Large-scale 3D printing has rapidly changed how professionals and creators build ambitious projects. Today, industries such as aerospace, automotive, and healthcare use large-format 3D printing to produce everything from prototypes to end-use parts. The market for large-scale 3D printing reached $28.5 billion in 2024, with companies reporting higher production volumes and cost savings. The table below shows key industry trends:

|

Statistic / Insight |

Detail |

|---|---|

|

Market Size (2024) |

USD 28.5 Billion |

|

Market Forecast (2033) |

USD 125.9 Billion |

|

Industry Adoption |

Aerospace, automotive, healthcare, fashion, electronics |

|

Strategic Trends |

Customization, on-demand production, decentralized manufacturing |

A shift from traditional fabrication to large format 3D printing empowers teams to create custom parts faster and with fewer resources. Readers can now imagine how this technology might transform their own workflow or creative process.

Key Takeaways

- Large-scale 3D printing lets you create big, strong parts in one piece, saving time and reducing assembly.

- This technology supports many industries like aerospace, healthcare, art, and construction with faster and cost-effective production.

- Choosing the right printer means balancing build volume, speed, material support, and cost to fit your project needs.

- Common challenges include warping and layer shifts, but proper maintenance and stable conditions help prevent these issues.

- Large-format 3D printing offers great flexibility, allowing complex designs and multiple materials for creative and industrial uses.

What Is Large-Scale 3D Printing

Key Concepts

Large-scale 3D printing uses advanced 3d printing technologies to create objects much larger than those made with standard desktop printers. These machines often have a build volume greater than 300×300×300mm, with some models reaching up to 1 cubic meter or more. Industries such as aerospace, automotive, and architecture rely on large-scale 3d printing to produce parts that measure several feet in length or height.

- Large-scale 3d printers can produce unibody parts, which means the entire object prints as one piece. This method improves strength and reduces the need for assembly.

- Complex geometries, such as lattice structures and internal channels, become possible with large scale additive manufacturing. Traditional manufacturing cannot easily achieve these shapes.

- Safety remains important. Operators must consider ventilation, personal protective equipment, and fire safety when working with these machines.

- The cost of a large-scale 3d printer and its materials can be high. Maintenance is also critical for reliable production.

Tip: Advanced slicing and material profiles help optimize print quality and reduce unwanted artifacts, such as layer misalignment or surface imperfections.

The table below compares technical parameters for large-scale 3d printing:

|

Parameter |

Large-Scale 3D Printing Example(s) |

Description/Value |

|---|---|---|

|

Build Volume |

BigRep One.1 |

|

|

Maximum Object Size |

Delta-style printer (SeeMeCNC) |

Up to 4 feet diameter, 10 feet height |

|

Maximum Object Size |

BAAM (Lockheed Martin) |

Up to 100 feet length |

|

Printing Speed |

BAAM (Cincinnati Incorporated) |

200-500 times faster than typical 3D printers |

|

Material Type |

Delta-style printer |

Plastic pellets instead of typical filaments |

|

Design Freedom |

Enables unibody parts, complex internal geometries |

Large scale additive manufacturing uses additive processes, building objects layer by layer from digital designs. Common 3d printing technologies include fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS). Each method has unique strengths. For example, FDM melts and deposits plastic, while SLA cures resin with light. Slicing software divides the digital model into printable layers, and advanced material profiles help match print settings to specific materials.

Key terms in large-scale 3d printing include:

- Artifacts: Unwanted imperfections in prints.

- Aspect orientation: Positioning the model for best strength and printability.

- Assembly printing: Printing parts separately for later assembly.

- Alignment: Calibration for accurate prints.

- All-in-one printers: Machines that combine multiple fabrication methods.

