As 3D printing continues to transform industries from prototyping to production, choosing the right filament remains crucial. This 2025 guide summarizes filament performance, key properties, and cost-effectiveness, based on ELO’s comprehensive comparison of material characteristics. Whether you're a hobbyist or engineer, this breakdown will help you select the best filament for your needs.

Material Performance Overview

The scatterplot comparison of Impact Strength vs. Tensile Strength highlights how different materials perform mechanically. Key insights include:

- PA12 and PC blends deliver high tensile strength and moderate to high impact strength — ideal for functional parts.

- ABS and ASA strike a balance between strength and durability.

- PLA, while user-friendly, sits lower in both metrics — suitable mainly for decorative or low-stress applications.

Key Characteristics by Application

For High-Stress/Load Applications:

- Tensile Strength: PA12, PC, and PA6 stand out with tensile strength >50 MPa.

- Heat Resistance: Materials like PA12, PC, and ASA offer high temperature deflection resistance, suitable for mechanical or outdoor parts.

For Functional and Cosmetic Use:

- Stiffness: PLA and PETG are rigid but less durable.

-

Flexibility: TPU and PA12 provide better elongation and flexibility for impact resistance or snap-fit parts.

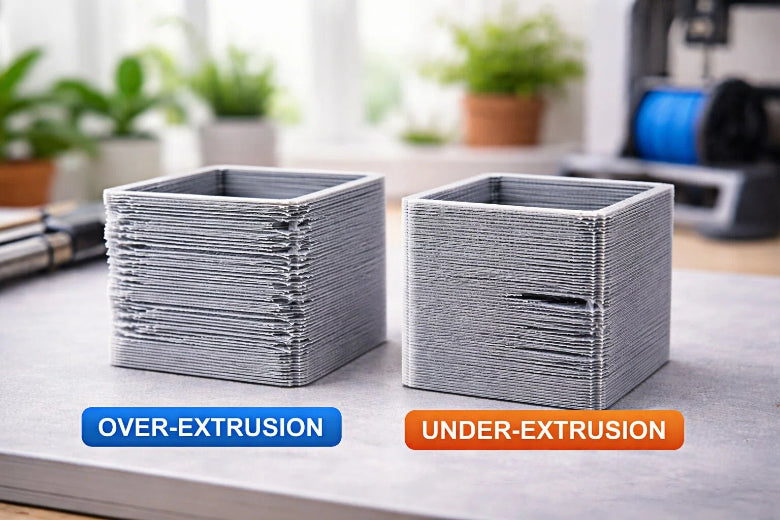

Practicality in Real-World Printing

Printability (Ease of Use): PLA scores highest, followed by PETG and TPU — great for beginners or daily printing.

Bed Adhesion & Warping Resistance: PLA and TPU excel in adhesion and minimal warping, while nylons (PA6, PA12) and PC are more prone to lifting and require heated enclosures or build surfaces.

Durability in Use: ASA, ABS, and PA-based filaments provide excellent weather, UV, and impact resistance.

Filament Profiles: Quick Comparison

A glance at each material’s traits:

| Filament | ✅ Pros | ❌ Cons | 🎯 Best Use Cases |

|---|---|---|---|

| PLA | Easy to print, wide color range, low cost, biodegradable. | Brittle, low heat and UV resistance. | Visual prototypes, hobbyist models, non-functional parts. |

| ABS | Tough, high heat resistance, can be acetone-smoothed. | Warps easily, requires enclosure, strong fumes. | Functional parts, enclosures, automotive interior parts. |

| ASA | Excellent UV and weather resistance, strong. | Warps like ABS, requires enclosure, strong fumes. | Outdoor items, automotive exterior parts, garden tools. |

| PETG | Good balance of strength and ease of use, low warp. | Prone to stringing, scratches easily. | Mechanical parts, food-safe containers, protective cases. |

| TPU | Extremely flexible, high impact and abrasion resistance. | Difficult to print, requires slow speeds, hygroscopic. | Flexible seals, phone cases, wearables, vibration dampeners. |

| PA6 | Extremely tough, high wear resistance, strong. | Very hygroscopic (absorbs moisture), requires high temps. | Gears, bearings, high-wear functional parts. |

| PA12 | Tough and flexible, lower moisture absorption than PA6. | Less strong than PA6, expensive, requires high temps. | Durable parts for humid environments, snap-fit components. |

| PC | Exceptional strength and impact resistance, very high heat resistance. | Very difficult to print, requires very high temps and enclosure. | High-strength engineering parts, protective shields. |

| Aesthetic | Unique visual finishes like wood, silk, or metal. | Often weaker and more brittle than standard PLA. | Decorative objects, trophies, architectural models, cosplay items. |

The Workhorse Filaments

The bar chart comparing PLA, PETG, ABS, ASA, and TPU across multiple performance metrics shows:

- PLA is unmatched in ease-of-use and affordability.

- PETG and TPU provide a balance between strength and ease.

- ASA and ABS are go-to options for more demanding prints that require strength and weather resistance.

Reinforced Filaments: Composite Power

Reinforced materials like Carbon Fiber Nylon, Carbon PETG, and Carbon ABS outperform base filaments in:

- Tensile Modulus

- Stiffness

- Thermal resistance

However, they are more abrasive to nozzles and costlier, requiring hardened nozzles and precise tuning.

Strength vs. Cost

When evaluating MPa per $ and Impact resistance per dollar, standout value picks include:

- PLA: Best tensile strength per cost — perfect for non-functional, aesthetic prints.

- PETG & ABS: Great mid-range balance.

- PC and Nylons: Higher performance, but less cost-effective unless durability is critical.

PA6 vs. PA12: Nylon Showdown

| Feature | PA6 | PA12 |

|---|---|---|

| Strength | ~80 MPa | ~55 MPa |

| Water Absorption | Higher | Lower (better stability) |

| Best Use Case | Structural parts | Functional, damp/chemical environments |

PA6 offers greater mechanical strength but at the cost of higher moisture sensitivity. PA12 sacrifices some strength but provides better dimensional stability, especially in humid or outdoor environments.

Conclusion

With 3D printing rapidly evolving, knowing your filament is more important than ever. Whether your priority is strength, durability, flexibility, or cost, this guide offers a snapshot of what to expect from each material. From PLA for quick prototypes to PA12 for mission-critical parts, the right filament can dramatically affect your success and print performance.

As we move through 2025, keeping this guide handy will ensure you make informed, efficient choices for all your printing needs.