The increase in printer speed is changing how makers work with 3d printing. Today, both hobbyists and professionals want faster machines because they need more rapid results. As more people use 3d printers at home and in small businesses, the market for high print speed continues to grow. This demand has led to new solutions like the Sovol Zero, which sets a new standard for speed and quality in 3d printing.

Key Takeaways

Faster 3D printers help people finish projects faster. This saves time and money. It also lets people be more creative and try new things. The Sovol Zero uses CoreXY technology. It can print up to 1200 mm/s. It prints with high accuracy and less shaking. This makes the prints look better. Smart features help make Sovol Zero easy to use. It has automatic bed leveling. It has a strong metal frame. It has a built-in camera. These features make it reliable. Faster printing lowers the cost and time for making models. This helps hobbyists and companies make ideas real faster. The 3D printing community shares ideas and tips. This makes fast, good printing easier and more creative for everyone.

Why Speed Matters

Productivity and Time

Speed is very important in 3d printing. When printers are faster, people finish projects sooner. This means they can make more things in less time. Many people use 3d printers for small batches or custom parts. 3d printing is not as fast as big factories. But faster printers help a lot with smaller jobs. A quick printer lets people test ideas without waiting long.

- Printing faster helps people get more done if the printer is also reliable and makes smooth prints.

- Being efficient means less waiting, saving money, and using many materials easily.

- Small printers that are fast and flexible help people grow their work and save money.

- Sometimes, being able to change and adapt is more important than just being fast.

When print time is shorter, work changes. Designers can turn ideas into models quickly. They find mistakes early, so there is less waste. Fast printing gives quick feedback, so teams fix problems before they get expensive. Making real models sooner helps teams show ideas to others. This makes it easier to get help or money. Finishing projects faster means less risk and cost, and people can make more and choose better.

Innovation for Makers

Makers can be more creative when they test and change designs quickly. New materials like PolySonic™ PLA let people print working models up to 150% faster and still keep them strong. This helps makers build important models and try new ideas much faster.

Better 3d printers and software let people make harder designs and use more automatic steps. Makers now can test new shapes and features without waiting a long time. Teams like Team Dynamics and Artitek used faster printers to cut their testing time from weeks to days or hours. This speed lets them make special parts, save money, and sell products sooner.

- Fast 3d printers help people go from idea to model quickly.

- Designers can change and make new versions fast, trying out hard ideas that would cost more with old ways.

- Testing early helps find problems before making lots of products, so things turn out better.

Faster 3d printing helps makers try new things, learn, and get better as fast as they can think of new ideas.

Increase in Printer Speed

Evolution of 3D Printing

Printer speed has changed 3d printing a lot. Old 3d printers were slow and made simple shapes. Now, new technology makes 3d printing much faster. Makers and companies want quick results and better machines.

Many things have helped printers get faster:

- Speed-modulated ironing uses two nozzles. One nozzle puts down material. The other heats it up. This makes different textures and finishes faster.

- Holographic 3d printing uses sound waves and special reactions. It hardens resin quickly. This method prints up to twenty times faster than old ways. It can print many things at once. You can also change designs while printing.

- Continuous printing does not use layers. It pushes out material in a steady flow. This makes printing faster and smoother.

- Parallel printing uses more than one print head or bed. It prints many objects at the same time. This saves a lot of time.

- Better hardware, smarter software, and real-time feedback help printers work faster and more accurately.

These new ways make 3d printing easier and cheaper for everyone. Big industries like aerospace, medicine, and cars use these advances to make hard parts quickly.

Impact on Prototyping

Faster printers have changed prototyping a lot. Companies can test ideas and make changes much faster. This helps them stay ahead of others.

|

Statistic Description |

Data Point |

|---|---|

|

Reduction in average prototyping time due to rapid prototyping with 3D printing (EY 2016) |

|

|

Increase in companies prioritizing accelerated product development via 3D printing (Sculpteo 2017 to 2018) |

From 29% to 39% |

|

Percentage of 3D printing work done in early product development phases |

57% |

|

Manufacturing companies reporting competitive advantages including reduced time-to-market (2018) |

93% |

|

Popular 3D printing applications in 2018: Prototyping |

55% |

These numbers show that faster printers help companies finish prototypes quickly. Most companies use 3d printing early in making products. They get big benefits, like selling products sooner and saving money.

