If you are new to 3d printing, you probably want a simple start. FDM (Fused Deposition Modeling) usually works best for beginners because it offers low cost and easy setup. Picking the right printer type shapes your first experience. The right choice helps you avoid frustration and wasted money. A good guide can show you the basics and help you understand the Different Types of 3D Printing. With the right guide, you can feel confident as you begin your journey.

Key Takeaways

- FDM printers are the best choice for beginners due to their low cost, easy setup, and wide availability.

- Choose your 3D printer based on your goals: simple models suit FDM, detailed miniatures fit SLA, and strong parts require SLS.

- Start with PLA filament for easy printing and low risk; try PETG or ABS as you gain experience and need stronger materials.

- Set a clear budget and consider ongoing costs like materials and maintenance before buying your first printer.

- Use beginner-friendly software and join online communities to learn, get support, and improve your 3D printing skills.

Why the Right 3D Printing Type Matters

Cost and Accessibility

When you start 3D printing, your budget and access to equipment shape your experience. FDM printers stand out as the most affordable and widely available option for beginners. You can find basic FDM models for around $200. The materials, like PLA filament, usually cost $20–$50 per kilogram. Maintenance is simple and does not require special tools. This makes FDM a great choice if you want to keep costs low and get started quickly.

SLA printers, which use liquid resin, cost a bit more. Entry-level models start at about $250–$300. Resin is more expensive than filament, often costing $100–$200 per liter. You also need extra equipment for cleaning and curing prints, which adds to the total cost. SLS printers, once only for industry, now have some compact models for small businesses and advanced hobbyists. However, these still cost $15,000 or more, so they are not practical for most beginners.

|

Cost Aspect |

FDM Printers (Beginner) |

SLA/Resin Printers (Beginner) |

SLS Printers (Beginner) |

|---|---|---|---|

|

Initial Purchase Price |

~$200 |

~$250–$300 |

$15,000+ |

|

Material Costs |

$20–$50/kg |

$100–$200/liter |

High, industrial scale |

|

Maintenance |

Simple, low cost |

More steps, extra equipment |

Complex, not for beginners |

|

Post-Processing |

Manual, low cost |

Needs washing, UV curing |

N/A |

Print Quality and Application

Your choice of printer also affects what you can make. FDM printers work well for basic prototypes, hobby models, and educational projects. They create objects with visible layer lines and moderate detail. If you need higher detail or smoother surfaces, SLA printers deliver better results. They use thinner layers and produce fine details, making them ideal for miniatures, jewelry, or dental models.

SLS printers can create strong, complex parts without support structures. They use powdered materials and a laser to fuse each layer. This method works best for advanced users who need durable, functional prototypes. However, SLS is less common for beginners due to cost and complexity.

|

Technology |

Layer Thickness |

Surface Finish |

Beginner Applications |

|---|---|---|---|

|

FDM |

Visible layer lines |

Prototyping, hobby models |

|

|

SLA |

0.05–0.15 mm |

Smooth, fine detail |

Miniatures, detailed models |

|

SLS |

0.06–0.15 mm |

Smooth, granular finish |

Advanced, functional parts |

You should match your printer to your goals. If you want to make simple models or learn the basics, FDM is the best starting point. If you need high detail, consider SLA. For strong, complex parts, SLS is an option, but it requires a bigger investment.

The Different Types of 3D Printing

When you start exploring the different types of 3d printing, you will notice that each technology has its own strengths and challenges. Understanding these differences helps you choose the right printer for your needs. Let’s look at the main options you will find as a beginner.

FDM (Fused Deposition Modeling)

FDM is the most popular choice for beginners. You use a spool of plastic filament, which the printer melts and pushes through a heated nozzle. The nozzle moves along three axes (X, Y, and Z) to build your object layer by layer. The melted plastic cools and hardens, bonding each layer together. Most FDM printers let you adjust settings like nozzle temperature, layer height, and cooling fan speed. You can print objects up to the size of the build area, which is usually about 200 x 200 x 200 mm for desktop models.

Key parts of an FDM printer include the hot end, nozzle, filament, and build platform. The nozzle size affects how much detail you get. Smaller nozzles give finer details but take longer to print. Filament comes in two main diameters: 1.75mm and 3mm. You can use different materials, but PLA is the easiest for beginners. Many FDM printers, like the Creality Ender 3 Pro, are affordable and simple to use. You can set up the printer, level the bed, and start printing with basic calibration.

