Klipper firmware transforms your 3D printing experience by delivering exceptional speed and precision. Its unique architecture offloads complex motion calculations to a host computer, enabling real-time command processing. This approach allows Klipper to achieve stepping rates of up to 175,000 steps per second on 8-bit microcontrollers and 600,000 steps per second on modern 32-bit systems. Features like Input Shaping and Smooth Pressure Advance minimize vibrations, ensuring smoother, high-quality prints even at faster speeds. Whether you're upgrading an older machine or optimizing a new one, Klipper sets a new standard for 3D Printer Firmware.

Key Takeaways

- Klipper firmware makes 3D printing faster and more accurate. It moves hard calculations to another device, like a Raspberry Pi.

- Cool features like Input Shaping and Smooth Pressure Advance reduce shaking. This helps prints look smoother and more precise.

- Klipper works with many printer types. It’s great for upgrading old printers or improving new ones.

What Is Klipper Firmware?

Overview of Klipper and Its Purpose

Klipper is an open-source firmware designed to enhance the capabilities of 3D printers. Unlike traditional firmware, it uses a unique approach by combining a microcontroller with an external processor, such as a Raspberry Pi. This architecture offloads complex computations from the printer's microcontroller to the Raspberry Pi, enabling faster processing and more precise control. Developed by Kevin O'Connor in 2014, Klipper gained early traction through its adoption by the Voron project, a community known for its high-performance 3D printers.

Klipper firmware supports a wide range of kinematics, including Cartesian, CoreXY, and delta configurations, making it versatile for various printer designs. Its purpose extends beyond basic functionality; it aims to overcome the limitations of traditional firmware by offering advanced features like Input Shaping and Smooth Pressure Advance. These features reduce common issues such as ringing and ghosting, ensuring smoother prints even at higher speeds.

The firmware's popularity has grown steadily over the years. By 2024, it comes pre-installed on several 3D printer models, including Gigabot 4 and Terabot 4, which prioritize precision and performance. Strategic partnerships, such as the collaboration with BigTreeTech in 2022, further highlight its role in advancing 3D printing technology.

|

Aspect |

Details |

|---|---|

|

Purpose |

Open source firmware for 3D printers that enhances control capabilities. |

|

Development |

Developed by Kevin O'Connor in 2014, with early adoption by the Voron project. |

|

Key Features |

Supports multiple kinematics, including Cartesian, CoreXY, and delta. |

|

Popularity |

Gained traction over time, pre-installed on various 3D printers by 2024. |

|

Partnerships |

Strategic partnership with BigTreeTech in 2022. |

|

Innovations |

Introduced input shaping in late 2020. |

Klipper's development process reflects its commitment to user experience. Regular updates, such as the upcoming v0.4.0 release, incorporate user feedback to improve error handling and add new modules. This responsiveness ensures that the firmware evolves alongside the needs of the 3D printing community.

Tip: If you're a Gigabot owner, consider joining the alpha/beta testing program for early access to new features. Your feedback helps refine the firmware and contributes to its continuous improvement.

How Klipper Differs from Traditional 3D Printer Firmware

Klipper firmware stands out due to its innovative architecture and advanced features. Traditional firmware, such as Marlin, relies solely on the printer's microcontroller for processing. This limits its ability to handle complex computations and achieve high stepping rates. Klipper, on the other hand, utilizes an external processor like a Raspberry Pi to offload these tasks, enabling stepping rates of up to 175,000 steps per second on 8-bit microcontrollers and 600,000 steps per second on modern 32-bit systems.

One of Klipper's most notable features is Input Shaping, which minimizes vibrations and reduces ringing or ghosting in prints. Traditional firmware lacks this capability, making Klipper a superior choice for achieving high-quality results. Smooth Pressure Advance is another standout feature, allowing you to calibrate extrusion settings in real-time for consistent layer adhesion.

Configuration is simpler with Klipper. You can edit settings directly through a text file, eliminating the need for complex firmware recompilation. This ease of use contrasts with traditional firmware, which often requires more technical expertise to adjust parameters.

|

Feature |

Klipper |

Marlin |

|---|---|---|

|

Processing Unit |

Utilizes an additional processor (e.g., Raspberry Pi) |

Runs on the printer's microcontroller |

|

Stepping Rate |

Limited by microcontroller capabilities |

|

|

Input Shaping |

Unique feature to reduce ringing/ghosting |

Not available |

|

Smooth Pressure Advance |

Easier calibration in real-time |

More complex to adjust |

|

Print Quality |

Higher quality due to precise motor movements |

Good, but less precise |

|

Configuration |

Easier to configure |

More complex configuration |

Klipper firmware also fosters a strong community. Its alpha and beta testing programs encourage users to contribute feedback, ensuring continuous improvement. This collaborative approach has solidified Klipper's reputation as a reliable and adaptable solution for 3D printing enthusiasts and professionals alike.

Note: If you're transitioning from traditional firmware, Klipper's documentation provides detailed guidance to help you get started. Its user-friendly design ensures a smooth learning curve, even for beginners.

