Turbine scanning stands at the heart of the Sovol SV08 Max’s outstanding print quality. You experience faster, more precise 3d printing as the advanced eddy current scanning system levels the bed with unmatched accuracy. Turbine scanning eliminates manual guesswork, so you spend less time setting up and more time printing. The Sovol SV08 Max leverages turbine scanning to reduce print failures, enhance first-layer quality, and make 3d printing easier for every user. Turbine scanning ensures consistent quality, even for large-format 3d projects, by providing reliable scanning before every print.

Key Takeaways

- Turbine scanning provides fast, precise bed leveling that improves first-layer adhesion and reduces print failures.

- The non-contact scanning method protects the printer and bed while delivering consistent, high-quality results.

- Automatic z-axis calibration saves setup time and eliminates manual adjustments for easier printing.

- Sovol SV08 Max supports large-format prints with high accuracy and speed, making complex projects simpler.

- Both beginners and experts benefit from turbine scanning’s user-friendly, reliable, and efficient printing process.

Eddy Current Scanning System

How Turbine Scanning Works

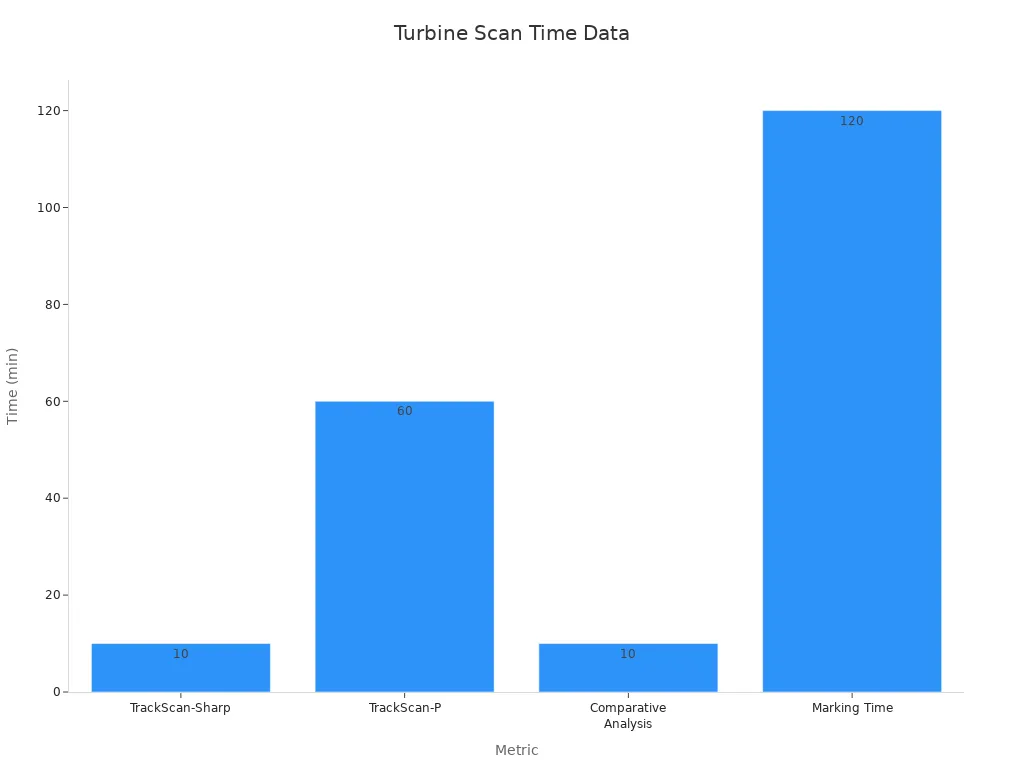

You rely on the Sovol SV08 Max to deliver consistent, high-quality prints. The secret lies in its advanced eddy current scanning system. This technology uses a turbine-inspired approach, integrating a high-resolution sensor array directly into the printer’s bed leveling mechanism. When you start a print, the system activates turbine scanning, which sweeps across the entire build surface. The system generates eddy currents by emitting a controlled electromagnetic field. As the turbine moves, the sensors detect subtle changes in the field caused by variations in the bed’s surface.