Tip: FDM printers are great for learning the basics, making prototypes, and printing hobby models. You will find lots of online guides and community support.

SLA (Stereolithography)

SLA is another important option when you look at the different types of 3d printing. This technology uses a UV laser or projector to cure liquid resin, building your object one thin layer at a time. The build platform lifts after each layer, allowing the next layer to form. SLA printers create parts with very high detail and smooth surfaces. You can print objects with layer heights as fine as 25 microns, which is much smoother than most FDM prints.

|

Aspect |

Explanation |

|---|---|

|

Working Principle |

Uses UV laser or projector to cure liquid resin layer by layer. |

|

Materials |

Photopolymer resins (standard, tough, flexible, castable, biocompatible). |

|

Resolution and Accuracy |

High; layer heights as fine as 25 microns. |

|

Process Steps |

Printing, washing, and UV post-curing. |

|

Unique Characteristics |

High precision, minimal warping, low waste. |

|

Limitations |

Brittle parts, smaller build volume, careful resin handling needed. |

|

Applications |

Dental models, jewelry, miniatures, product design. |

You will need to wash and cure your prints after they come out of the printer. SLA printers cost more than FDM models, and the resins are more expensive. However, if you want to make detailed miniatures or smooth prototypes, SLA is a strong choice.

SLS (Selective Laser Sintering)

SLS stands out among the different types of 3d printing for its ability to create strong, complex parts. This method uses a laser to fuse powdered material, usually nylon, layer by layer. The unsintered powder supports the object as it prints, so you do not need extra support structures. SLS printers can make parts with high strength and durability, which is useful for functional prototypes.

|

Aspect |

FDM (Fused Deposition Modeling) |

SLA (Stereolithography) |

|

|---|---|---|---|

|

Basic Process |

Laser sinters powder layer by layer; powder acts as support. |

Melts and extrudes filament; needs support structures. |

UV light cures resin; supports needed. |

|

Material Form |

Powder (nylon, polyamides) |

Filament (PLA, ABS) |

Liquid resin |

|

Support Structures |

Not required |

Required |

Required |

|

Surface Finish |

Rough, may need post-processing |

Layer lines visible |

Smooth, high detail |

SLS printers used to be only for industry, but now some models, like the Formlabs Fuse 1, are more affordable. Still, SLS costs much more than FDM or SLA and requires careful handling of powder. Most beginners do not start with SLS, but it is good to know about this option if you want to make strong, complex parts in the future.

Other Types of 3D Printers

You will also find other technologies when you research the different types of 3d printing. Some of these include:

- PolyJet Printing: Uses inkjet-like heads to deposit resin. It can print in multiple materials and colors but is expensive and less common for beginners.

- Selective Heat Sintering (SHS): Fuses powder with a thermal printhead at lower temperatures. It is safer and more affordable than SLS, making it more approachable for some beginners.

- ColorJet Printing (CJP): Binds colored ink to gypsum powder, creating full-color models. These prints are best for display, not for strength.

- Laser Metal Deposition (LMD): Melts metal feedstock with a laser. This is for industrial use and not suitable for beginners.

- Multi-Jet Modeling (MJM): Jets multiple materials for high-resolution prints. It is mainly for professional prototyping.

|

Technology |

Description |

Suitability for Beginners |

|---|---|---|

|

PolyJet Printing |

Multi-material, high precision, inkjet-like resin printing. |

Expensive, not common for hobbyists. |

|

SHS |

Thermal printhead fuses powder at lower temperatures. |

More approachable, safer, and lower cost than SLS. |

|

CJP |

Full-color models using binder and colored ink on powder. |

Good for education and presentations, not for strong parts. |

|

LMD |

Laser melts metal for industrial parts. |

Industrial only, not for beginners. |

|

MJM |

Multiple print heads for complex, high-res prints. |

Professional use, not beginner-friendly. |

Most beginners choose FDM because it is the easiest and most affordable. SLA is a good second choice if you want high detail. SLS and other types of 3d printing are better for advanced users or special projects. As you learn more, you can explore these other technologies and decide if they fit your goals.

