Sovol Zero enters the 3d printing scene as a compact powerhouse. This 3d printer uses a CoreXY system to deliver rapid 3d printing speeds. Sovol Zero features advanced auto-leveling, enabling users to achieve precise 3d printer results. The printer supports demanding 3d printing materials, setting a new benchmark in 3d printer technology.

Key Takeaways

- Sovol Zero uses a fast and precise CoreXY system with advanced auto-leveling for reliable, high-quality 3D prints.

- It supports a wide range of materials, including advanced filaments, and offers a compact build volume ideal for detailed projects.

- The printer arrives preassembled with safety features and modern connectivity, making it easy and safe for beginners and experts alike.

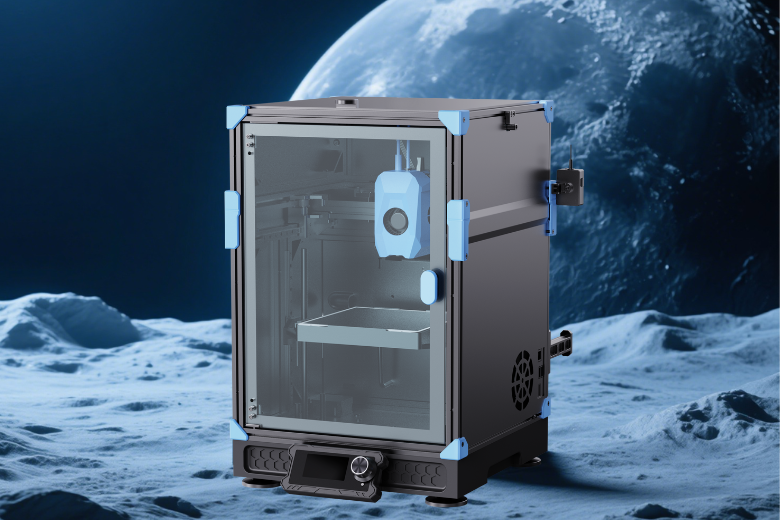

Sovol Zero 3D Printer

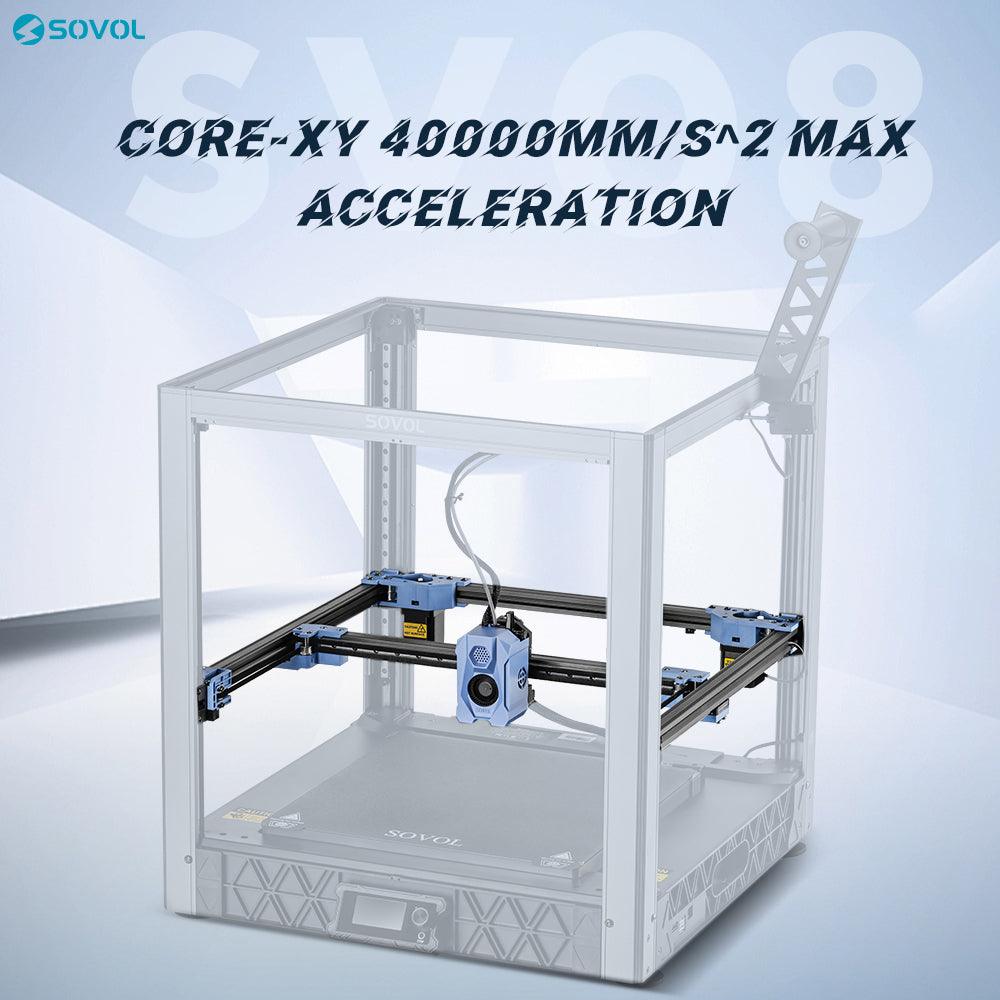

CoreXY System

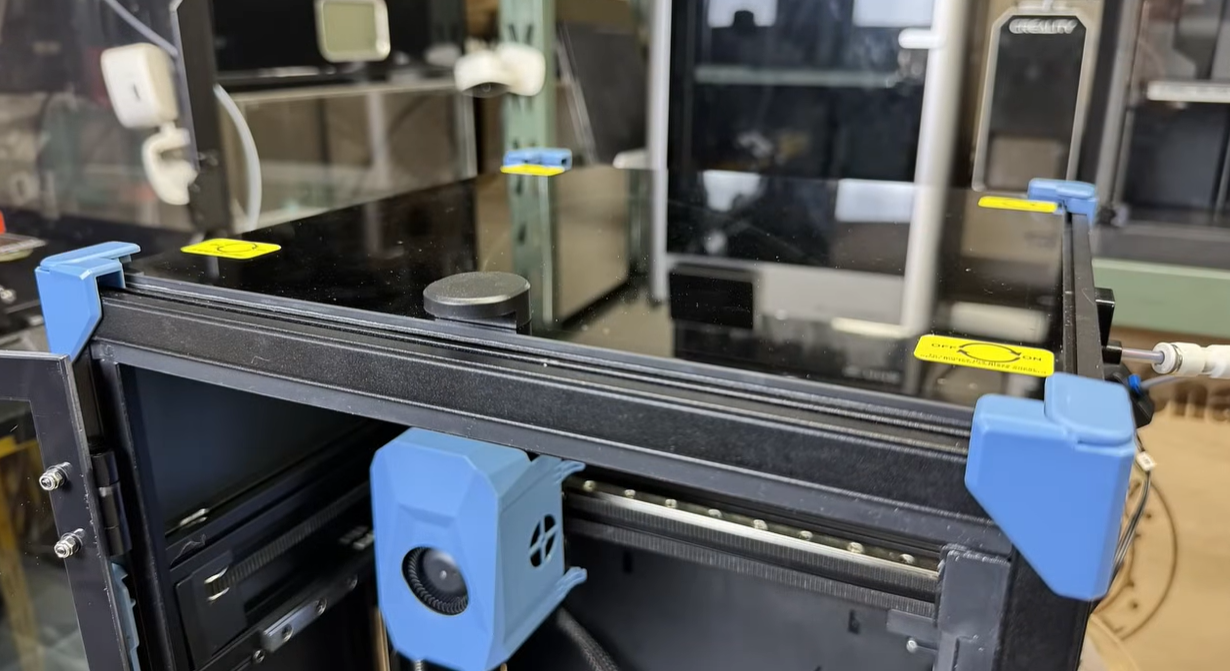

Sovol has built a reputation for innovation in the 3d printing industry. The Sovol Zero 3d printer stands out as a compact, high-speed core xy printer. The core xy motion system uses two motors working together, which reduces the moving mass on the y-axis. This design allows the 3d printer to achieve faster and more precise 3d printing compared to traditional systems. Users benefit from enhanced efficiency and accuracy, making the Sovol Zero ideal for demanding 3d printing tasks. The core xy structure, combined with full linear rails on all axes, ensures smooth movement and consistent results. Makers and engineers can rely on this 3d printer for both speed and detail.

Build Volume

