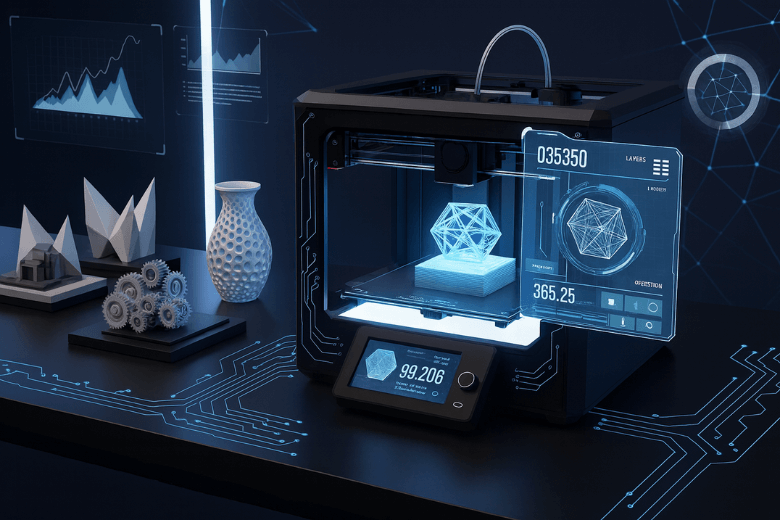

3d printing, also known as additive manufacturing, helps you make things by adding one thin layer at a time. You begin with a digital design. The 3d printer uses this plan to build your object from the bottom up. Think about stacking slices of bread to make a loaf. Each layer helps shape the final object. This process lets you create complex shapes that are hard to make in other ways. Many companies use 3d printing today:

- 20 percent use this technology.

- 49 percent use it for making more than 10 parts.

The layer-by-layer method gives you more choices. It is easy to change designs, especially for small groups or tricky parts.

Key Takeaways

- 3D printing makes things one layer at a time. This lets you build hard shapes. It does not waste much material.

- You can make special parts fast. This helps with home work, school, and jobs.

- First, you make a design on a computer with CAD software. Then, you get it ready to print with slicing software.

- After printing, you can make your items look better. You can also make them stronger. This helps them last longer.

- 3D printing is used in many fields now. It helps make things faster and with less waste.

What is 3D Printing

Additive Manufacturing Explained

3d printing lets you make things by adding layers. This is called additive manufacturing. You start with a digital design made on a computer. The 3d printer reads the design and builds from the bottom up. You watch as each layer is added and the object grows. You do not need to cut or carve anything away. The printer puts down thin layers of plastic or metal. The shape appears as more layers are added.

Additive manufacturing lets you design in new ways. You can make shapes that are hard to build with old methods. You design for how something works, not just how it looks. Complex shapes do not cost more to make. In 3d printing, making tricky shapes is easy and cheap. You can add holes, curves, or twists that are tough to do with other tools.

Tip: 3d printing helps you make models, custom parts, or finished products. You can turn your idea into a real thing quickly.

In the last ten years, more companies use additive manufacturing. Now, manufacturers use 3d printing for more than just testing. They make real parts for cars, medical tools, and new products. About 47% of manufacturers use this technology. In car making, 22.1% of companies use it. Product teams use it at 12.5%. Medical makers use it too, with 4.8% using additive manufacturing.

3D vs. Traditional Manufacturing

You might wonder how 3d printing is different from old ways. Traditional manufacturing often cuts away from a big block. You remove pieces until you get the shape you want. This makes waste, like chips and scraps. Even if you recycle, you still lose some material.

Additive manufacturing is not the same. You only use what you need. The 3d printer adds layers to build the object. You waste very little. This saves money and resources. You can also make more complex designs without extra cost.

Here is a simple comparison:

|

Manufacturing Type |

Material Usage |

Waste Generation |

|---|---|---|

|

Additive Manufacturing |

Mainly plastics and select metal powders |

Generates far less scrap |

|

Subtractive Manufacturing |

Supports a wide range of materials |

Typically results in more material waste due to removal from larger blocks |

Additive manufacturing is more efficient. You make less scrap. Subtractive manufacturing lets you use more types of strong materials, but you lose more material.

