tables

Modular tables are very popular in modern furniture. Designers use large format 3d printing to make table parts that fit together. Each part can connect or come apart. This gives people many ways to use the tables. Both offices and homes like this idea. People can move or change the tables easily. They do not need any tools. Large format 3d printing makes strong joints and smooth connections. It also lets designers make special shapes and sizes. Old methods cannot do this. Many modular tables use eco-friendly materials. This makes them a smart pick for green furniture.

Note: Modular tables made in one piece save time and last longer.

Gaming and Interactive Tables

Gaming and interactive tables are growing fast because of new tech. Large format 3d printing helps designers add screens, LED lights, and cable spaces. These features work for board games and digital games. More people want custom gaming tables now. Companies offer special shapes, colors, and features. It is cheaper and faster to test new ideas. AR/VR and 3D graphics make games more fun. AI and IoT add even more cool things for players.

- Faster design and lower costs

- More ways to customize and make cool shapes

- More people want custom gaming tables

- AR/VR and interactive games are growing

Gaming tables are more than just flat surfaces now. They are the main spot for fun and creativity in any room.

Display and Workbenches

Display tables and workbenches get many benefits from large format 3d printing. This tech removes size limits. Designers can print big or tricky pieces all at once. Display tables often have special shapes that stand out in stores or shows. Workbenches can have tool holders, storage, or cable spaces built in. Large format 3d printing makes the time from idea to finished table much shorter. It also saves money and needs less work than old ways like woodworking or fiberglass.

|

Performance Aspect |

Large-Format 3D Printing Benefits |

Traditional Methods Limitations |

|---|---|---|

|

Production Time |

Can reduce prototype production time by up to 50% |

Longer production cycles |

|

Cost Savings |

Up to 75% savings in manufacturing costs |

Higher costs due to molds and assembly |

|

Material Usage |

Lower material costs due to on-demand usage |

Higher due to bulk purchasing |

|

Labor Requirements |

Requires fewer skilled workers |

Requires more skilled labor |

|

Assembly Steps |

Reduced or eliminated by printing large parts in one piece |

Multiple assembly steps required |

Display and workbench tables made with large format 3d printing are fast, flexible, and save money. These tables show how new tech is changing furniture.

Large Format 3D Printing Benefits

Customization and Speed

Large format 3d printing lets designers make custom tables fast. They can print a whole table at once. This means there are fewer steps to put it together. The process makes shapes and features that old ways cannot do. Large-scale 3d printing helps people change designs quickly and test new ideas. Some printers, like the Sovol SV08 Max, print up to 700 mm/s. Special systems keep the prints steady and correct. Companies can make prototypes 50% faster and have fewer mistakes. Fewer skilled workers are needed for setup and finishing.

|

Parameter/Feature |

Value/Description |

|---|---|

|

Maximum Print Speed |

Up to 700 mm/s |

|

Acceleration Rate |

40,000 mm/s² |

|

Build Volume |

Up to 1 cubic meter (BigRep One.1) |

|

Assembly Reduction |

Print large parts as single pieces |

|

Comparative Speed |

200-500 times faster than typical 3D printers |

Designers can try new ideas and finish tables in just days.

Sustainability

Large format 3d printing is good for the environment. It uses only the material needed, so there is less waste. Many companies pick materials like PLA, hemp-based, or recycled filaments. This method also uses less energy and water than old factories. Making tables on-site means less shipping and less pollution. Big companies like BMW and Ford use this technology to help the planet.

- Material reuse: Old supports can become new filament.

- PLA and hemp-based filaments: These are renewable and break down naturally.

- Lower energy demand: FDM printing uses less power than metal methods.

- Waste reduction: Layer-by-layer printing makes less scrap.

- Localized production: Less travel means less pollution.

Making tables this way helps companies follow rules and meet green goals.

Structural Integrity

Tables made with large format 3d printing are strong. Engineers check each table for smoothness, fit, and strength. They use smart tools to find problems early. Extra steps like filling and bonding make tables last longer. Studies show 3D printed ceramic parts can be as strong as cast ones. How the table is printed helps make it stronger and more accurate. Large-scale 3d printing can make special inside shapes, like lattices, to help the table hold more weight.

|

Test Type |

Purpose |

Outcome |

|---|---|---|

|

Check layer line quality and slicing |

Improved surface quality, fewer defects |

|

|

Partial Printing Test |

Assess fit and connectivity |

Optimized part interfaces and assembly logic |

|

Full Model Assembly Test |

Validate assembly sequence |

Better structural performance and teamwork |

Large-format additive manufacturing makes sure each table is safe, strong, and lasts a long time.