Key Benefits of Klipper Firmware

Enhanced Performance and Speed

Klipper firmware redefines what you can achieve with your 3D printer by significantly improving performance and speed. Its unique architecture, which offloads complex calculations to an external processor like a Raspberry Pi, allows your printer to handle higher stepping rates. This means your printer can execute commands faster and more accurately, resulting in smoother movements and higher print speeds.

One standout feature is Input Shaping, which reduces vibrations during high-speed printing. This ensures that even at faster speeds, your prints maintain exceptional quality without defects like ringing or ghosting. Additionally, Klipper's Smooth Pressure Advance optimizes extrusion control, reducing oozing and ensuring consistent layer adhesion. These features work together to deliver better print quality while enabling higher print speeds, making Klipper a game-changer for both hobbyists and professionals.

Pro Tip: If you're looking to push your printer to its limits, pair Klipper with 32-bit hardware for even greater performance gains.

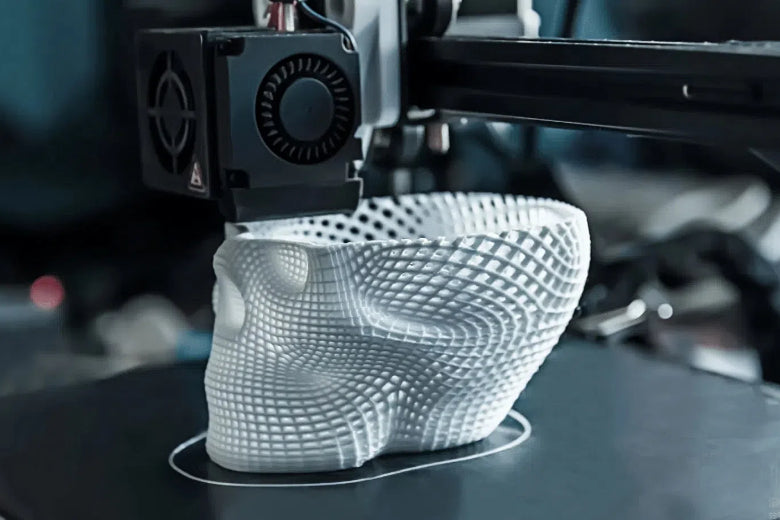

Improved Print Quality with Advanced Features

Klipper firmware offers advanced features that directly enhance print quality. Input Shaping minimizes vibrations caused by rapid movements, resulting in cleaner and more precise prints. Smooth Pressure Advance further improves print quality by controlling extrusion dynamics, reducing issues like oozing and inconsistent layer adhesion.

Here are some key features that contribute to better print quality:

- Input Shaping: Reduces vibrations, leading to cleaner prints.

- Smooth Pressure Advance: Optimizes extrusion, minimizing oozing.

These features ensure that your 3D prints not only look better but also maintain structural integrity. Whether you're printing intricate designs or large models, Klipper's advanced capabilities help you achieve professional-grade results.

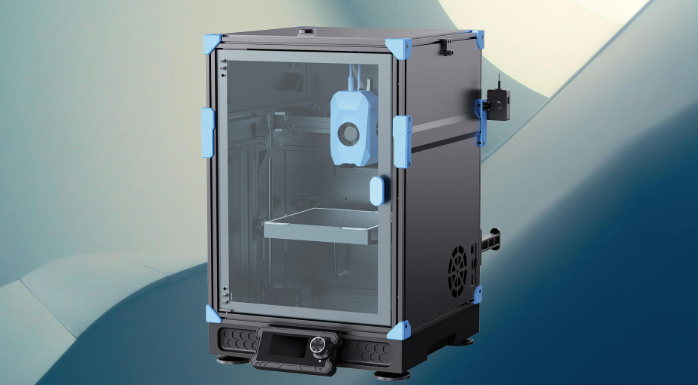

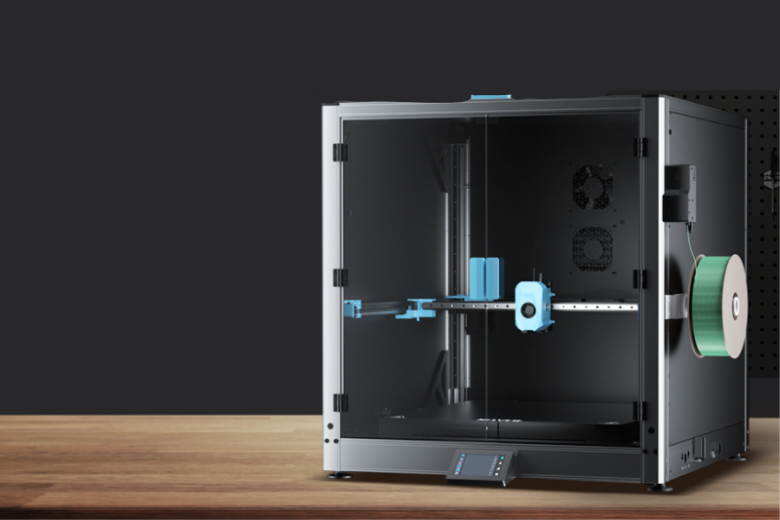

Compatibility with a Wide Range of Printers

Klipper firmware is designed to work seamlessly with a variety of 3D printers, making it one of the most versatile options available. It supports multiple kinematics, including Cartesian, CoreXY, and delta configurations, ensuring compatibility with both common and specialized printer designs.

