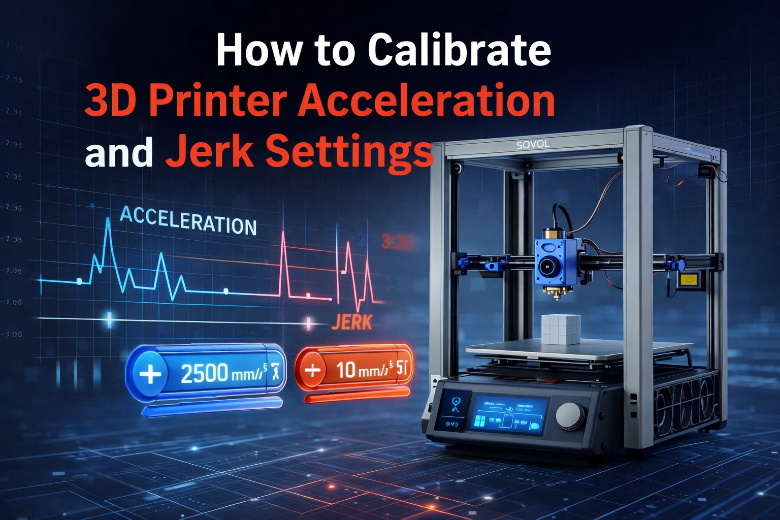

You can change 3D printer acceleration and jerk settings by adjusting motion values on your printer. Then you test with calibration prints. These settings control how fast your printer changes speed and direction. If the settings are too high, you might see wavy lines or rough spots on your prints. Lower settings make prints look better but can make printing slower. The table below shows what usually happens:

|

Acceleration Setting (mm/s²) |

Trade-off Description |

|---|---|

|

Prints faster, but may cause ghosting or ringing |

Calibration helps you find the best balance for smooth and accurate prints.

Key Takeaways

- Adjust acceleration and jerk settings to make prints look better. This can help stop problems like ghosting and ringing.

- Lower acceleration can make prints look nicer but might make printing slower. Try to find a good balance for your printer.

- Print test models to see how changes work. These prints show how your settings change the print quality. This helps you adjust settings better.

- Check and change settings often when you use new materials or upgrade parts. This helps your prints stay nice.

- Write down your old settings before you change anything. This way, you can go back if the new settings are not good.

3D Printer Acceleration and Jerk Basics

What Is 3D Printer Acceleration?

Acceleration is how fast your printer speeds up or slows down. Think about riding a bike. You start slow, then go faster. In 3D printing, acceleration controls how the print head changes speed. This helps your printer avoid sudden stops and starts. Sudden moves can make your prints shake or look messy.

Tip: Lower acceleration makes your printer move gently. This can make prints look better, but it might take longer.

Here is a table to help you understand the standard definitions:

|

Term |

Definition |

|---|---|

|

Acceleration |

The limit on how fast you can change velocity, represented as the slope of the line in a graph. |

|

Jerk |

The rate of change of acceleration, indicating how quickly acceleration changes. |

What Is Jerk in 3D Printing?

Jerk is how quickly your printer changes speed. It does this without slowly speeding up or slowing down. Imagine walking and then running right away. That quick change is jerk. If jerk is too high, your printer might shake or make rough corners. If jerk is too low, your printer slows down a lot at corners. This can make prints take longer.

- Example: The command

M205 X8 Y8sets jerk for X and Y axes to 8 mm/s.

Acceleration vs. Speed Differences

Speed is how fast your printer moves while printing. Acceleration and jerk control how your printer gets to that speed. They also control how it turns or changes direction. If you only make speed higher, you might see problems like ringing or ghosting. The printer cannot handle quick changes well. CoreXY printers can use higher acceleration. They have less moving mass. This lets them print faster without losing quality.

- High acceleration (over 3000 mm/s²) makes prints faster. But it can cause surface problems.

- Lower acceleration makes prints look better. But it slows down printing.

Why Calibration Matters

You need to calibrate 3d printer acceleration and jerk for good results. Calibration helps reduce print problems. It makes corners sharper and keeps your printer working well. When you learn to set 3d printer acceleration and jerk, your prints look better. Your printer lasts longer. Changing these settings helps you avoid ghosting, ringing, and loud noises. Many beginners forget to calibrate these values. This can make prints look bad and wear out the printer faster.

Note: Always test changes with calibration prints. This shows how 3d printer acceleration and jerk affect your prints.

Check and adjust 3d printer acceleration and jerk when you use new materials or upgrade your printer. This keeps your prints looking great.

Common Problems with Acceleration and Jerk Settings

If you set acceleration and jerk wrong, your 3D prints can have problems. You might see wavy lines or layers that do not line up. Corners can look rough, and the printer can get loud. Knowing about these problems helps you spot and fix them fast.