Pros and Cons of Types of 3D Printers

FDM: Strengths and Weaknesses

FDM stands out as one of the most popular types of 3d printers for beginners. You benefit from affordable machines, easy setup, and a wide range of materials. Many models, like the Bambu Lab X1-Carbon and Creality K1, offer features such as fast printing, touchscreen controls, and automatic filament management. These features help you get started quickly and reduce the learning curve.

|

Printer Model |

Key Advantages for Beginners |

|---|---|

|

Bambu Lab X1-Carbon |

Easy setup, fast printing, multi-material support, AI print failure detection |

|

Bambu Lab P1S Combo |

Simple filament handling, multi-material printing, user-friendly interface |

|

Bambu Lab P1P |

Budget-friendly, minimalist design, fast printing |

|

Creality K1 |

Fully enclosed, remote printing, affordable, easy-to-use touchscreen |

However, you may face some challenges with FDM printers:

-

Build plate leveling and surface cleaning can affect print adhesion.

-

Nozzle clogs may occur if you use low-quality or moist filament.

-

Print quality issues like layer misalignment and stringing are common.

-

Warping and adhesion problems can happen, especially with certain materials.

-

Post-processing, such as removing supports, is often needed for a smooth finish.

SLA: Strengths and Weaknesses

SLA printers offer you high precision and smooth surface finishes. You can print detailed models, miniatures, and prototypes with fine features. SLA types of 3d printers use a UV laser to cure resin, which results in tight dimensional tolerance and minimal visible layers. You also benefit from a variety of resin materials and quick post-processing.

Some weaknesses exist for beginners:

- Standard resins are brittle and not suitable for mechanical stress.

- Resin and printer costs are higher than FDM.

- Build volumes are smaller, limiting the size of your projects.

- Handling resin requires safety precautions due to fumes and toxicity.

- Dedicated printing spaces are needed to avoid accidental curing.

SLS: Strengths and Weaknesses

SLS types of 3d printers let you create strong, complex parts without support structures. You can print multiple objects at once, and the powder bed supports intricate designs. Benchtop SLS printers are now more accessible, with simplified workflows and lower energy use. SLS parts have excellent mechanical properties and allow you to recycle unused powder, reducing waste.

|

Drawback |

Explanation |

|---|---|

|

SLS parts often have porous, rough surfaces that may need extra finishing. |

|

|

Tricky Post-Print Cleaning |

Cleaning powder from prints can be difficult for beginners. |

|

Powder Hazards |

Fine powders require safety gear and careful handling. |

|

Design Learning Curve |

Designing for SLS differs from FDM, which can be challenging for new users. |

|

Limited Material Options |

Fewer choices compared to other types of 3d printers. |

Quick Comparison Table

|

Feature |

FDM |

SLA |

SLS |

|---|---|---|---|

|

Cost |

Low |

Moderate |

High |

|

Print Quality |

Moderate |

High |

High |

|

Ease of Use |

Easy |

Moderate |

Challenging |

|

Material Handling |

Simple |

Requires safety steps |

Requires safety steps |

|

Post-Processing |

Basic |

Washing & curing |

Powder removal |

|

Best For |

Beginners, hobbyists |

Detail, prototypes |

Complex, strong parts |

3D Printing Materials for Beginners

Choosing the right 3d printing materials helps you get the best results from your first projects. The ultimate 3d printing materials guide always starts with the basics. You will find that some materials are easier to use and safer for beginners.