- 3d printing uses less material and makes less waste.

- Subtractive methods cut away material and make more scrap.

- 3d printing gives you more freedom to design.

With a 3d printer, you can make objects with tricky shapes and small details. You do not need special tools for each new design. You just change your digital file and print again. This saves time and planning. You see your ideas become real faster.

3d printing works with many materials, but most printers use plastics or metal powders. You pick the best material for your project. You can make strong, bendy, or even medical parts.

3d printing changes how you make things. You use digital designs, add layers, and waste less. You get more choices and faster results.

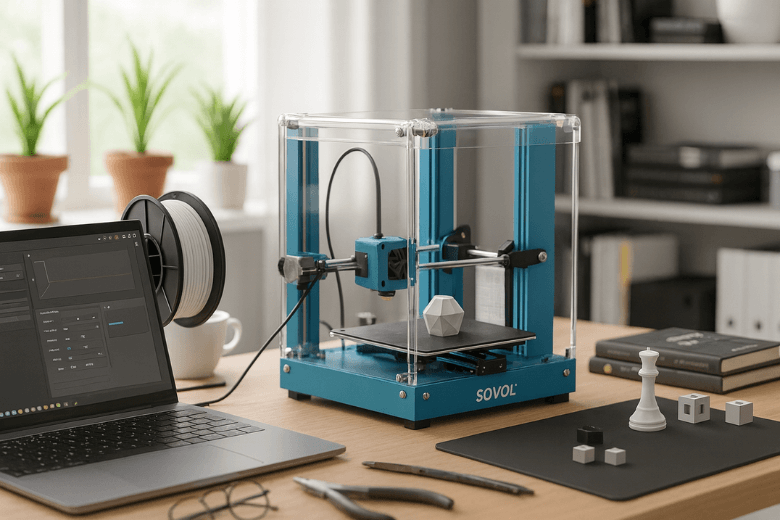

How a 3D Printer Works

CAD Models and Slicing Software

You begin 3d printing with a digital design. This design is called a CAD model. You make it using special computer software. The CAD model is the plan for your 3d printer. You can change your design many times before printing. A good CAD model helps your object work well. Keep the shape simple and use thick walls. Make sure your model fits on the printer bed.

Tip: Always check if your CAD model can be printed. This helps you avoid mistakes and saves time.

After your CAD model is ready, you prepare it for printing. You use slicing software for this step. The software turns your model into an STL file. Then, it slices the model into thin layers. Each layer is a cross-section of your object. Slicing software makes G-code for your 3d printer. G-code tells the printer how to build each layer. You can change settings like layer height and infill density. You send the G-code to your printer with an SD card, Wi-Fi, LAN, or USB.

Here are the steps you follow:

- Make a CAD model.

- Check if the model can be printed.

- Change the model to an STL file.

- Use slicing software to split the model into layers.

- Set up printing settings.

- Send the G-code to your 3d printer.

Setting up is important. The first layer must stick to the print bed. If the first layer does not stick, the print can fail.

The Role of the Extruder/Printhead

Your 3d printer uses an extruder or printhead to build objects. It works by making one layer at a time. The extruder melts and pushes out the printing material. Most 3d printers use a spool of thermoplastic filament. Filaments like ABS or PLA are common. The extruder heats the filament to melt it. The temperature is usually between 180°C and 230°C. The melted plastic goes through a small nozzle. The nozzle is often 0.4mm wide. The printer moves the extruder in the X and Y directions. It draws each layer. After one layer is done, the print bed lowers a little. This lets the printer add the next layer. The process repeats until your object is finished.

If you use an SLA 3d printer, things are different. You use liquid resin instead of filament. The printhead uses a laser to harden the resin. The build platform sits in the resin and moves down after each layer.

The printhead controls how the material is placed. It uses pressure to push out the material. The nozzle design helps control the flow. It also stops backflow. Some printers mix materials to change the object’s properties. The printer manages the yield stress. This keeps the shape after extrusion. Sometimes curing happens right after extrusion. This lets you use low-viscosity materials.