The Sovol Zero 3d printer offers a build volume of 152.4 x 152.4 x 152.5 mm. This size meets the needs of users who focus on small, detailed 3d printing projects. The compact build area supports efficient 3d printer operation and reduces wasted space. The core xy system, high-speed capabilities, and linear rails work together to maintain accuracy, even at rapid speeds. This makes the Sovol Zero a strong choice for those who require precise 3d prints in a smaller format.

Auto-Leveling

Sovol Zero features a next-generation auto-leveling system that combines eddy current scanning with pressure sensing. This advanced technology maps the bed surface quickly and adjusts for any unevenness. The system uses sensors with no moving parts, which increases reliability and reduces wear. Calibration processes compensate for temperature and humidity changes, ensuring consistent 3d printing results. The auto-leveling system improves print reliability by providing a perfect first layer every time, making the 3d printer easier to use and more dependable for all users.

3D Printing Features

Speed and Precision

Sovol Zero sets a new standard in 3d printing with its remarkable speed and accuracy. The printer reaches a maximum speed of 1200mm/s and an acceleration of 40,000mm/s². This high-speed capability allows users to complete 3d prints much faster than with traditional machines. The core xy system, combined with full linear rails, ensures that every movement is smooth and precise. Users can expect consistent 3d printing results, even when working on complex or detailed 3d prints. The advanced motion system reduces vibrations, which improves the overall quality of each 3d print. Makers and engineers benefit from rapid prototyping and efficient 3d printing process, saving valuable time without sacrificing detail.