Common Filaments: PLA, ABS, PETG

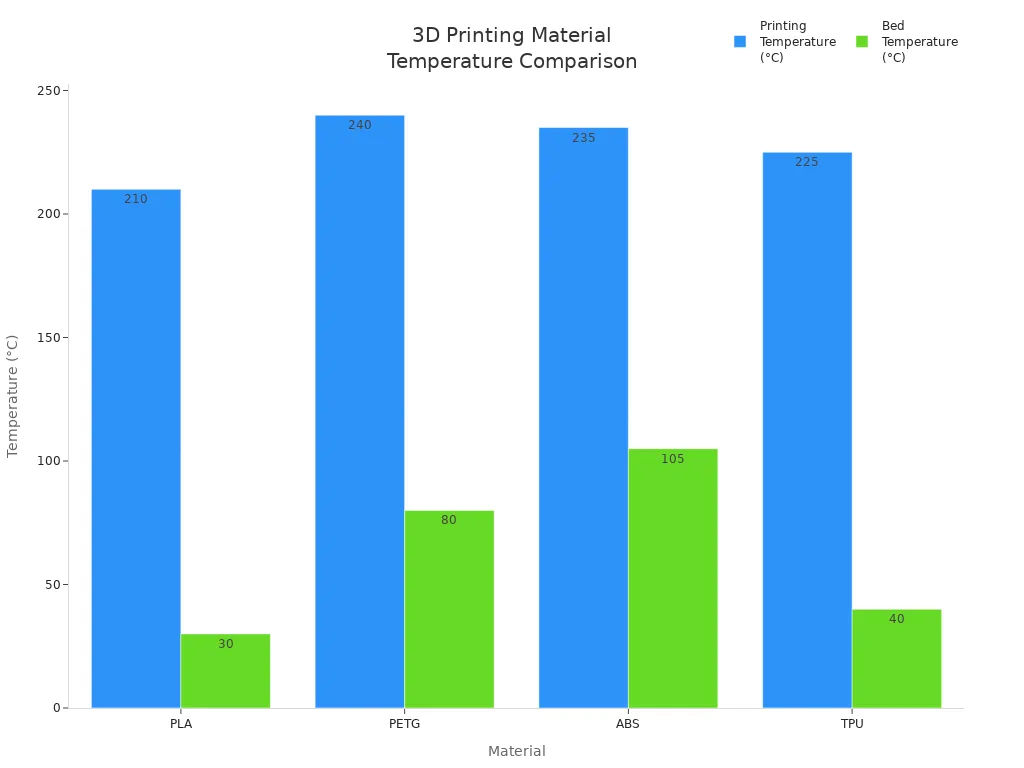

Most beginners start with PLA. PLA (polylactic acid) prints at low temperatures, sticks well to the print bed, and rarely warps. You do not need a heated bed, and you get smooth, detailed prints. PLA is also non-toxic and safe to use at home or in a classroom. You can find it in many colors and blends, making it perfect for models, toys, and prototypes.

PETG is a good next step after PLA. PETG offers more strength and flexibility. It resists impact and heat better than PLA. However, PETG needs a heated bed and higher print temperatures. You should use good ventilation because it can release mild fumes.

ABS is tougher and more heat-resistant than PLA or PETG. It works well for strong, functional parts. However, ABS is harder to print. It needs a heated bed and an enclosed printer to prevent warping. ABS also gives off strong fumes, so you must use it in a well-ventilated area.

Here is a quick comparison to help you choose:

|

Material |

Ease of Use |

Printing Temperature |

Bed Temperature |

Warping Risk |

Flexibility |

Best For Beginners Because |

|---|---|---|---|---|---|---|

|

PLA |

Very Easy |

0-60°C (optional) |

Low |

Low |

Prints at low temperature, minimal warping, sticks well, good surface finish |

|

|

PETG |

Moderate |

220-260°C |

70-90°C |

Moderate |

Medium-High |

Stronger and more flexible than PLA, good layer adhesion |

|

ABS |

Difficult |

220-250°C |

100-110°C |

High |

Medium |

Tough and heat resistant but requires heated bed and enclosure |

Resin and Powder Options

If you use SLA printers, you will work with resin. UV resin is the easiest for beginners. It cures quickly under UV light and does not need mixing. Always wear gloves and work in a well-ventilated space. Epoxy resin is another option, but it needs careful mixing and takes longer to cure. Polyurethane resin cures very fast and reacts to humidity, so it is not recommended for beginners.

Powder materials, like those used in SLS printers, are less common for new users. These powders require special handling and safety gear. Most beginners do not start with powder-based 3d printing materials.

The ultimate 3d printing materials guide also covers advanced options. After you master the basics, you can try flexible filaments like TPU or strong engineering plastics. Each new material brings new challenges and possibilities.

How to Choose

Selecting your first 3D printer can feel overwhelming, but a clear guide makes the process much easier. You can break down your decision into simple steps. This guide will help you define your goals, set your budget, consider ease of use, match materials and print quality, and review common beginner scenarios.

Define Your Goals

Start by thinking about what you want to create. Your goals shape every other decision in your 3D printing journey. Ask yourself these questions:

- Do you want to print simple models, toys, or prototypes?

- Are you interested in detailed miniatures or jewelry?

- Do you need strong, functional parts for repairs or projects?