The Sovol SV08 Max leverages this system to capture precise 3D data about the bed’s topography. The high-speed scanning process collects thousands of data points in seconds. You benefit from real-time feedback, as the system instantly identifies even the smallest deviations. The turbine scanning system achieves remarkable accuracy, with scan resolutions as fine as 0.192 mm. This level of precision ensures that every print starts on a perfectly leveled surface.

The system architecture in the Sovol SV08 Max minimizes power loss and temperature drift. Multiple microcontrollers handle digital processing, while wireless data transmission keeps the scanning process efficient. The excitation coil, decoupled from the sensing coils, allows for high excitation amplitude and miniaturized sensors. This design boosts sensitivity and spatial resolution, giving you a clear advantage in print quality. The Sovol SV08 Max’s turbine scanning system operates at production speeds, so you never sacrifice efficiency for accuracy.

Tip: The Sovol SV08 Max’s turbine scanning system provides automatic z-axis calibration, eliminating manual adjustments and reducing setup time.

Non-Contact Bed Leveling

You experience the benefits of non-contact scanning every time you use the Sovol SV08 Max. The system never touches the bed, so it avoids wear and tear on both the sensors and the print surface. This no-touch method ensures long-term reliability and consistent performance. Non-contact scanning uses electromagnetic fields to measure the bed’s surface, making it immune to dust, debris, or filament residue.

The Sovol SV08 Max’s turbine scanning system completes a full scan of the 500×500 mm bed in just 80 seconds. High-speed scanning means you spend less time waiting and more time printing. The system’s automatic z-axis calibration guarantees that the nozzle maintains the perfect distance from the bed, which is critical for first-layer adhesion and overall print success.

You gain several advantages with this technology:

- Unmatched accuracy: The system detects even the smallest surface imperfections, ensuring flawless first layers.

- Superior precision: The turbine scanning process delivers consistent results across the entire build area, even for large-format prints.

- Reduced print failures: Automatic z-axis calibration and non-contact scanning minimize human error and setup mistakes.

- Effortless operation: You no longer need to manually level the bed or worry about uneven surfaces.

The Sovol SV08 Max’s turbine scanning system sets a new standard for large-format 3D printing. You achieve professional results with every print, thanks to the combination of high-speed scanning, non-contact technology, and precise 3D data collection. The system’s automatic z-axis calibration and turbine-driven accuracy make complex projects simple and reliable.

Note: Non-contact scanning technology in the Sovol SV08 Max supports a wide range of materials and print sizes, making it ideal for both creative and industrial applications.

Sovol SV08 Max Printing Benefits

Print Quality and Accuracy

You demand the highest print quality when working with large 3d manufacturing projects. The Sovol SV08 Max delivers this through its advanced turbine scanning system. This system uses turbine scanning to map the bed surface with extreme precision. You get accurate shapes and flawless first layers every time. The scanning process detects even the smallest imperfections, so you avoid common issues like warping or poor adhesion.

When you use the Sovol SV08 Max, you notice the difference in every print. The turbine scanning system ensures that the nozzle maintains the perfect distance from the bed. This leads to consistent manufacturing accuracy and superior print quality. You can create detailed 3d models with sharp edges and smooth surfaces. The Sovol SV08 Max’s design supports both creative and industrial manufacturing, giving you the flexibility to tackle any 3d printing challenge.

Tip: For complex 3d printing projects, such as full-scale prototypes or intricate architectural models, the Sovol SV08 Max’s turbine scanning system guarantees reliable performance and high accuracy.

You can trust this technology to deliver professional results. The Sovol SV08 Max’s turbine scanning system reduces print failures by eliminating manual errors. You achieve high-quality prints, even when working with challenging materials or oversized designs. The system’s performance optimization ensures that every layer adheres perfectly, so you spend less time troubleshooting and more time creating.

Speed and Efficiency

You want your 3d manufacturing projects to finish quickly without sacrificing quality. The Sovol SV08 Max excels in both speed and efficiency. Its turbine scanning system completes a full bed scan in just 80 seconds. This rapid scanning process means you start printing sooner and finish projects faster.