Faster printers also lower costs. For example, Centor cut prototype costs from $800 to $10. They also made parts in 12 hours instead of a week. Caldwell Manufacturing dropped part costs from $500-$3,000 to $30. They made parts in three days instead of eight weeks. These results show how faster printers save money and help new ideas.

- Faster printers remove the need for costly tools and extra steps.

- Teams can make and test many designs at once, which saves time.

- In-house 3d printing gives companies more control and flexibility, so they can change things fast.

Faster printers have changed how people design, test, and launch new products. They help both small makers and big companies bring ideas to life faster and for less money.

Technology Behind High-Speed 3D Printing

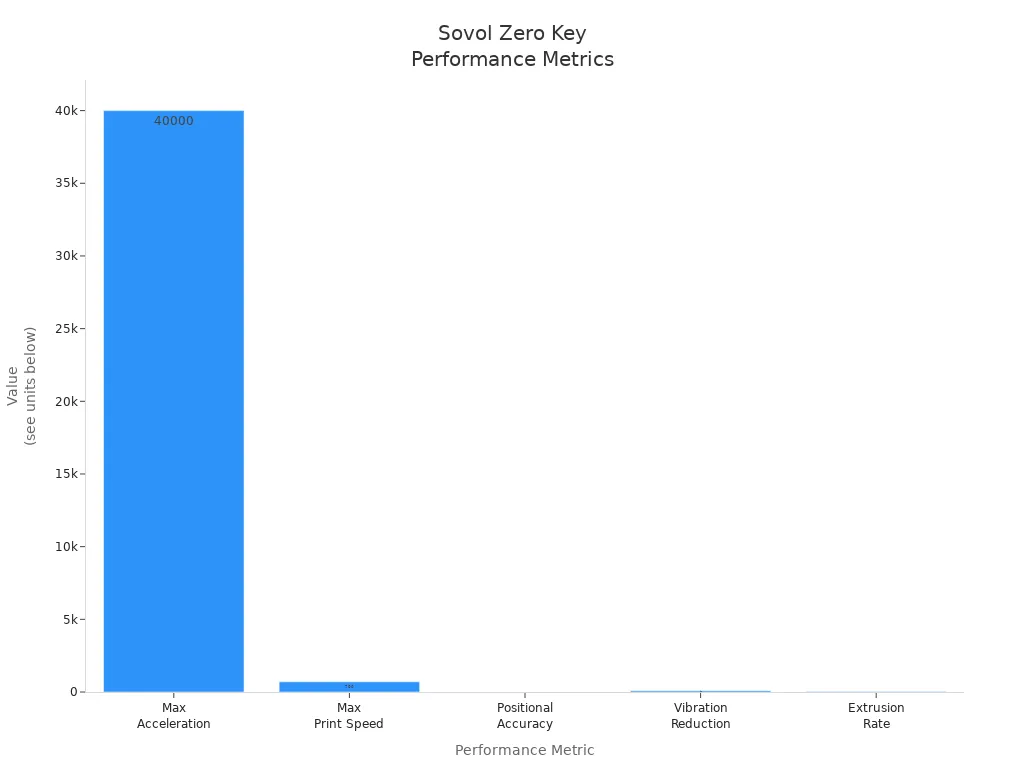

CoreXY System

CoreXY is a big step forward in 3d printing. It uses two motors that do not move and a belt system. This moves the print head on the X and Y axes. The motors stay still, so the moving parts are lighter. This makes the printer speed up fast and go very quickly. The Sovol Zero can print up to 1200mm/s because it uses corexy.