Technical Considerations

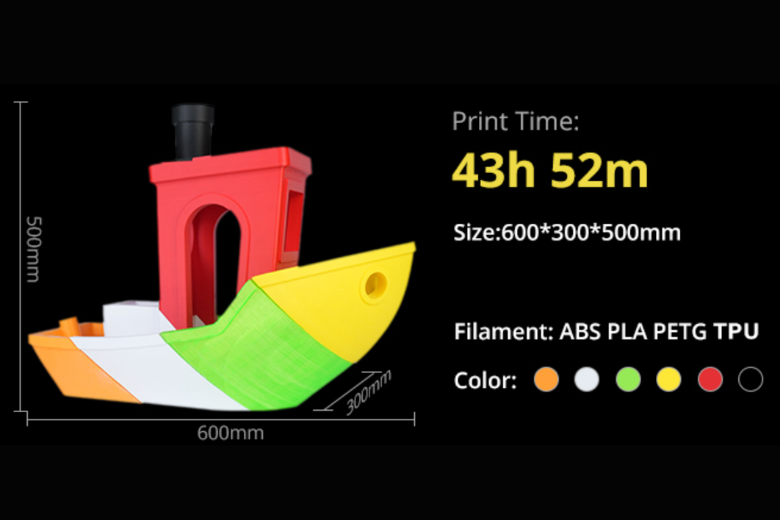

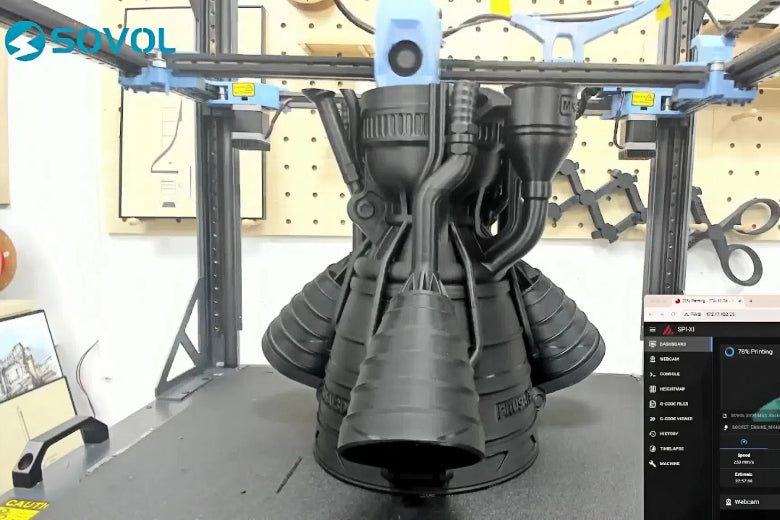

Printer Specifications

Large format 3d printing uses special machines for big projects. The Sovol SV08 Max has a big build area of 500×500×500 mm. This lets people print whole table tops or legs in one go. It is bigger than most other printers. This helps keep tables strong because there are fewer parts to put together. The printer works with PLA, ABS, PETG, and TPU. This means it can make many kinds of tables for different uses.

|

Specification |

Detail |

|---|---|

|

Build Volume |

500 x 500 x 500 mm |

|

Maximum Print Speed |

Up to 700 mm/s |

|

Heated Bed Power |

|

|

Bed Leveling System |

Advanced Eddy Current Scanning |

|

Motion System |

CoreXY kinematics |

|

Positional Accuracy |

As fine as 0.02 mm |

Smart tools like auto-bed leveling and dual Z motors help prints come out even. The CoreXY system moves fast and is very exact. This is important for large format 3d printing. The frame is made from aluminum and steel. This keeps the printer steady, even when it moves quickly. These features help people print big tables with fewer problems and less waiting.

Tip: Always put large printers on a strong table or workbench. Make sure there is enough space and power.

Durability and Post-Processing

Large format 3d printing makes strong tables, but extra steps help even more. After printing, people take off support pieces and sand the surface. This removes lines and makes it smooth. Spray paint or powder coating gives a nice finish. It also protects the table from scratches and weather. Some people use water-resistant coatings for outdoor tables.

- Sanding and filling holes make the table look and feel better.

- Spray paint and powder coating add color and protect from damage.

- Taking off supports and smoothing surfaces make tables stronger and more exact.

- Quality checks and assembly tests make sure each table is good.

Post-processing helps large format 3d printing make tables that look great and last long. These steps get the furniture ready for homes, offices, or public places.

Large format 3D printed tables let people design furniture in new ways. These tables can have special shapes and are made quickly. They use strong materials to last a long time. Many people like them for homes, offices, and creative rooms. The Sovol SV08 Max makes it easy to print big, cool tables.

Anyone who likes modern furniture can use large format 3D printing for their next table.

- Check out more real-life examples and product info.

- Get free table model files or write a comment to share your thoughts.

FAQ

What makes a large format 3d printed table different from traditional tables?

A large format 3d printed table is made with new technology. This lets designers make cool shapes and strong tables. They can print the whole table in one piece. There are fewer steps to put it together. People can pick more styles than with old ways.

Can large format 3d printing create durable furniture for daily use?

Yes. Large-scale 3d printing uses tough materials like PLA and PETG. Engineers check each table to make sure it is safe. Many 3d printed tables last as long as regular ones.

How do designers customize a large format 3d printed table?

Designers use computers to change the size, color, and look. Large-format additive manufacturing can add cable spaces or storage. People can ask for special shapes or finishes to fit their room.

Is large format 3d printing eco-friendly for furniture production?

Large format 3d printing uses just the right amount of material. Many companies use recycled or plant-based filaments. This way makes less waste and uses less energy than old methods.

What are the main steps after printing a large format 3d printed table?

After printing, workers take off supports and sand the table. They might paint or coat it to keep it safe. Quality checks make sure the table is ready for homes, offices, or parks.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.