The table below highlights differences between large-scale 3d printing and traditional manufacturing:

|

Aspect |

Large-Scale 3D Printing |

Traditional Manufacturing |

|---|---|---|

|

Process Type |

Additive (builds parts layer-by-layer) |

Mainly subtractive (removes material from stock) |

|

Typical Object Size |

Varies, often limited by tooling and molds |

|

|

Material Types |

Plastic pellets, high-strength polymers |

Wide range: wood, steel, plastic, etc. |

|

Design Flexibility |

High; complex internal geometries, unibody parts |

Limited; complex shapes often impossible or costly |

|

Production Volume |

Suited for low to medium volume, customization |

Best suited for mass production |

|

Speed |

High speed in large printers (e.g., BAAM 200-500x faster) |

Generally slower due to tooling and setup |

|

Cost Considerations |

High initial printer cost, lower tooling cost |

High tooling and setup cost, lower per-unit cost at scale |

|

Advantages |

Customization, design freedom, reduced assembly |

Material variety, repeatability, batch quality control |

Why Scale Matters

Scale plays a critical role in the success of 3d printing projects. Large scale additive manufacturing allows companies to produce parts that fit specific needs, such as custom aerospace components or architectural models. In the medical field, large-scale 3d printing enables the creation of patient-specific implants and models. For example, doctors have used bioresorbable airway splints for children, printing each device to match the patient’s size and anatomy. This approach improves surgical outcomes and fills gaps where standard equipment does not work.

Big area additive manufacturing, such as the BAAM system, can produce objects up to 100 feet long. This capability supports the production of large industrial parts, furniture, and even construction elements. The ability to print large, complex shapes in one piece reduces assembly time and increases structural integrity.

Production costs and print quality also depend on scale. Larger prints require more material and energy, which increases operational costs. Specialized staff may need to manage these projects. Print fidelity remains high, but user skill and machine calibration affect the final result. Companies must balance the benefits of large format 3d printing with the investment needed for equipment and training.

In pharmaceutical manufacturing, scale determines the feasibility of using 3d printing technologies. While traditional methods work best for mass production of simple items, large-scale 3d printing excels at producing customized products in smaller batches. For example, some manufacturers use large scale additive manufacturing to produce thousands of personalized hearing aids each day, each tailored to the user’s ear.

Big area additive manufacturing and large-scale metal 3d printing have expanded the possibilities for industries that need strong, lightweight, and complex parts. Large-scale metal 3d printing, in particular, supports the production of aerospace and automotive components that must withstand high stress and temperature.

Note: As scale increases, so do the challenges. Companies must plan for higher costs, longer print times, and more complex quality control. However, the rewards include greater design freedom, faster prototyping, and the ability to meet unique production needs.

Large Format 3D Printer Features

Build Volume

A large format 3d printer stands out because of its impressive build volume. Standard desktop printers usually offer a space of about 200x200x200 mm. In contrast, large-format 3d printing machines can reach 500x500x500 mm or even larger. Some industrial 3d printing systems go up to 1500x1500x2000 mm. This extra space lets users print big objects like furniture, car parts, or architectural models in one piece. Printing larger items in a single run saves time and makes the final product stronger. However, bigger prints need more material and longer print times. Choosing the right build volume helps match the printer to the project’s needs and avoids unnecessary assembly steps.

|

Typical Build Volume (mm) |

Common Project Types |

|

|---|---|---|

|

Standard 3D Printer |

200 x 200 x 200 |

Small models, toys |

|

Large Format 3D Printer |

500 x 500 x 500 |

Furniture, prototypes, tools |

|

Extra Large Industrial Printer |

1500 x 1500 x 2000 |

Industrial parts, automotive, molds |

Precision and Materials

Large-format 3d printing relies on advanced hardware to deliver both size and accuracy. These printers use strong frames and precise motion systems, such as CoreXY kinematics, to reduce vibration and improve print quality. Many large 3d printers support high-grade engineering thermoplastics like ULTEM and PEEK. These materials need high temperatures and special nozzles. Studies show that large format 3d printers can handle these materials well, keeping good layer adhesion and mechanical strength. Heated chambers and thick aluminum beds help prevent warping and ensure even heating. This combination allows for detailed prints, even with tough materials.

Industrial Capabilities

Industrial 3d printing demands more than just size. A modern industrial 3d printer, such as the Builder Extreme 1500 PRO, offers features like heated chambers, dual extrusion, and smart sensors. For example, the Builder Extreme 1500 PRO printed a full-size Tyrannosaurus rex replica for a museum, showing how large-format 3d printing can handle ambitious projects. Other models, like Modix and BigRep ONE.4, provide modular platforms, magnetic beds, and advanced leveling systems. These features make large format 3d printer models reliable for factories, schools, and creative studios. Phrozen Sonic Mega 8K stands out for its high-resolution prints, making it a strong choice for detailed prototypes and art.