Ringing and Ghosting Issues

Ringing and ghosting look like light ripples or shadows near sharp edges. These problems happen when acceleration or jerk is too high. The print head moves too fast and shakes. You often see these lines on flat spots or around holes.

|

Common Defects |

Cause of Defects |

|---|---|

|

Ringing |

|

|

Ghosting |

High jerk settings causing vibrations |

You can lower acceleration and jerk to help stop these problems. Smooth moves help stop shaking that causes ghosting. If you see ghosting on every print, check your acceleration and jerk settings first.

Layer Shifts and Missed Steps

Layer shifts happen when the print head skips or moves out of place. This can mess up your print. High acceleration or jerk can make the motors work too hard. The printer might miss steps, especially when it changes direction fast.

|

Evidence Description |

Impact on 3D Printing Issues |

|---|---|

|

Proper jerk control settings are crucial for preventing printhead speed changes. |

Minimizes layer shifts and ghosting effects. |

|

A stable printer base is essential to avoid exacerbating vibrations during printing. |

Helps prevent layer shifts and ghosting. |

To fix this, lower your acceleration and jerk. Make sure your printer sits on a strong table. This keeps the print head steady and helps stop missed steps.

Rough Corners and Surface Artifacts

Rough corners and surface marks show up when acceleration or jerk is not set right. High jerk can make corners look rough or jagged. Low jerk can make corners look round and slow down your print.

|

Common Defects |

Cause of Defects |

|---|---|

|

Rough surfaces |

High jerk settings leading to noise |

|

Rounded corners |

Low jerk settings resulting in slow print times |

Try changing acceleration and jerk a little at a time. Print a test cube and look at the corners. If you see rough spots, lower the jerk. If corners look too round, raise jerk a bit.

Noise and Mechanical Wear

Loud sounds and extra wear can come from high acceleration or jerk. Fast, sharp moves can hurt the motors and belts. Over time, this can break your printer.

You can make your printer quieter by lowering acceleration and jerk. Your printer will run smoother and last longer. Always listen for new sounds after you change these settings.

Tip: Change acceleration and jerk slowly. Watch your prints and listen to your printer. Small changes can help a lot.

When you know about these problems, you can tune acceleration and jerk for better prints. Always use calibration prints to test your changes.

How to Adjust 3D Printer Acceleration Settings

You can improve your print quality and machine life by learning how to adjust 3d printer acceleration settings. This section will guide you through step-by-step tuning for faster 3d printing, show you how to access and change acceleration and jerk settings, and help you avoid common mistakes.

Accessing Motion Settings on Your Printer

You can find acceleration and jerk settings in your printer’s menu or through your slicer software. Many printers let you change these values right from the control screen. Here is how you can do it in popular slicers like Ultimaker Cura:

- Open Ultimaker Cura and load your 3D model.

- Switch to 'ALL' mode to see advanced settings.

- Scroll to the 'Speed' section.

- Check the boxes for 'Enable acceleration control', 'Enable travel acceleration', 'Enable jerk control', and 'Enable travel jerk'.

- Enter your desired values for each setting.

You can also access these settings on the printer’s LCD screen. Look for a menu called “Motion” or “Control.” There, you will see options for acceleration and jerk. Write down your current values before making changes. This helps you go back if something does not work.

Tip: Always record your original settings before changing acceleration settings. Take a photo or write them in a notebook.

Using M503 and G-code for Calibration

You can use G-code commands to check and change acceleration and jerk settings. This works well for printers running Marlin or Klipper firmware. You send these commands through your printer’s terminal or over USB.

Here is a table of useful commands:

|

Command |

Description |

|---|---|

|

M205 |

Set various motion settings, including jerk and acceleration parameters. |

|

M503 |

View current settings, including acceleration and jerk. |

- Use

M503to see your current acceleration and jerk settings. - Use

M205to set new values for acceleration and jerk.

For example, you can send this command to set jerk:

M205 X10 Y10

This sets the X and Y axis jerk to 10 mm/s. Always check your settings with M503 after making changes.

Note: If you use Klipper, you can edit the

printer.cfgfile and restart the firmware to apply new values.

Adjusting in Firmware and Slicer (Marlin, Klipper, Cura, PrusaSlicer)

You can change acceleration and jerk settings in both firmware and slicer software. Each platform has its own method:

-

Marlin: Use the LCD menu or send G-code commands like

M204andM205. Save changes withM500. -

Klipper: Edit the

printer.cfgfile. Change the values under[stepper_x]and[stepper_y]. Restart Klipper to apply. - Cura: Enable acceleration and jerk controls in the Speed section. Enter your values for each print.

- PrusaSlicer: Go to Print Settings > Speed. Set acceleration and jerk for different features like infill and walls.

