To choose the right large 3D printer, you need to clarify what you want to print and what your project requires. You may feel overwhelmed by the many options, especially as industries from aerospace to healthcare demand faster production, precision, and eco-friendly materials. Consider how the market for large 3d printer solutions continues to grow:

|

Metric/Segment |

Statistic/Projection |

|---|---|

|

USD 2.92 billion |

|

|

Market size (2029 projected) |

USD 6.27 billion |

|

CAGR |

16.5% |

|

Prototyping application share (2023) |

Over 54% of global revenue |

When choosing a 3d printer, match features to your needs. Start by thinking about your goals, available space, and budget. Many users now look for large 3d printer models that support customization, reduce waste, and handle advanced materials. The 3d printer buying guide will help you find the right 3d printer for your projects.

Key Takeaways

- Identify your main printing needs and project types before choosing a large 3D printer to ensure the machine fits your goals.

- Match the printer’s build volume to the size of your largest parts and workspace to avoid limitations and allow future growth.

- Choose the right printing technology, with FDM best for large, strong parts and SLA for detailed, smaller models.

- Check material compatibility and features like heated beds and enclosures to print high-quality parts with various filaments.

- Consider printer speed, reliability, connectivity, and support to improve efficiency and enjoy a smooth printing experience.

Define Your Needs

Applications

When you start your search for a large 3d printer, you must first identify your primary 3d print applications. Each industry and project type brings unique requirements. For example, aerospace companies need lightweight, multi-material parts that meet strict safety standards. Automotive manufacturers focus on prototyping, custom parts, and tooling, often using durable materials. The marine sector looks for corrosion-resistant components, such as hulls and propulsion systems, and values faster production times. Theme parks use large-format 3d printers to create immersive installations that traditional methods cannot easily produce.

You will also notice that technological trends shape the way you use a 3d printer. Material innovation, speed improvements, and digital integration with AI drive the industry forward. By 2025, you can expect breakthroughs in multi-material printing, automation, and sustainability. However, challenges like material limitations, printing speed, and scalability still exist. These issues vary by industry but continue to improve through research and development.

Tip:

Consider how your industry uses large-format 3d printers. A recent survey found that 70% of companies use 3d printers for small series production, while 49% use them for larger series. About 68% rely on 3d printers for prototyping, and 40% produce functional parts. These numbers show that your application will influence your choice of machine.

Market data from a 2024 trend report highlights the rapid growth of the 3d printing market, driven by adoption in construction, agriculture, and transportation. Construction and agriculture often use FDM technology, while medical sectors prefer SLA. Automation, AI, and new materials improve speed, quality, and cost efficiency. Your application performance will depend on your industry’s demands, the technology you choose, and the latest innovations.

Case studies show how different industries benefit from large-format 3d printers. Apis Cor uses robotic concrete 3d printers to build homes quickly, addressing housing shortages. ICON 3D prints sustainable homes with low-carbon materials, reducing waste and energy use. Automotive leaders like Ford and Audi use 3d printers for tooling and custom parts, improving speed and cost-effectiveness. These examples show that speed, cost, material efficiency, and customization matter most when you define your needs.