Benefits of Large-Format 3D Printing

Efficiency and Cost

Large-format 3D printing delivers clear advantages in production speed and cost efficiency. Businesses using these printers often see faster project completion and lower expenses. For example, in dental model production, large-scale 3D printing reduces both material waste and production time. Studies show that printing 50 dental models horizontally takes 54 hours, while vertical orientation cuts this to 33 hours. The cost difference can reach up to 26% depending on the print angle. In construction, large-format 3D printing shortens the supply chain and reduces labor and supervision costs. Onsite printing brings raw materials directly to the site, while offsite printing benefits from controlled environments and better scheduling. Companies using Stratasys FDM large-format printers report fewer failed prints, less maintenance, and faster cycles. Heated build chambers also improve print accuracy and reliability. These factors combine to create strong returns on investment and measurable time savings.

|

Feature |

Large-Format 3D Printing |

Traditional Methods |

|---|---|---|

|

Prototype Time |

Longer production cycles |

|

|

Cost Savings |

Up to 75% savings in sand casting costs |

Higher due to molds and assembly |

|

Material Costs |

Lower due to on-demand usage |

Higher due to bulk purchasing |

|

Maintenance |

Generally lower maintenance costs |

Higher due to complex machinery |

|

Labor |

Requires fewer skilled workers |

Requires more skilled labor |

|

Assembly Steps |

Reduced or eliminated |

Multiple assembly steps required |

Reduced Assembly

Manufacturing large parts with large-format 3D printing often means printing entire objects in one go. This process combines multiple components into a single part, which reduces the need for assembly. Printing large parts as one piece removes gaps and joints that would otherwise need extra work. This approach leads to faster production and cost savings by removing tooling and assembly steps. Complex shapes and intricate designs become possible in a single print, something traditional manufacturing cannot easily achieve. Industries such as aerospace, healthcare, and architecture benefit from these streamlined workflows.

- Large-scale 3D printing combines parts, reducing assembly.

- Printing in one piece eliminates joints and post-processing.

- Faster production and lower costs result from fewer steps.

- Complex designs are possible in a single process.

- Many industries see improved efficiency and workflow.

Flexibility

Large-format 3D printing offers unmatched flexibility for different project scales and materials. Experimental data shows that advanced printers can use several thermoplastic materials at once, even on large objects. For example, a multi-extrusion FDM printer with a 900 mm × 1100 mm × 770 mm bed can print with five materials at the same time. This flexibility helps users adapt to various project needs and material requirements. Build volume sets the maximum object size, while material properties like strength and thermal stability affect print quality. Techniques such as bed leveling and temperature tuning help maintain accuracy for both small and large projects. Proper orientation and support structures also ensure successful prints, even for complex models. These features highlight the benefits of large format 3d printing and support additive manufacturing for bulk production.

The advantages of large-format 3d printing include cost efficiency, time savings, and the ability to handle a wide range of production needs. These strengths change how companies approach manufacturing large parts and support new creative possibilities.

Applications

Prototyping

Large format 3d printing services help companies create large prototypes quickly. Engineers use these printers to test new designs before full production. They can print 3d printed objects with complex shapes that traditional methods cannot make. Companies like Adidas have produced thousands of midsoles using advanced 3d printing applications, showing how fast and cost-effective this technology can be. Teams improve their designs faster because they can print and test new versions in days, not weeks. Metrics such as print success rate, dimensional accuracy, and production speed show how effective large-scale printers are for prototyping.

|

Metric |

Importance in Prototyping |

|---|---|

|

Print Success Rate |

Fewer failed prints save time and money |

|

Dimensional Accuracy |

Ensures prototypes match design specs |

|

Iteration Speed |

Faster cycles improve product quality |

|

Cost Reduction |

Lowers expenses for each prototype |

Large-Scale Art and Sculptures

Artists and museums use large-scale art and sculptures to create impressive displays. Large-format printers can produce detailed pieces, such as the “Purple S.T.E.A.M.” sculpture in North Carolina, which stands 17 feet high. These printers handle a wide range of materials, including thermoplastics and composites. Artists can print large components in one piece, which reduces assembly and labor costs. The Sovol SV08 Max, with its 500×500×500mm build volume, allows creators to make oversized props and intricate sculptures with smooth surfaces. The art world now relies on 3d printing applications for both restoration and new creations.