Here is a table that shows how the printhead works:

|

Aspect |

Description |

|---|---|

|

Pressure Application |

Controls flow and placement of material for each layer. |

|

Nozzle Design |

Changes flow resistance and prevents backflow. |

|

Material Mixing Techniques |

Mixes materials at different ratios for custom properties. |

|

Yield Stress Management |

Keeps the shape after extrusion and allows in-situ curing. |

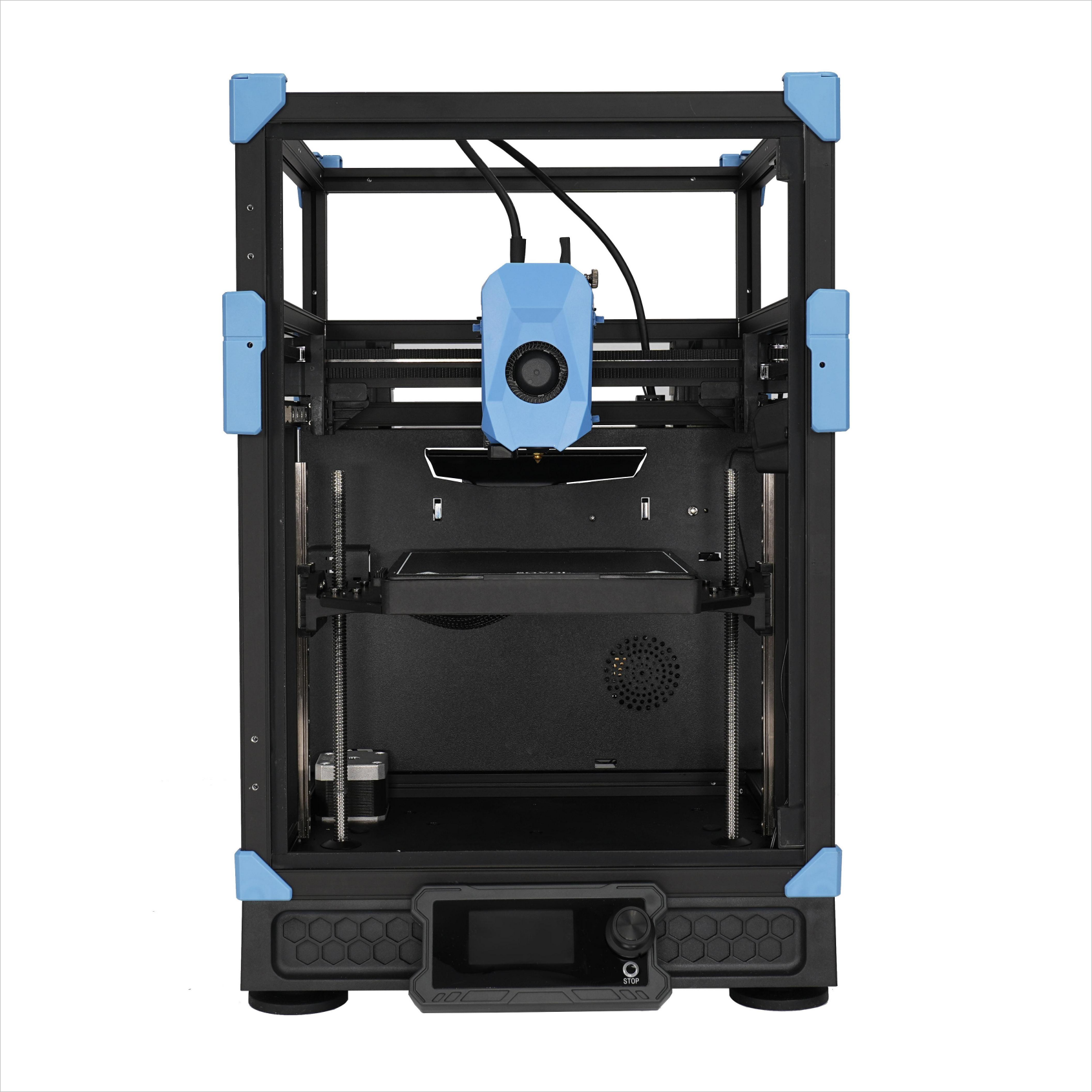

Your 3d printer has many parts. Each part does a special job. Here is a table of the main parts:

|

Component |

Function |

|---|---|

|

Frame |

Holds all parts and gives support for printing. |

|

Stepper Motors |

Moves parts to exact spots for printing. |

|

Conveyor Belt |

Replaces the print bed in belt printers for continuous printing. |

|

Threaded Rod |

Helps parts move, but can clog in big machines. |

|

End Stops |

Stops parts from breaking by holding them in place. |

|

Power Supply Unit |

Changes AC to DC and controls voltage for the printer. |

|

Print Bed |

Holds the object while printing, heated beds help quality. |

|

Print Bed Surface |

Helps the first layer stick, different surfaces have pros and cons. |

Different 3d printing technologies use different ways to work. Here is a table to compare them:

|

3D Printing Technology |

Operational Mechanism |

|---|---|

|

Fused Filament Fabrication (FFF) |

Uses a long filament of thermoplastic, melts and pushes it out layer by layer. |

|

Selective Laser Sintering (SLS) |

Uses a laser to fuse powder, making solid parts where needed. |

|

Stereolithography (SLA) |

Uses a UV laser to harden liquid resin layer by layer. |

|

Direct Metal Laser Sintering (DMLS) |

Like SLS but for metal powders, uses a laser to fuse metal. |

|

Multi Jet Fusion (MJF) |

Adds agents to powder, then fuses it with energy. |

|

Material Jetting |

Jets layers of photopolymer, then cures them with UV light. |

|

PolyJet |

Puts down layers of liquid photopolymer, cures them like inkjet printing. |

All 3d printers use the layer by layer method. You build objects by adding thin layers. This lets you control the shape and size. You can use different materials for different results. Additive manufacturing helps you make complex shapes with less waste.

Note: You can print models, tools, or finished products. You only need a digital design and the right settings.

Now you know how a 3d printer works. You use CAD models and slicing software to guide the printer. The extruder or printhead builds your object layer by layer. You pick the best materials and settings for your project. This makes 3d printing flexible and strong.

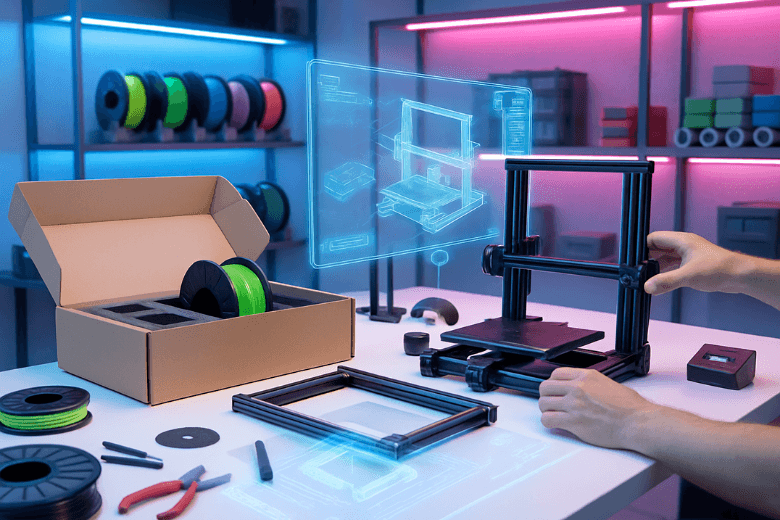

3D Printing Process

File Preparation

You start your 3d printing journey by preparing your digital file. You use a 3d modeling program to create your design. You can choose software like Sloyd or ZBrush with the 3D Print Hub plugin. Here is a typical workflow:

- Create your 3d model in CAD software.

- Import or export your design as an STL file.

- Scale your model and set the dimensions.

- Inspect the mesh and repair any issues.

- Hollow the model if you want to save materials.

- Add supports for stability during printing.

- Export your final file for the 3d printer.