You should always back up your configuration files before making changes. Save a copy of your old settings. This helps you restore them if you have problems.

Tip: Make small changes and test with a calibration print after each adjustment.

Recommended Starting Values and Safe Ranges

You want to start with safe values to avoid damaging your printer. Many users set 3d printer acceleration settings around 3000 mm/s² for the X and Y axes. Jerk values close to 10 mm/s work well for most machines. These values help you avoid ringing and missed steps.

Here is a table of recommended acceleration and jerk settings for different print features:

|

Aspect |

Recommended Jerk Value (mm/s) |

|---|---|

|

Print Jerk |

8-20 |

|

Travel Jerk |

10-30 |

|

Infill Jerk |

10-25 |

|

Wall Jerk |

8-15 |

|

Top/Bottom Jerk |

8-15 |

Controlled movements, which are slower and more gentle, give you better print results. High speeds and sharp moves can strain your printer’s parts. This can cause damage or shorten the life of your machine.

Alert: Never set acceleration and jerk settings too high. Start low and increase slowly if your printer can handle it.

Differences for X/Y Axes and Printer Types

Not all printers use the same acceleration and jerk settings. You need to know your printer type before changing acceleration settings.

- Cartesian printers: These use a moving bed or gantry. They work best with lower acceleration and jerk values. Start with 1000-2000 mm/s² for acceleration and 8-10 mm/s for jerk.

- CoreXY printers: These have a lighter moving mass. You can use higher acceleration and jerk settings. Try 3000-5000 mm/s² for acceleration and 10-20 mm/s for jerk.

- Bedslinger printers: These move the bed back and forth. Use lower acceleration and jerk to avoid ringing. Start with 1000-1500 mm/s² and 8-10 mm/s for jerk.

You should always test new values with a calibration print. Watch for ringing, layer shifts, or rough corners. If you see problems, lower your values.

Tip: Write down each change you make. This helps you track what works best for your printer.

By following these steps, you can adjust 3d printer acceleration settings safely and effectively. You will find the recommended acceleration ranges for your printer type and print style. Careful tuning of acceleration and jerk settings leads to smoother prints, less noise, and a longer-lasting machine.

Using Calibration Prints for Optimization

When you want to get the best results from your 3D printer, using calibration prints for optimization is one of the most effective methods. These prints help you see how changes in acceleration and jerk settings affect your print quality. You can use different test models to spot problems and make improvements step by step.

Calibration Cube and Test Models

You can start with simple shapes and special test models to tune your printer. These models show you how your settings affect the final print.

- Calibration cubes are small, easy-to-print blocks. You can quickly see ringing, ghosting, or rough corners on their surfaces.

- The fidget cube and tolerance test models help you check if your printer can handle tight fits and moving parts. These models show if your acceleration and jerk settings are too high or too low.

- The bed adhesion test checks if your first layer sticks well. It also helps you see how changes in jerk and acceleration affect the start of your print.

- Towers or vertical columns let you test different settings at different heights. You can change acceleration and jerk in segments and see the results in one print.

Tip: Print several test models to compare results. Each model highlights different issues, so you get a complete picture of your printer’s performance.

Setting Jerk and Acceleration for Smooth Prints

You can use your printer’s terminal software, like Pronterface or Octoprint, to set up your machine for calibration prints. Start by generating G-code that changes acceleration and jerk values at different heights. This lets you see how each setting affects the print.

Here is a basic process you can follow:

- Connect your printer to your computer using terminal software.

- Generate or download a calibration tower G-code file. This file changes acceleration and jerk settings at set heights.

- Print the calibration tower and watch for changes in print quality as the tower grows.

- Use commands like

M204for acceleration andM205for jerk to adjust settings. For example: M204 P1000 T2000 M205 X8 Y8- Save your new settings to EEPROM with

M500if you like the results.

You should start with safe jerk values between 5 and 10 mm/s. These values help you avoid ringing and rough surfaces. If you want to test higher values, increase them slowly and watch for defects.

Note: Higher acceleration and jerk can speed up prints but may cause surface problems. Lower values make prints smoother and reduce wear on your printer.

Interpreting Calibration Results

After you finish your calibration prints, you need to look closely at the results. Each print tells you something about your settings.

- If you see ripples, shadows, or rough surfaces, your jerk setting may be too high. Lower it for a smoother finish.

- If corners look too round or your print takes too long, your jerk setting may be too low. Try raising it a little.

- If you notice layer shifts or missed steps, your acceleration may be too high. Lower it to help your printer move smoothly.

- If your print looks clean and sharp, you have likely found a good balance.

You should always compare different sections of your calibration tower. Each segment shows how a specific setting affects the print. This helps you pick the best values for your printer.

Tip: Take notes or photos of each print. This makes it easier to remember which settings gave you the best results.