Large format 3d printing services support rapid iteration and customization, helping artists refine their work efficiently.

Construction and Models

Construction companies use large-scale 3d printing to build homes, custom facades, and architectural models. In Austin, Texas, printers created 400-square-foot homes for unhoused residents using concrete-like materials. This process reduces waste and speeds up production. Architectural firms print detailed models to show clients new building designs. Projects like the Galleria Gwanggyo Facade in South Korea use 3d printed moulds and formwork to create unique structures. These advances show how additive technology changes construction and urban planning.

|

Project Name |

Application Description |

|---|---|

|

Austin 3D Printed Homes |

Full-sized homes for community housing |

|

Galleria Gwanggyo Facade |

Unique glass walk facade with 3d printed joints |

|

Siedle House Museum |

3d printed formwork for concrete casting |

Industrial Parts

Manufacturers rely on large-scale printers to produce end-use parts and machine components. Aerospace companies print lightweight brackets and rocket engine parts, reducing lead times from months to weeks. Foundries use 3d printed moulds for casting complex shapes, improving quality and reducing scrap. The automotive industry prints custom tools and end-use parts for vehicles, enhancing performance and speeding up production. These 3d printing applications support industries such as defense, aviation, and shipbuilding.

- Cutting tool bodies with custom channels improve tool performance.

- Large valve manifolds printed for naval ships reduce supply chain delays.

- Titanium satellite brackets and copper combustion chambers support aerospace missions.

Large-scale applications in manufacturing show how additive technology delivers strong, reliable end-use parts for demanding environments.

Printing Challenges

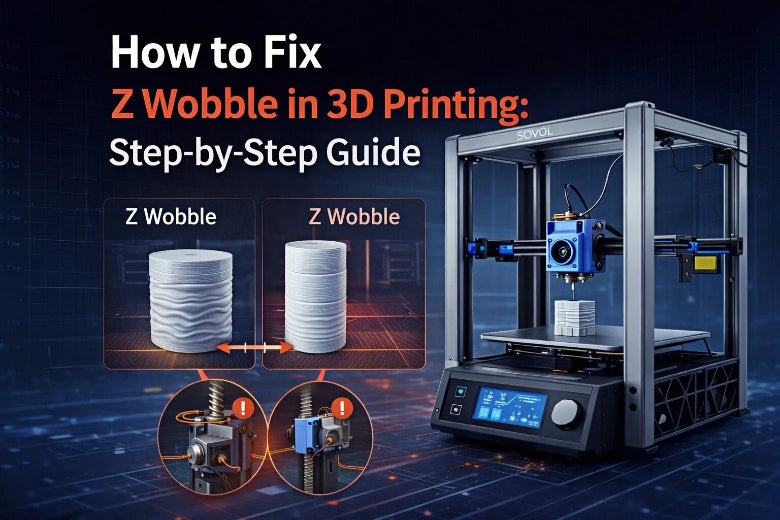

Warping and Layer Shift

Large-scale 3D printing often faces warping and layer shift issues. Warping happens when the corners of a print lift off the build plate, causing distortion. This problem usually results from poor bed adhesion or sudden temperature changes. Layer shifts occur when the print layers do not align, often due to loose belts, stepper motor problems, or vibrations in the environment.

- Warping: Print corners lift, causing shape distortion.

- Layer Shifts: Layers misalign, leading to failed prints.

- Environmental Factors: Temperature swings, humidity, and airflow affect print quality.

- Calibration: Uneven bed leveling and poor extruder calibration increase defects.

- Hardware Issues: Loose belts or misaligned parts cause layer misalignment.

- Surface Contamination: Dust or residue on the bed reduces adhesion.

Statistical data shows that failure rates in FDM printing can reach 41.1%. Human error accounts for over a quarter of these failures. Warping and layer shifts lower the strength of large prints, sometimes reducing it to 42% of the strength seen in small-scale prints. Using carbon fiber additives can help reduce warping by limiting thermal expansion.

Tip: Regular maintenance, proper calibration, and stable environmental conditions help prevent most warping and layer shift problems.