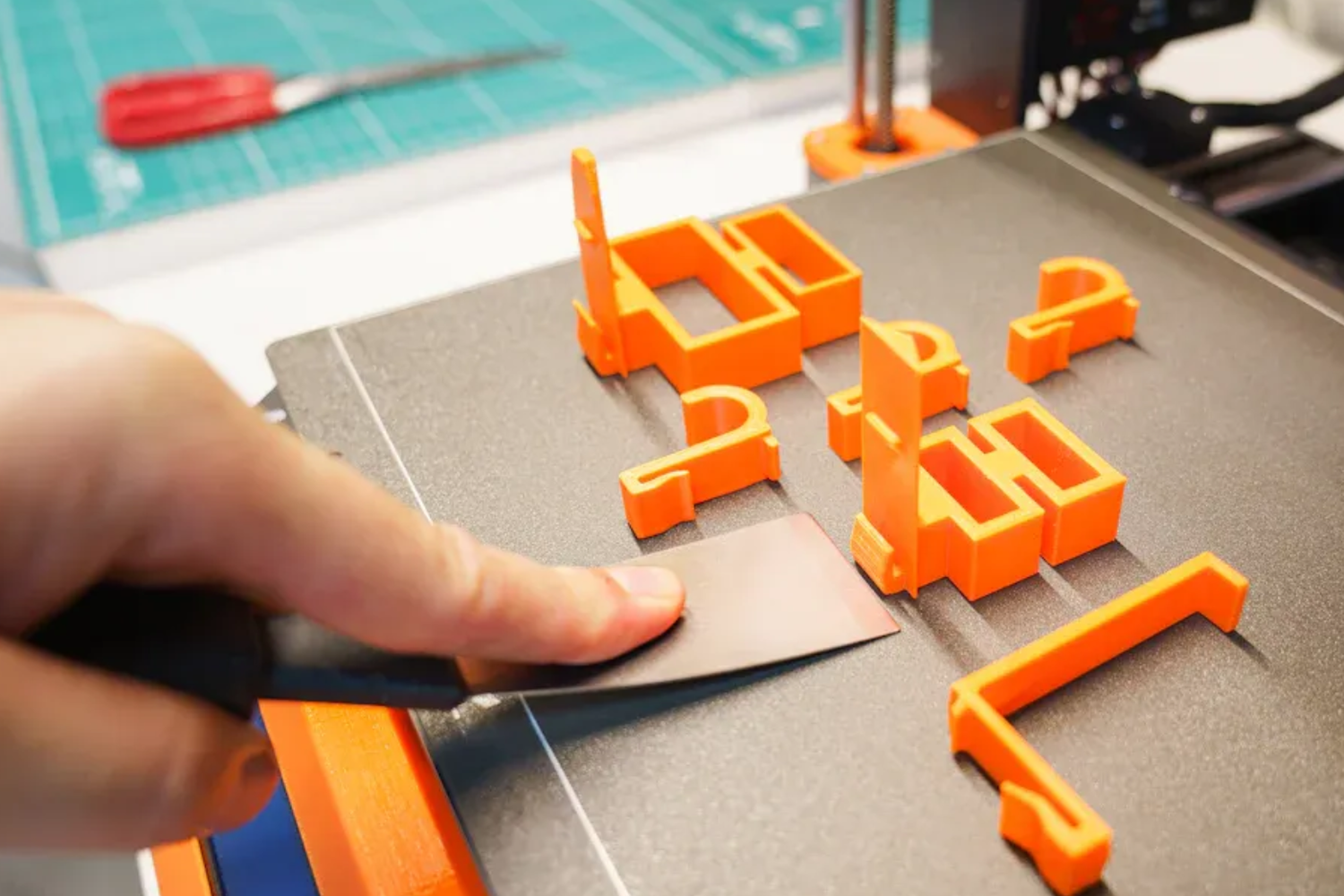

You should also consider the tools and skills you need. Have basic tools like a spatula, flush cutters, brass brush, calipers, and a hex key set ready. Practice safety when removing prints and cleaning up. Many beginners find it helpful to join online communities. You can ask questions, share your progress, and learn from others. Remember, learning 3D printing involves trial, error, and support from others.

When you define your goals, focus on these important factors:

1. Choose materials that match your project needs. 2. Decide on infill percentage to balance strength and print time. 3. Pick a resolution (layer height) for the detail you want. 4. Select a nozzle diameter for the right mix of speed and detail. 5. Set the right printing temperature for your chosen material. 6. Adjust printing speed for accuracy and strength. 7. Use supports and slicer settings to improve print success. 8. Plan print orientation for better strength and surface quality.