Size Requirements

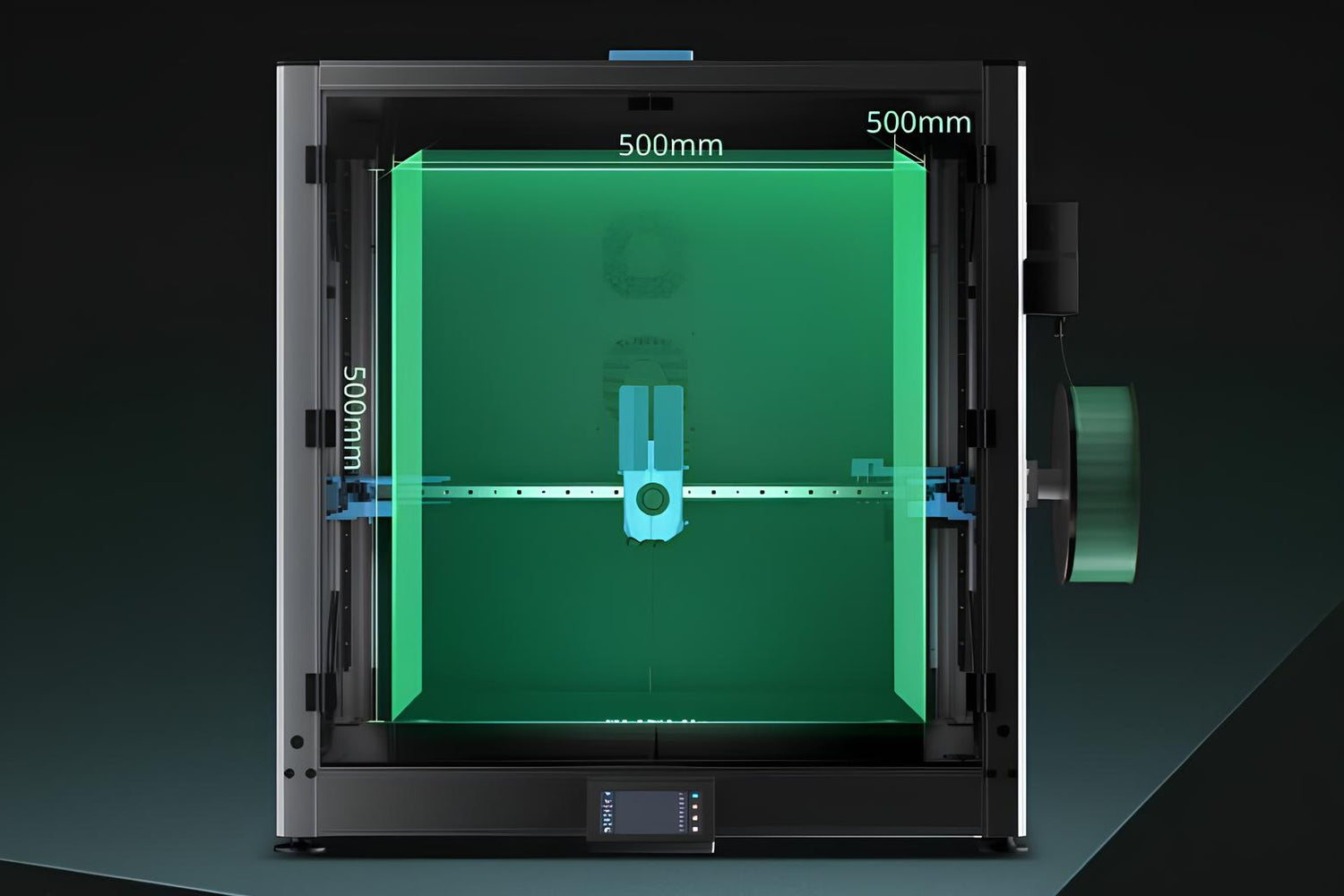

After you identify your application, you must determine the right size for your 3d printer. The size of your projects will dictate the build volume and build envelope you need. If you plan to print large prototypes, architectural models, or functional parts, you should look for a printer with a generous build envelope. For example, a 3d printer with a 500×500×500mm³ build volume, like the Sovol SV08 Max, allows you to create sizable objects in one piece, reducing the need for assembly.

Think about the maximum size of the parts you want to produce. Measure your largest design and add extra space for support structures. The build envelope should always exceed your largest part to avoid limitations. If you work in industries such as construction or marine, you may need a 3d printer with an even larger build volume to handle oversized components.

Note:

The size of your workspace also matters. Make sure your chosen 3d printer fits comfortably in your available area. Consider the full build envelope, including the printer’s frame and movement range.

You should also consider the scalability of your 3d printer. If your business grows or your projects become more complex, a larger build envelope gives you flexibility. Many companies find that investing in a bigger size upfront saves time and money later. The right size ensures you can handle a wide range of 3d print applications without frequent upgrades.

A recent study of managers in the UK found that company size affects how you use and benefit from 3d printers. Larger firms often need bigger machines to meet higher production demands, while smaller firms may prioritize flexibility and cost. Always match the size of your 3d printer to your current and future needs.

Large 3D Printer Types

When you explore the world of large format 3d printer solutions, you will find several types of 3d printers designed for different needs. Understanding the main types helps you choose the right large 3d printer for your projects.