Fine-Tuning for Best Quality

You can fine-tune your acceleration and jerk settings by making small changes and printing again. This process helps you get the best quality without causing new problems.

- Adjust acceleration and jerk in small steps. Change one value at a time and print a new test model.

- Lowering acceleration and jerk often improves layer bonding and reduces stress on your printer’s parts.

- Watch for pattern defects, like ringing or ghosting. Smoother movements from lower settings usually fix these issues.

- If you want to print faster, raise your values slowly. Always check for new defects after each change.

You can use segment-based G-code changes in your calibration towers. This means each part of the tower uses different settings. You can see exactly where problems start and stop.

Alert: Many beginners try to change too many settings at once. Always adjust one value at a time. This makes it easier to see what works.

By following these steps and using calibration prints, you can find the best acceleration and jerk settings for your printer. You will get smoother prints, sharper corners, and a longer-lasting machine.

Troubleshooting and Best Practices

Diagnosing Persistent Print Issues

If you still have print problems after changing acceleration and jerk, try these steps to find out why: Reset your printer to its default settings. Run a full calibration routine to check everything. Look at all the mechanical parts for loose belts, worn pulleys, or broken bearings. Make sure your printer sits on a strong, steady table. Change slicer settings if your prints look strange. Check that your firmware settings match your printer’s hardware. After each change, look for ringing or ghosting. If you see problems, adjust acceleration and jerk again.

Tip: Always check belt tension. Belts that are too loose or too tight can cause layer shifts and bad print quality.

Avoiding Common Calibration Mistakes

Many people make the same mistakes when they calibrate acceleration and jerk. You can avoid these problems by following some simple rules: Use a step-by-step method, like the binary search method, to find the best values. Write down your settings before you change anything. Start with basic values for acceleration and jerk. Try S-curve motion profiles if your firmware lets you. These profiles help reduce jerk and make movements smoother.

Note: Change only one setting at a time. This makes it easier to see what works.

Maintenance and Re-Calibration Tips

Doing regular maintenance keeps your printer working well and helps your settings stay correct: Clean your printer and workspace to keep dust away. Level the build plate and keep it clean for good first layers. Check and clean the extruder to stop clogs. Lubricate moving parts to make them move smoothly. Check and adjust belt tension often. Tighten the printer frame and hardware. Update your firmware for better performance. Run test prints and look at them to catch problems early.

Practical Checklist for Reliable Printing

You can use this checklist to keep your printer working well:

|

Task |

How Often |

|---|---|

|

Clean printer and workspace |

Weekly |

|

Level build plate |

Before prints |

|

Check belt tension |

Monthly |

|

Lubricate moving parts |

Monthly |

|

Inspect extruder |

Monthly |

|

Update firmware |

As needed |

|

Run test prints |

After changes |

✅ Following these steps helps you get smooth, reliable prints every time.

When you calibrate acceleration and jerk, your 3D printer works better. You get prints that are the right size. Your printer can go faster and still make good prints. The quality of your prints looks better, even if you print slowly. You do not need high acceleration and jerk to get sharp edges.

|

Benefit Description |

|---|

|

You get more accurate prints because edges do not bleed. |

|

You can print faster without losing quality. |

|

Your prints look and feel better, even at slow speeds. |

|

Sharp edges happen without using high acceleration and jerk. |

Use calibration prints and keep your printer clean to help it work well. These steps stop problems and keep your prints fast and nice. Check your settings after you upgrade or use new materials. For better results, change print speed and layer height, then run test prints. Try these tips for steady quality and speed:

- Write down your settings before you change them.

- Change only one setting each time.

- Print a test model after every change.

- Look for ghosting, ringing, or rough spots.

- Keep trying until your prints look great.

FAQ

How do I know if my acceleration and jerk settings are correct?

Print a calibration cube to check your settings. Look for smooth sides and sharp corners on the cube. If you see these, your settings are good. Try changing the settings and compare the cubes. Pick the settings that give the best results.

What happens if I set velocity too high?

If velocity is too high, your printer can skip steps. You might see layers out of place or hear loud noises. The printer can shake and lose accuracy. Lowering velocity helps stop these problems. Always print a test model before using new settings for big projects.

Can I use the same settings for all materials?

You need different settings for each material. PLA works well with medium settings. ABS and PETG need lower velocity and softer moves. Always print a test when you use a new material. Change your settings to fit what the material needs.

Why do my prints have ringing even after lowering settings?

Ringing can happen if belts are loose or parts are worn. Check your printer’s frame and belts before changing settings again. Sometimes you must fix hardware problems first. Use a checklist to look over your printer, then adjust your settings.

How often should I recalibrate my settings?

Recalibrate when you use new materials or upgrade your printer. Also recalibrate if you see problems in your prints. Regular checks keep your printer working well. You can do this every month or after big changes to your printer.