Materials and Nozzle

The Sovol Zero 3d printer features a high-temperature nozzle that can reach up to 350°C. This capability opens the door to advanced 3d printing materials such as PA, PC, and carbon fiber composites. The printer supports a wide range of filaments, making it suitable for both standard and high-performance 3d printing applications.

- Tensile strength tests at nozzle temperatures of 390°C and 415°C show that higher temperatures improve filament bonding and layer fusion.

- Printing at 350°C has been confirmed for PEI blends, with mechanical and rheological tests supporting optimal results.

- PEEK printing at temperatures from 380°C to 440°C demonstrates reduced porosity and improved density, with mechanical properties close to bulk material at 390°C.

Mechanical testing methods, including tensile and flexural tests, confirm the durability and reliability of the nozzle and material handling features. Universal Testing Machines apply controlled loads to measure deformation, ensuring the nozzle performs well under stress. Repeated testing and certification provide confidence in the printer’s ability to handle demanding 3d printing tasks.

|

Test Type |

Standard |

Material Tested |

Key Metrics Measured |

Repeatability & Reliability Measures |

|---|---|---|---|---|

|

ASTM D638 |

ABS, PLA |

Tensile strength, tensile strain, modulus |

15 repetitions per sample; low standard deviation |

|

|

Flexural Test |

ASTM D790 |

ABS, PLA |

Flexural strength, flexural modulus |

Standardized specimen prep and testing conditions |

These results show that Sovol Zero delivers reliable 3d printing performance across a variety of materials.

Enclosure and Safety

Sovol Zero features a fully enclosed design that enhances both safety and print quality. The fully enclosed chamber maintains a stable temperature, which is essential for high-performance 3d printing materials. The AC heated bed reaches up to 120°C, providing a strong foundation for 3d prints and reducing the risk of warping. The fully enclosed structure also protects users from hot components and moving parts during the 3d printing process. Overheating protection adds another layer of safety, giving users peace of mind during long 3d printing sessions. The enclosed environment supports consistent results, especially when printing advanced filaments that require precise temperature control.

Tip: The fully enclosed design not only improves safety but also boosts the quality of every 3d print by creating a controlled environment.

Connectivity

Sovol Zero offers modern connectivity options that make 3d printing more convenient. The printer includes both Ethernet and 2.4 GHz Wi-Fi, allowing users to monitor and control the 3d printing process remotely. A built-in camera lets users watch their 3d prints in real time and create time-lapse videos. The printer also features power loss recovery and a filament sensor, which help prevent failed 3d prints and wasted material. These user-friendly features ensure that the 3d printer fits seamlessly into any workflow, whether in a home, classroom, or professional setting.

3D Printer Market Impact

Comparison

Sovol Zero enters the 3d printing market as a strong competitor to other CoreXY machines like the Voron V0.2. Unlike many DIY kits, Sovol Zero ships as a preassembled unit. Users can start 3d printing almost immediately after unboxing. This printer stands out as an affordable option, making high-speed 3d printing accessible to more people. Many CoreXY printers require advanced assembly skills, but Sovol Zero removes that barrier. The affordable price point and robust feature set position it among the best budget 3d printers available today.

Target Users

This 3d printer appeals to a wide range of users. Makers and engineers who need fast prototyping find value in its speed and precision. Hobbyists who focus on small, detailed 3d prints benefit from the compact build volume. Educators and students use this affordable printer for classroom projects and hands-on learning. Anyone seeking reliable 3d printing with advanced material support will appreciate Sovol Zero’s capabilities.

Community Response

Early feedback from the 3d printing community highlights excitement about Sovol Zero’s features and price. Unboxing videos show users impressed by the sturdy enclosure and ready-to-use design. Many praise the affordable nature of the printer and its ability to handle advanced 3d printing materials. Social media posts and forums reflect growing interest in Sovol Zero as a game-changer for affordable 3d printing. The community recognizes its potential to make high-quality 3d prints more accessible.

- Sovol Zero introduces advanced CoreXY speed, precise auto-leveling, and broad material support.

- Both beginners and experts find value in its performance.

- Watch for user reviews, creative community mods, and its impact on future 3D printing.

The Sovol Zero signals a new era in desktop 3D printing innovation.

FAQ

What slicers work with Sovol Zero?

Sovol Zero supports OrcaSlicer and any slicer that exports G-code. Users can choose their preferred workflow for maximum flexibility.

Does Sovol Zero require assembly?

Sovol Zero arrives preassembled. Users only need to remove packaging, connect power, and start printing. This design saves time and reduces setup errors.

Which filaments can Sovol Zero print?

|

Supported Filaments |

Examples |

|---|---|

|

Standard |

PLA, PETG, TPU, ABS |

|

Advanced |

ASA, PA, PC, Carbon Fiber |

Sovol Zero handles both standard and advanced materials with ease.