The corexy system helps stop shaking when printing fast. Less shaking means prints look better and are more exact. The belts and pulleys help the printer move just right. The print bed usually does not move, which keeps things steady and helps prints come out well. Corexy printers are small but can make big things.

CoreXY gives 3d printers an edge over older systems. It helps them work faster and more accurately, so projects finish sooner and still look great.

Here is a table that shows why corexy is good:

|

Feature |

Benefit |

|---|---|

|

Maximum Print Speed |

Up to 1200 mm/s with corexy kinematics |

|

Acceleration |

40,000 mm/s² for rapid starts and stops |

|

Positional Accuracy |

Deviation ≤0.02 mm during fast moves |

|

Vibration Reduction |

92% less ringing artifacts, smoother surfaces |

|

Stability |

Strong frame supports high-speed, precise 3d printer results |

Precision and Stability

Fast 3d printing needs special tech to keep prints correct. The Sovol Zero has a strong metal frame that stays steady when printing quickly. Its corexy system makes sure there is less weight moving and less shaking. This helps the printer stay accurate even when it is fast.

AI tools now help with 3d printing. They make models, fix designs, and watch for mistakes. These tools also change settings to get the best speed and quality. Making sure the bed is level and the nozzle is at the right height helps the first layer stick. Changing the heat and speed helps the material flow well. All these steps help prints come out right and last.

New printers use tech to stop shaking and keep the heat just right. This stops problems like warping or lines on the print. Fast cooling helps each layer dry quickly, so shapes stay sharp. The Sovol Zero’s smart leveling and motion control help it make sharp edges and smooth prints, even when printing fast.

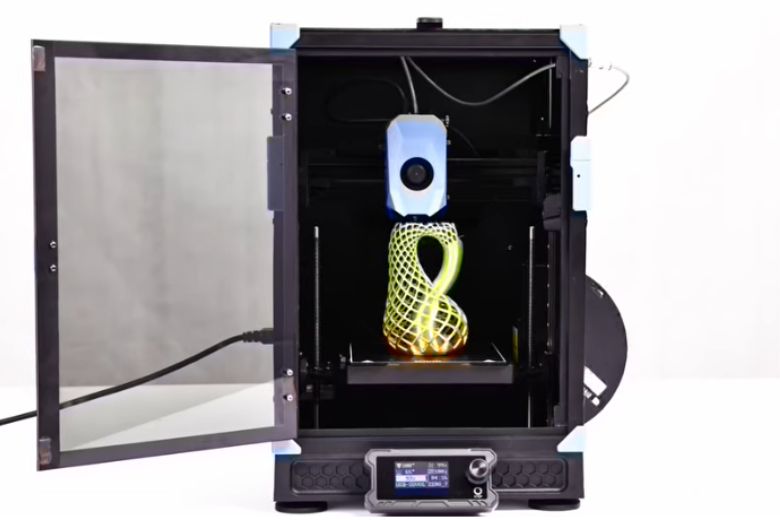

Sovol Zero 3D Printer

Key Features

The Sovol Zero 3D printer is special in high-speed 3d printing. It mixes smart engineering with a design that is easy to use. This printer uses CoreXY, so it can move fast and very accurately. Sovol Zero can print up to 1200mm/s and speed up to 40,000mm/s². These numbers are better than most other printers.

|

Performance Metric |

Value/Description |

|---|---|

|

Maximum Acceleration |

40,000 mm/s² |

|

Maximum Print Speed |

Up to 1200 mm/s |

|

Positional Accuracy |

≤0.02 mm during high acceleration |

|

Vibration Reduction |

92% less vibration compared to non-corexy setups |

|

Extrusion Rate |

35 mm³/s for all layer sizes |

The Sovol Zero has a build space of 152 x 152 x 152 mm. This gives users room for bigger prints or more than one print at once. The strong frame keeps the printer steady, so prints look better. The printer comes almost ready to use, so you can start fast.