- Klipper integrates with numerous 3D printer models, including those with Klipper pre-installed, such as the Gigabot 4 and Terabot 4.

- Features like easy PID tuning and support for multiple microcontrollers make it adaptable to different hardware setups.

This broad compatibility allows you to upgrade your existing printer or choose a new one that already includes Klipper firmware. Whether you're using an older 8-bit microcontroller or a modern 32-bit system, Klipper ensures optimal performance and precision.

Customization and User Control

Klipper firmware stands out for its extensive customization options, giving you unparalleled control over your 3D printing experience. Its modular design supports multiple microcontrollers, allowing you to tailor your setup to meet specific needs. You can easily adjust settings through a simple text file, eliminating the need for complex firmware recompilation.

|

Feature |

Klipper Benefits |

|---|---|

|

Smooth Pressure Advance |

Reduces oozing during extrusion |

|

Input Shaping |

Minimizes vibrations for cleaner prints |

|

Modular Design |

Supports multiple microcontrollers for customization |

Users have reported that Klipper's advanced kinematic calculations improve accuracy and precision, even on older hardware. Additionally, the firmware's ability to optimize performance with 32-bit systems ensures that you can push your printer to its full potential.

Note: Klipper is particularly easy to set up with printers that have endstop switches, making it accessible even for beginners.

How to Set Up Klipper Firmware

Hardware and Software Requirements

To set up Klipper, you need specific hardware and software to ensure smooth operation. Start with a Raspberry Pi 3 or higher, as it provides the necessary computing power. Pair it with a reliable power supply rated at 3A/5V to avoid interruptions. A Micro SD card with at least 8 GB of memory is essential for storing the firmware and related files. Additionally, you’ll need a Windows 10 PC or a Mac running macOS Sierra or later for initial configuration.

For software, install tools like Putty for SSH access to the Raspberry Pi. Optional utilities such as WinSCP for file transfers and balenaEtcher for writing the image file can simplify the process. Klipper firmware integrates seamlessly with a Linux-based host, making a Raspberry Pi the ideal choice for running the software.

Tip: Use Mainsail OS, Octoprint, or Fluidd as interfaces to interact with your 3D printer and unlock Klipper’s full potential.

Step-by-Step Installation Process

Follow these steps to install Klipper firmware:

- Download the FluidPI or Mainsail image from their GitHub repositories.

- Use Raspberry Pi Imager to set up your Raspberry Pi.

- Install MainsailOS on the Raspberry Pi to manage your printer.

- Access the Raspberry Pi via SSH using Putty and configure Klipper for your printer model.

- Build the firmware and transfer it to your printer’s SD card.

These steps ensure a smooth installation process, allowing you to take full advantage of Klipper’s features.

Using Web Interfaces like Mainsail and Fluidd

Web interfaces like Mainsail and Fluidd enhance your experience with Klipper firmware. Mainsail offers advanced customization options, making it ideal for users who enjoy fine-tuning settings. Fluidd, on the other hand, provides a simpler interface with performance benefits, especially for devices with limited resources.

Both interfaces allow you to monitor your 3D printer remotely, adjust settings, and view real-time print progress. Users often find Fluidd easier to install, while Mainsail’s additional features cater to those seeking more control. Choose the interface that best suits your needs to optimize your 3D printing workflow.

Note: Both Mainsail and Fluidd have active communities, providing support and updates to improve your printing experience.

Klipper firmware transforms your 3D printing experience by combining speed, precision, and versatility. Its innovative design enables older hardware to exceed 100,000 steps per second, while modern systems surpass 600,000. Features like Input Shaping and Smooth Pressure Advance reduce vibrations and improve print quality. By choosing Klipper, you unlock unmatched performance and customization for your printer.

Key advantages of Klipper firmware include:

- Stepping rates up to 175,000 steps per second on 8-bit microcontrollers.

- Real-time processing for smoother, faster operations.

- Modular architecture for better synchronization and control.

Pro Tip: Upgrade to Klipper firmware to maximize your printer's potential and achieve professional-grade results effortlessly.

FAQ

What makes Klipper different from other firmware options?

Klipper uses an external processor, like a Raspberry Pi, to handle complex calculations. This improves speed, precision, and print quality compared to traditional firmware.

Can Klipper firmware work with older 3D printers?

Yes, Klipper supports older printers by optimizing their performance. Its compatibility with 8-bit microcontrollers ensures smooth operation even on outdated hardware.

Is Klipper firmware difficult to configure?

No, Klipper simplifies configuration through editable text files. You can easily adjust settings without recompiling, making it user-friendly for beginners and experts alike.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.