Material Waste

Material waste remains a concern in massive 3D printing projects. Large-format printers reduce waste by allowing single-piece construction, which eliminates the need for extra joins and assembly. This process also removes the need for molds and tooling, which often generate scrap.

- Single-piece prints reduce weak points and assembly steps.

- Less waste compared to traditional molding or CNC methods.

- The solid-to-envelope ratio measures how much raw material becomes the final part.

- Additive manufacturing often uses less energy and material, especially for complex shapes.

In aerospace, the buy-to-fly ratio shows that less than 10% of raw material may remain in the final part. Additive manufacturing improves this ratio, making production more efficient and sustainable.

Post-Processing

Post-processing large prints can be time-consuming and complex. Manual support removal and surface finishing often lead to inconsistent results and higher breakage rates. Safety risks also arise from using flammable cleaning agents like IPA.

- Manual post-processing increases labor costs and slows production.

- Automated cleaning systems improve safety and consistency.

- New detergents, such as organic-based rinses, last longer and reduce chemical waste.

- Automated solutions enable batch processing and reduce human error.

Advanced post-processing tools, including AI-driven inspection and automated cleaning stations, help ensure high-quality results. These systems speed up workflows and improve safety, especially in industries like healthcare and aerospace.

Note: Investing in automated post-processing solutions can boost productivity and deliver more reliable, high-quality parts.

Choosing a Large Format 3D Printer

Selecting the right large format 3d printer shapes the success of ambitious projects. Professionals and creators must evaluate several technical criteria to match their printer to their workflow and production goals. The following sections break down the most important factors.

Build Volume and Speed

Build volume determines the maximum size of objects a printer can produce in a single run. Larger build volumes, such as the 500×500×500 mm capacity of the Sovol SV08 Max, allow users to print oversized models and reduce assembly steps. This feature proves essential for industries that require large prototypes, furniture, or architectural components. High build volume also minimizes the risk of assembly errors and increases structural integrity.

Speed plays a critical role in production efficiency. Printers like the Sovol SV08 Max reach speeds up to 700 mm/s, supported by CoreXY kinematics for stability and reduced vibration. High-flow nozzles, capable of extruding up to 50 mm³/s, further boost throughput without sacrificing accuracy. Metrics such as throughput, capacity utilization, lead time, and cycle time help users compare printers beyond just speed and size.

|

Measurement Aspect |

Sovol SV08 Max |

Creality K1 Max |

|---|---|---|

|

Build Volume |

500×500×500 mm |

300×300×300 mm |

|

Maximum Print Speed |

700 mm/s |

600 mm/s |

|

Acceleration |

40,000 mm/s² |

N/A |

|

Frame Design |

CoreXY design for stability |

Aluminum alloy frame |

|

Positional Accuracy |

≤0.02 mm |

N/A |

Tip: Regular nozzle cleaning, lubrication of moving parts, and frequent bed leveling checks keep large format 3d printers running smoothly and maintain high print quality during long production cycles.

Material Support

Material compatibility expands the range of possible applications for a large format 3d printer. Advanced models support common filaments like PLA, PETG, ABS, and TPU, as well as engineering-grade materials such as carbon-fiber composites. High-temperature hotends and heated beds enable reliable printing with these advanced materials. The Smart Auxiliary Feeder System in some printers actively monitors filament feeding, preventing tangles and clogs that could interrupt production.

|

Aspect |

Details |

|---|---|

|

Material Compatibility |

PLA, PETG, ABS, TPU, carbon-fiber composites, engineering-grade materials |

|

Extrusion System |

Smart Auxiliary Feeder System for uninterrupted printing |

|

Motion Control |

CoreXY kinematics for high acceleration and consistent quality |

|

Quality Assurance |

Eddy Current Scanning for fast auto-leveling and filament monitoring |

|

Dimensional Accuracy |

±0.15% tolerance for industrial-grade prints |

Empirical studies confirm that optimizing printing parameters, such as nozzle temperature, improves the mechanical properties of materials like PLA, PETG, ABS, and PEEK. This ensures that large format 3d printing can meet the demands of both rapid prototyping and end-use part production.