Some top features are:

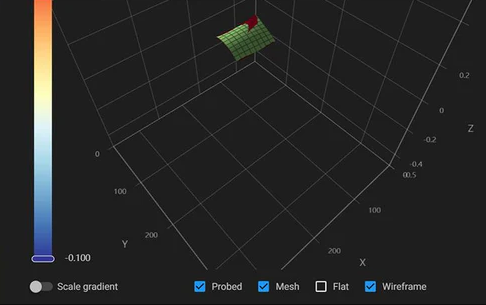

- Automatic bed leveling uses eddy current scanning and pressure sensing for great first layers.

- The nozzle heats up to 350°C and the bed to 120°C. This lets you print with tough materials like PA and PC.

- Linear rails on every axis help the printer move smoothly and stay accurate.

- There is a camera built in for watching prints and making time-lapse videos.

- An air filter helps keep your work area safer.

- Silicone pads cut down on shaking and make prints look better.

- The open-source design lets you change things if you want.

- Customer support is quick to help if you need it.

The Sovol Zero makes great prints with little setup. Both new and skilled users say it is easy and works well.

User Experience

People say the Sovol Zero is easy to set up and use. Most finish putting it together in about 30 minutes. The instructions are clear, so anyone can follow them. The strong metal frame and rails help prints come out even and steady.

The auto-leveling system means you do not have to adjust the bed by hand. This saves time and helps you get good prints right away. Taking care of the printer is simple because parts are easy to reach and the guide is helpful.

The Sovol Zero has a touchscreen that is easy to use. You can change settings, level the bed, and watch prints with a few taps. The camera and Wi-Fi or Ethernet let you check your prints from anywhere. This helps you feel calm, even if you are not near the printer.

Many people who use the Sovol Zero like how fast it sets up and how well it works. The helpful community and good support team make fixing problems easy. Most users say the printer is fast, accurate, and gives steady results.

The build plate comes off, so cleaning is easy. The auto-leveling means you do not have to fix the bed much. Changing nozzles is quick. The air filter keeps your area cleaner. If you take care of it, the Sovol Zero can print for thousands of hours.

Comparing Printers

Sovol Zero vs Others

When you look at fast 3d printers, Sovol Zero is special. It has new features and works really well. Other printers can do a good job, but Sovol Zero mixes speed, accuracy, and new tech together. The table below shows how Sovol Zero matches up with other top models:

|

Feature / Printer |

Sovol Zero |

Voron Zero / Sovol SV06 (Competitors) |

|---|---|---|

|

Maximum Print Speed |

Up to 1200 mm/s |

200-300 mm/s (Voron Zero ~250 mm/s, SV06 150 mm/s) |

|

Print Time (Benchy) |

~9 minutes |

~20-25 minutes |

|

Motion System |

CoreXY with full XYZ linear rails |

Voron Zero: CoreXY; SV06: Cartesian |

|

Positional Accuracy |

≤0.02 mm at high speed |

Lower speed, precision focus |

|

Auto-Leveling |

Advanced 3.0 system |

Inductive sensor |

|

Nozzle Temperature |

Up to 350°C |

Up to 300°C |

|

Build Volume |

152.4 x 152.4 x 152.5 mm |

Larger in SV06 (220 x 220 x 250 mm) |

|

Material Compatibility |

PLA, PETG, TPU, ABS, ASA, PA, PC, Carbon Fiber |

Limited to standard filaments |

|

Connectivity |

Wi-Fi, Ethernet, built-in camera |

USB only, no camera (SV06) |

|

Additional Features |

Input Shaping, Pressure Advance, air filtration |

Fewer advanced features |

|

Assembly |

Ships preassembled |

Often DIY kits or more assembly required |

Sovol Zero can print up to 1200 mm/s, which is much faster than most others. Its CoreXY system and linear rails help keep prints neat, even when printing fast. The auto-leveling system uses eddy current scanning and pressure sensing, so setup is easy and works well. Sovol Zero can use many materials, even strong engineering plastics.