You need to check your file for errors before you print. Common problems include boundary edges, intersecting faces, and non-manifold edges. These issues can cause your 3d printer to fail. You can see some typical errors in the table below:

|

Error Type |

Description |

Recommendation |

|---|---|---|

|

Boundary edges |

Holes in the model |

Repair the STL or re-model areas |

|

Intersecting faces |

Surfaces collide |

Combine bodies or repair STL |

|

Non-manifold edges |

Unclear design |

Adjust design and add thickness |

|

Over-refined mesh |

Too many triangles |

Reduce triangle count |

Printing Steps

After you prepare your file, you move to the printing stage. You use slicing software to split your model into thin layers. The software creates instructions for your 3d printer. You set up your materials and check the print bed. You start the printing process and watch as the 3d printer builds your object layer by layer.

The steps look like this:

- Slice your model into layers.

- Set up your materials and printer.

- Start the printing process.

- Monitor the print for errors.

Printing time depends on the object and technology. For example:

|

Technology |

Object Type |

|

|---|---|---|

|

FFF |

Standard-size vase |

4-6 hours |

|

SLA |

Small, detailed figurine |

2-4 hours |

|

SLS |

Complex, medium-sized part |

10-12 hours |

Tip: Always check your printer settings and materials before you start. This helps you avoid failed prints.

Post-Processing

When printing finishes, you need to post-process your object. You use techniques like sanding, priming, painting, vapor smoothing, and polishing. You may fill gaps, bond parts, or dye your model. These steps improve the look and strength of your 3d printed item.

Post-processing gives you several benefits:

- Enhanced surface finish and better appearance

- Improved mechanical strength and durability

- Increased lifespan for your 3d printed parts

You can use different materials and methods to get the best results. Post-processing makes your 3d printing projects look professional and last longer.

3D Printing Technologies & Materials

Main Methods (FDM, SLA, SLS)

There are a few main 3d printing methods. Each one builds objects in a special way. Here are the most common types:

- Fused Deposition Modeling (FDM): This method melts plastic and lays it down in layers. Many home and school 3d printers use FDM.

- Selective Laser Sintering (SLS): This method uses a laser to join powder together. It makes strong and tough parts.

- Stereolithography (SLA): This process uses UV light to harden liquid resin. It makes prints that are smooth and detailed.

- Direct Metal Laser Sintering (DMLS): This method uses a laser to join metal powder. It is good for strong metal parts.

- PolyJet: This method uses liquid resin and gives very precise prints.

You can look at the good and bad sides of each method:

|

Method |

Advantages |

Disadvantages |

|---|---|---|

|

FDM |

Safe, many materials, low cost, strong, big prints |

Not many design choices, weak up and down, not very exact, hard to control heat |

|

SLA |

Smooth finish, good for small batches |

Costly materials, messy cleanup, resin is unsafe, weak up and down |

|

SLS |

No extra supports, strong prints, can reuse powder |

Machines cost a lot, takes a long time, needs careful cleaning when changing powder |

Materials Used

You have lots of choices for 3d printing materials. Each one has different uses and features. Here are some common ones:

- Plastic: PLA is safe for the earth and bends easily. ABS is strong and cheap. You use these for toys and things at home.

- Metal: Stainless steel does not rust. Aluminum is light and strong. Titanium is very strong. You use metals for pans, planes, and thin parts.

- Graphene: This material carries electricity, bends, and is strong. You find it in electronics and building things.

- Composite materials: These are very strong and steady. You use them for tough engineering jobs.

Here is a table to show how materials work for 3d printing:

|

Material Type |

Properties |

Applications |

|---|---|---|

|

Plastic (PLA) |

Safe for earth, bends, many colors |

Toys, home items |

|

Plastic (ABS) |

Strong, cheap, bends |

Toys, jewelry, home stuff |

|

Metal (Stainless Steel) |

Does not rust, strong |

Pans, kitchen tools |

|

Metal (Aluminum) |

Light, strong |

Thin metal parts |

|

Metal (Titanium) |

Very strong |

Parts for planes |

|

Graphene |

Carries electricity, bends, strong |

Electronics, building |

|

Composite Materials |

Strong but light |

Tough engineering jobs |

Tip: Pick your material by thinking about how strong, bendy, or costly it is.