Set Your Budget

Your budget will guide your choices. Entry-level FDM printers usually cost between $200 and $400. These models work well for most beginners. If you want higher detail, SLA printers start around $250, but you will spend more on resin and post-processing tools. SLS printers cost much more and are not practical for most first-time users.

Think about ongoing costs too. Filament for FDM printers is affordable and easy to find. Resin for SLA printers costs more and needs careful storage. You may also want to buy extra tools or upgrades, such as adhesives for print removal or better nozzles.

|

Printer Type |

Typical Entry Cost |

Material Cost |

Maintenance/Extras |

|---|---|---|---|

|

FDM |

$200–$400 |

$20–$50/kg |

Low |

|

SLA |

$250–$500 |

$100–$200/L |

Moderate |

|

SLS |

$15,000+ |

High |

High |

Consider Ease of Use

Ease of use is key for a smooth start. FDM printers are the easiest to set up and operate. They work with beginner-friendly software like Tinkercad, Ultimaker Cura, and PrusaSlicer. These programs have simple interfaces, step-by-step guides, and strong community support.

|

Software |

Beginner-Friendly Features |

|---|---|

|

Tinkercad |

Drag-and-drop, browser-based, ideal for students and novices |

|

Ultimaker Cura |

Easy setup, presets, free, supports many printers |

|

PrusaSlicer |

Simple interface, strong community, supports many filaments |

|

3D Slash |

Game-like tools, fun for kids and beginners |

SLA and SLS printers require more setup and safety steps. You need to handle resin or powder carefully and follow extra post-processing steps. If you want the easiest start, choose an FDM printer that works with popular beginner software.

Match Materials and Print Quality

The material you choose affects your print quality and project success. PLA is the best starting point. It prints easily, looks good, and works for most models and prototypes. PETG is a good next step if you want more strength and flexibility. ABS is tougher but harder to print and needs a heated bed and good ventilation.

|

Material |

Ease of Printing |

Best Use Cases |

Suitability for Beginners |

|---|---|---|---|

|

PLA |

Very easy |

Models, prototypes, toys |

Excellent |

|

PETG |

Moderate |

Functional, outdoor parts |

Good |

|

ABS |

Challenging |

Strong, heat-resistant parts |

Advanced |

|

TPU |

Difficult |

Flexible items |

Advanced |

You should also store your filament in a dry place. Moisture can ruin print quality. If you want to print flexible or outdoor parts, try PETG or TPU after you master PLA.

Beginner Scenarios

You can use this guide to match your needs to the right 3D printing type. Here are some common beginner scenarios:

- Printing simple models or toys: FDM printers with PLA filament work best. You get easy setup, low cost, and good results.

- Making detailed miniatures or jewelry: SLA printers offer higher detail and smoother surfaces. Choose this if you want fine features and do not mind extra steps.

- Building strong, functional parts: PETG on an FDM printer gives you more strength. ABS is an option if you have an enclosed printer and good ventilation.

- Printing large parts: Look for FDM printers with a large build volume. You may need to print in sections and assemble the parts.

- Minimizing the learning curve: Choose an FDM printer with good reviews and strong community support. Avoid complex kits if you want to start printing right away.

A step-by-step guide helps you make smart choices. Define your goals, set your budget, consider ease of use, match materials and print quality, and review beginner scenarios. With this guide, you can start your 3D printing journey with confidence.

You now know that FDM often works best for beginners, but your needs and goals matter most. Use the comparison table and the step-by-step guide to help you decide. Try making a simple checklist or take a quick quiz to see which printer fits you. With the right guide, you can start 3D printing and enjoy the process. Anyone can learn this skill with the right support.

FAQ

What is the easiest 3D printer for a beginner to use?

You will find FDM printers the easiest to use. They have simple setup, affordable materials, and lots of online support. You can start printing right away with basic instructions.

Can I print with more than one material as a beginner?

Yes, you can try different materials like PLA, PETG, or ABS on most FDM printers. Start with PLA. When you feel confident, experiment with other filaments for different results.

Do I need special software to design 3D models?

You can use free, beginner-friendly software like Tinkercad or Ultimaker Cura. These programs help you design and prepare models for printing. You do not need advanced skills to get started.

How safe is 3D printing at home?

3D printing is safe if you follow basic safety steps. Use good ventilation, especially with ABS or resin. Wear gloves when handling resin. Keep your workspace clean and organized.