FDM vs. SLA

You will encounter two leading types of 3d printers for large-format applications: FDM (Fused Deposition Modeling) and SLA (Stereolithography). Each type offers unique strengths and limitations.

|

Aspect |

FDM 3D Printing |

SLA 3D Printing |

|---|---|---|

|

Technology |

Extrudes melted thermoplastic filament |

Uses laser to cure liquid resin layer by layer |

|

Build Volume |

Widely available in large formats; scalable and affordable |

Limited build volume; large-format SLA is rare |

|

Print Speed |

Faster, especially with larger nozzles |

Slower; longer print and post-processing times |

|

Material Costs |

Lower; uses thermoplastics like PLA, ABS, Nylon |

Higher; uses photopolymer resins |

|

Mechanical Properties |

Strong, durable, suitable for functional parts |

Weaker, best for detailed or cosmetic parts |

|

Surface Finish |

Rougher, visible layer lines |

High resolution, smooth finish |

|

Typical Applications |

Functional parts, prototypes, industrial 3d printers |

Dental, jewelry, precision models |

Most industries prefer FDM when they need a large format 3d printer. You get faster production, lower costs, and strong, functional parts. SLA types of 3d printers excel in detail and surface finish but rarely scale to large-format 3d printer sizes. You will see SLA used for small, precise models, while FDM dominates large 3d printer applications in aerospace, automotive, and consumer goods.

Tip:

If you need a large 3d printer for functional parts or rapid prototyping, FDM types offer the best balance of speed, strength, and affordability.

SOVOL Open-Source Options

When you want flexibility and innovation, open-source types of 3d printers stand out. Sovol leads this space with large format 3d printer models like the Sovol SV08 Max. This large-format 3d printer features a 350×350×345mm build volume, high-speed CoreXY motion, and full open-source hardware and software. You can customize, upgrade, and optimize your 3d printer to match your workflow.

Sovol’s approach supports both beginners and advanced users. You benefit from a strong community, regular updates, and the freedom to adapt your large format 3d printer as your needs change. The Sovol SV08 Max, inspired by the Voron 2.4, brings industrial 3d printers’ performance to your workspace without the complexity of a scratch build. You get reliability, speed, and the ability to print large, functional parts with ease.

Open-source types of 3d printers like Sovol’s SV08 Max help you break the limits and unleash infinite creativity.

Materials & Quality

Filament Compatibility

When you select a large 3D printer, you must consider which 3d printing materials the machine supports. Understanding 3d printing materials helps you match your printer to your project needs. Many advanced printers, such as the Sovol SV08 Max, support a wide range of 3d print materials, including PLA, PETG, ABS, TPU, and even carbon-fiber composites. This flexibility allows you to choose materials based on the required strength, durability, and finish of your parts.

Heated beds and enclosures play a key role in material compatibility. These features stabilize the printing environment by maintaining consistent temperatures. You avoid warping and improve layer adhesion, especially when working with temperature-sensitive materials like ABS and nylon. Enclosures also block drafts, so you can print in colder rooms without sacrificing print quality.

Tip:

Always check the printer’s specifications for supported materials and look for features like heated beds and enclosures. These features ensure you achieve high strength and consistent print quality with every project.

|

Specification Aspect |

Impact on Print Quality and Material Compatibility |

|---|---|

|

Heated Beds & Enclosures |

Prevent warping, improve adhesion, support advanced materials |

|

Material Compatibility |

Enables use of PLA, PETG, ABS, TPU, composites, engineering-grade |

|

Extrusion System |

Ensures smooth feeding, reduces clogs, maintains print quality |

Print Resolution

Print resolution in 3d printing determines the level of detail and surface finish you can achieve. High accuracy is essential for producing parts that fit together perfectly or meet strict design standards. Many large 3D printers now offer dimensional accuracy within ±0.15%, which ensures your parts match your digital models.

You should also consider the printer’s motion control system. CoreXY kinematics, for example, provide high acceleration and stability. This reduces vibration and boosts accuracy, resulting in high-quality prints with sharp details and smooth surfaces. Smart sensors and live feedback systems further enhance print quality by detecting and correcting errors during long production runs.

Understanding 3d printing materials and their behavior at different resolutions helps you choose the right settings for each project. When you combine the right material with precise accuracy, you achieve both strength and high-quality prints every time.