Additive Manufacturing Innovations

New ideas in additive manufacturing come out every year. These help you make better 3d prints and use new materials. Here are some new things:

|

Innovation Type |

Description |

|---|---|

|

High-performance Polymers |

New plastics make prints stronger and last longer. |

|

Metallic Materials |

New metal powders make 3d prints tougher and stronger. |

|

Ceramic Materials |

Special ceramics let you print for medicine and factories. |

|

4D Printing Technologies |

4D printing uses smart stuff that changes shape with time or heat. |

You can use these new materials and ways to make things that last longer and work better. 3d printing keeps getting better, so you have more choices for your projects.

Applications of 3D Printing

Everyday Uses

3d printing is used in many daily things. You can make phone stands that fit your desk. You design charging docks and holders for cables. These keep your space tidy. In the office, you use 3d-printed pen holders and trays. These help you organize your supplies. At home, you make storage boxes and dividers for drawers. These items help you stay neat and save time. You also print parts to fix appliances. For example, you can make clips for dishwashers or shelves for fridges. You do not need to buy new things. You print a part that fits just right. You can even create special home decor that matches your style.

Here are some common ways people use 3d printing:

- Phone stands made for your desk

- Custom pen holders and trays for your office

- Storage boxes and dividers for your home

- Replacement parts like dishwasher clips and fridge shelves

- Unique home decor that fits your style

You get to pick the size, color, and shape you want. 3d printing lets you make things that fit your needs. You also help the planet by making less waste. Additive manufacturing uses only what is needed for each item. You print things layer by layer, so you save materials.

Industry Examples

Many businesses use 3d printing to solve problems and make better products. You see 3d printing in healthcare, aerospace, cars, consumer goods, factories, and schools. Each group uses 3d printing for different jobs. In healthcare, you see custom medical devices and fake limbs. Aerospace companies make light parts for spaceships. Car makers use 3d printing to test ideas and make new parts. Consumer goods companies make custom products and fashion items. Factories use 3d printing for tools and building things. Schools use 3d printing for hands-on learning.

|

Industry |

Purpose |

|---|---|

|

Healthcare |

Custom medical devices, fake limbs, surgery models, drug delivery devices |

|

Aerospace |

Light parts, lower costs, making spaceship parts |

|

Automotive |

Fast testing, making new parts, improving designs |

|

Consumer Goods |

Custom products, personal designs, fashion and shoes |

|

Industrial |

Making parts, tools, and products, building things |

|

Education |

Learning tools, research in many subjects |

Big companies like Boom Supersonic and Lockheed Martin use 3d printing for planes. Rocket Crafters uses it for rocket engines. These examples show how 3d printing helps businesses and gives you better products. You get faster results, less waste, and more choices in design.

You have learned that 3d printing turns digital designs into real things. The printer builds objects one layer at a time. This lets you print things when you need them. It also works for shapes that are hard to make. Additive manufacturing gives you new ways to create. You should know about finishing steps and what materials you can use.

- 3d printing lets you make custom parts fast.

- You can use 3d printing for home, school, or work.

- Think about your needs, money, and time before you start.

|

Future Trend |

What to Expect |

|---|---|

|

New Materials |

More choices for 3d designs |

|

Sustainability |

|

|

Local Production |

Faster, cheaper 3d parts near you |

3d printing is growing. Try it to see how it can help you make your ideas real!

FAQ

What materials can you use in a 3D printer?

You can use plastics like PLA and ABS, metals such as steel and titanium, and even special materials like ceramics or graphene. Each material works best for different projects.

How long does it take to print something?

Printing time depends on the object's size and the printer type. Small items may take a few hours. Large or detailed objects can take a whole day.

Is 3D printing safe for you to use at home?

Most desktop 3D printers are safe if you follow instructions. You should keep the printer in a well-ventilated area and avoid touching hot parts during printing.

Can you print moving parts with a 3D printer?

Yes, you can design and print objects with moving parts. Hinges, gears, and joints work if you plan the design carefully and use the right material.

Do you need special skills to start 3D printing?

You do not need advanced skills. You can learn basic design and printer setup with online guides. Many beginner-friendly software options help you get started.