The Sovol SV08 Max’s design includes a powerful CoreXY motion system and a high-flow nozzle. You benefit from fast acceleration and smooth movement, which boosts overall performance. The turbine scanning system works seamlessly with these features to maintain accuracy at high speeds. You can print large 3d objects, such as furniture or industrial parts, in a single run. This eliminates the need for assembly and increases your manufacturing efficiency.

- Key benefits for your workflow:

- Faster setup with automatic turbine scanning

- Consistent print quality across the entire build area

- Reduced downtime due to fewer print failures

- High efficiency for both small and large 3d manufacturing tasks

You see the impact of this technology in every project. For example, when printing oversized cosplay props or engineering prototypes, the Sovol SV08 Max maintains quality and speed. The turbine scanning system ensures that each layer is perfectly aligned, so you achieve the best possible results. You can rely on this system for both everyday 3d printing and demanding manufacturing applications.

Note: The Sovol SV08 Max’s turbine scanning system supports large 3d printing, making it ideal for users who need both speed and precision in their manufacturing process.

The Sovol SV08 Max stands out for its combination of quality, efficiency, and performance. You get reliable results, whether you are a hobbyist or a professional. The turbine scanning system, advanced design, and robust manufacturing capabilities make this printer a leader in the 3d printing industry.

Turbine Scanning vs. Other Methods

Manual Leveling

You may have used manual leveling as your first bed leveling method. This method requires you to adjust the bed by hand, often using paper or feeler gauges. Manual leveling can take a lot of time. You must check each corner and make small changes until the bed feels even. This method often leads to mistakes. You might miss small bumps or dips on the bed. These errors can cause poor first layers or failed prints.

Turbine scanning changes your experience. The turbine system uses advanced scanning to map the bed surface with high precision. You do not need to touch the bed or guess the right height. The scanning process finds every small change in the bed. You get a perfect level every time. This method saves you time and gives you better results.

Tip: If you switch from manual leveling to turbine scanning, trust the system. Let the turbine handle the scanning. You will see fewer print failures and better first layers.

Mesh Bed Leveling

Mesh bed leveling is another popular method. This method uses a probe to measure points across the bed. The printer creates a mesh map and adjusts the nozzle height during printing. Mesh bed leveling works better than manual leveling, but it still has limits. The probe touches the bed, which can wear out sensors or scratch the surface. The process can also take several minutes, especially on large beds.

Turbine scanning uses a non-contact method. The turbine moves quickly and scans the entire bed in seconds. You do not need to worry about sensor wear or slow setup. The scanning system gives you a detailed map of the bed. You get reliable results, even on large-format printers like the Sovol SV08 Max.

|

Method |

Accuracy |

Speed |

Reliability |

|---|---|---|---|

|

Manual Leveling |

Low |

Slow |

Inconsistent |

|

Mesh Bed Leveling |

Medium |

Moderate |

Good |

|

Turbine Scanning |

High |

Fast |

Excellent |

Note: Some users think turbine scanning is hard to use. In reality, the system is simple. Start the scanning process, and the turbine does the work. If you see any issues, check for dust or debris on the bed before scanning.

You can move from older methods to turbine scanning with confidence. The turbine system gives you the best mix of speed, accuracy, and reliability. You spend less time setting up and more time printing.

3D Printing User Experience

Beginners and Experts

You want a 3d printer that makes manufacturing simple, whether you are just starting or have years of experience. The Sovol SV08 Max, with its turbine scanning system, removes the barriers that often slow down both beginners and professionals. You no longer need to worry about manual bed leveling or complex calibration. The automatic turbine scanning system handles these steps for you, so you can focus on your 3d design and manufacturing goals.