Space & Setup

Workspace

Setting up your workspace for a large 3D printer requires careful planning. You need to consider the size of your printer and the available area. A spacious, well-organized station helps you manage large prints and maintain safety. Place your printer on a sturdy, level workbench to prevent vibrations that can affect print quality. Stability is essential, especially when working with a printer that handles heavy or oversized projects.

Mobility also plays a key role in workspace design. Many users install swivel casters with locking brakes on their workbenches. This setup lets you reposition your printer easily for cleaning, maintenance, or adjusting airflow. Polyurethane wheels work best for most environments because they resist chemicals, roll smoothly, and tolerate heat. If you work in a quieter or cleaner space, thermoplastic rubber wheels offer a softer, quieter option. For industrial settings, phenolic wheels provide durability, though they can be noisy and tough on floors.

A human-centered approach to workstation design improves both comfort and productivity. Ergonomic risk assessments and smart spatial planning help you reduce strain and boost efficiency, especially when you operate large 3D printers in busy environments.

Always measure your workspace before installation. Make sure you have enough clearance around the printer for loading filament, removing prints, and performing maintenance. The size of your workspace should match the size of your printer and the parts you plan to produce.

Power & Ventilation

Large 3D printers require reliable power sources. Check that your electrical outlets can handle the printer’s voltage and wattage. Use surge protectors to safeguard your equipment from power spikes. Avoid using extension cords for long-term setups, as they can cause voltage drops and safety risks.

Proper ventilation is just as important as power. Some 3D printing materials release fumes or particles during printing. Set up your printer in a well-ventilated area or use an air filtration system. This step protects your health and keeps your workspace comfortable. If you print with materials like ABS or composites, consider an enclosure with an exhaust fan to direct fumes outside.

Tip: Regularly inspect your power and ventilation systems. Good airflow and stable electricity help you achieve consistent, high-quality prints, no matter the size of your project.

Features to Consider

Build Volume & Speed

When you evaluate a large format 3d printer, build volume stands out as a top priority. The build volume defines the maximum size of the object you can print in one piece. If you work on prototypes, architectural models, or functional parts, a generous build envelope lets you create larger items without splitting them into smaller sections.

A larger build envelope also improves production efficiency. You can print multiple parts at once, saving time and reducing the need for repeated setups. Studies show that printers with bigger platforms allow you to produce more models simultaneously, which speeds up mass production. Printing orientation affects efficiency as well. Printing vertically increases time by nearly 39% compared to horizontal orientation because of the extra layers required. By maximizing your build volume and optimizing orientation, you boost your workflow and reduce delays.

Speed is another critical factor. The Sovol SV08 Max reaches up to 700 mm/s, making it one of the fastest options in its class. High speed does not mean you sacrifice print quality. Advanced motion systems, such as CoreXY kinematics and linear rails, maintain stability and accuracy even at top speeds. This combination ensures you get strong, precise parts quickly, which is essential for both rapid prototyping and production runs.

Tip:

Always check the 3d printer specifications for build volume and maximum speed. These numbers directly impact your ability to meet deadlines and scale your projects.

Reliability & Safety

Reliability ensures your large format 3d printer delivers consistent results, especially during long or complex prints. The Sovol SV08 Max uses a reinforced frame and linear rails to reduce vibration and mechanical wear. This design keeps your prints stable and accurate, even when you run the printer at high speeds. The integration of Klipper firmware allows you to fine-tune acceleration and motion planning, which leads to better print quality and fewer errors.

Advanced features like Pressure Advance and Input Shaping Technology help you avoid common flaws such as ringing and uneven edges. The Smart Auxiliary Feeder monitors filament flow, preventing clogs and tangles. This reduces interruptions and material waste, which is vital for large projects. The Eddy Current Scanning system provides fast, accurate bed leveling by detecting tiny surface changes. This ensures your first layer sticks perfectly, which is the foundation for strong, high-quality prints.

|

Feature / Metric |

Description / Value |

|---|---|

|

Maximum Print Speed |

Up to 700 mm/s |

|

Maximum Acceleration |

40,000 mm/s² |

|

Positional Accuracy |

≤0.02 mm during fast moves and acceleration tests |

|

Ringing Artifacts Reduction |

92% reduction compared to disabled configurations |

|

Motion System |

CoreXY kinematics with belt-driven motion and stationary motors |

|

Stability Features |

Linear rails and sturdy frame reduce vibration and mechanical wear |

|

Firmware Integration |

Klipper firmware enables precise acceleration control and motion planning |

|

Extrusion Rate |

35 mm³/s |

|

Frame Strength |

180% stronger than comparable aluminum frames |

These features support the reliability and safety of your 3d printer. While there are no formal industry safety certifications listed, Sovol’s engineering choices focus on robust mechanical design and intelligent monitoring. This approach gives you peace of mind when running long prints or working with advanced materials.