Value for Makers

Sovol Zero is a good deal for both hobbyists and pros. It costs about $424, which is a fair price for a CoreXY printer with these features. Makers get fast prints and great quality. The smart design, like the built-in camera and air filter, helps users watch prints and keep their area safe.

- Sovol Zero gives both speed and quality, so you do not have to pick just one.

- The open-source design lets makers change settings and try new things.

- The printer is good for small batches, quick testing, and fun projects.

Many people say Sovol Zero is easy to set up and use. The auto-leveling and strong frame help stop mistakes and keep prints looking good. It works with many materials, so you can print simple or hard parts. The active maker group and helpful support team make Sovol Zero a smart pick for anyone who wants a reliable and modern printer.

Real-World Impact

Maker Stories

Makers everywhere are seeing big changes with fast 3d printing. They finish their projects faster and try out new ideas more often. Many real-life stories show how this technology helps people build things quickly and waste less.

- In the Netherlands, a team made a 3d printed house in only 120 hours. This showed that fast printing can make strong homes. France and Spain have also built houses like this.

- The Dubai Future Foundation built the world’s biggest 3d printed office. They cut labor costs in half and lowered waste by 60%.

- Companies like Apis Cor use robots to print homes in two or three months. They want to make this even faster, hoping to do it in one week.

- ICON uses 3d printing to make green homes with low-carbon materials. These houses save energy and look different from normal homes.

- Ford and Audi use 3d printing to make special tools and parts for cars. This helps them work faster and waste less.

- Adidas and Cobra use 3d printing to make sports gear. They can test new designs quickly.

- Boeing uses 3d printing to make helicopter parts in just hours, not months.

People using Sovol Zero also get faster results. The printer comes almost ready, so you can start printing in about 30 minutes. Its CoreXY design and auto-leveling help finish projects fast and with good quality. Batch printing lets users make more parts at once, so they get more done.

Community Innovation

The 3d printing community works together to solve problems and share ideas. Faster printing has helped people make new tools and ways to print.

- Some people made print head parallelization. This uses many print heads at once and cuts print time from 35 hours to just 5 hours.

- Makers share their designs and tips on sites like Thingiverse and GitHub. This helps everyone learn and make better projects.

- Open-source 3d printers let users change hardware and software. This freedom helps people find new answers and move faster.

- The RepRap project started a trend where people could download and change printer designs. This made 3d printing easier and cheaper for more people.

- People help each other fix problems and get better at printing.

These actions show how 3d printing is changing the world. Makers and companies finish projects faster, save money, and make new things. The community’s teamwork helps everyone and makes 3d printing better.

Faster 3d printing lets makers work and build things in new ways. Sovol Zero is special because it uses CoreXY, has smart auto-leveling, and prints up to 1200 mm/s. Makers can finish their projects fast and with great detail. The simple setup and support for many materials help people test new ideas. Now, many can make prototypes in just minutes instead of hours. Anyone who wants to do more with 3d printing can use this speed and trust it to work well.

FAQ

How fast can the Sovol Zero 3D printer print?

The Sovol Zero prints very fast, up to 1200mm/s. This means you can finish your projects much sooner. Makers can try out ideas and make models in less time.

What materials can Sovol Zero print with?

Sovol Zero works with many materials. You can use PLA, PETG, TPU, ABS, ASA, PA, PC, and carbon fiber composites. The nozzle gets very hot, so you can use special filaments.

Does Sovol Zero require much assembly?

Sovol Zero comes almost ready to use. You just need to put on the antenna, screen, and filament sensor. Most people can start printing in about 30 minutes.

How does the auto-leveling system work?

The printer uses eddy current scanning and pressure sensing to check the bed. It does not touch the bed while checking. This helps you get a perfect first layer every time.

Can users monitor prints remotely?

Yes, Sovol Zero has a built-in camera. You can watch your prints live with Wi-Fi or Ethernet. The camera can also make time-lapse videos.

Tip: Try using Obico software to watch your printer from far away and make cool time-lapse videos.