Print Quality

Print quality depends on several factors, including dimensional accuracy, print speed, and the technology used. Performance indicators such as build volume, print resolution, and automation features directly impact the final result. Customer reviews highlight the importance of reliability, ease of use, and consistent output. Printers with smart sensors and live feedback systems, like the Sovol SV08 Max, receive praise for preventing print failures and maintaining high quality throughout long production runs.

|

Description |

Impact on Print Quality |

|

|---|---|---|

|

Dimensional Accuracy |

Precision in printed part dimensions |

Ensures parts meet design specs |

|

Print Speed |

Rate of printing layers or parts |

Balances quality with efficiency |

|

Material Efficiency |

Material used vs waste |

Reduces cost, improves sustainability |

|

Automation & Sensors |

Smart cameras and sensors |

Detect and correct errors in real-time |

|

User Interface |

Ease of setup and control |

Reduces user errors, improves outcomes |

Users often share tips and experiences in online communities, providing practical insights into print size, speed, and quality. Brands with strong reputations and active support communities, such as Sovol and Prusa, tend to deliver higher customer satisfaction.

Cost Factors

Cost considerations extend beyond the initial purchase price of a large format 3d printer. Material costs vary widely; for example, ABS is more affordable than advanced materials like Ultem. In-house printing requires investment in equipment, post-processing tools, and skilled personnel, all of which affect operational costs. Outsourcing to service bureaus can lower capital expenses but may increase per-part costs and reduce control over the production process.

|

Cost Factor Category |

Key Points |

|---|---|

|

Initial Purchase Price |

Influenced by build volume, precision, automation, and brand reputation |

|

Operational Costs |

Maintenance, material use, software, energy, and training |

|

Hidden Costs |

Consumables, after-sales support, and training |

|

Market Dynamics |

Technology advances, material availability, and competition |

|

Budgeting & Financing |

Leasing and bulk material purchases optimize investment |

|

Maintenance Variability |

Costs vary by brand and service agreements |

Cost reduction strategies include selecting printers with only necessary features, optimizing designs to use less material, and buying supplies in bulk. Training and expertise remain critical for efficient in-house production.

Recommended Models for Different Needs

- Sovol SV08 Max: Offers a large build volume, high speed, and advanced automation features. Suitable for professional studios and industrial production.

- EVO 2X: Designed for engineering applications, supports a wide range of materials, and provides robust construction for demanding environments.

- Omni3D: Focuses on industrial-grade reliability and material compatibility, making it ideal for continuous production and large-scale prototyping.

Note: Key criteria for choosing a large format 3d printer include build volume, nozzle size, heated bed, Z-axis stability, and material compatibility. Regular maintenance, such as nozzle cleaning and firmware updates, ensures long-term performance and print quality.

Large-format 3d printing continues to transform manufacturing and creative industries.

- Teams now produce custom prosthetics at lower costs, with rapid design changes and improved user comfort.

- Large-format 3d printing reduces assembly, saves time, and supports diverse applications from art to aerospace.

|

Benefit |

Impact |

|---|---|

|

Cost Efficiency |

Up to 60% savings and less material waste |

|

Versatility |

Enables large, complex projects in many industries |

Professionals should assess their current workflow and consider investing in advanced printers to unlock new possibilities.

FAQ

What is the main advantage of using a large-format 3D printer?

Large-format 3D printers allow users to create bigger parts in one piece. This reduces assembly steps and increases strength. Many industries use these printers to speed up production and lower costs.

Which materials work best for massive 3D printing projects?

Most large-format printers support PLA, PETG, ABS, and TPU. Some advanced models handle engineering plastics like ULTEM or PEEK. Material choice depends on the project’s strength, heat resistance, and flexibility needs.

How can users prevent warping in large prints?

Users should keep the print bed clean and level. Heated beds and enclosed chambers help control temperature. Printing with the right settings and using adhesives or brims can also reduce warping.

Are large-format 3D printers suitable for beginners?

Many large-format printers offer user-friendly interfaces and auto-leveling. Beginners can start with basic materials and simple models. However, larger machines may require more setup and maintenance than desktop models.

What types of projects benefit most from a 500x500x500mm 3D printer?

A 500x500x500mm 3D printer works well for cosplay props, furniture prototypes, architectural models, and large art pieces. These projects need big build volumes and strong, seamless parts.