Connectivity & Software

Modern large format 3d printer models offer advanced connectivity and software options. The Sovol SV08 Max supports WiFi and Ethernet, allowing you to monitor and control your printer remotely. You can check print progress, adjust settings, or pause jobs from your computer or mobile device. The built-in camera provides real-time monitoring and time-lapse recording, which helps you track print quality and catch issues early.

Open-source firmware and software give you the freedom to customize your 3d printer. Sovol’s commitment to open-source principles means you can upgrade, tweak, or integrate new features as your needs evolve. This flexibility appeals to both beginners and experienced makers. You can use popular slicers like OrcaSlicer, Cura, and PrusaSlicer, ensuring compatibility with your preferred workflow.

Note:

User-friendly software and reliable connectivity make your 3d printer easier to operate. You spend less time troubleshooting and more time creating.

Sovol focuses on making 3d printers that are both powerful and easy to use. You benefit from customizable features, strong community support, and a design philosophy that puts your needs first. Whether you prioritize build volume, speed, accuracy, or connectivity, Sovol’s large format 3d printer options help you break the limits and unleash your creativity.

Budget & Value

Upfront Cost

When you consider a large 3D printer, the upfront cost often becomes your first concern. Industrial-grade machines and advanced models can require a significant initial investment. Market studies show that the price of large-format 3D printing equipment remains high, especially for machines designed for professional or industrial use. The table below highlights recent market trends and investment factors:

|

Aspect |

Details |

|---|---|

|

Market Size 2024 |

USD 8.54 Billion |

|

Upfront Investment Factors |

High cost of 3D printing equipment, especially industrial-grade models |

|

Material Costs |

Expensive specialized materials such as metals and composites |

|

Investment Barriers |

Financial challenges for small manufacturers and startups |

|

Market Trends |

Shift from analog to digital for better flexibility and efficiency |

You should always compare the features and build volume you need with the price. Some brands, like Sovol, offer large-format 3D printers with advanced features at a more accessible price point.

Tip: Always factor in the cost of materials and accessories when planning your budget. The initial price of the printer is only part of your total investment.

Long-Term Investment

A large 3D printer represents more than just an upfront purchase. You must also consider the long-term value and the total cost of operation. Ongoing expenses include maintenance, upgrades, and material replenishment. Rapid technological advancements mean you may need to upgrade your equipment or software to stay competitive.

|

Aspect |

Details |

|---|---|

|

Long-term Investment Factors |

Frequent upgrades, ongoing maintenance costs |

|

Market Size 2023 |

USD 23.7 Billion |

|

Projected Market Size 2030 |

USD 149.4 Billion |

|

CAGR (2023-2030) |

20.5% |

|

Market Challenges |

High total cost of ownership restrains growth for smaller businesses |

Choosing an open-source, customizable printer like the Sovol SV08 Max can help you manage long-term costs. You gain the flexibility to upgrade hardware and software as needed, which extends the useful life of your machine. Reliable support and a strong user community also reduce downtime and help you solve problems quickly.

Note: Investing in a high-quality, adaptable 3D printer can save you money over time by reducing maintenance needs and allowing for future upgrades.

Support & Community

Warranty & Service

When you invest in a large 3D printer, you want to know that support stands behind your purchase. Reliable warranty and service options give you peace of mind. Most leading brands, including Sovol, offer a clear warranty and support structure. You can see a typical framework in the table below:

|

Aspect |

Details |

|---|---|

|

Warranty Period |

12 months manufacturer warranty |

|

Technical Support |

6 months unlimited technical support |

|

Extended Service Plans |

Available |

|

VIP Program Benefits |

Prioritized feature requests, early access to upgrades, white glove service |

|

Return Policy |

14-day return policy with 20% restocking fee |

You receive a 12-month manufacturer warranty, which covers most hardware issues. For the first six months, you also get unlimited technical support. Some brands provide extended service plans and VIP programs. These programs offer benefits like early access to upgrades and prioritized requests. If you need to return your printer, you have a 14-day window, though a restocking fee may apply.