The Sovol SV08 Max offers fast, accurate scanning and automatic displacement correction. This means you spend less time on setup and more time on actual printing. The system’s advanced algorithms reduce post-processing, making the entire 3d printing workflow smoother for everyone. You can see how this technology improves accessibility and reliability in the table below:

|

Feature |

Quantitative Detail |

Accessibility Impact |

|---|---|---|

|

Full-body Data Capture Time |

Enables quick scanning sessions, suitable for users of all skill levels |

|

|

Automatic Displacement Correction |

Algorithm reduces post-processing |

Minimizes technical barriers for beginners and speeds workflow for professionals |

|

Versatile Scanning Modes |

Supports various sizes/materials |

Enhances usability across diverse applications and user expertise |

You benefit from up to 0.025 mm precision, which ensures your 3d design matches your vision. The Sovol SV08 Max’s turbine scanning system gives you confidence in every print, whether you are making your first 3d model or producing complex manufacturing parts.

Tip: The Sovol SV08 Max’s user-friendly interface and turbine scanning make 3d printing accessible for everyone, reducing errors and improving performance.

Large-Format Applications

You need a large format 3d printer that can handle ambitious manufacturing projects. The Sovol SV08 Max stands out for its ability to print oversized 3d models in one piece, thanks to its massive 500×500×500 mm build volume and turbine scanning system. You save time and reduce assembly steps, which boosts your manufacturing efficiency and performance.

The Sovol SV08 Max supports print speeds up to 700 mm/s, powered by its CoreXY kinematics and high-flow nozzle. You achieve high accuracy (≤0.02 mm) and reliable results, even for complex 3d designs. The Smart Auxiliary Feeder System and heated bed further reduce print failures, so you can trust your manufacturing process from start to finish.

|

Measurement Aspect |

Sovol SV08 Max / Large-Format 3D Printing Benefits |

Traditional Methods |

|---|---|---|

|

Production Time |

Longer production cycles |

|

|

Cost Savings |

Up to 60-75% savings in specific applications |

Higher costs due to molds and assembly |

|

Print Speed |

Up to 700 mm/s with high accuracy (≤0.02 mm) |

Generally slower |

|

Build Volume |

500×500×500 mm allows printing large parts in one piece |

Limited by machine size, requires assembly |

|

Assembly Steps |

Reduced or eliminated by printing large parts as single pieces |

Multiple assembly steps required |

|

Failure Rate Reduction |

Features like heated chambers and Smart Auxiliary Feeder reduce failures |

Higher failure rates and maintenance |

|

Material Waste |

Reduced due to single-piece prints eliminating joins and tooling |

More waste from molds and machining |

|

Labor Requirements |

Fewer skilled workers needed due to streamlined process |

More skilled labor required |

You see the benefits in industries like aerospace, healthcare, construction, and art. You can print large 3d objects, such as furniture, prototypes, or props, with fewer errors and less waste. The Sovol SV08 Max’s turbine scanning system ensures your 3d manufacturing projects finish faster and with higher quality.

Note: The Sovol SV08 Max’s turbine scanning and design features make it the ideal choice for anyone seeking top-tier performance in large 3d printing and advanced manufacturing.

You unlock a new level of printing with the Sovol SV08 Max. The turbine scanning system transforms your printing by delivering unmatched print quality, speed, and reliability. You see the turbine system work for both beginners and professionals, making large-format printing simple and precise. The Sovol SV08 Max uses turbine scanning to optimize every print, boost performance, and reduce errors. You choose this turbine-driven solution to set your printing apart in the 3D printing market.

FAQ

How does the turbine scanning system improve first-layer adhesion?

You get a perfectly leveled bed every time with the turbine scanning system. This technology detects even tiny surface changes. Your first layer sticks better, which reduces warping and print failures.

Is the turbine scanning system difficult to use for beginners?

You find the turbine scanning system easy to use. Just start the scan, and the printer handles the rest. You do not need special skills or tools. The process is automatic and user-friendly.

Can the turbine scanning system handle large-format prints?

You can rely on the turbine scanning system for large-format prints. It scans the entire 500×500 mm bed quickly and accurately. You achieve consistent results, even with oversized models or complex designs.

What maintenance does the turbine scanning system require?

You do not need much maintenance for the turbine scanning system. Keep the bed clean and free of debris. The non-contact design means less wear and longer sensor life.

Does the turbine scanning system support different materials?

You can use many materials with the turbine scanning system. The technology works with PLA, ABS, PETG, and more. You get reliable bed leveling for each material type.