Tip:

Always review the warranty terms before you buy. Strong support and clear policies help you solve problems quickly and keep your projects on track.

User Community

A strong user community can make your 3D printing journey smoother and more enjoyable. When you join a brand like Sovol, you become part of a global network of makers, educators, and professionals. You can share ideas, ask questions, and find solutions from people who use the same equipment.

You benefit from:

- Online forums and social media groups

- Step-by-step guides and video tutorials

- Open-source resources for customization

- Regular software and firmware updates

You can also participate in community events and contests. Many users share their projects and tips, which helps everyone learn and grow. Sovol’s open-source philosophy encourages you to experiment and innovate. You never have to solve problems alone when you have a supportive community behind you.

A vibrant community and responsive support team help you get the most from your large 3D printer. You gain confidence, solve challenges faster, and unlock new creative possibilities.

3D Printer Buying Guide

Checklist

You want to make the best decision when you invest in a 3d printer. Use this 3d printer buying guide checklist to stay organized and focused. Review each point before you finalize your purchase.

-

Define Your Application

Identify what you want to print. Consider the types of projects you plan to tackle. -

Determine Build Volume

Measure the largest part you need to produce. Make sure the 3d printer can handle it. -

Select the Right Technology

Compare the main types of 3d printers, such as FDM and SLA. Choose the one that fits your needs. -

Check Material Compatibility

Confirm the 3d printer supports the types of filament or resin you require. -

Evaluate Speed and Precision

Look for features that improve print speed and accuracy. -

Assess Connectivity and Software

Make sure you can use your preferred slicer and monitor prints remotely if needed. -

Review Support and Community

Choose a brand with strong customer support and an active user base.

Tip: Print this checklist and keep it handy while you research different 3d printer models.

Common Mistakes

Many users make similar errors when choosing a 3d printer. Avoid these pitfalls to ensure a smooth experience.

- You might overlook the importance of matching the 3d printer’s build volume to your project size.

- Some users ignore the types of materials supported, which can limit future projects.

- You may focus only on price and forget to check for essential features or long-term value.

- Skipping research on the types of 3d printer technologies can lead to frustration if the machine does not meet your needs.

- Neglecting to join a user community means you miss out on valuable tips and troubleshooting help.

Note: The 3d printer buying guide helps you avoid these mistakes and choose the right machine for your goals.

Selecting the best device for your needs means focusing on what matters most. Review these key points before you decide:

- Intended print use and project types

- Available workspace and printer size

- Material compatibility and print environment

- Print speed, reliability, and real-world performance

- Setup effort and upgrade options

- Budget, long-term value, and support

- Quality-of-life features like remote monitoring

Revisit your goals and compare options. SOVOL’s open-source, high-value printers help you make an informed, confident choice.

FAQ

What size workspace do you need for a large 3D printer?

You need a stable, level surface with enough space around the printer for loading filament and removing prints. Measure your printer’s dimensions and add extra clearance for maintenance and airflow.

Can you use different filaments with the Sovol SV08 Max?

Yes, you can use PLA, PETG, ABS, TPU, and more. The Sovol SV08 Max supports a wide range of filaments, including advanced engineering materials. Always check the recommended temperature settings for each material.

How do you monitor prints remotely on the Sovol SV08 Max?

The Sovol SV08 Max includes a built-in camera and supports WiFi or Ethernet connections. You can monitor your prints in real time and receive alerts using compatible software on your computer or mobile device.

What maintenance does a large 3D printer require?

You should regularly clean the print bed, check for loose screws, and lubricate moving parts. Inspect the extruder and replace worn nozzles as needed. Routine maintenance helps you achieve consistent, high-quality prints.

Why choose an open-source 3D printer?

Open-source 3D printers let you customize hardware and software. You can upgrade components, install new features, and join a community of makers. This flexibility helps you adapt your printer to changing project needs.